1. Electromagnetic forming is a high-energy rate forming technique that uses a pulsed magnetic field to rapidly deform electrically conductive materials like aluminum alloys. It offers benefits like improved formability, reduced wrinkling, and lower springback compared to conventional forming.

2. The process involves storing electrical energy in capacitors and discharging it through a coil to generate an intense magnetic field. This induces eddy currents in a conductive workpiece within the coil, creating repelling magnetic forces that deform the workpiece at velocities of 100 m/s or more.

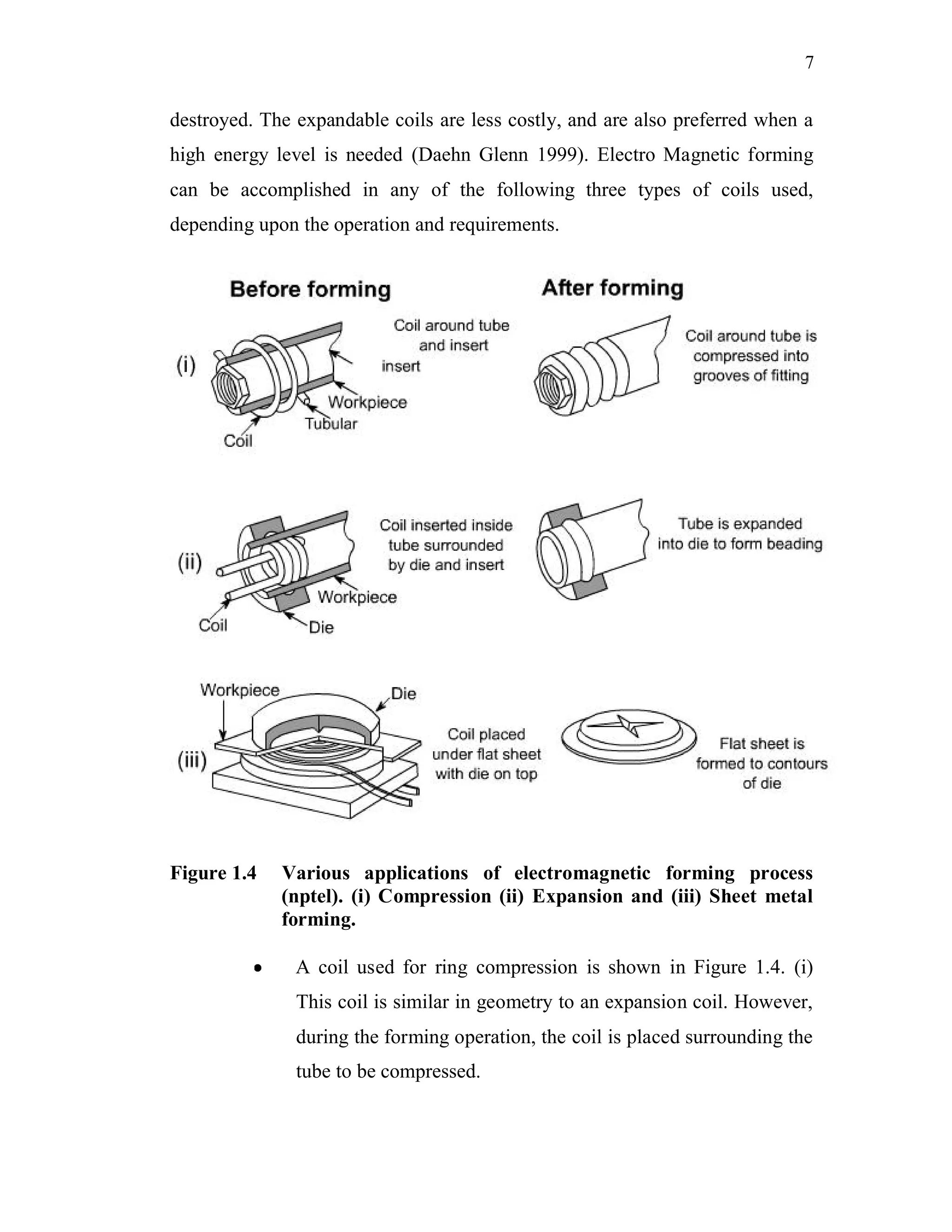

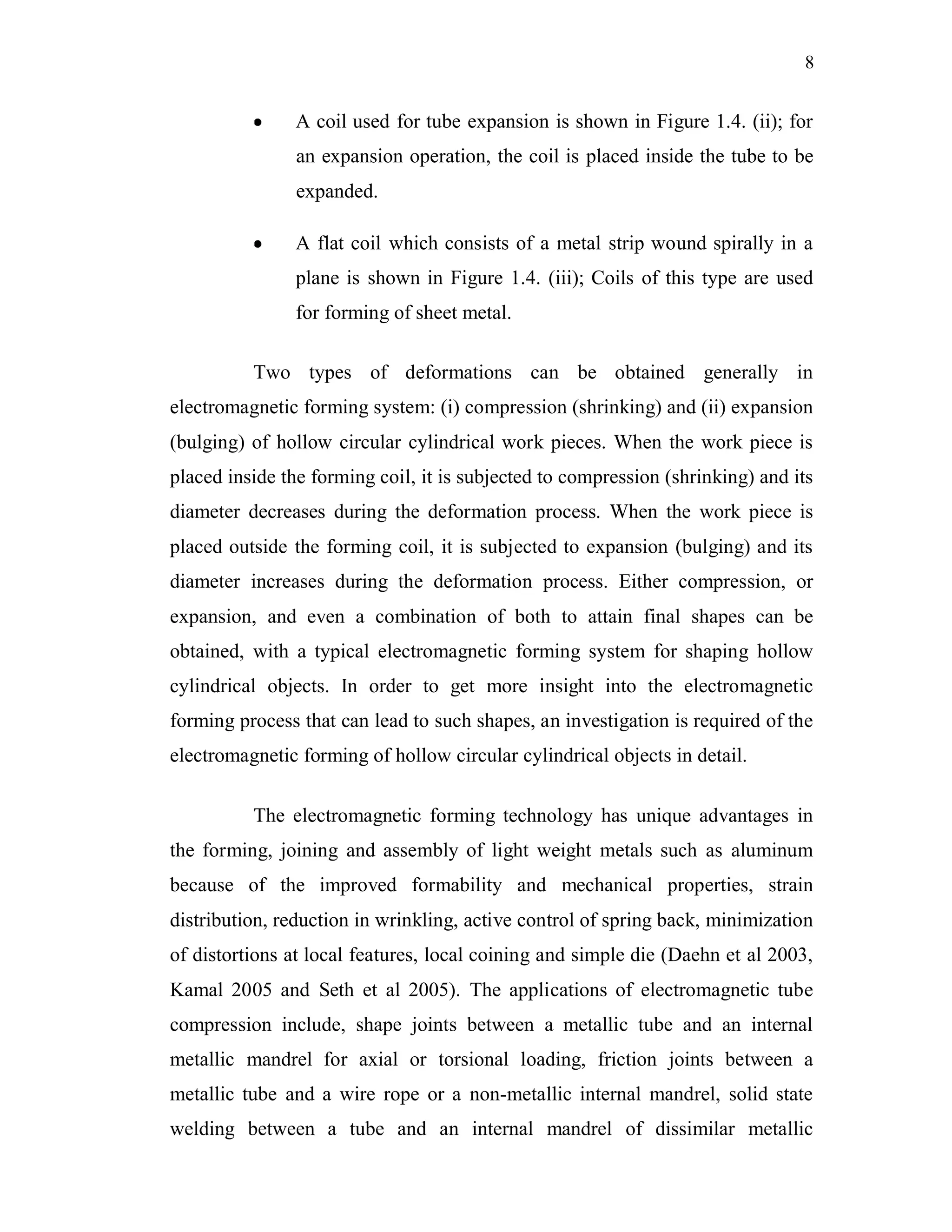

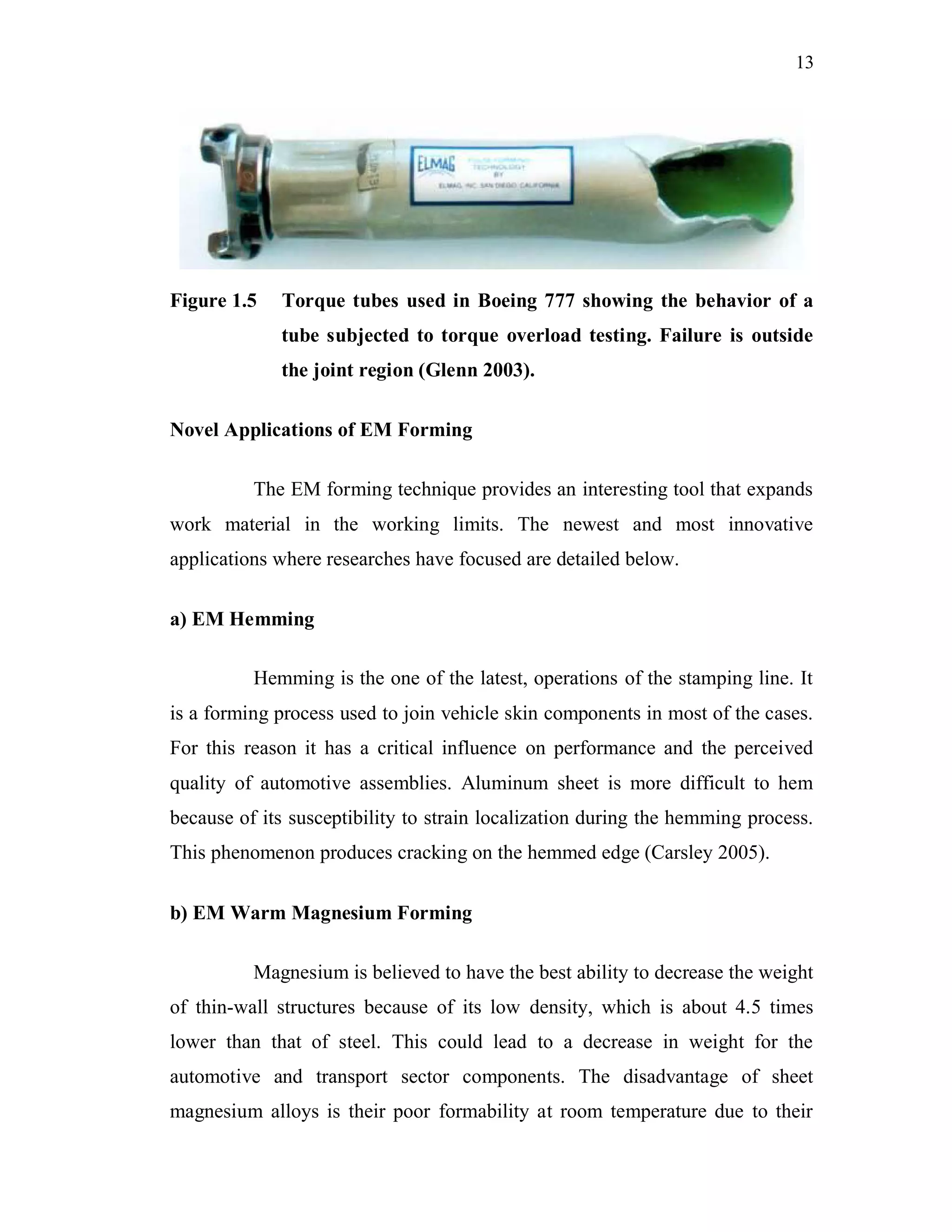

3. Electromagnetic forming has applications in tube compression/expansion and sheet metal forming. It is commonly used for assembly operations and has advantages over conventional forming like