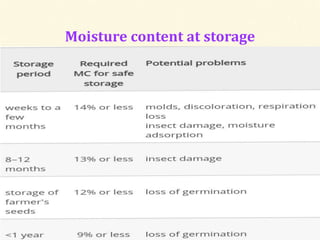

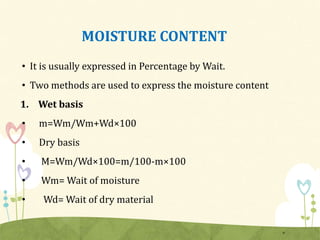

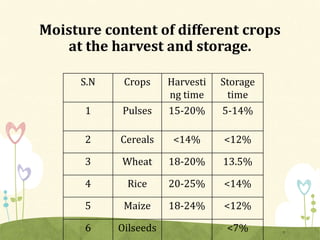

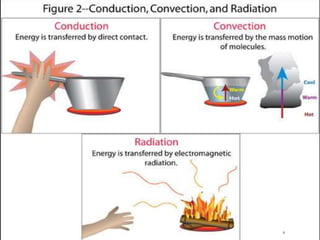

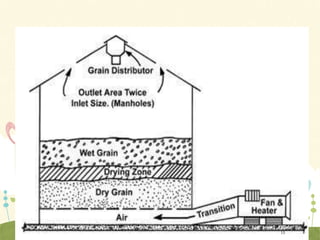

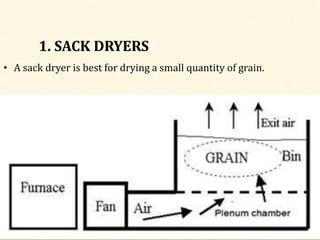

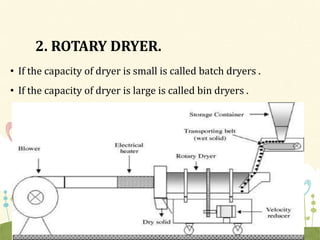

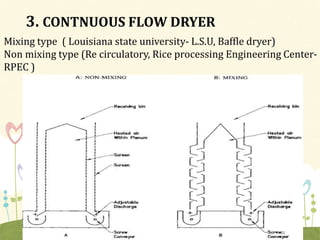

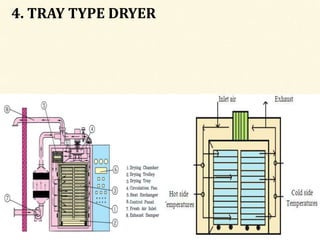

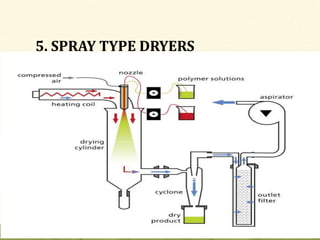

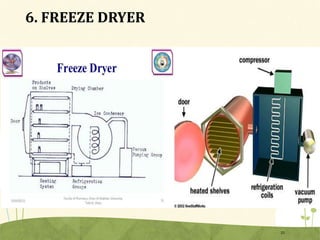

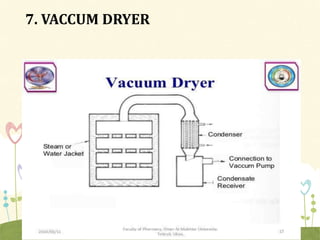

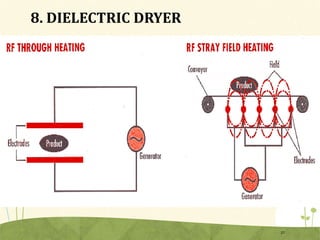

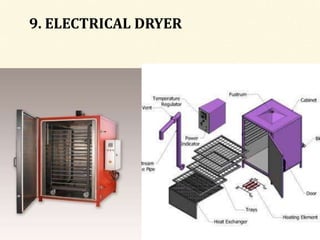

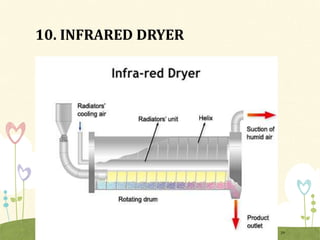

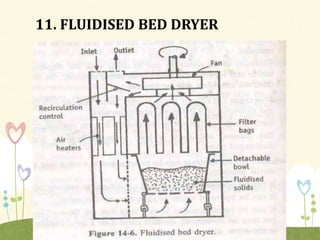

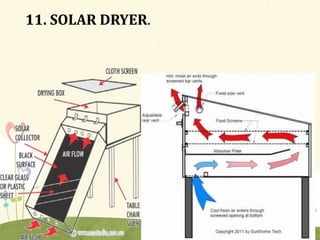

This document provides an overview of grain drying methods and dryer classification. It begins with an introduction to drying as a method for conditioning grains through moisture removal. Common drying methods are then described, including conduction, convection and radiation. Grain dryers are classified based on thin layer drying vs deep bed drying principles. Various mechanical dryer types are also outlined, including sack, rotary, continuous flow, tray, spray, freeze, vacuum, dielectric, electrical, infrared and fluidized bed dryers. Optimal moisture contents for storing different crops are listed. In conclusion, the document states that dryers play an important role in food security by allowing crops to be stored safely below their critical moisture levels.