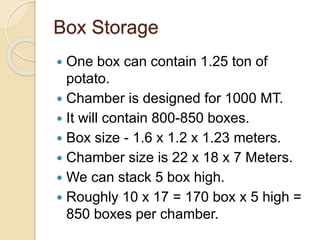

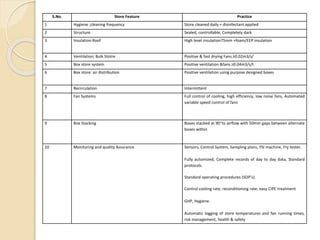

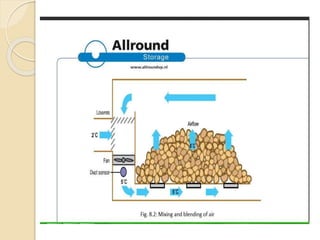

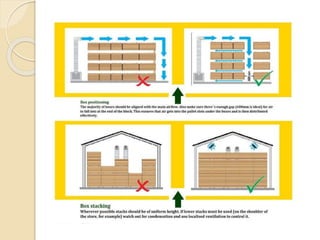

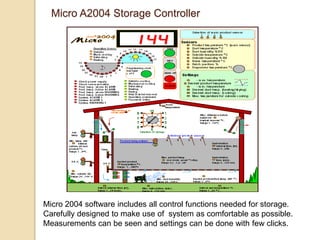

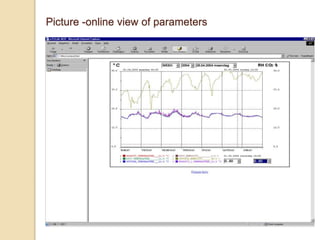

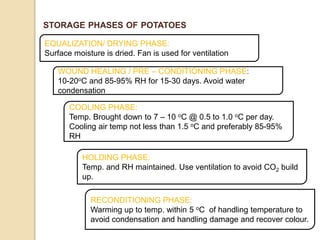

This document provides information about Aastha Hi-Tech Storage LLP, a potato storage facility located in Gujarat, India. It has a capacity of 8,000 metric tons and uses both bulk and box cold storage. The facility uses automated control systems to regulate temperature, humidity, ventilation and other storage conditions throughout the various phases of potato storage to maintain quality. It aims to deliver potatoes that meet market specifications for attributes like uniform fry color, low disease and sprouting levels.