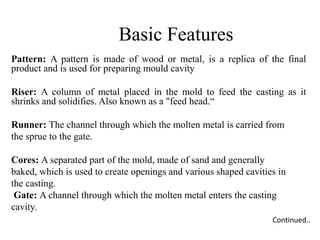

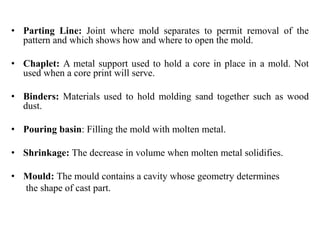

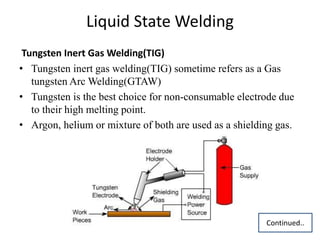

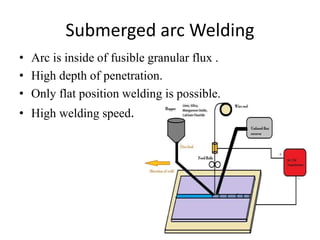

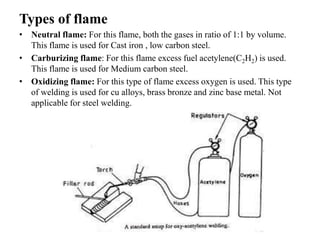

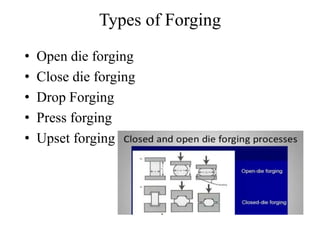

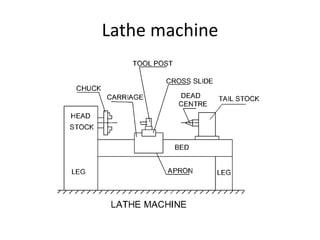

The document provides information about various manufacturing processes presented by Rajesh Kumar. It discusses casting processes such as sand casting and permanent mold casting. It also describes various joining processes including welding techniques like arc welding, TIG, MIG etc. and brazing. Forming processes covered are forging, rolling, extrusion, sheet metal working, bending and deep drawing. Finally, machining processes like lathe, drilling, planning, milling and grinding are explained along with the basic operations performed by these machines.