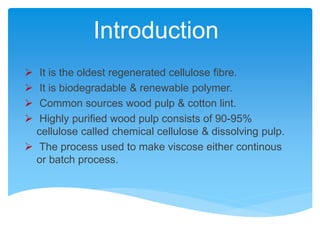

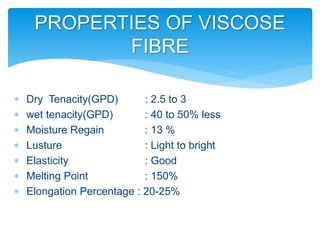

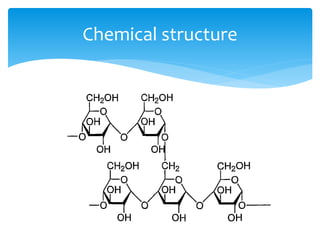

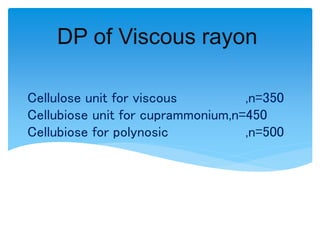

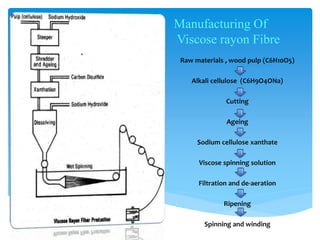

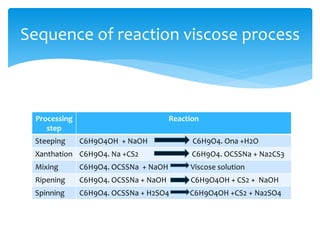

Viscose rayon is a regenerated cellulose fiber made from cellulose derived from wood or cotton. It is produced through a process involving the conversion of cellulose to a soluble compound called viscose, which is then spun through a spinneret into fibers and treated with acid. Viscose rayon is highly absorbent, soft, easy to dye, and drapes well. It is biodegradable and versatile. The manufacturing process involves treating cellulose with alkali and carbon disulfide to form sodium cellulose xanthate, which is then dissolved to create the viscose solution and spun into fibers.