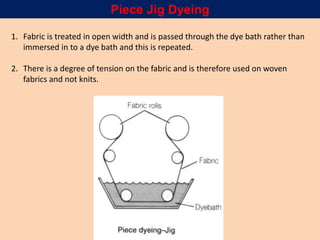

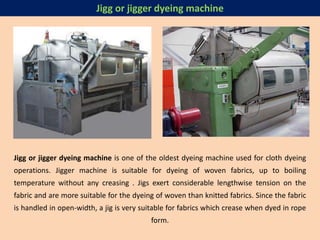

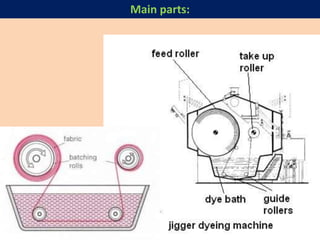

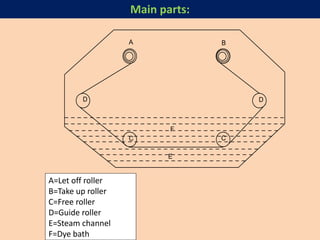

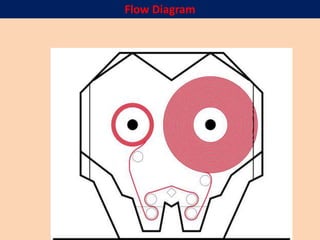

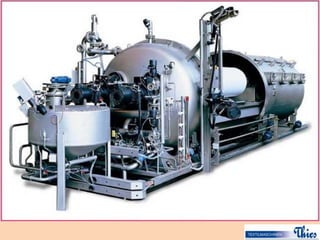

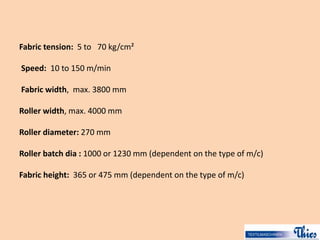

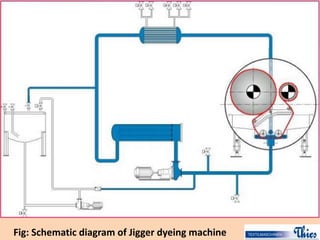

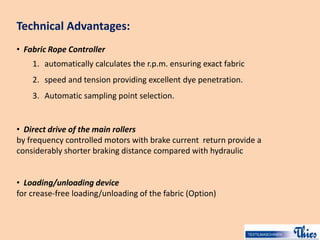

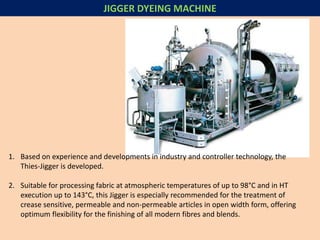

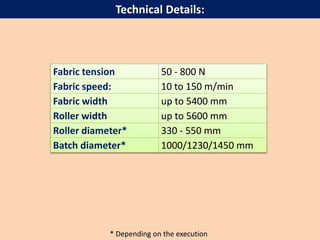

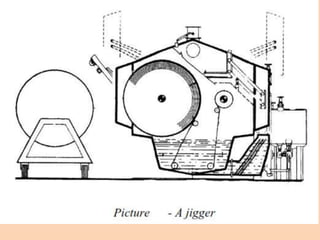

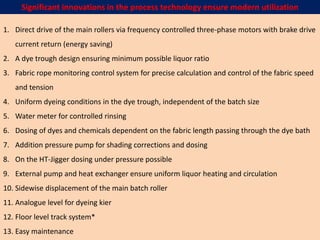

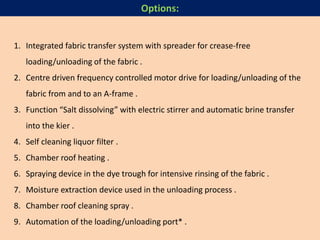

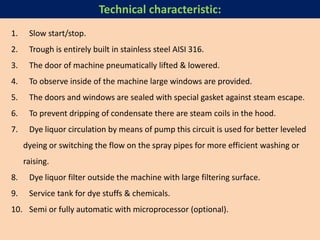

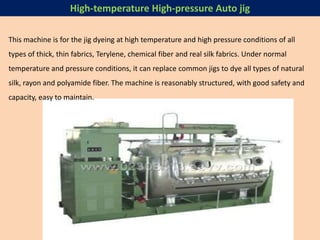

The document discusses the jigger dyeing machine, focusing on its operation, main components, and technical advantages. It highlights the suitability of jigger dyeing for woven fabrics, the types of jigger machines, and various innovations in their design for improved efficiency. Additionally, it addresses the limitations of traditional jigger dyeing and provides insights into modern advancements in dyeing technology.