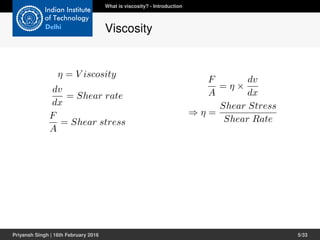

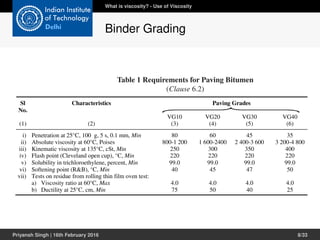

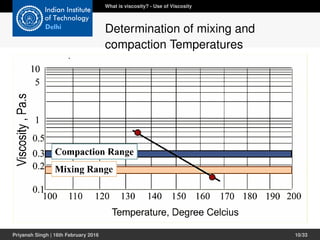

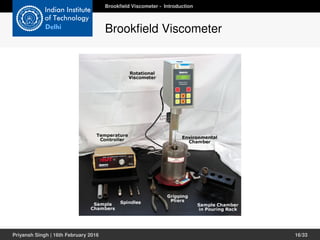

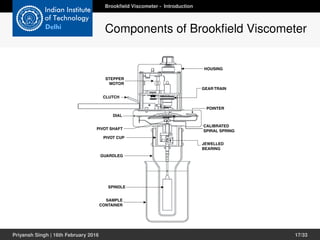

The document discusses the viscosity of binders at elevated temperatures, detailing its definition, measurement methods, and the functioning of the Brookfield viscometer. It explains how viscosity reflects a fluid's resistance to deformation and highlights the importance of viscosity measurement for understanding binder behavior and asphalt applications. Various empirical and absolute methods for measuring viscosity are presented, with an emphasis on the Brookfield viscometer's design and operational principles.

![instrument (dyne-cm)

L = effective length of

spindle (cm)

(see Appendix A.4)

Rc

Rb

L

ω

Rc

should not exceed 2Rb

for well defined

5.1 Advanced Methods for Rheological Analysis

As mentioned in Chapter 1, those who follow the

Academic school of thought on viscosity measurement

have more complex needs than those who follow the

Pragmatic or “Theoretical” schools. They need viscos-

ity data that are defined in rheological terms. This usu-

ally requires a complete mathematical description of

the Viscometer’s operating parameters and an analysis

of the rheological behavior of the fluid being studied.

Previous chapters have described various types of

fluid behavior and their relationship to measurements

made with Brookfield Viscometers/Rheometers and

accessories. The Appendix details the significant

operating parameters of this equipment and presents

simplified formulas for obtaining shear rate and shear

stress values. However, for many this information is

still inadequate to perform the type of analysis they

require. Having identified a particular flow behavior

and defined it mathematically, these people need more

information to understand how the fluid will react in a

certain situation, and how to control that reaction. If

is for these people that this chapter is provided.

In it you will find basic formulas from which the

simplified shear rate and shear stress information in

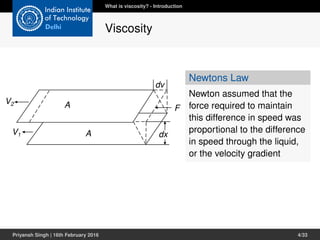

SHEAR STRESS

(dynes/cm2): τ =

M

2 π Rb2L

2 ω Rc2 Rb2

x2 (Rc2 — Rb2)

SHEAR RATE

(sec-1): = (1)

(2)

(3)

VISCOSITY

(poise): η =

τ

⋅γ

Definitions: ω = angular velocity of spindle

(rad/sec)

[ = N], N = RPM

Rc = radius of container (cm)

Rb = radius of spindle (cm)

x = radius at which shear rate

is being calculated (cm)

M = torque input by

instrument (dyne-cm)

L = effective length of

spindle (cm)

(see Appendix A.4)

2 π

60( )

⋅γ

CHAPTER 5: Data Analysis

system. If the dispersed phase has a tendency

to settle, producing a non-homogeneous fluid, the

rheological characteristics of the system will change.

In most cases, this means that the measured

viscosity will decrease. Data acquired during such

conditions will usually be erroneous, necessitating

special precautions to ensure that the dispersed

phase remains in suspension.

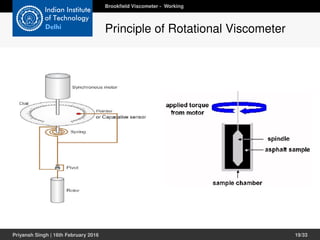

Brookfield Viscometer - Working

Principle of Rotational Viscometer

Priyansh Singh | 16th February 2016 21/33](https://image.slidesharecdn.com/brookfield-160626164937/85/Viscosity-of-Binder-at-Elevated-Temperature-Using-Brookfield-Viscometer-21-320.jpg)