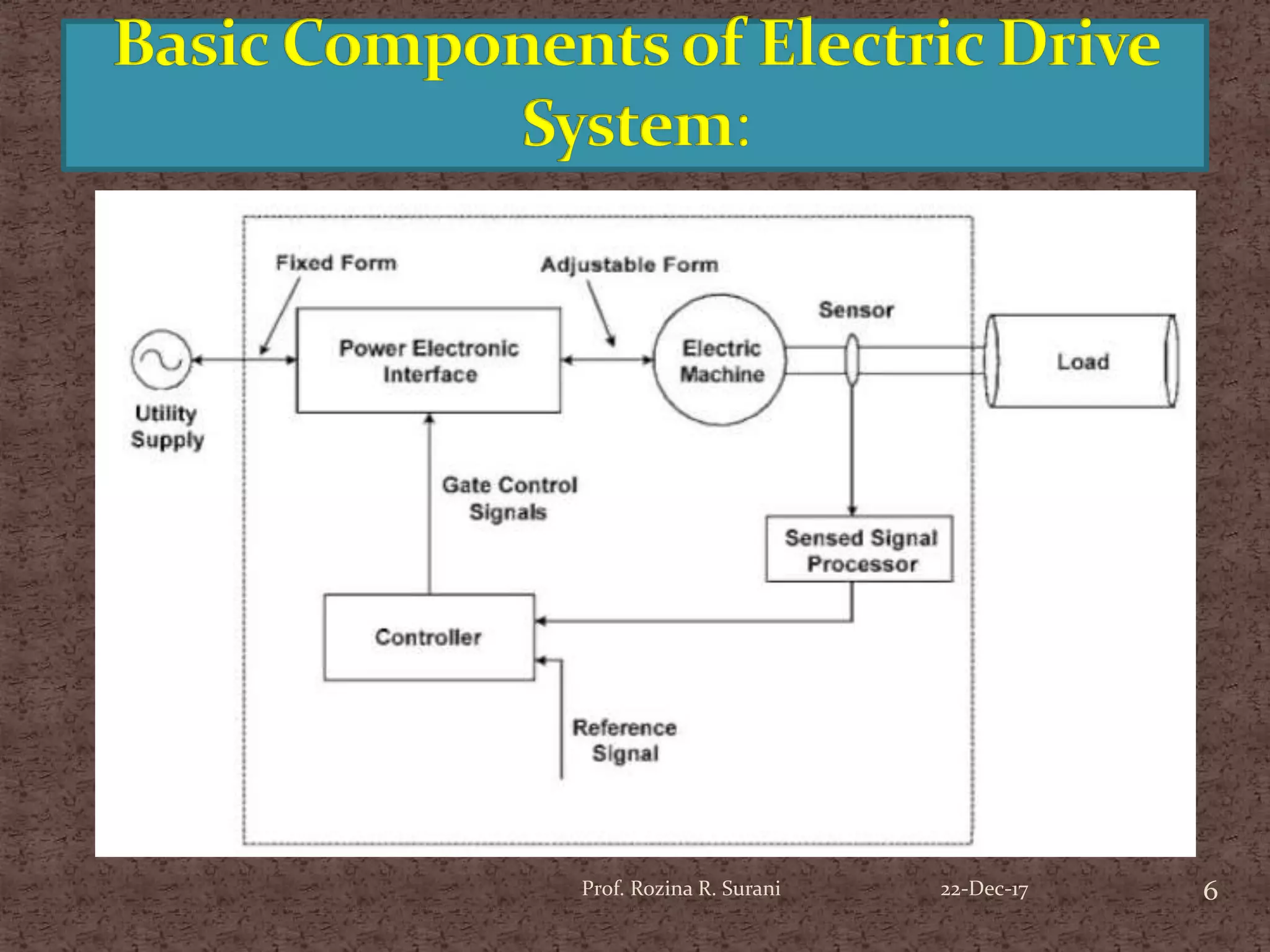

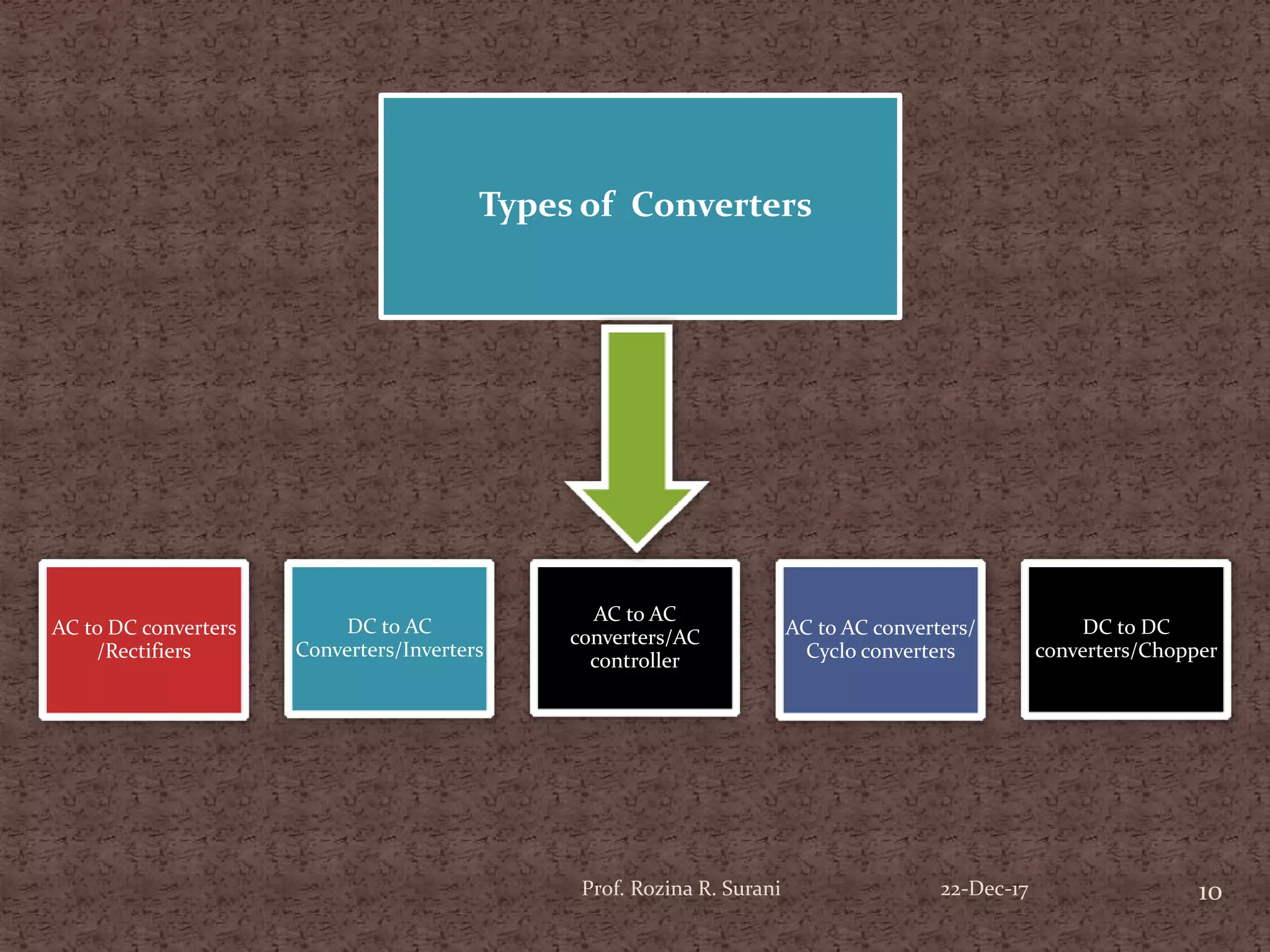

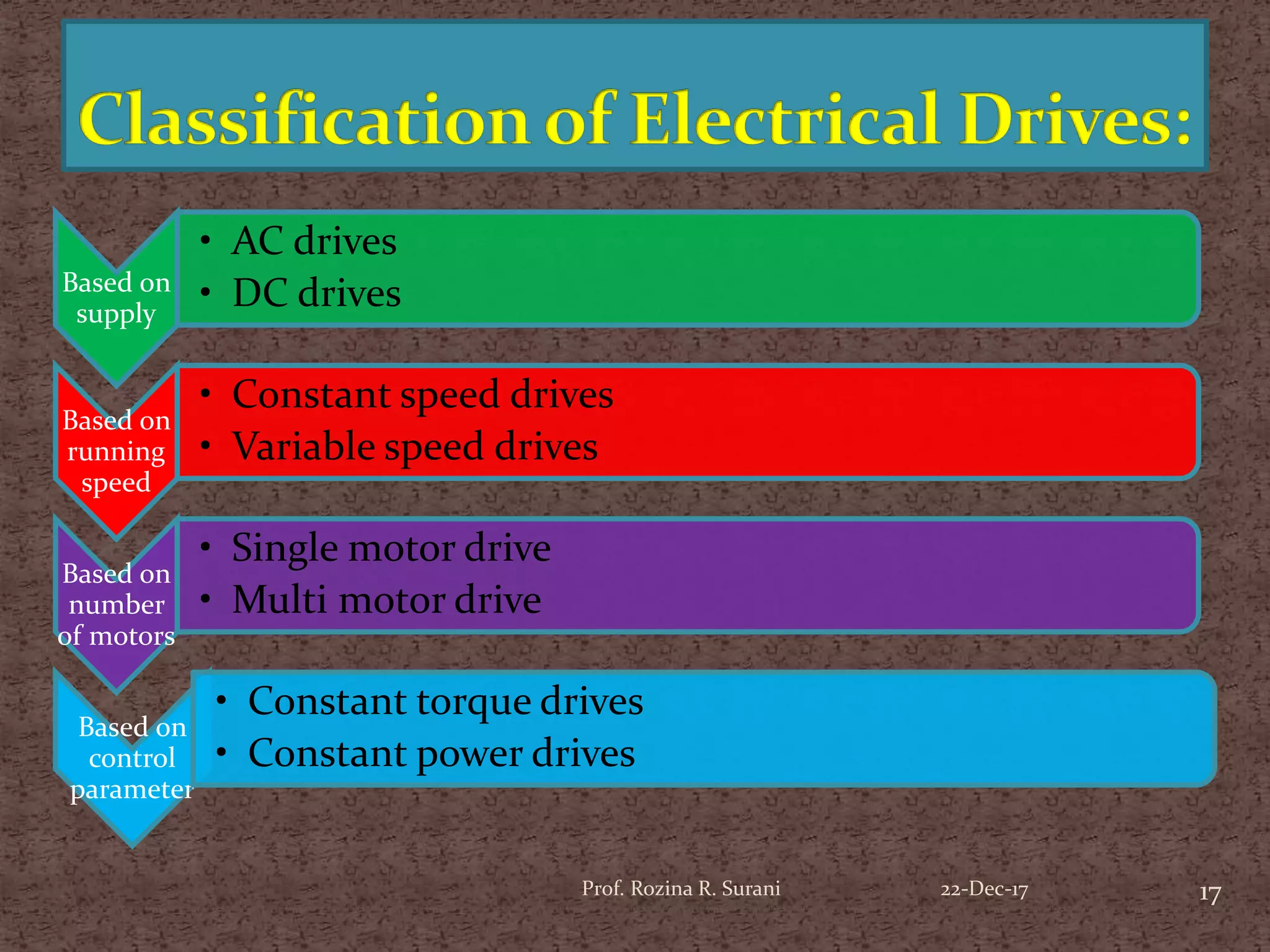

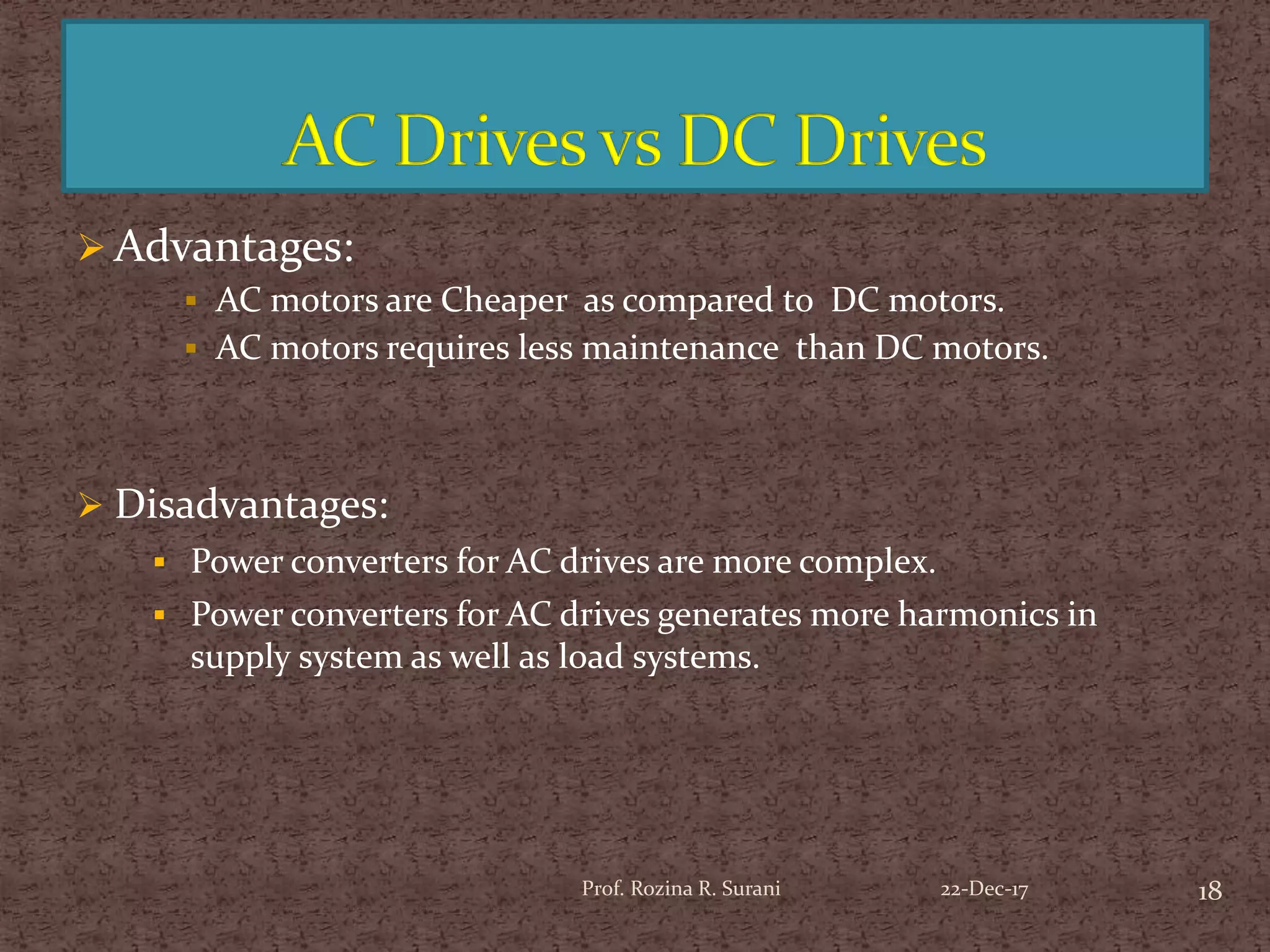

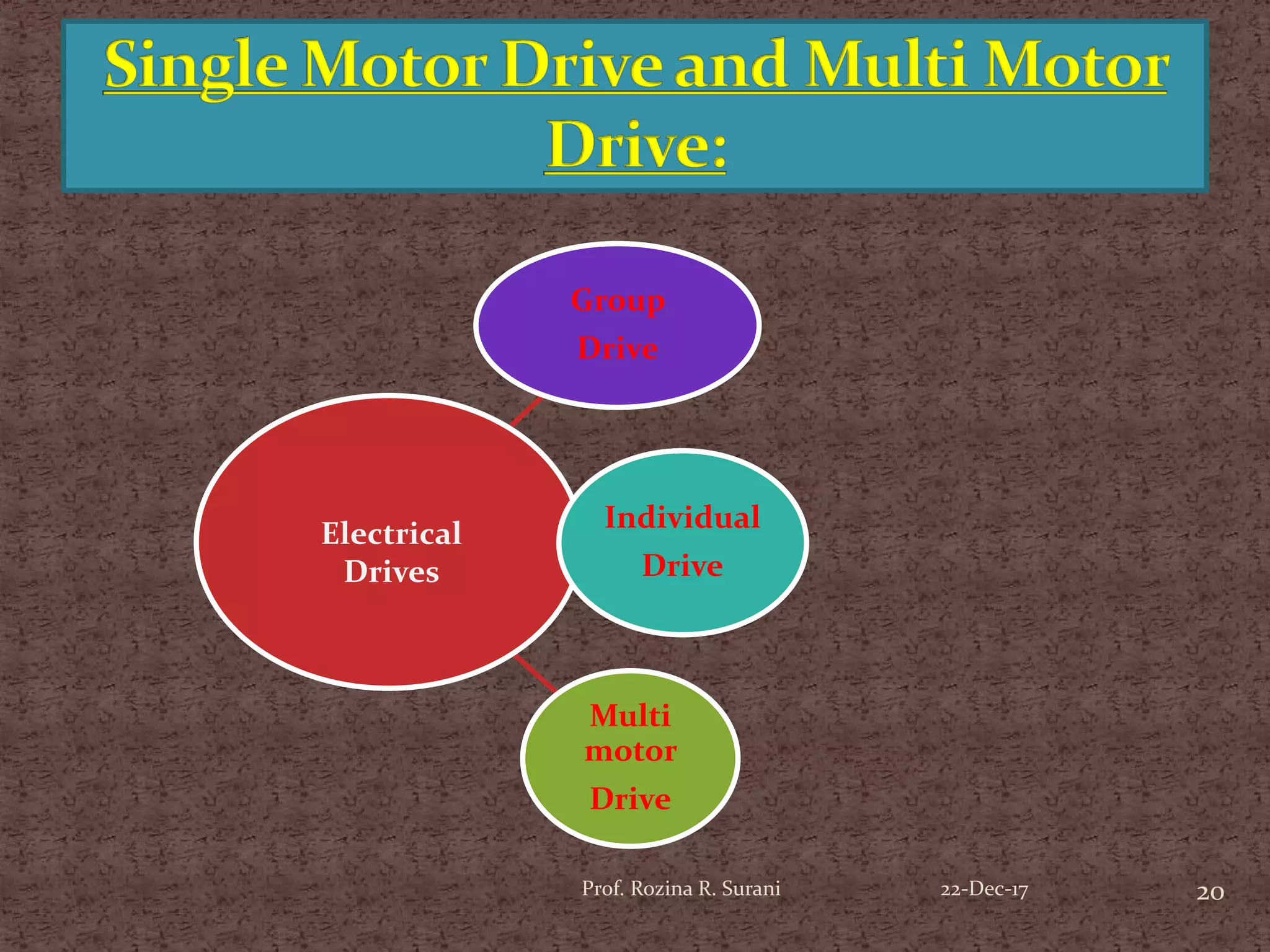

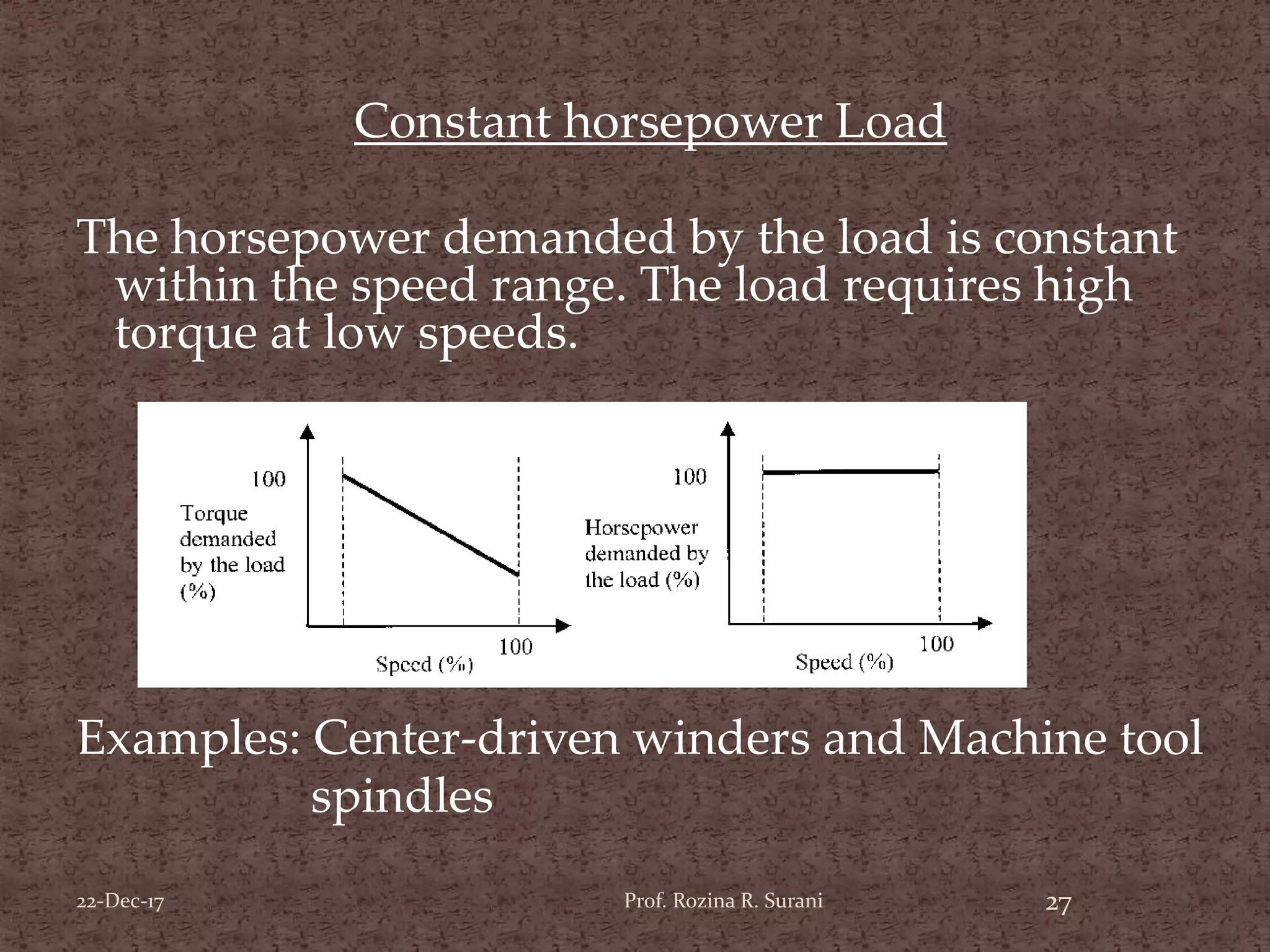

This document provides an introduction to electric drives. It discusses the key components of an electric drive system including the power source, power modulator, motor, mechanical load, and control unit. AC and DC drives are compared in terms of their operating principles, advantages, and applications. Common motor types for electric drives are also outlined along with examples of industrial and domestic applications that employ electric drives for motion control.