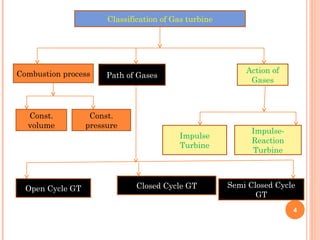

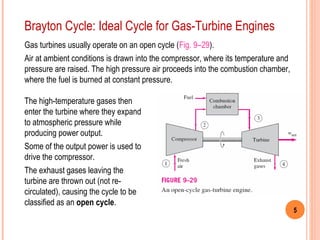

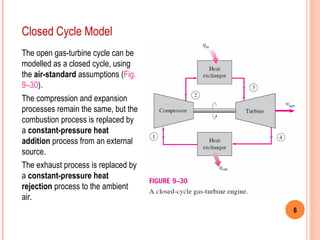

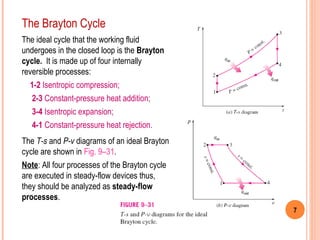

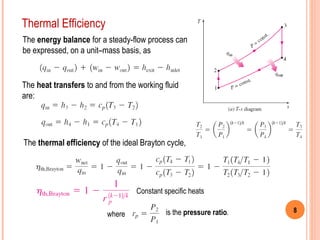

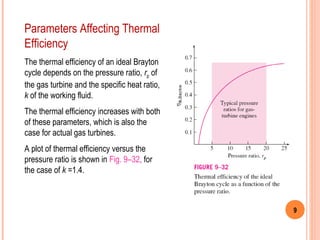

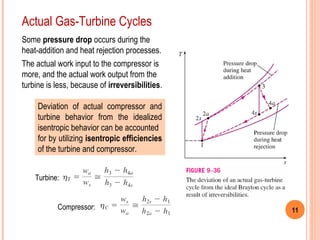

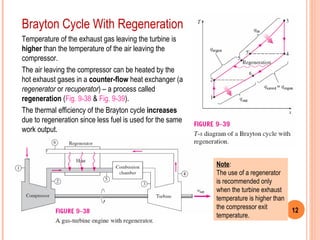

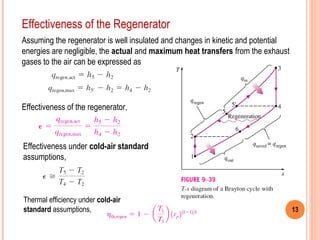

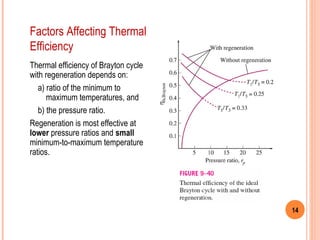

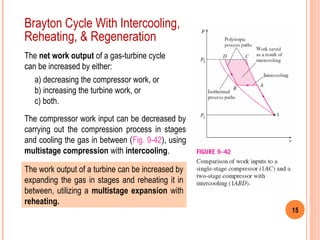

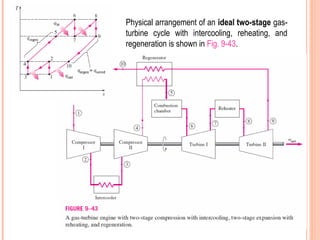

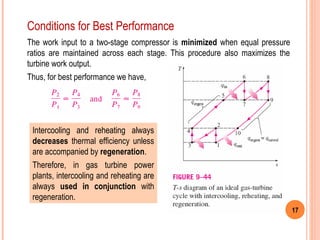

Gas turbines operate using the Brayton cycle, which involves compressing air, adding heat through combustion at constant pressure, expanding the hot gases through a turbine, and rejecting heat at constant pressure. Early gas turbines had low efficiency around 17% but efficiency has increased through higher turbine inlet temperatures, more efficient components, and modifications like regeneration, intercooling, and reheating. Regeneration improves efficiency by heating the compressed air with the turbine exhaust, while intercooling and reheating involve multistage compression and expansion with cooling or heating between stages. Open cycle gas turbines exhaust combustion gases while closed cycle models re-circulate gases, improving efficiency but requiring more complex components.