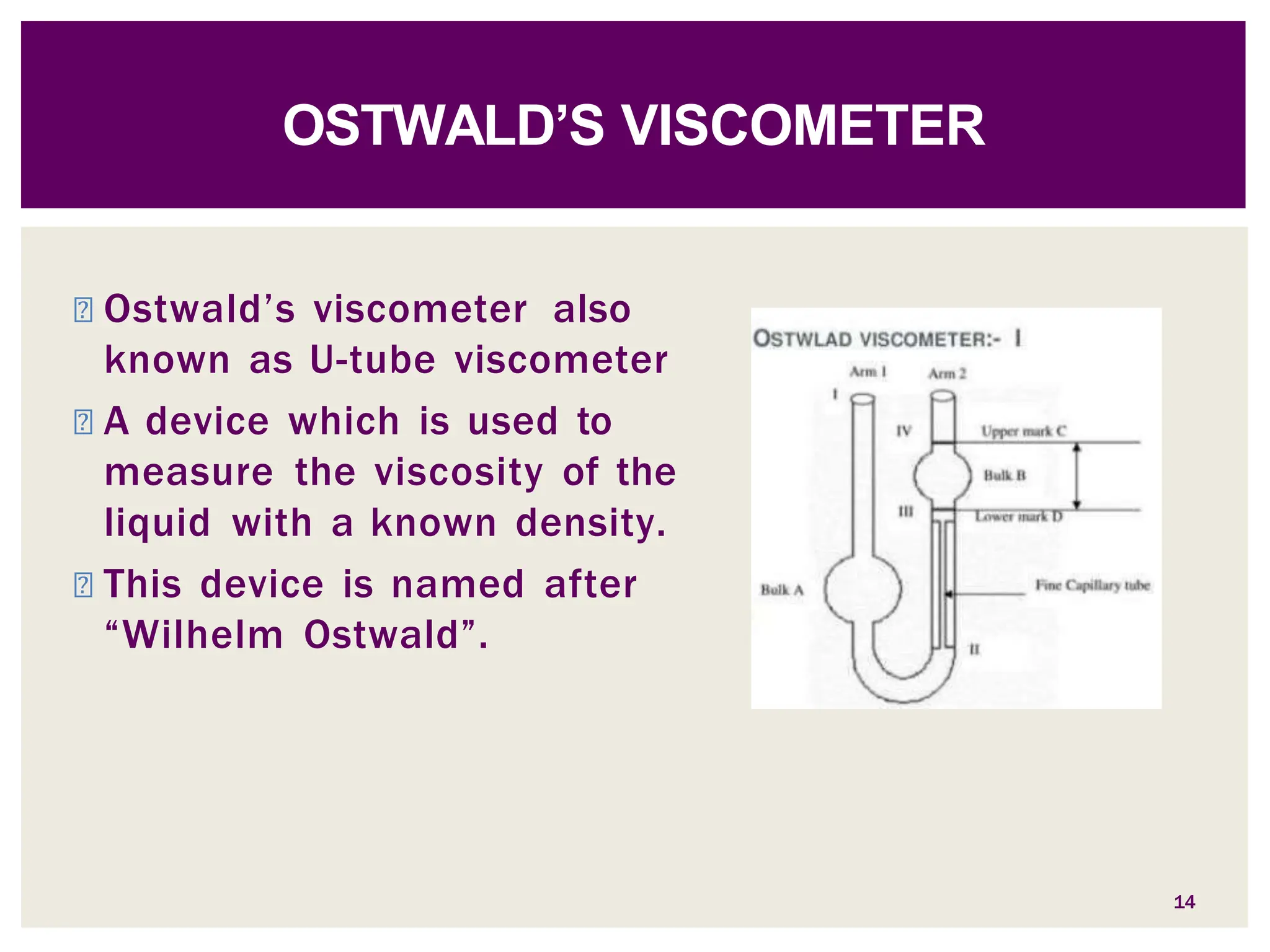

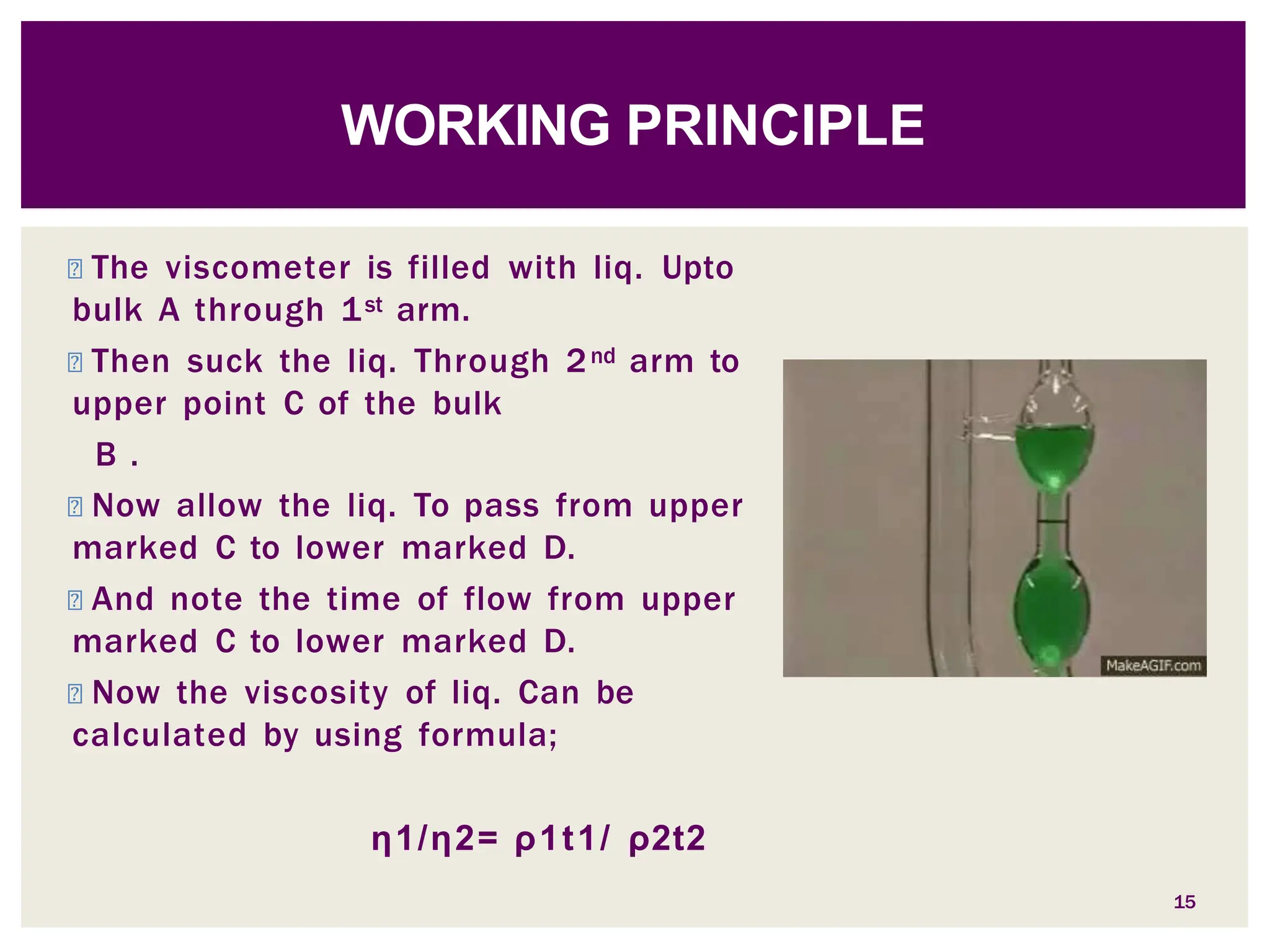

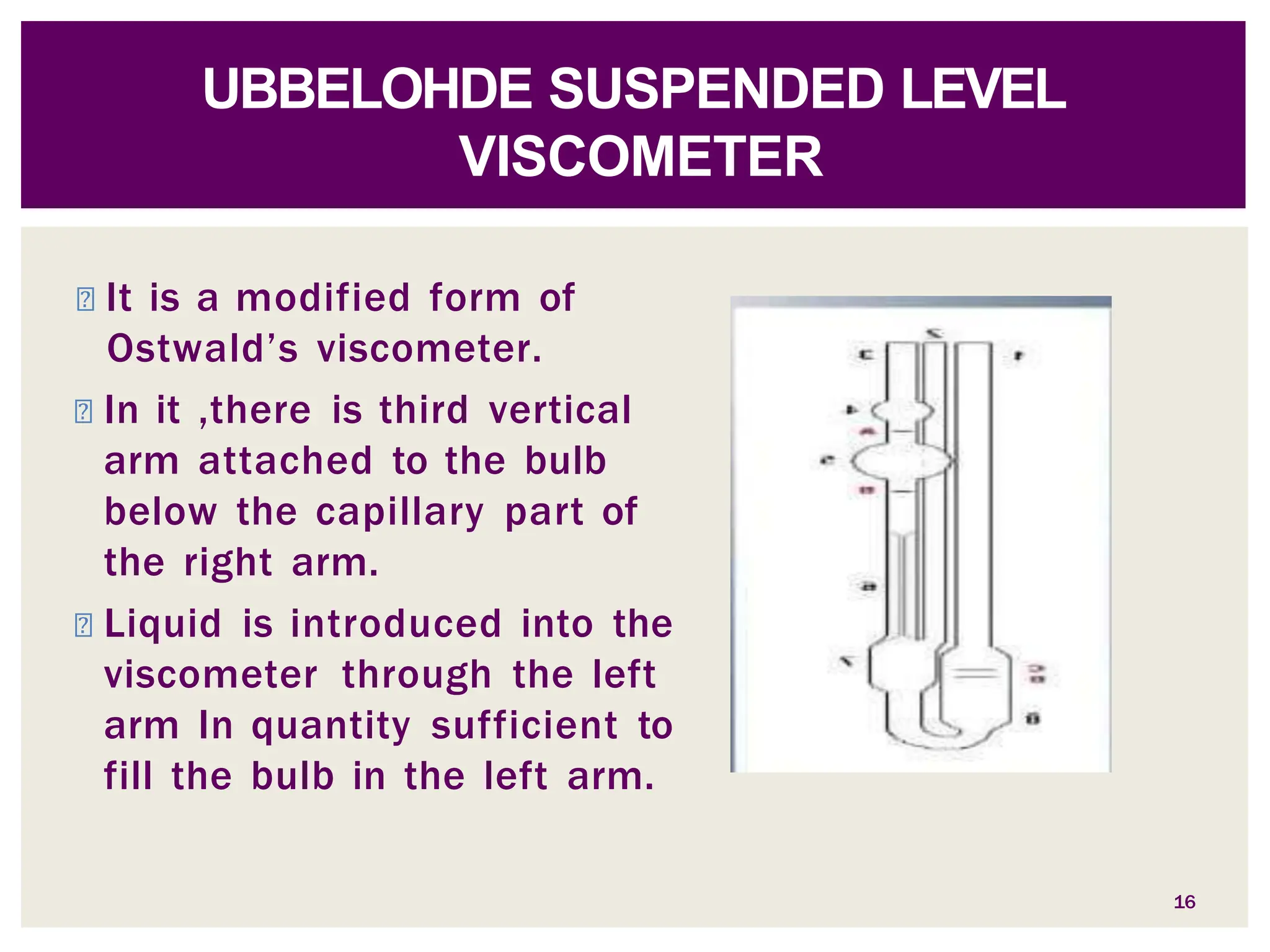

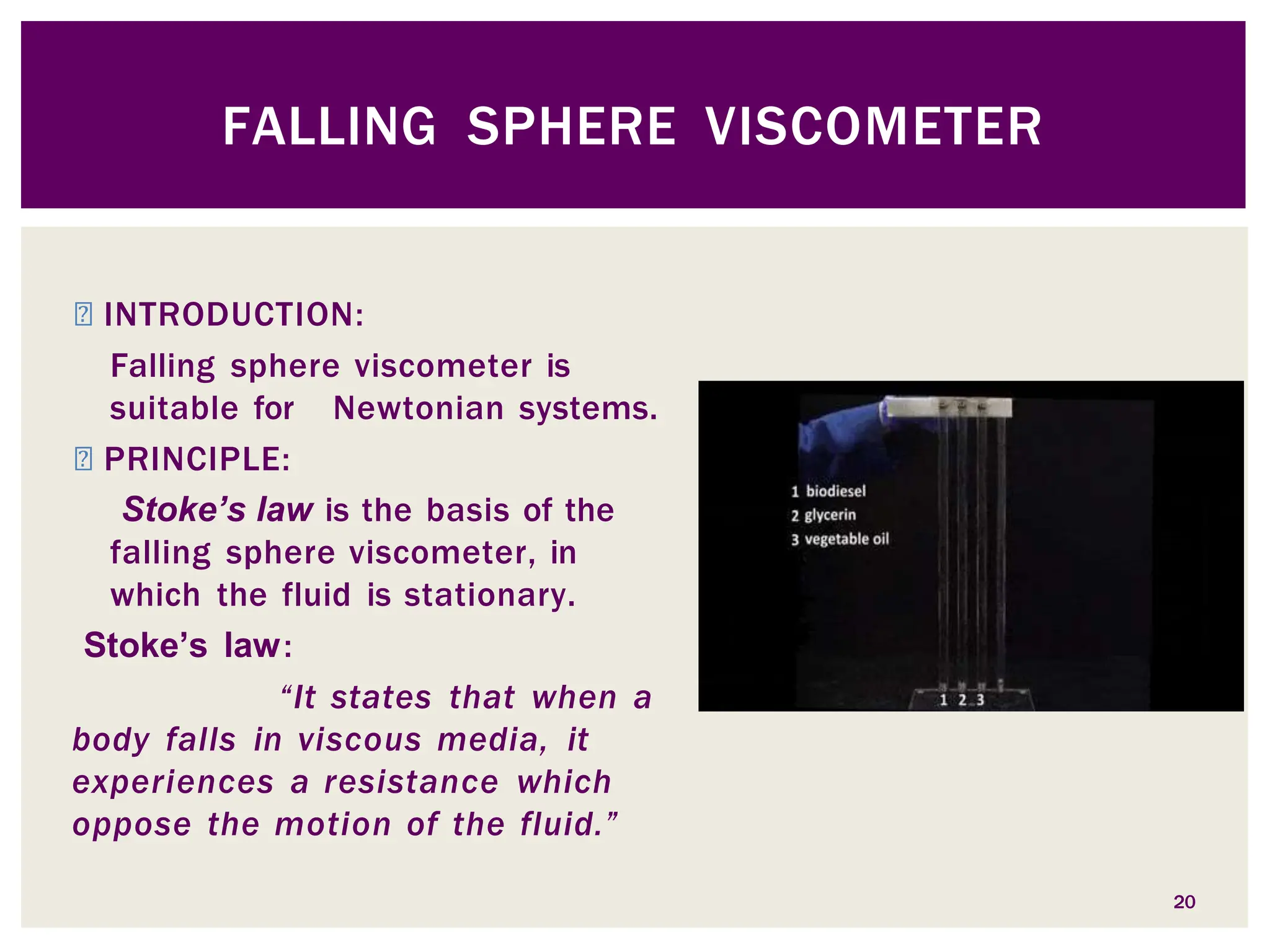

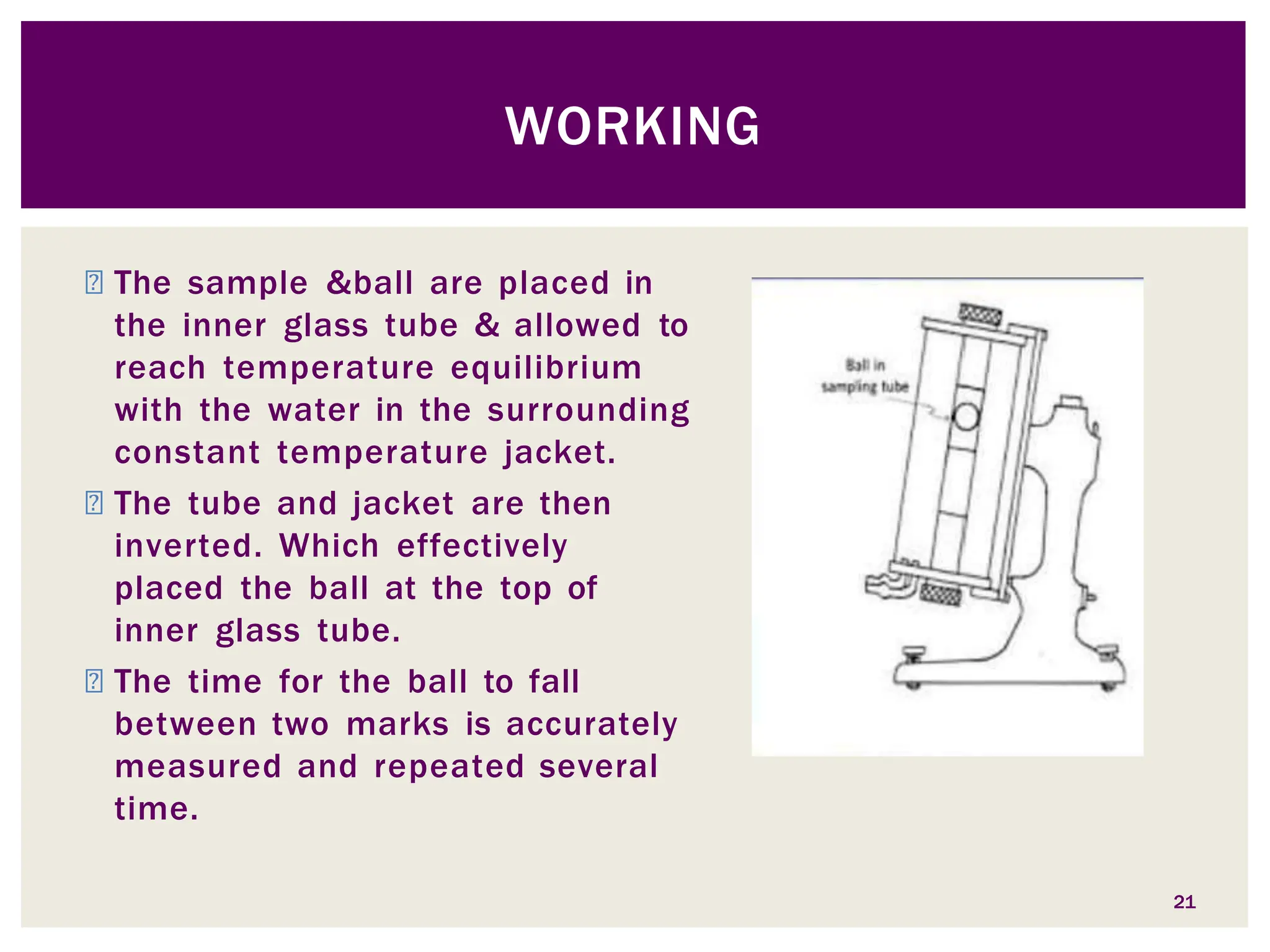

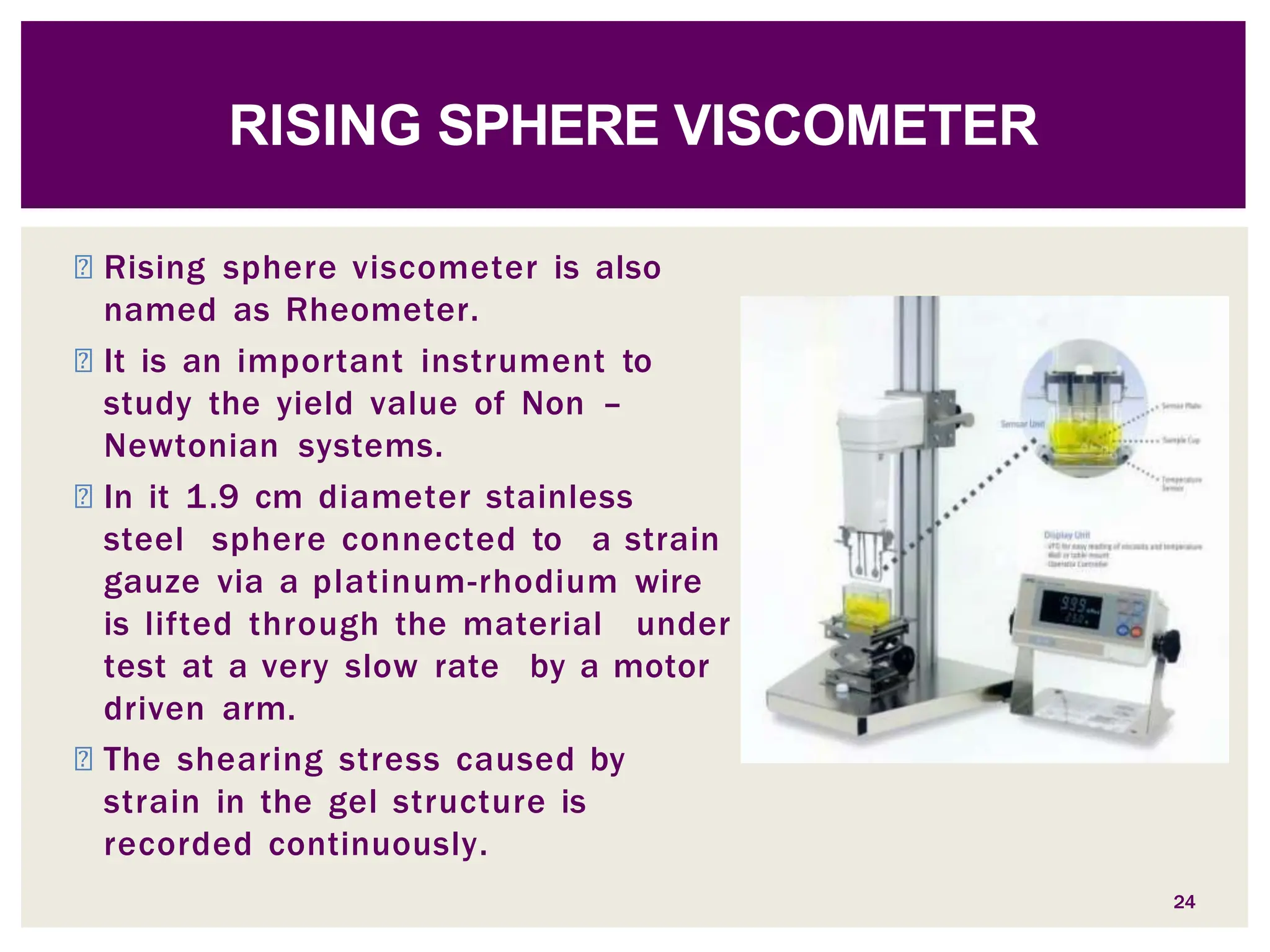

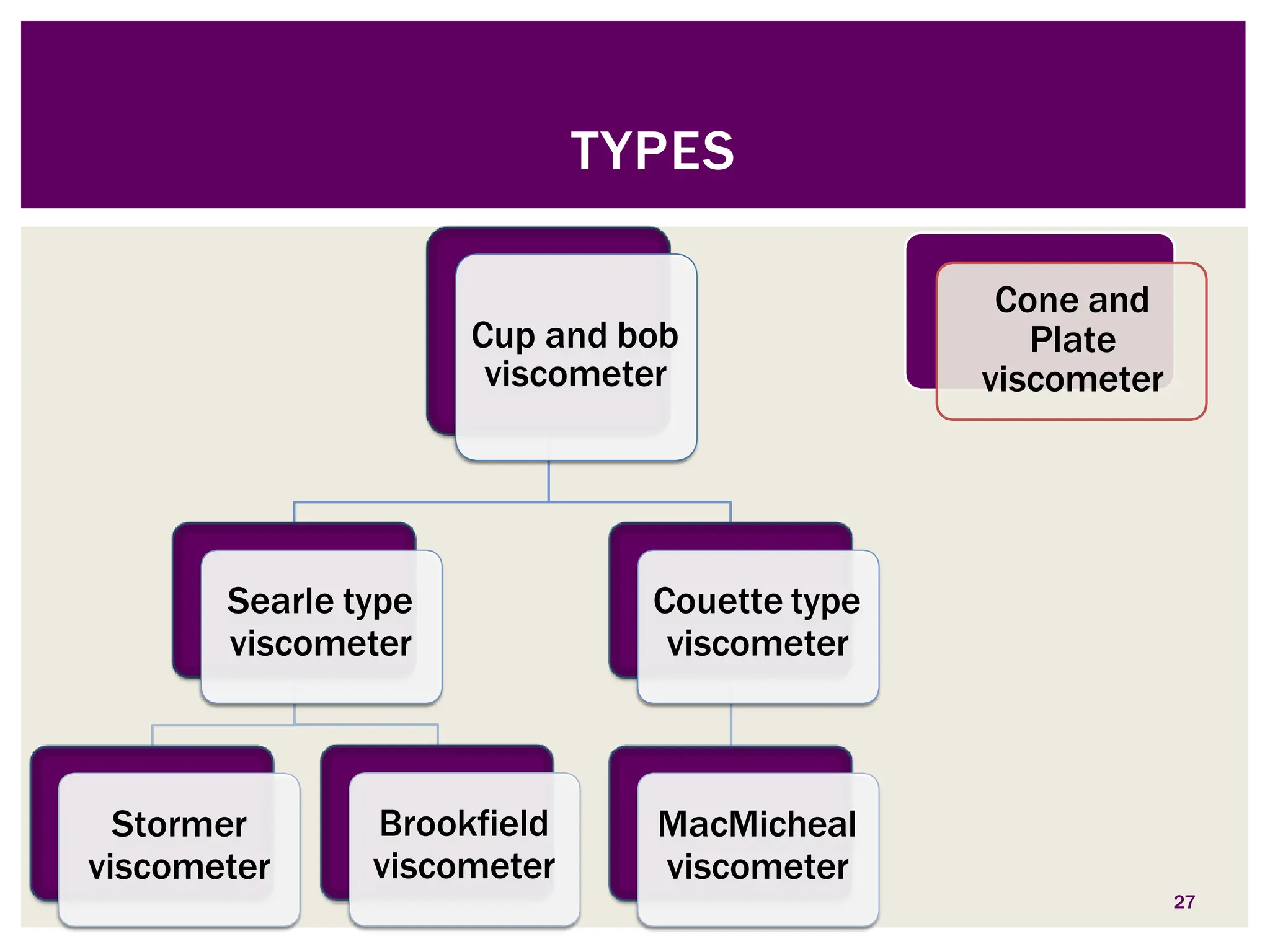

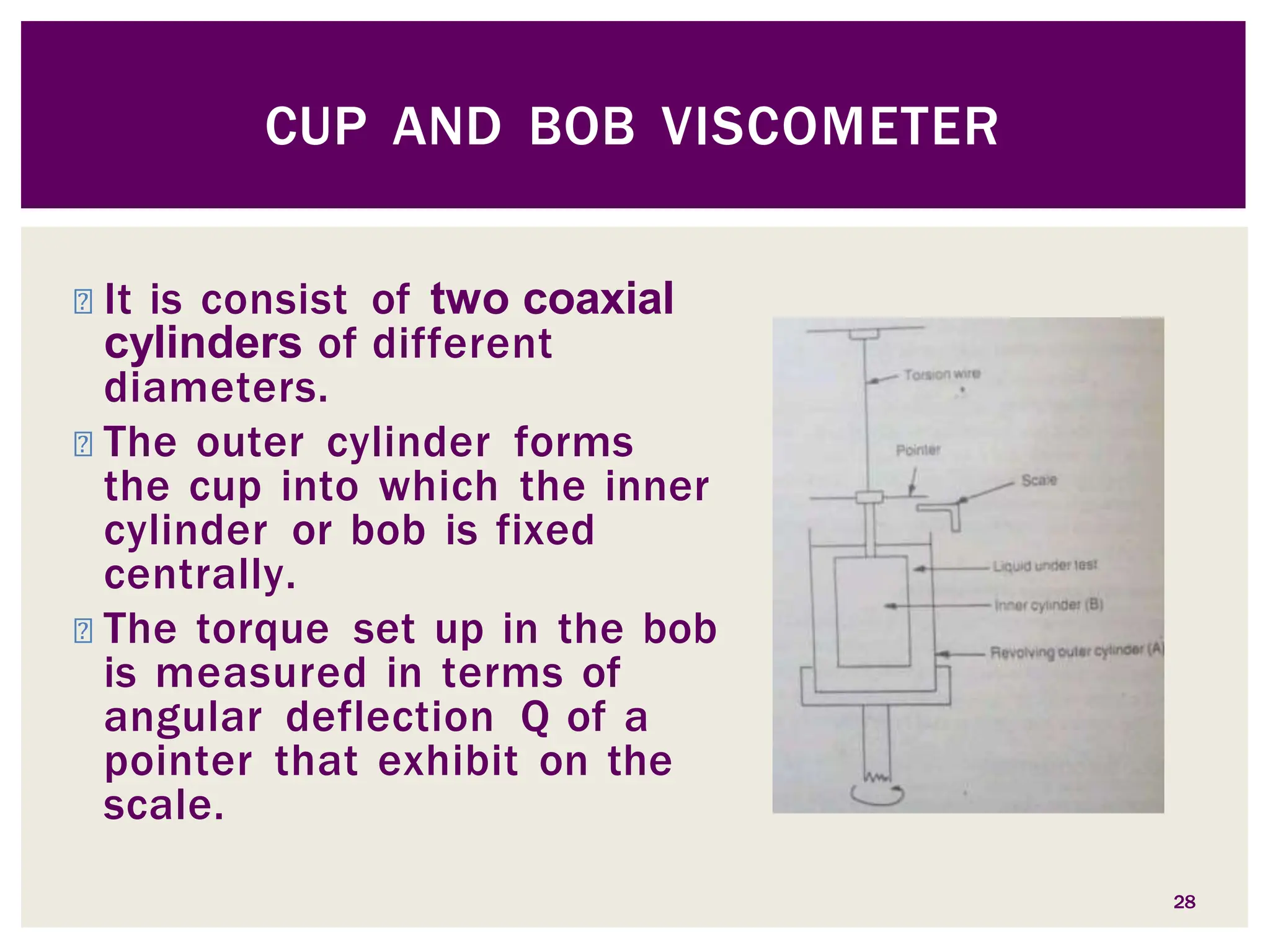

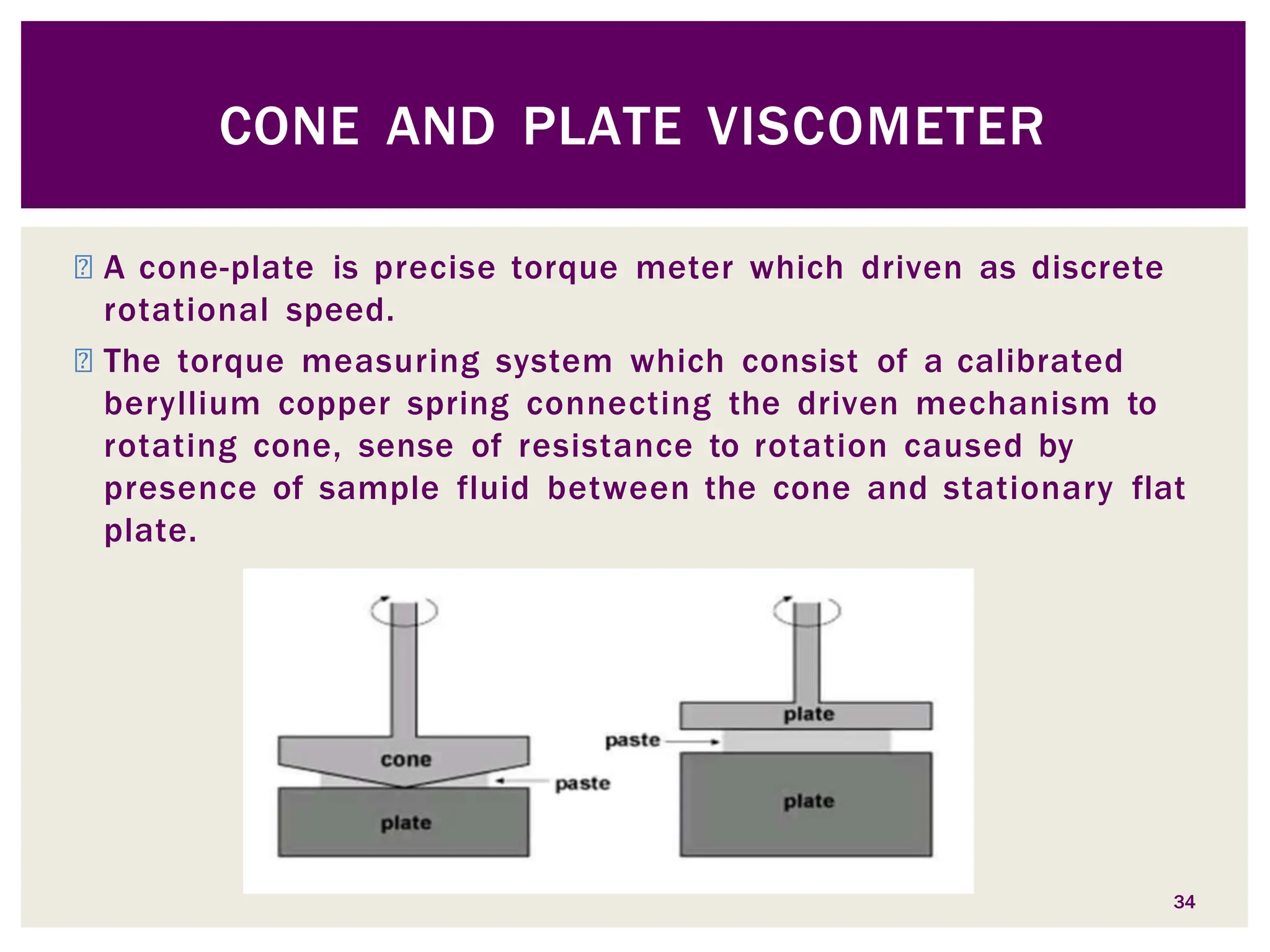

Viscosity is a measure of a fluid's resistance to flow. There are several types of viscometers used to measure viscosity, including capillary, falling/rising body, and rotational viscometers. Capillary viscometers measure the time it takes for a fluid to flow through a capillary tube, falling/rising body viscometers use Stokes' law to measure the terminal velocity of a ball falling or rising in a fluid, and rotational viscometers apply shear stress by rotating either a cup or bob and measuring the torque or rotation. Measuring viscosity is important for processes involving pumped or piped fluids.