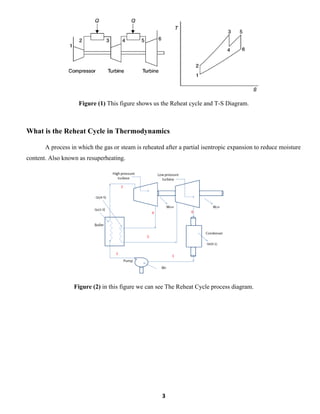

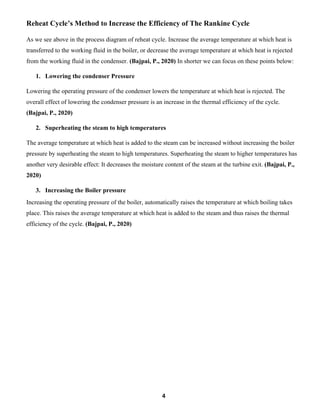

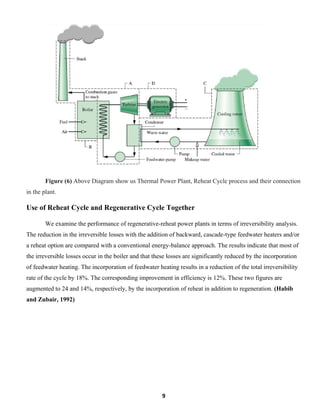

This document discusses the reheat cycle in thermodynamics. The reheat cycle is a modification of the Rankine cycle that is used in steam power plants. It works by reheating the steam after it expands in the high-pressure turbine and before it expands further in the low-pressure turbine. This increases the efficiency by raising the mean temperature of heat addition and reducing moisture content in the steam. Reheating allows for higher turbine work extraction and thermal efficiency compared to the basic Rankine cycle. The document examines the working of reheat cycles in steam turbines and thermal power plants, and their advantages in improving efficiency and reducing blade erosion.

![11

References

1. chegg, 2020. Definition of The Reheat Cycle. [Online] Available at:

https://www.chegg.com/homework-help/definitions/the-reheat-cycle-5 [Accessed 3 Dec 2020].

2. KAPOORIA, R K; KUMAR, S and KASANA, K S. 2008. An analysis of a thermal power plant

working on a Rankine cycle: A theoretical investigation. Journal of Energy South. Africa. [online].

vol.19, n.1, pp.77-83. Available at: http://www.scielo.org.za/scielo.php?pid=S1021-

447X2008000100008&script=sci_abstract&tlng=en [Accessed 3 Dec. 2020].

3. Ust, G Gonca & H K Kayadelen (2011). Determination of optimum reheat pressures for single and

double reheat irreversible Rankine cycle. Journal of the Energy Institute. [online] VOL 84, 215-219.

Available at:

https://www.tandfonline.com/doi/abs/10.1179/174396711X13116932751994?journalCode=yeni20

[Accessed 3 Nov 2020].

4. Bajpai, P., 2020. Reheat Rankine Cycle. [Online] Available at:

http://home.iitk.ac.in/~suller/lectures/lacture29.doc [Accessed 3 Dec 2020].

5. Boyce, M., 2012. The Reheat Cycle - An overview. [Online] Available at:

https://www.sciencedirect.com/topics/engineering/reheat-cycle [Accessed 3 Dec 2020].

6. Ibrahim Dincer, C. Z., 2014. Reheat Cycle - An Over View. [Online] Available at:

https://www.sciencedirect.com/topics/engineering/reheat-cycle [Accessed 3 Dec 2020].

7. Everybody, 2020. Reheat cycle - EverybodyWiki Bios & Wiki. [Online] Available at:

https://en.everybodywiki.com/Reheat_cycle#cite_ref-1 [Accessed 3 Dec. 2020].

8. Gambini, M., Guizzi, G.L. and Vellini, M. (2004). H 2 ∕ O 2 Cycles: Thermodynamic Potentialities

and Limits. Journal of Engineering for Gas Turbines and Power, 127(3), pp.553–563. Available at:

https://doi.org/10.1115/1.1924401 [Accessed 3 Dec. 2020].

9. Peter B. Whalley, Kenneth D. Forbus, M. E. Brokowski., (1997). Using Reheat Cycles. [online]

qrg.northwestern Available at: https://www.qrg.northwestern.edu/thermo/design-

library/reheat/reheat.html [Accessed 3 Dec. 2020].

10. Chaplin, R. A., 2009. Thermal Power Plants. 1st ed. [Ebook] Oxford: Encyclopedia of Life Support

Systems. Available at:

https://books.google.iq/books?id=6kAZAwAAQBAJ&dq=Thermodynamic+Analysis+of+Reheat+C

ycle+Steam+Power+Plants&source=gbs_navlinks_s [Accessed 3 Dec. 2020].

11. Francisco, G. (2012). Thermal power plant performance analysis. [Ebook] London [U.A.] Springer.

Available at:](https://image.slidesharecdn.com/thereheatcyclenonparaphrased-210319150040/85/The-reheat-cycle-13-320.jpg)

![12

https://books.google.iq/books?id=P76AAjX2DEQC&dq=Thermodynamic+Analysis+of+Reheat+Cyc

le+Steam+Power+Plants&source=gbs_navlinks_s [Accessed 3 Dec. 2020].

12. Chen. W., Lei. X., Chang. F., Li. H., (2020). Energy Conversion and Management. Journal of

Elsevier Available at: https://doi.org/10.1016/j.enconman.2020.113382 [Accessed 3 Dec 2020].

13. Habib, M.A. and Zubair, S.M. (1992). Second-law-based thermodynamic analysis of regenerative-

reheat Rankine-cycle power plants. Energy. Journal of Elsevier J 17(3), pp.295–301. Available at:

https://doi.org/10.1016/0360-5442(92)90057-7 [Accessed 3 Dec 2020].](https://image.slidesharecdn.com/thereheatcyclenonparaphrased-210319150040/85/The-reheat-cycle-14-320.jpg)