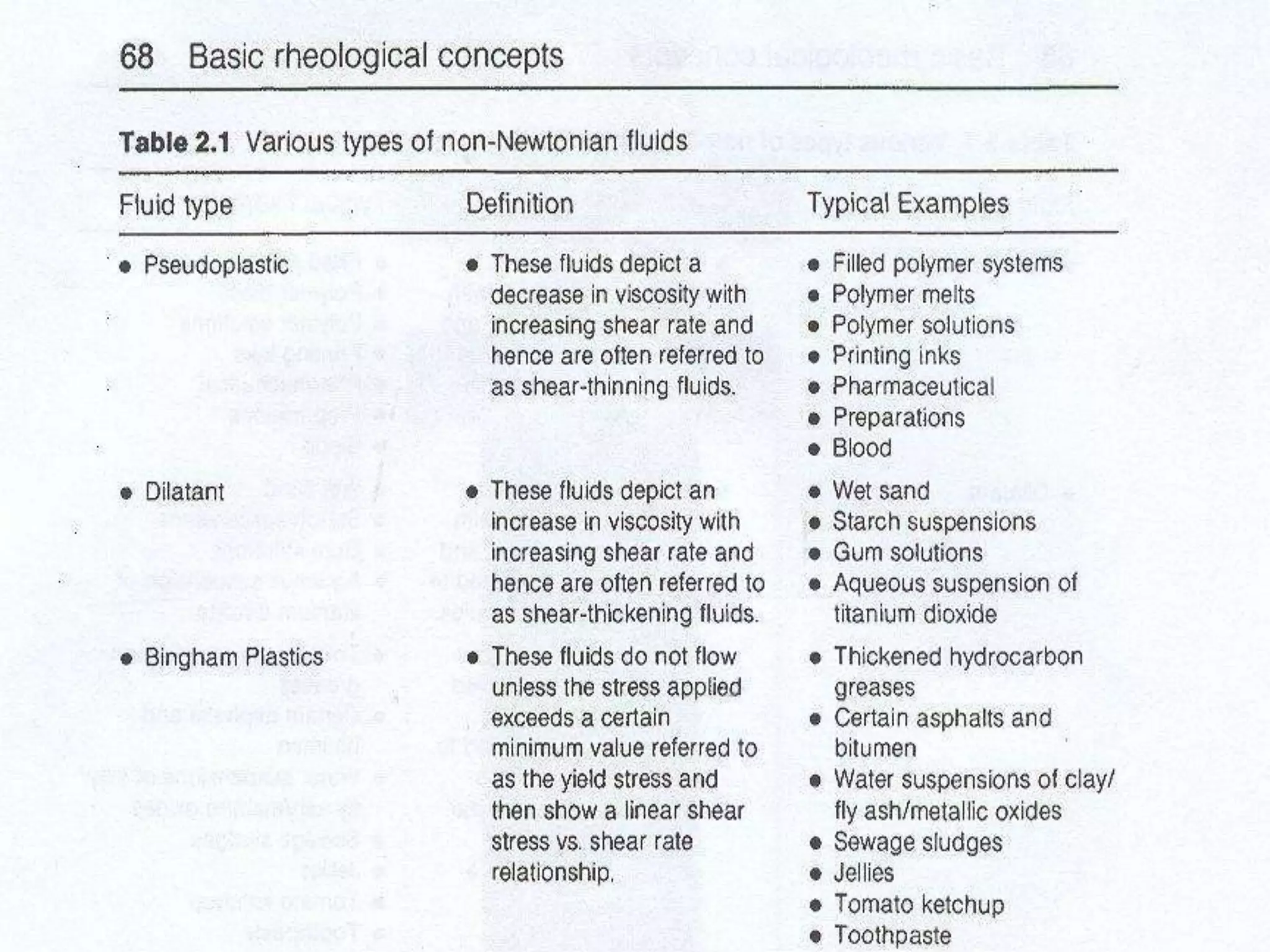

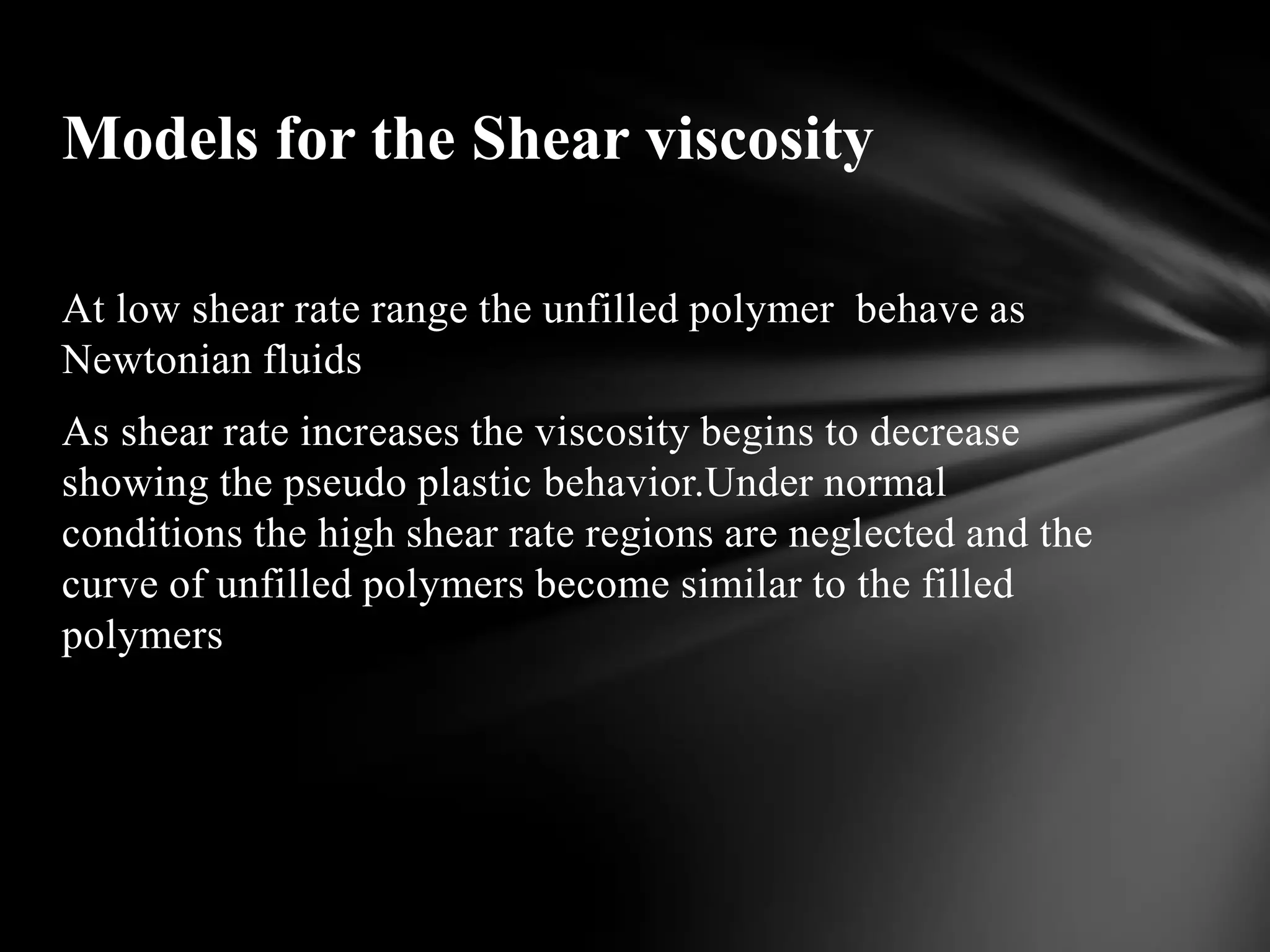

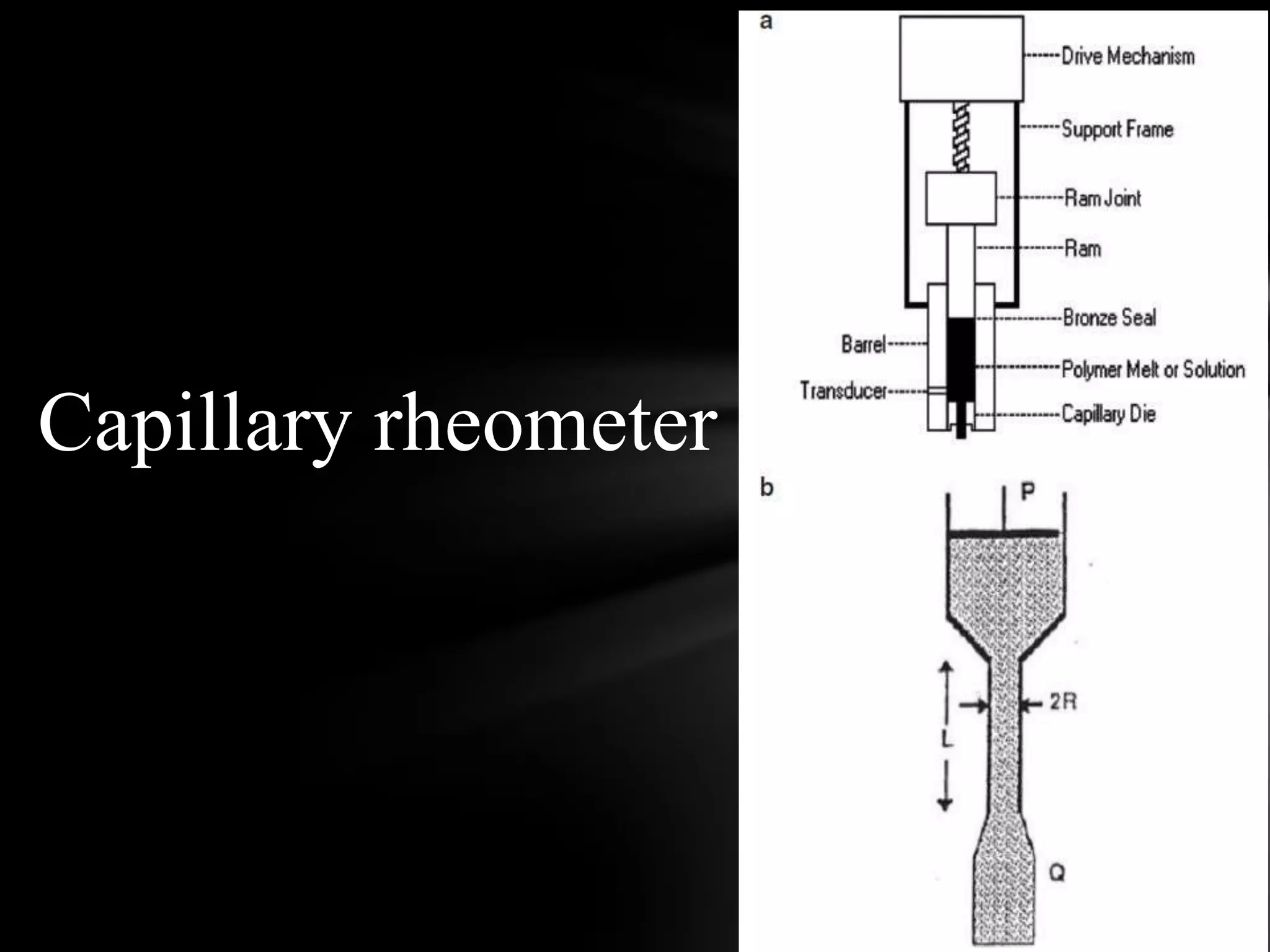

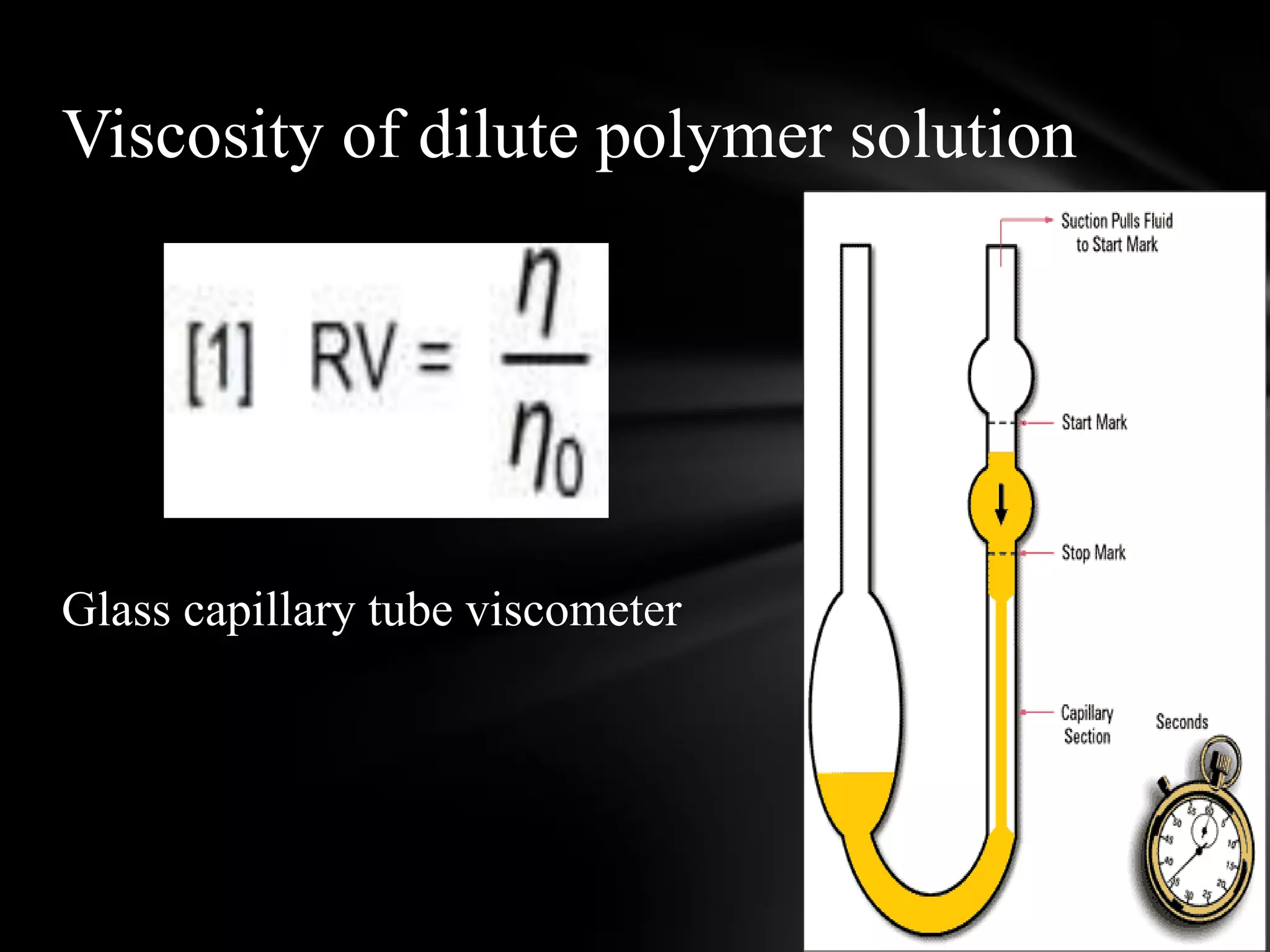

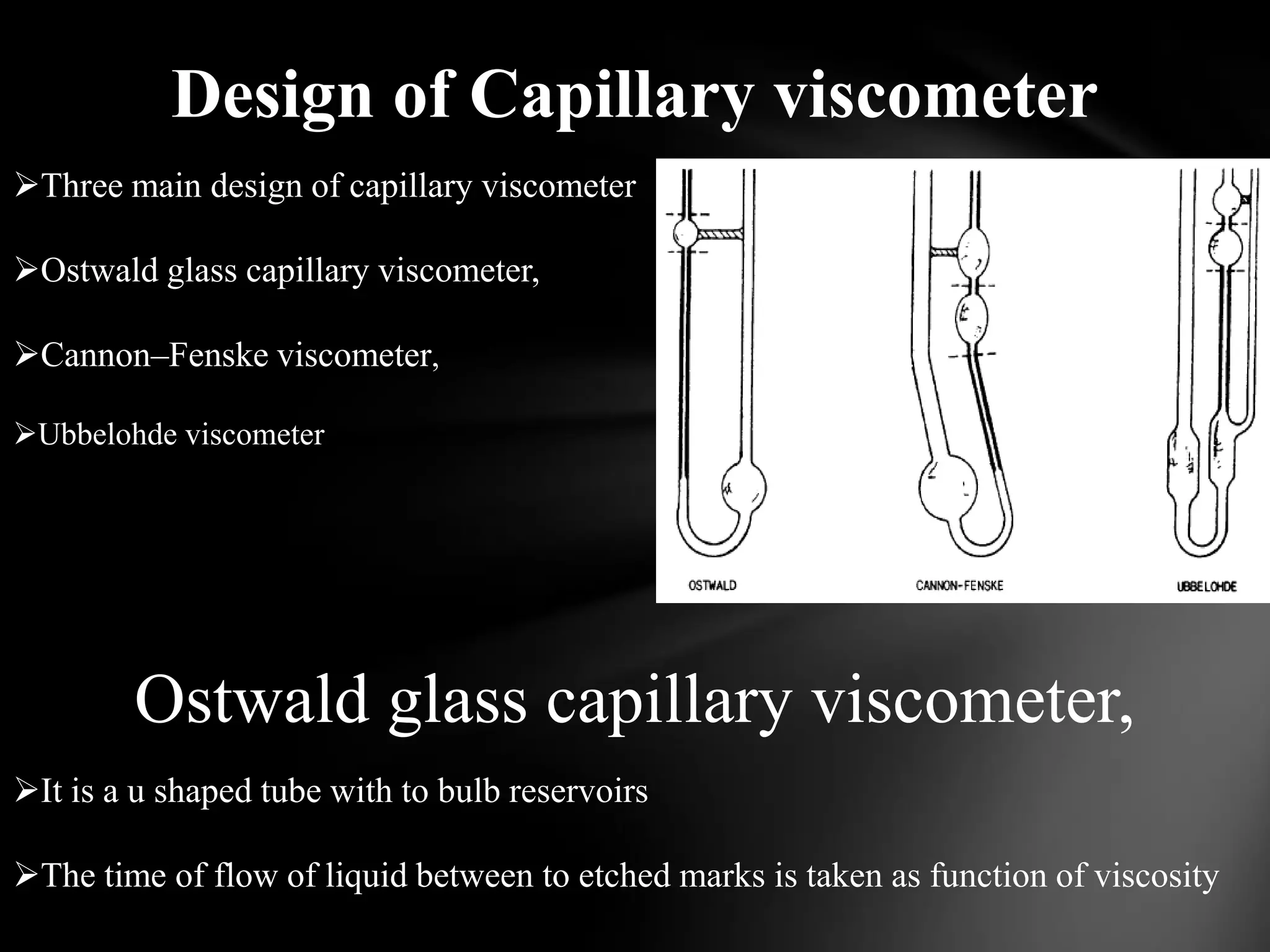

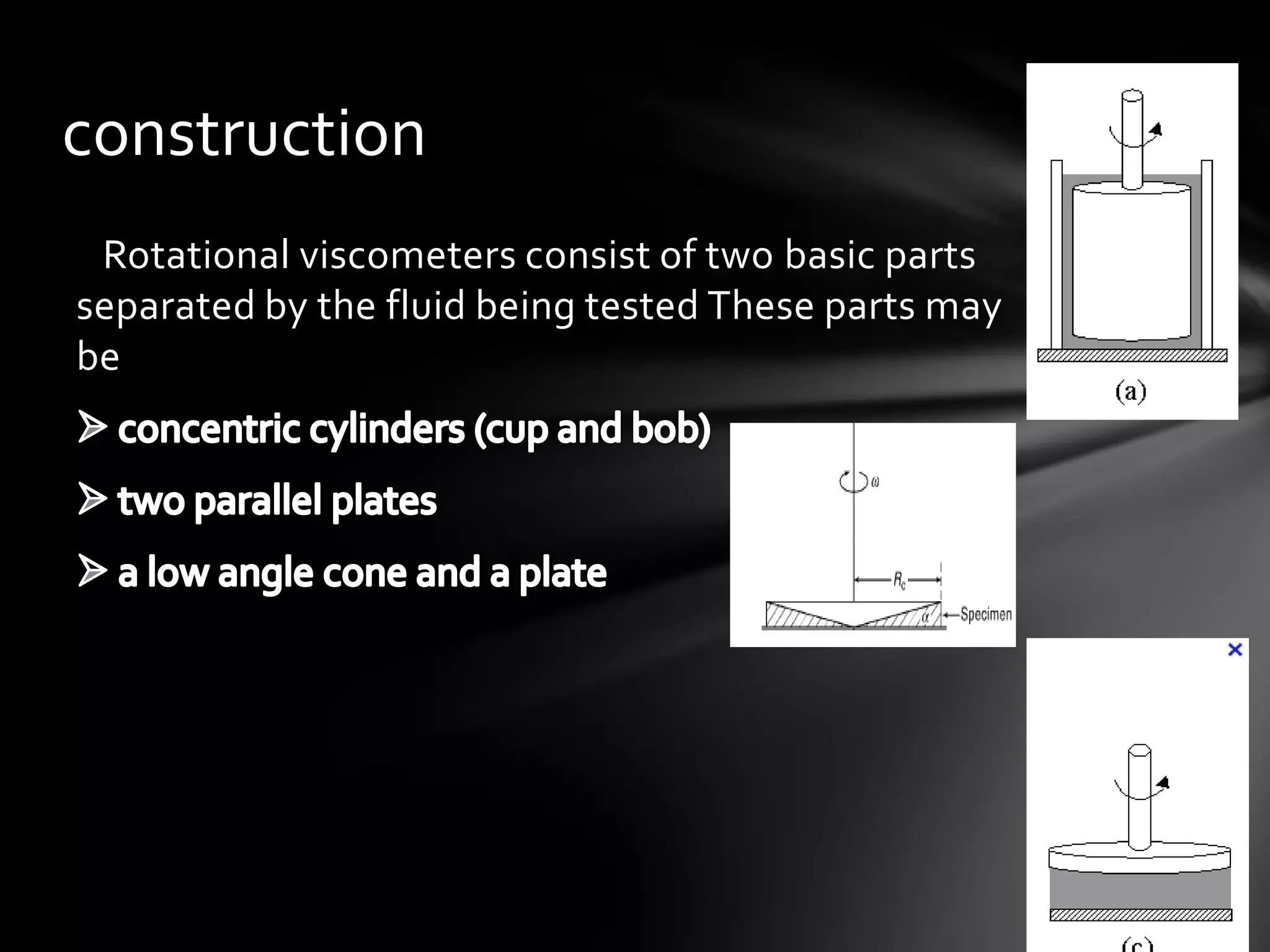

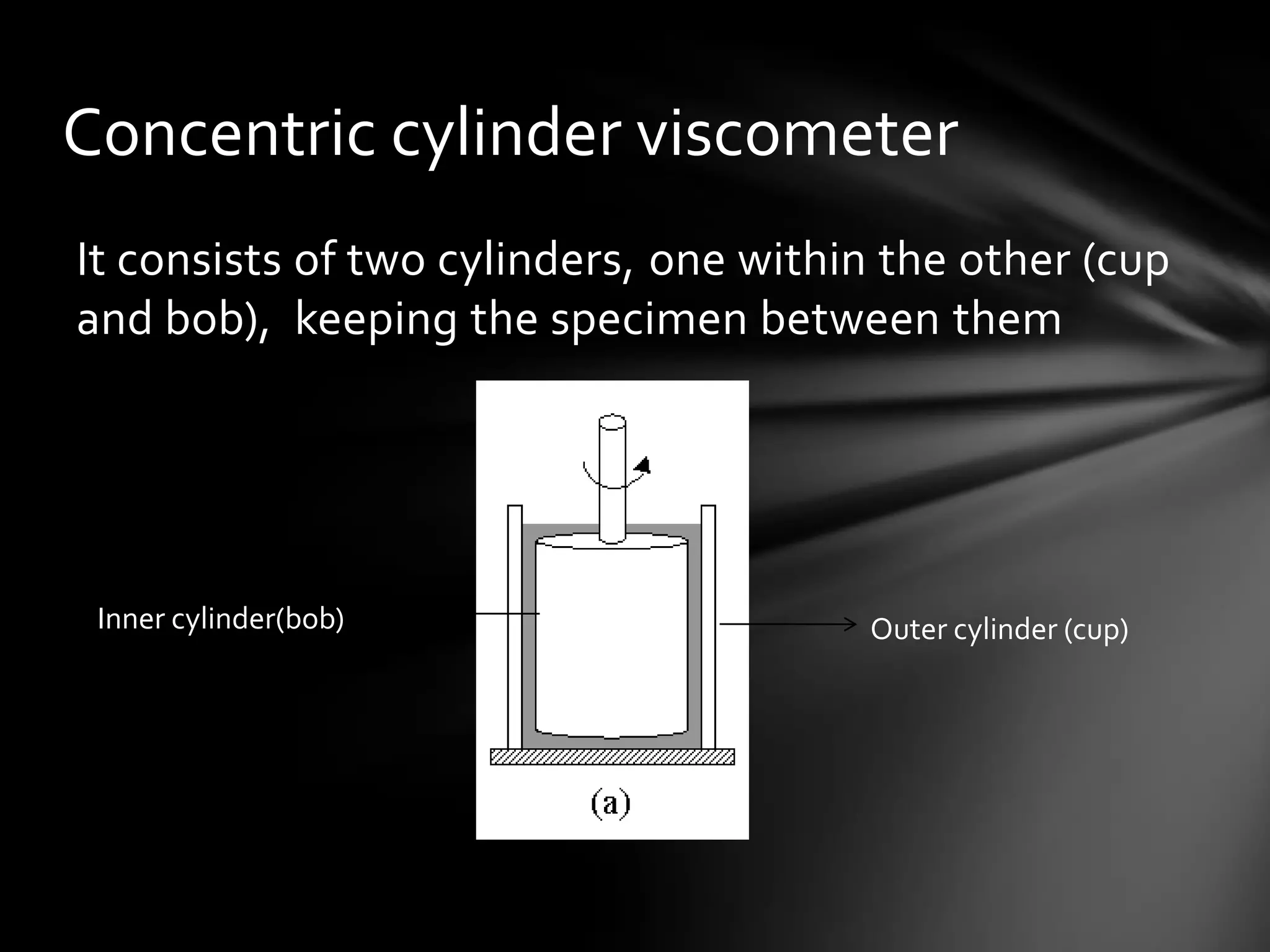

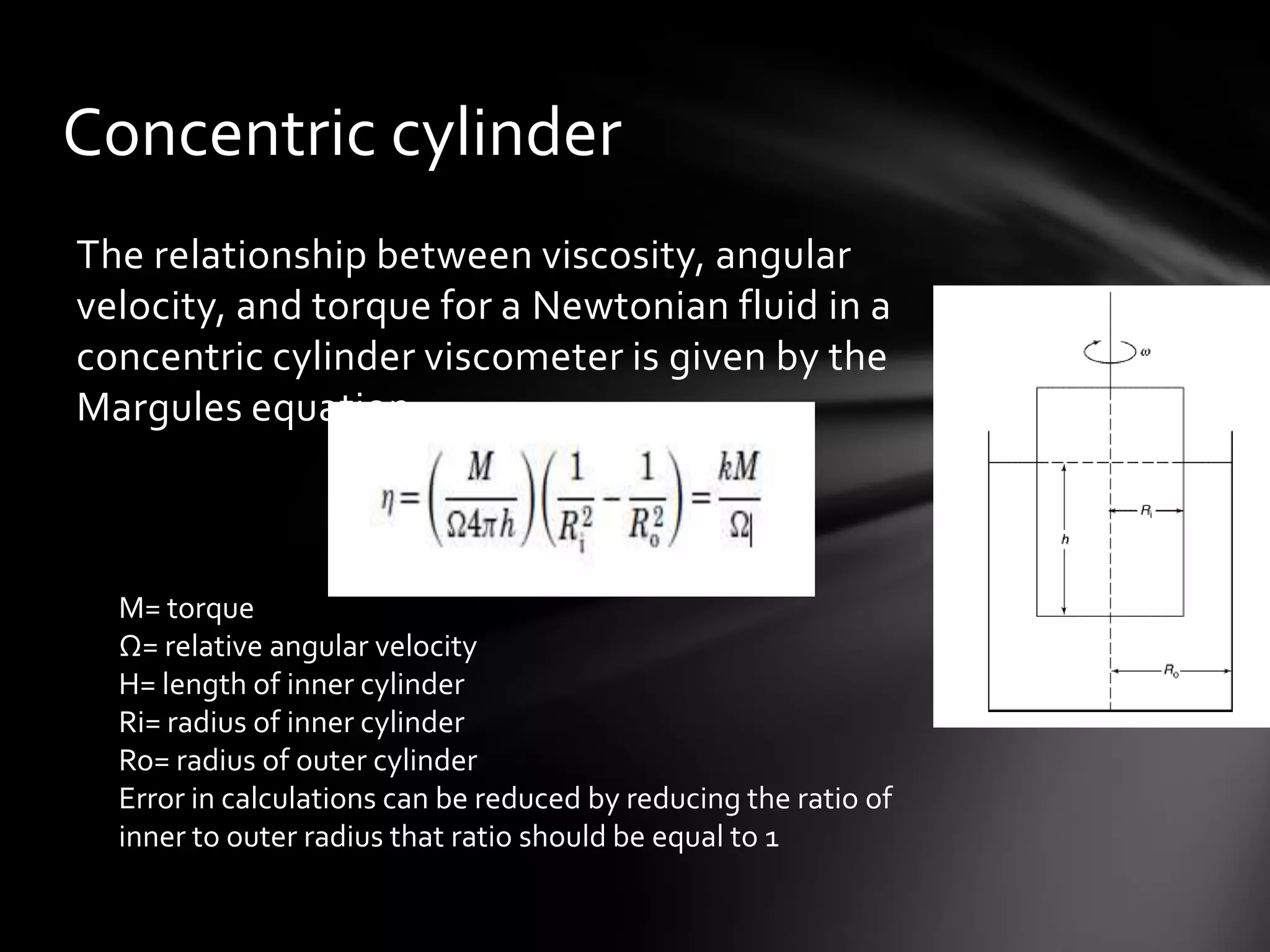

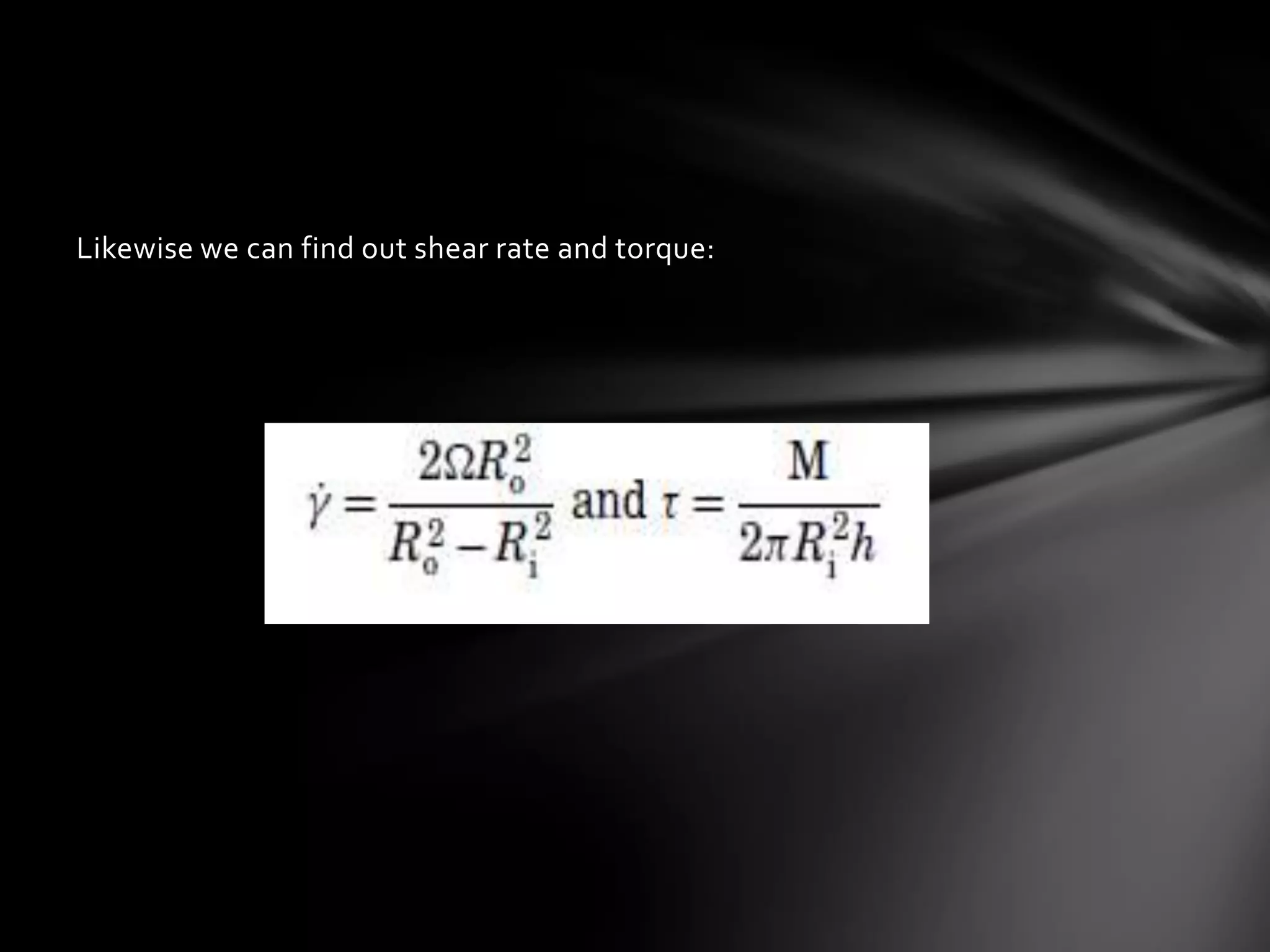

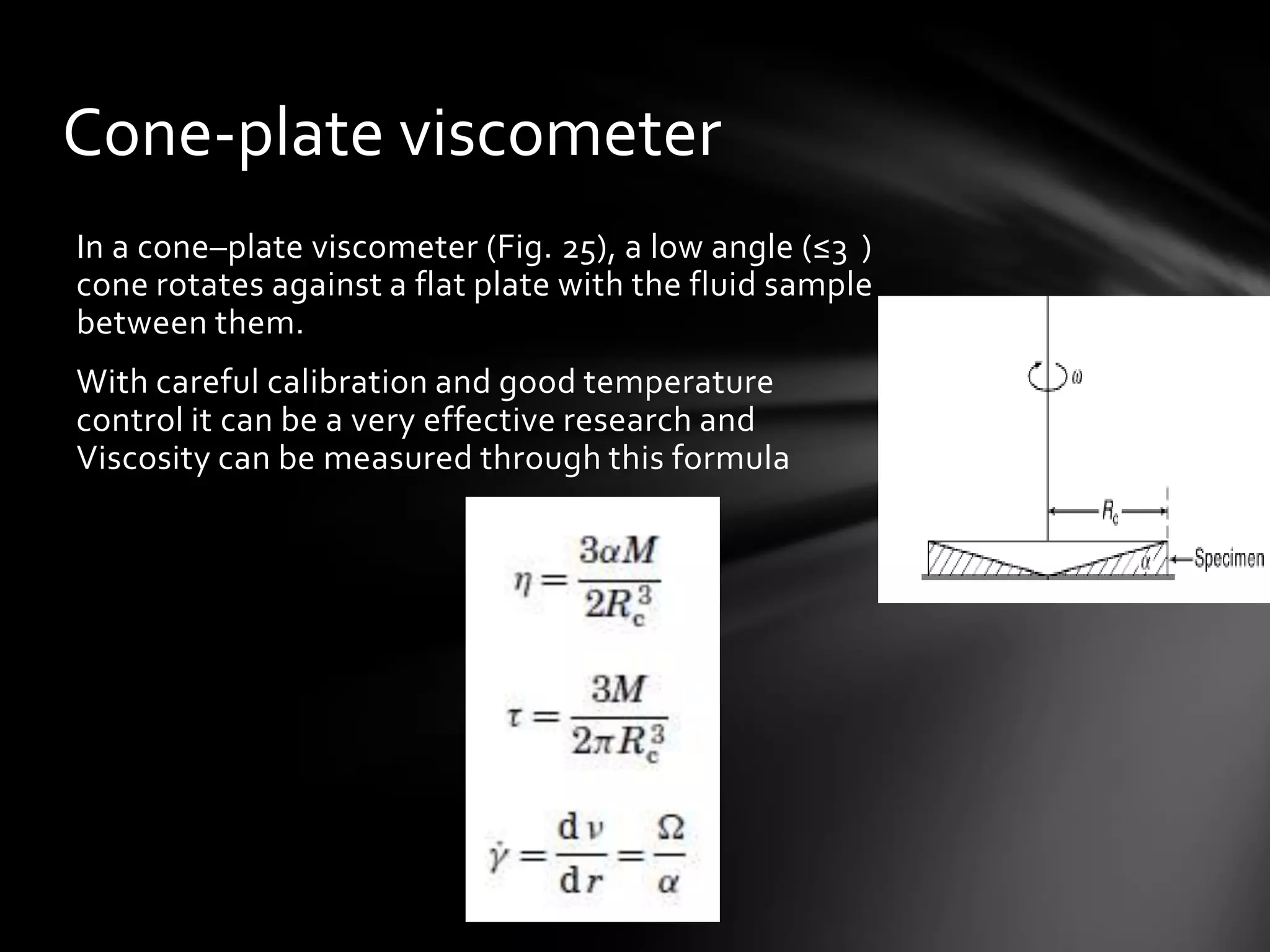

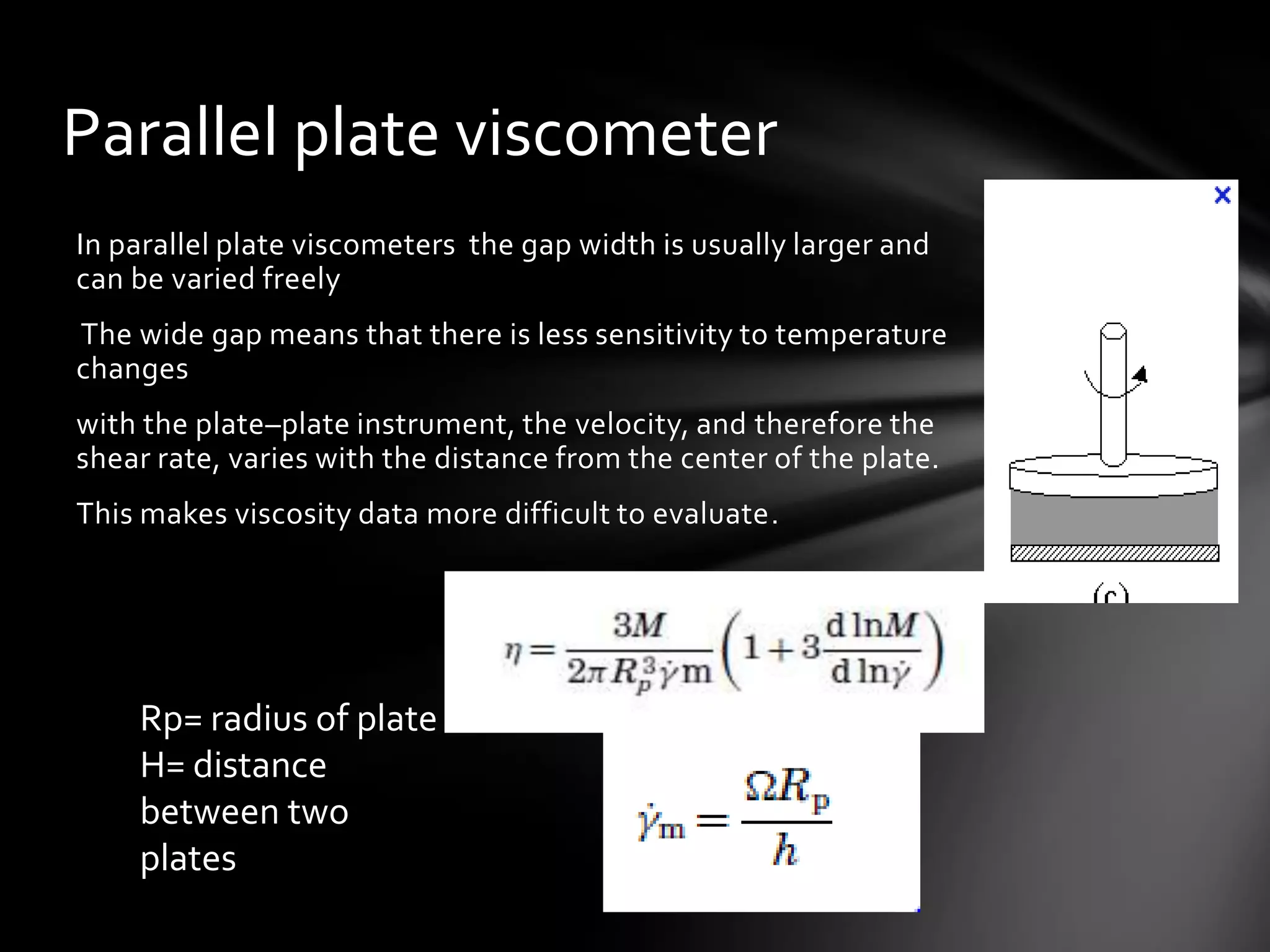

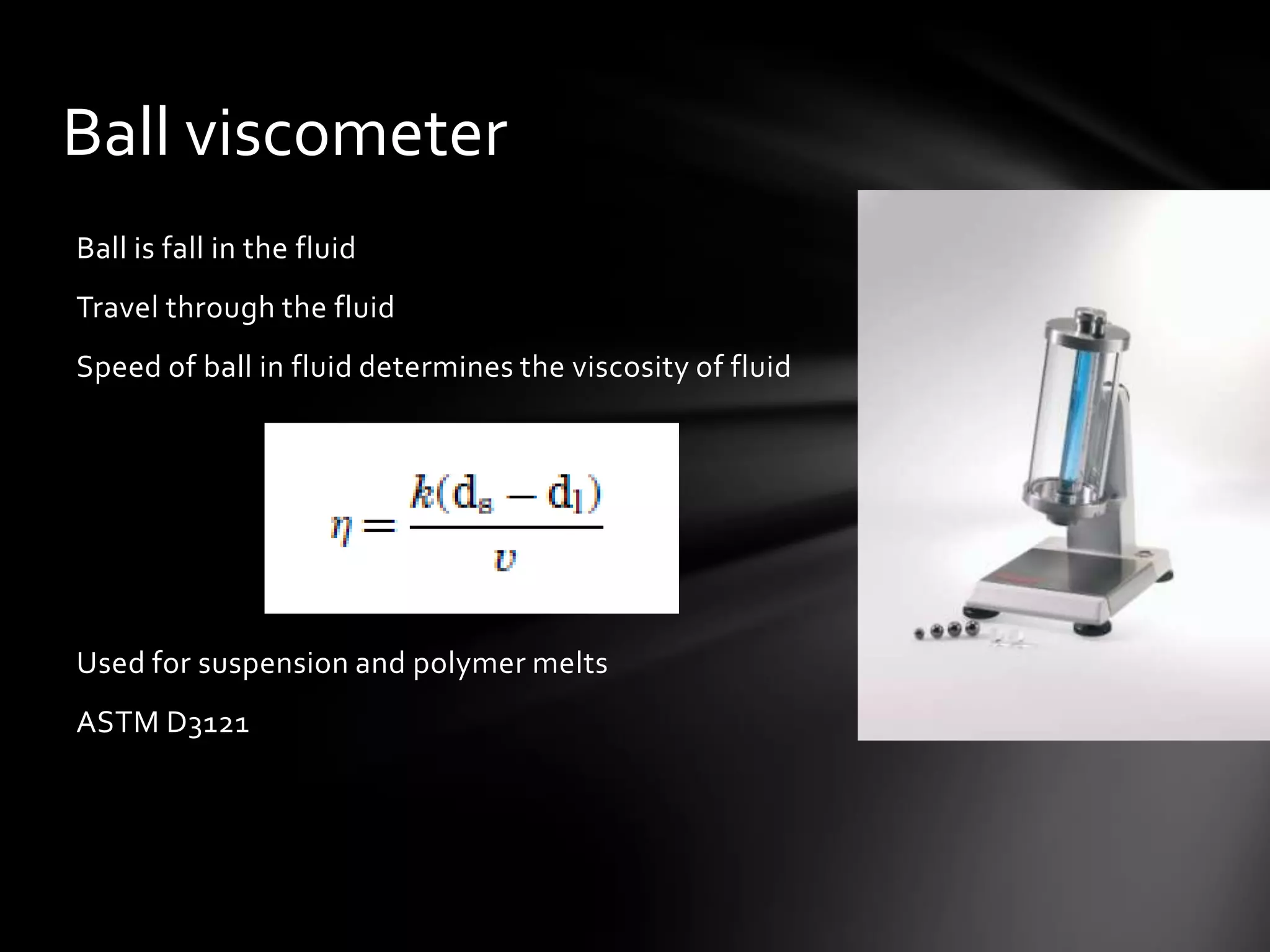

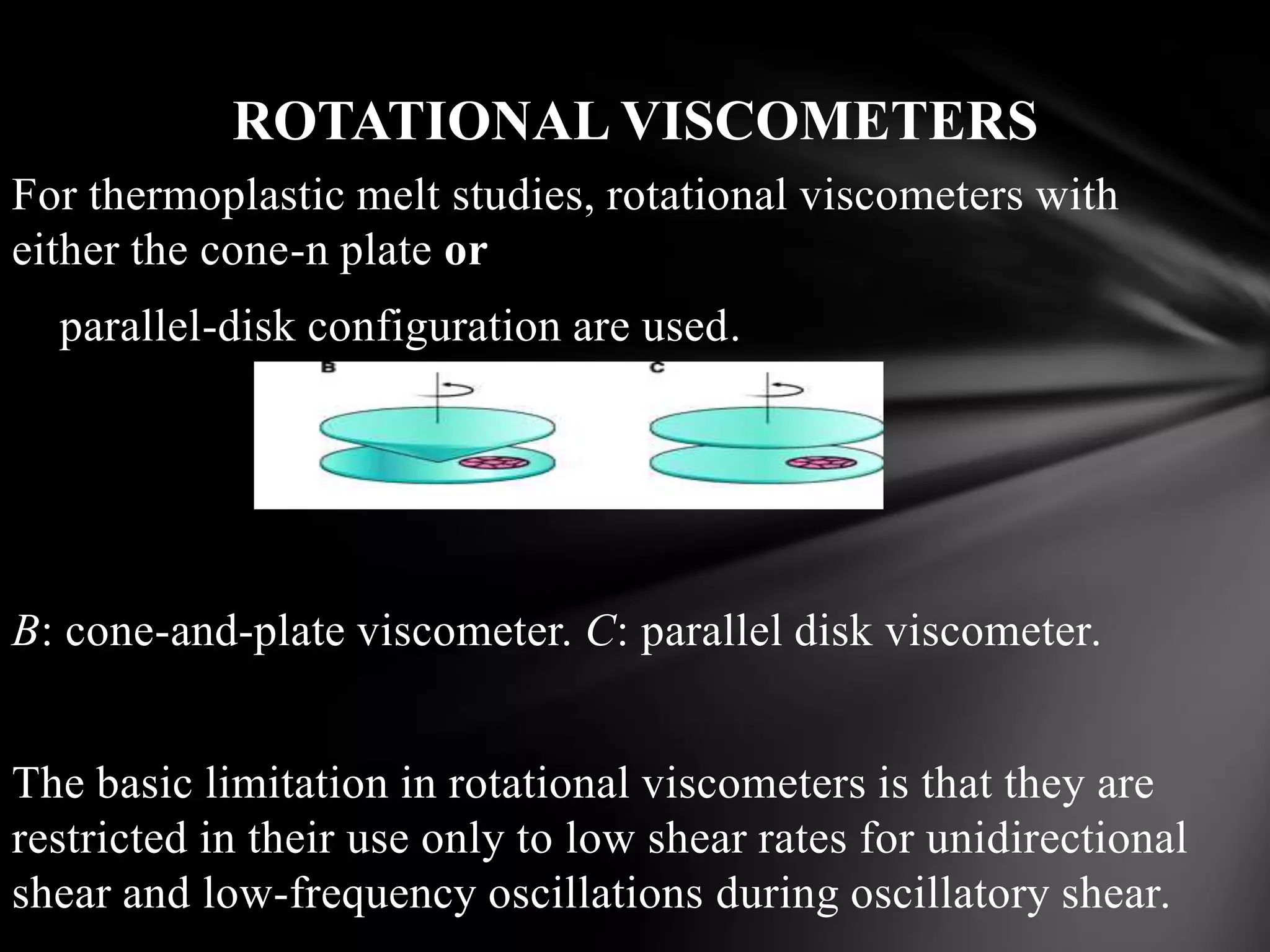

Rheology is the study of deformation and flow of matter. It involves measuring the viscosity and viscoelastic properties of materials under different conditions like temperature, pressure and shear rates. Various types of instruments called rheometers are used to measure rheological properties including rotational viscometers, capillary rheometers and other moving body viscometers. The document discusses different types of viscometers and rheometers used for measuring rheological properties of polymers and other materials.