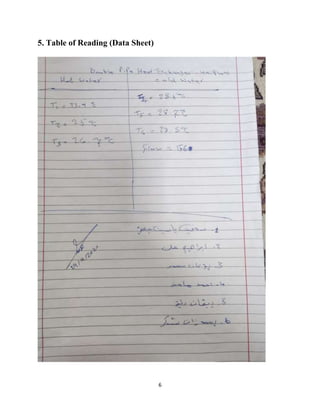

This lab report summarizes an experiment conducted to calculate the overall heat transfer coefficient in a shell and tube heat exchanger with uniflow configuration. Temperature and flow rate data was collected for the hot and cold fluids. The average temperature difference and heat transfer rate were calculated. The overall heat transfer coefficient was determined to be 1285.8 W/m2.K.

![8

V

̇ = 3

𝑙 ×

1𝑚3

1000𝑙

𝑚𝑖𝑛×

60𝑠

1𝑚𝑖𝑛

= 5 × 10−5 𝑚3

𝑠

, V

̇ = 1.73

𝑙 ×

1𝑚3

1000𝑙

𝑚𝑖𝑛×

60𝑠

1𝑚𝑖𝑛

= 2.8 × 10−5 𝑚3

𝑠

∆Tlm =

(T1 − t2) − (T2 − t1)

ln

(T1 − t2)

(T2 − t1)

=

(39.1 − 10.8) − (35.2 − 0.43)

ln

(39.1 − 10.8)

(35.2 − 0.43)

∆Tlm = 31.42 o

C

ρ =

m

v

ṁ = ρ × V

̇ = (For hot water)

ṁ = 993.21 × 5 × 10−5

= 0.04967

kg

s

q = 0.04967 × 4.174[(312.25) − (308.35)] = 0.808 kW = 808 W

q = U×A×∆Tlm

U =

q

A × ∆T𝑙𝑚

=

808

0.02 × 31.42

= 1285.8

w

m2. k](https://image.slidesharecdn.com/htrlab-exp-02a-g-a2-231202135439-bc974fd5/85/HTR-Lab-Exp-02a-G-A2-pdf-10-320.jpg)

![9

6. References

1. Cavallo, C. (2021). All About Double Pipe Heat Exchangers - What You

Need To Know. [online] www.thomasnet.com. Available at:

https://www.thomasnet.com/articles/process-equipment/double-pipe-heat-

exchangers/. [Accessed 30 Sep. 2021].

2. Ghani, S., Gamaledin, S.M.A., Rashwan, M.M. and Atieh, M.A. (2018).

Experimental investigation of double-pipe heat exchangers in air

conditioning applications. Energy and Buildings, [online] 158, pp.801–811.

Available at:

https://www.sciencedirect.com/science/article/pii/S0378778817311866

[Accessed 1 Oct. 2021].](https://image.slidesharecdn.com/htrlab-exp-02a-g-a2-231202135439-bc974fd5/85/HTR-Lab-Exp-02a-G-A2-pdf-11-320.jpg)