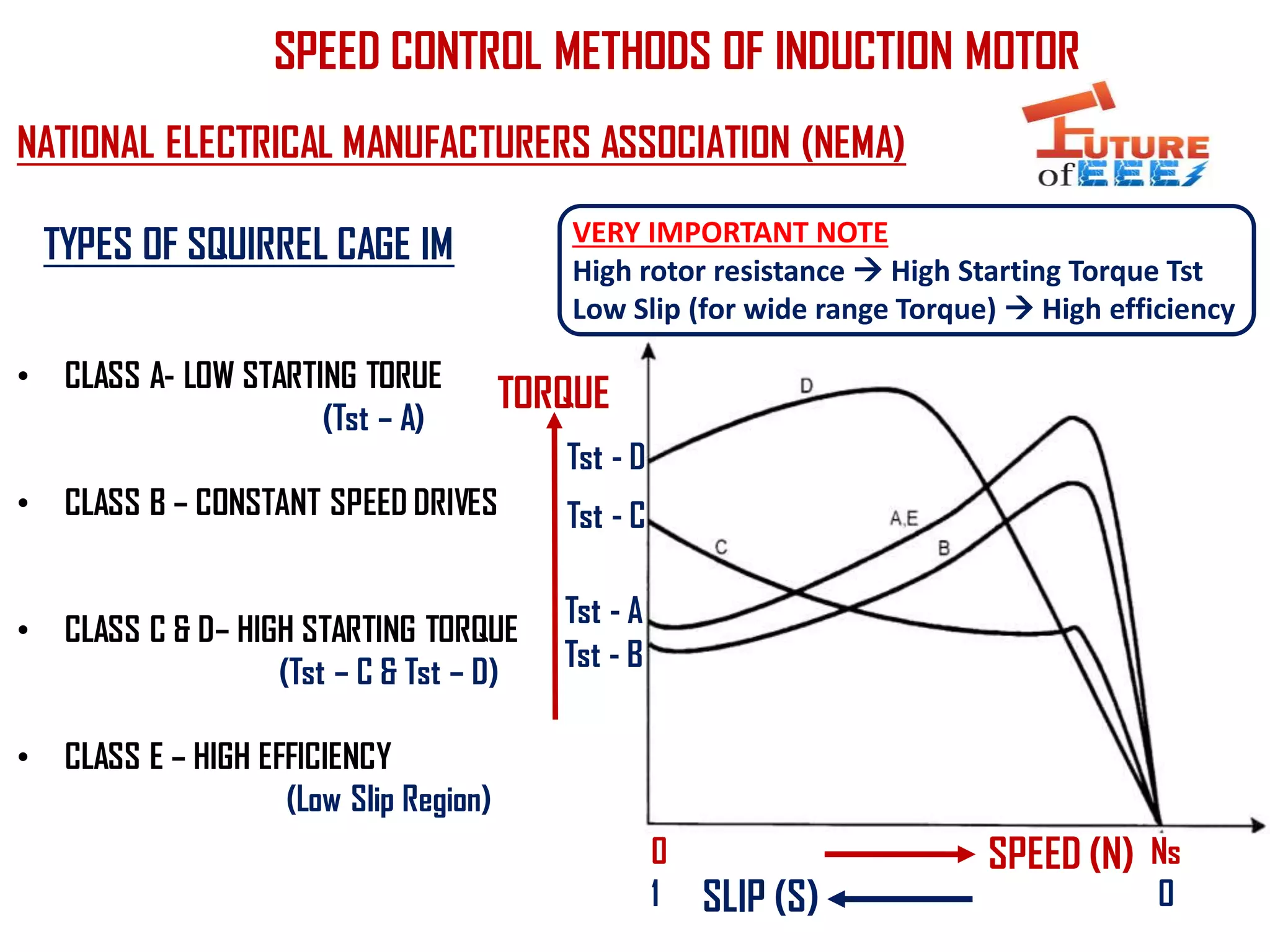

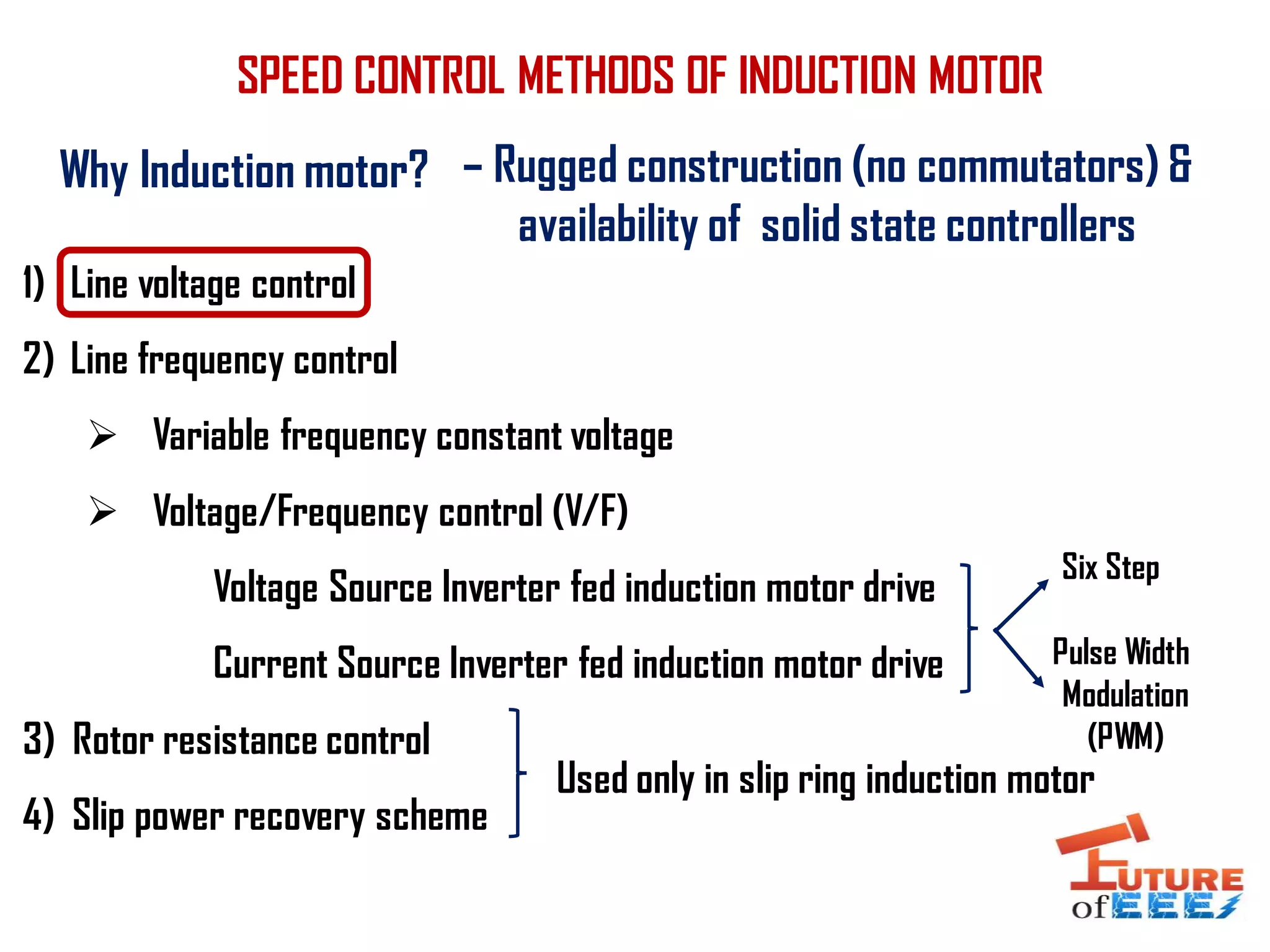

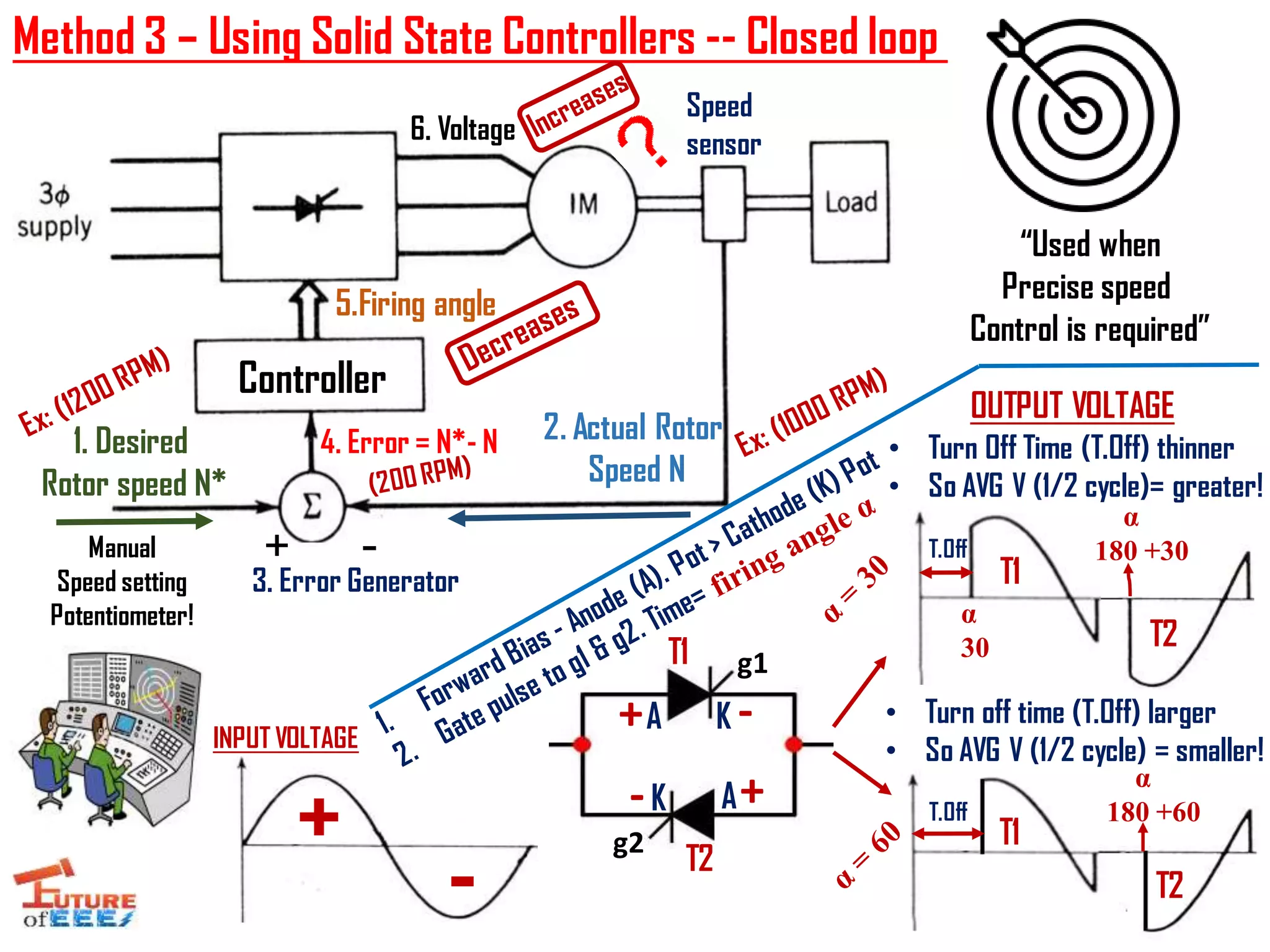

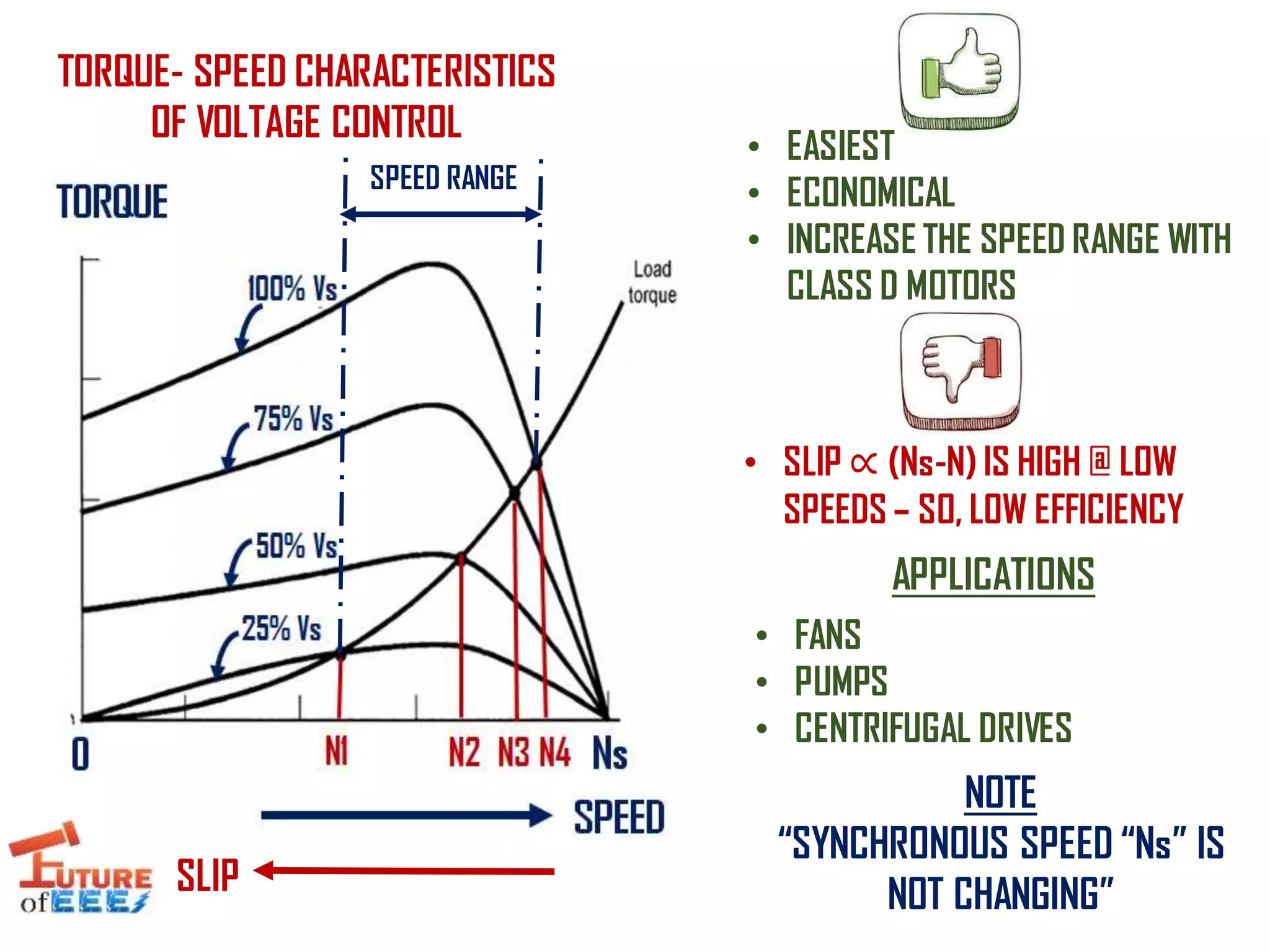

The document outlines various types of squirrel cage induction motors as classified by NEMA, highlighting their starting torque characteristics and applications. It also describes several speed control methods for induction motors, including line voltage, line frequency, and rotor resistance control. Additionally, it emphasizes the efficiency and performance advantages of class D motors in applications like fans, pumps, and centrifugal drives.