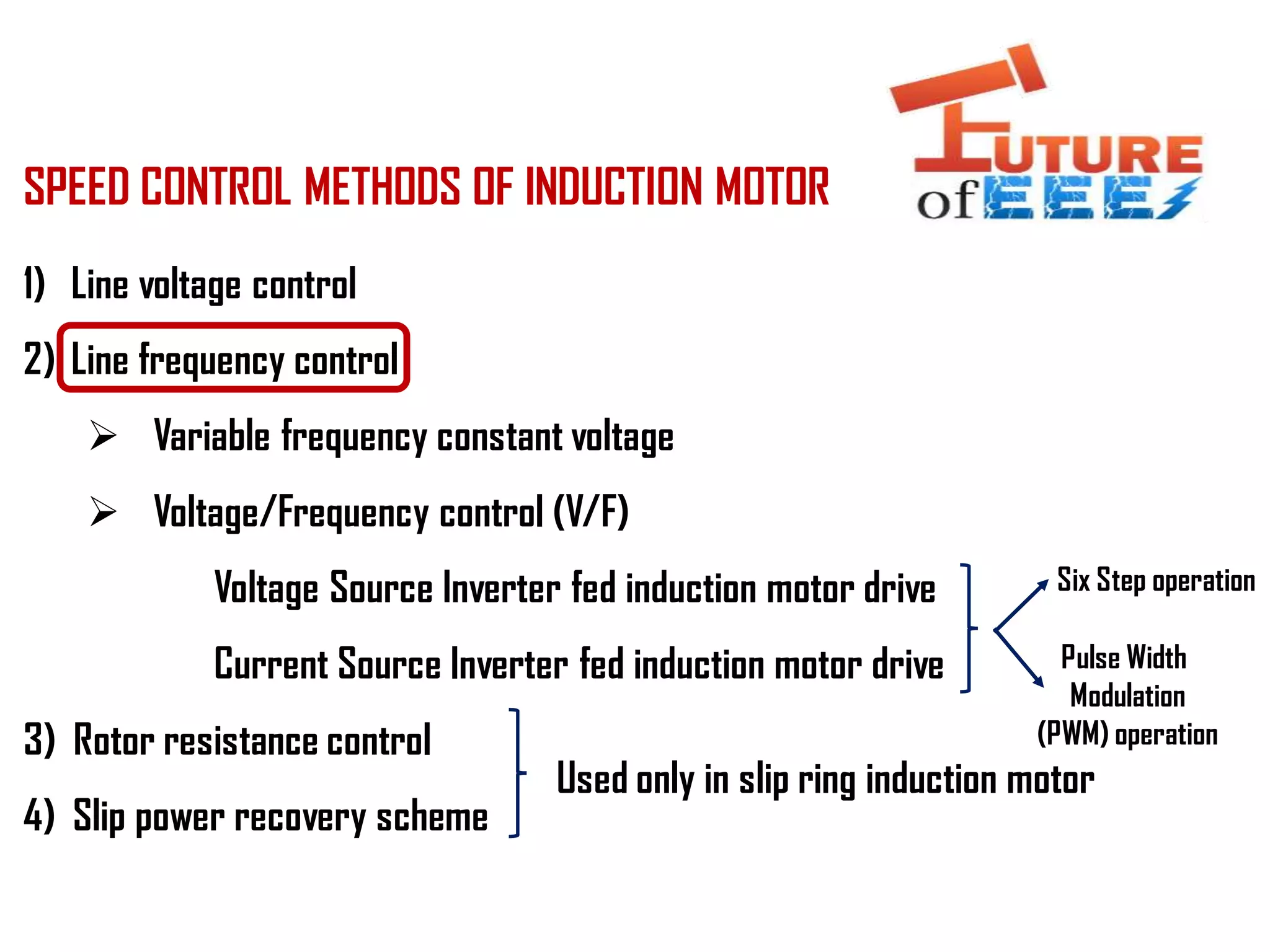

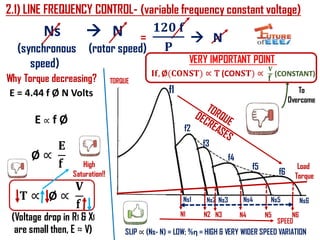

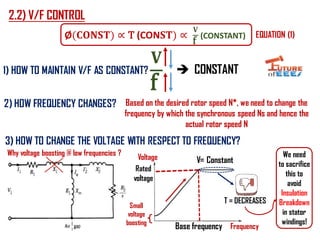

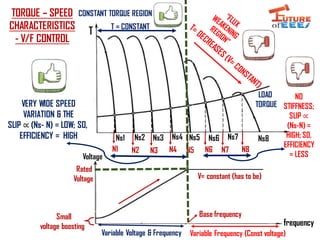

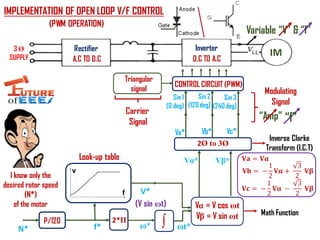

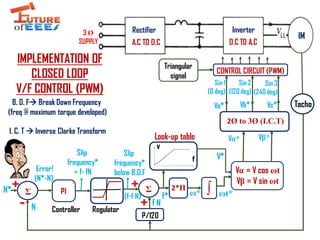

The document discusses various speed control methods for induction motors, including line voltage control, line frequency control, rotor resistance control, and slip power recovery schemes. It emphasizes techniques like voltage/frequency (v/f) control and pulse width modulation (PWM) for controlling the motor's operation. The document also outlines the mathematical framework and implementation strategies for both open-loop and closed-loop v/f control systems.