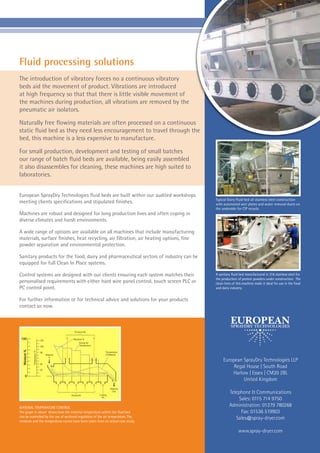

European SprayDry Technologies produces a wide range of fluid bed machines for industries such as dairy, food processing, chemicals, and pharmaceuticals. Fluid beds can perform various functions including drying, roasting, blending, and more. They are highly efficient due to superior heat and mass transfer rates compared to other drying methods. Specialized designs include closed circuit systems for drying solvents and flammable materials.