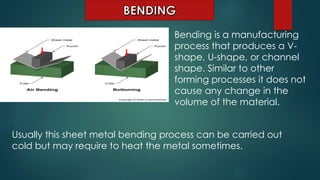

1. Forming is a metalworking process that shapes metal by deforming it without removing material. Common forming processes include rolling, extrusion, forging, and die forming.

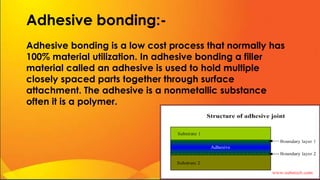

2. Joining processes like welding, brazing, and adhesive bonding are used to connect metal components together. Welding involves melting materials to join them, while brazing uses a filler metal below the melting point of the base materials.

3. Machining removes material using tools like lathes, mills, drills and grinders to shape a workpiece. It allows for tight tolerances but incurs significant material removal and waste.