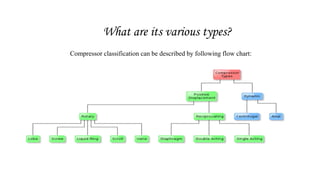

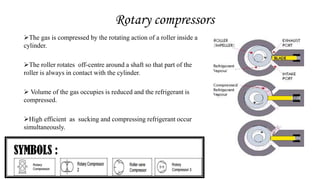

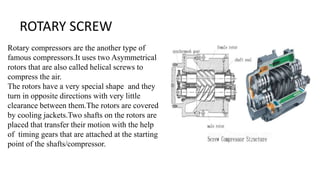

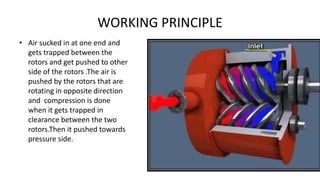

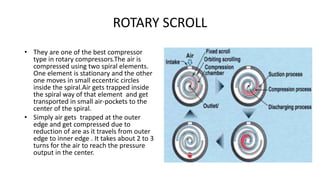

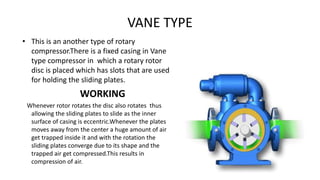

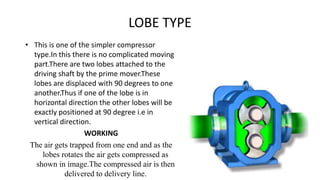

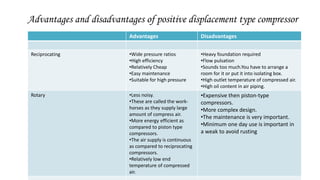

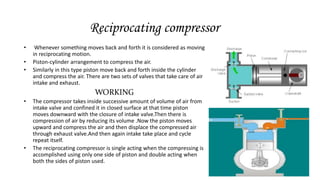

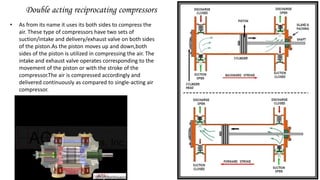

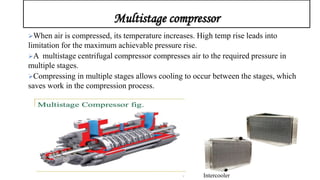

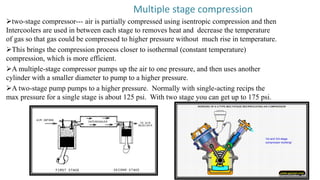

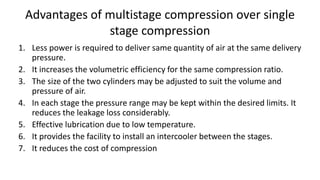

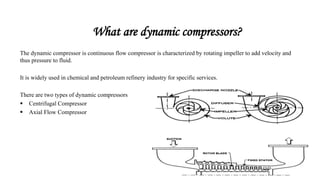

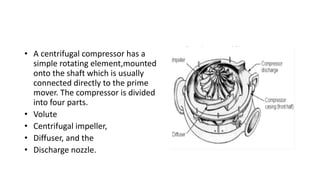

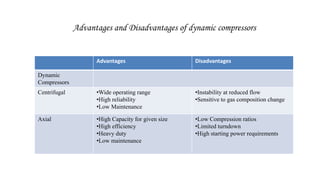

This document discusses different types of compressors used in the chemical industry. It describes positive displacement compressors, which include reciprocating and rotary compressors. Reciprocating compressors use pistons moving back and forth in cylinders to compress air. Rotary compressors include screw, scroll, vane, and lobe types that use rotating parts to compress air. Dynamic compressors like centrifugal compressors are also discussed, which use impellers to add velocity and pressure to flowing gases. Multistage compression is explained as a way to compress air to higher pressures by cooling between stages.