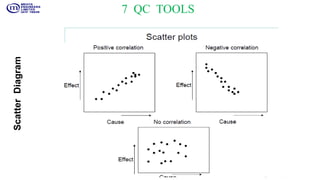

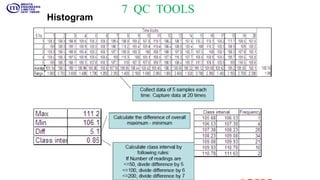

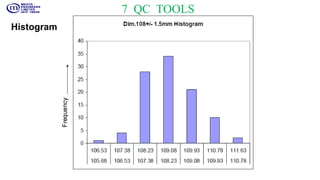

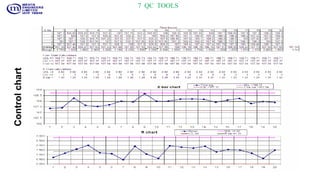

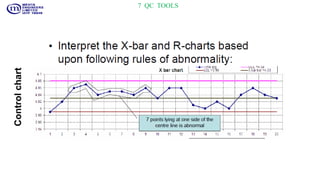

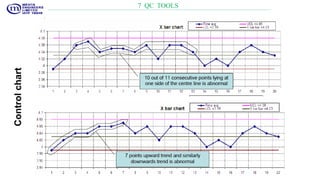

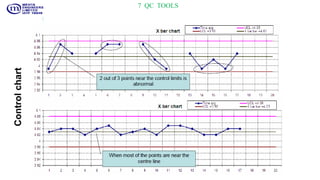

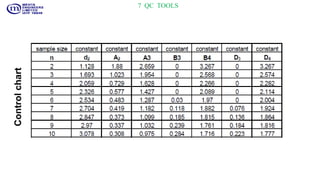

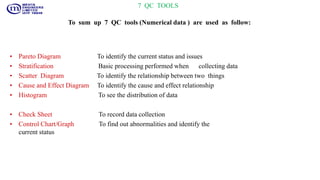

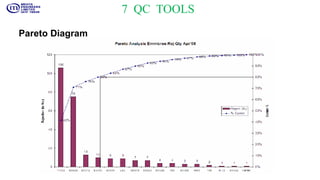

The document discusses the 7 main quality control tools used for collecting and analyzing numerical data. The tools are: Pareto diagram, check sheet, stratification, cause and effect diagram, scatter diagram, histogram, and control chart/graph. Each tool is explained briefly. The Pareto diagram identifies important issues. Stratification involves basic data processing. The scatter diagram shows relationships between two variables. The cause and effect diagram identifies causes and their effects. The histogram depicts data distribution. The check sheet records collected data. And the control chart finds abnormalities and status. Together these 7 QC tools are used to collect, analyze, identify root causes, and measure results.

![7 QC TOOLS

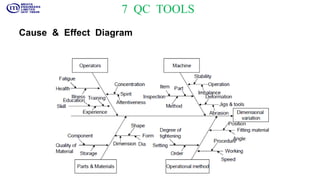

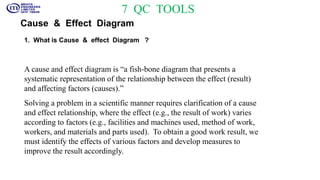

Cause & Effect Diagram

Can obtain a clear

overall picture of causal

relation. (A change in

the cause triggers a

variation in the

result.)○ Can clarify

the cause and effect

relationship.

Can list up all causes

to identify important

causes.

Can determine the

direction of action

(countermeasure).

Method Usage Result

Used when

clarifying a cause

and effect

relationship.[Used

during a phase to

analyze causes.]

Used to develop

countermeasures.

[Used during a phase to plan

countermeasures.]

Material Method

ManMachine

Cause (4M’s) Result

(Controlled State)

Effect

Cause and EffectCause and Effect

DiagramDiagram

Material Method

ManMachine

Cause (4M’s) Result

(Controlled State)

Effect

Cause and EffectCause and Effect

DiagramDiagram](https://image.slidesharecdn.com/7qctool-191217063203/85/7-QC-TOOL-19-320.jpg)