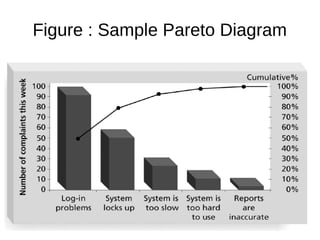

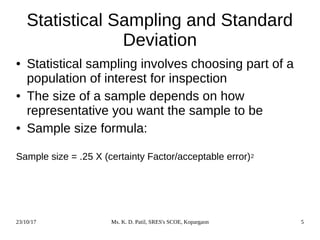

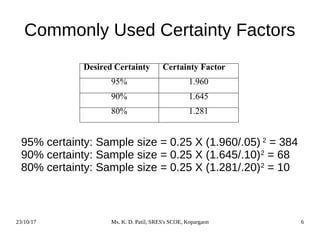

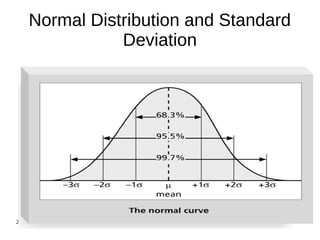

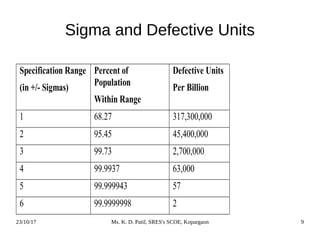

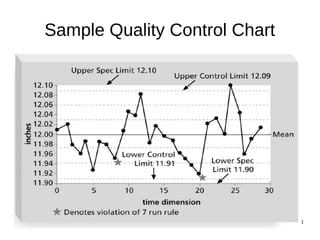

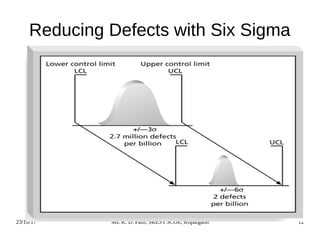

The document discusses quality control in software engineering and project management, outlining key outputs such as acceptance decisions and rework. It covers tools and techniques including Pareto analysis, statistical sampling, and quality control charts, emphasizing the importance of measuring variations in data through standard deviation. The document highlights methods for reducing defects, including the use of six sigma and control charts.