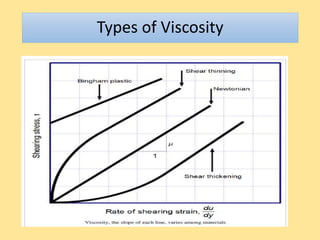

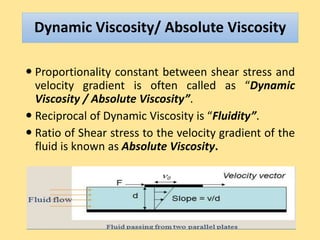

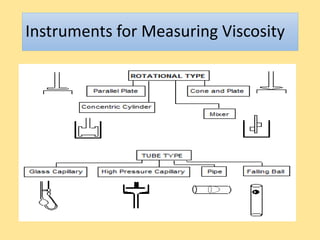

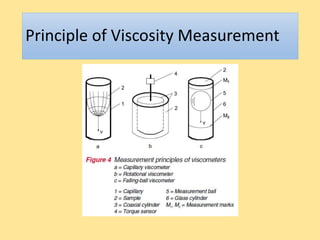

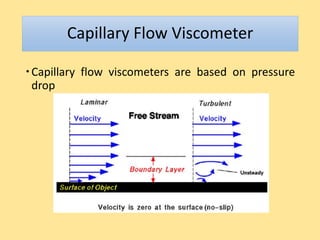

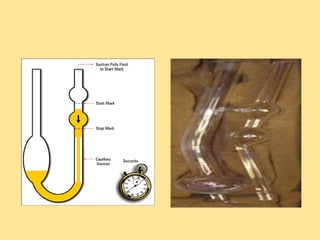

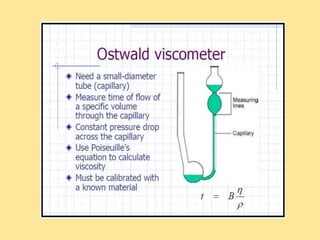

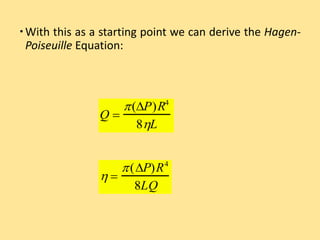

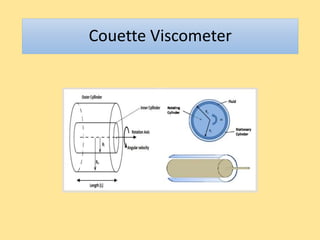

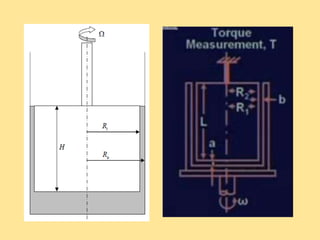

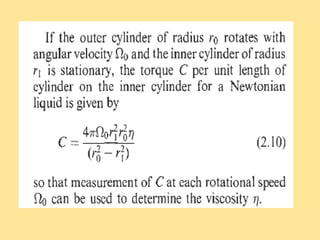

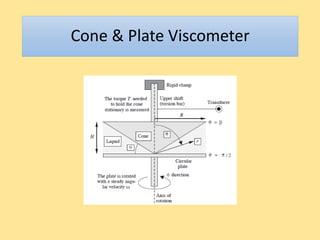

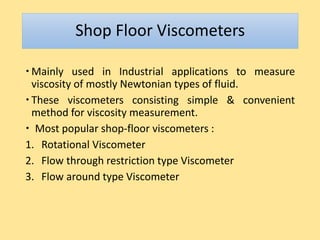

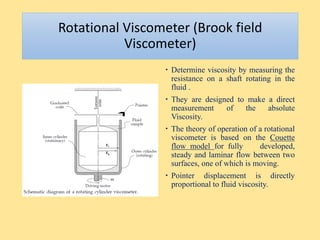

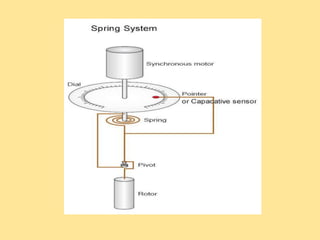

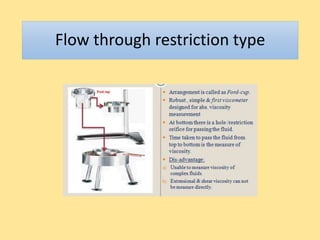

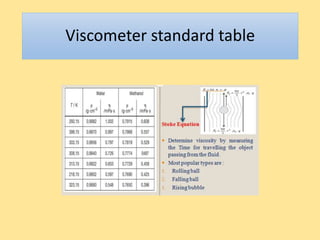

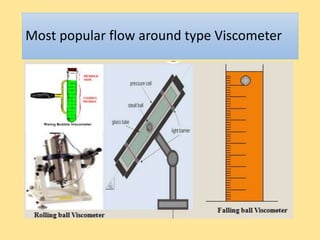

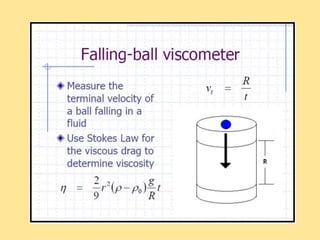

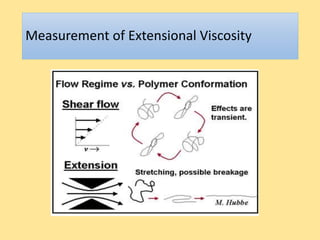

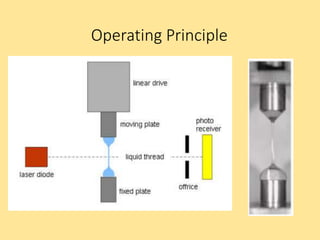

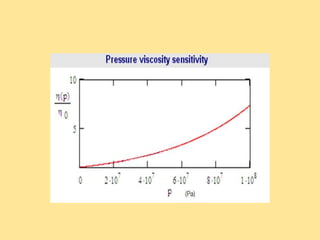

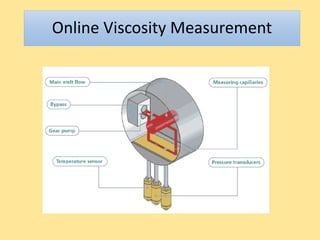

The document presents an overview of viscosity measurement, defining viscosity as the internal friction of fluids and its relation to shear forces. It discusses the importance of measuring viscosity for quality control and product consistency, along with different types of viscosity and the instruments used for measurement, such as viscometers. It also touches on the effects of temperature on viscosity and its applications in various industries.