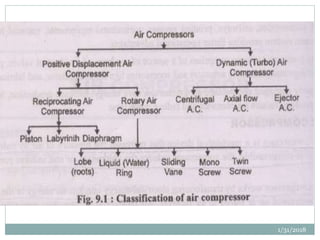

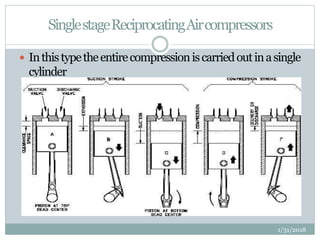

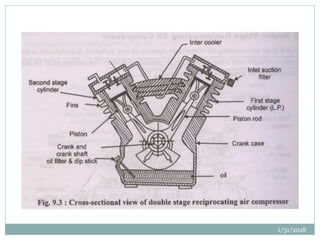

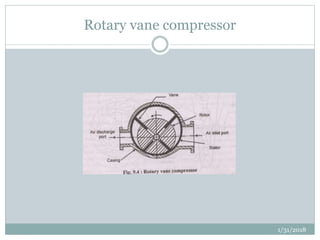

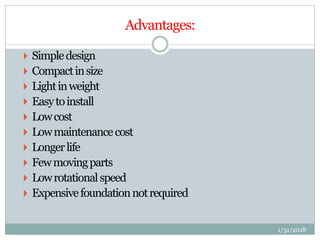

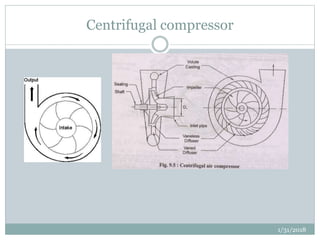

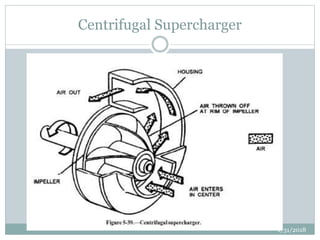

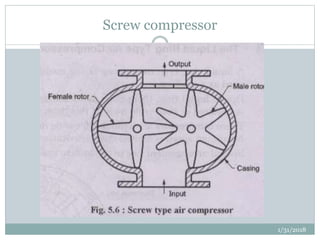

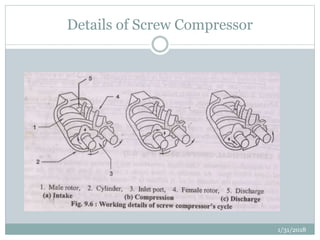

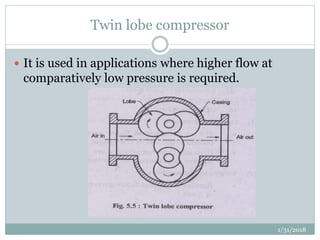

The document discusses different types of compressors used to compress gases. It describes positive displacement compressors like reciprocating, screw, and rotary vane compressors which work by reducing the gas volume. Dynamic compressors like centrifugal compressors are also discussed which increase gas pressure using an impeller. Key components, working principles, advantages and disadvantages of reciprocating, screw, rotary vane and centrifugal compressors are summarized. Selection factors for compressors like required pressure, flow rates, piston speed and system layout are also highlighted.