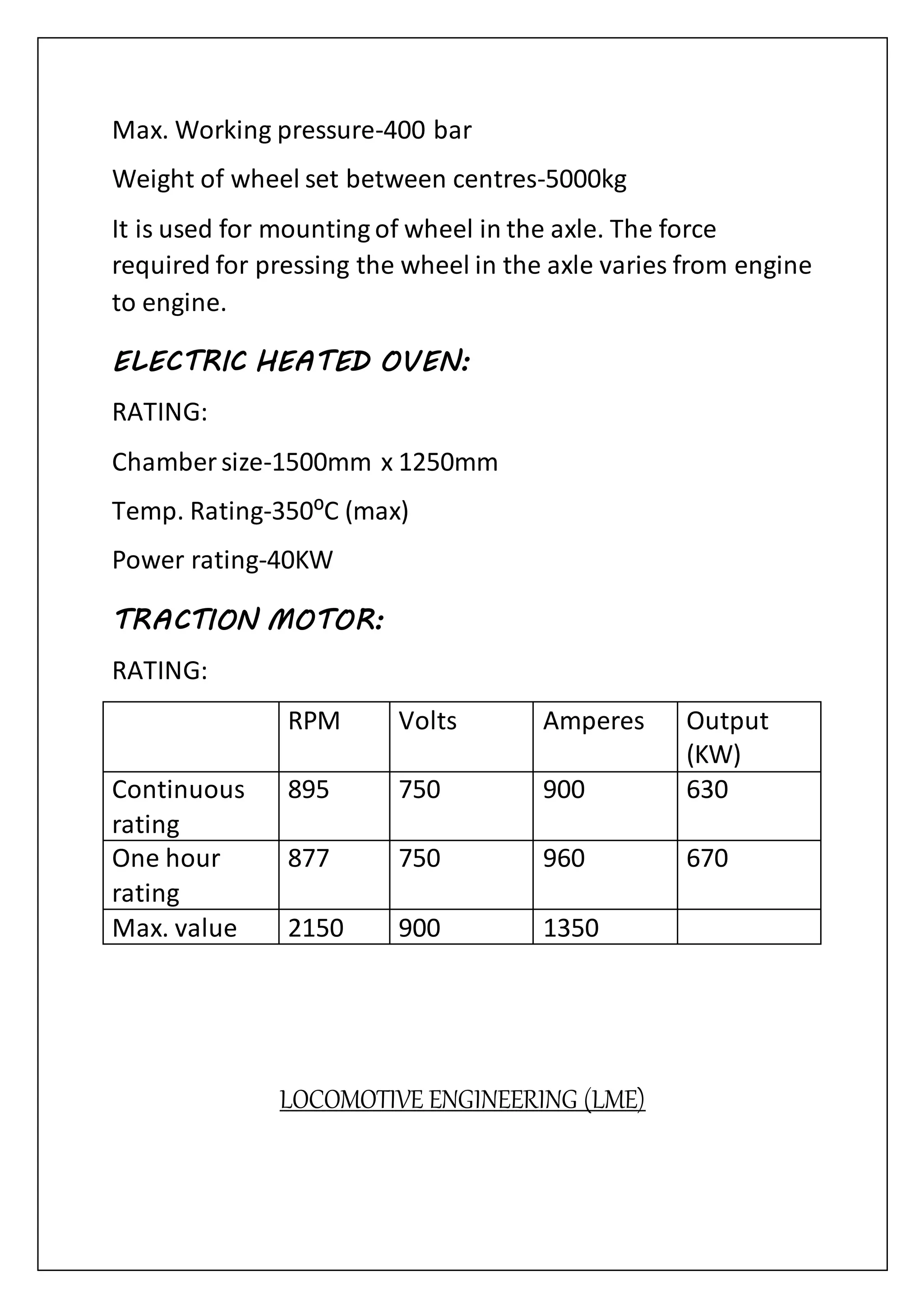

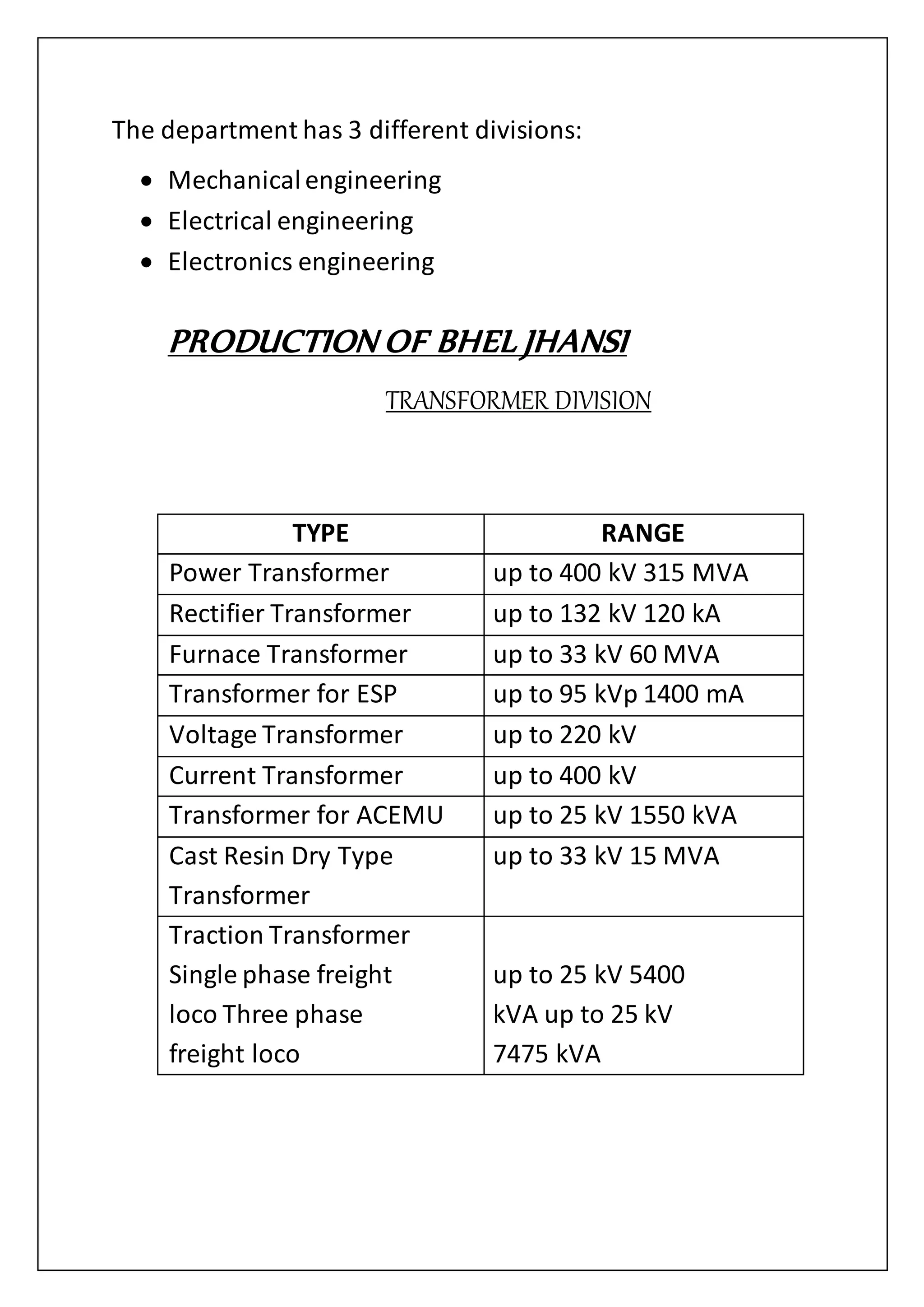

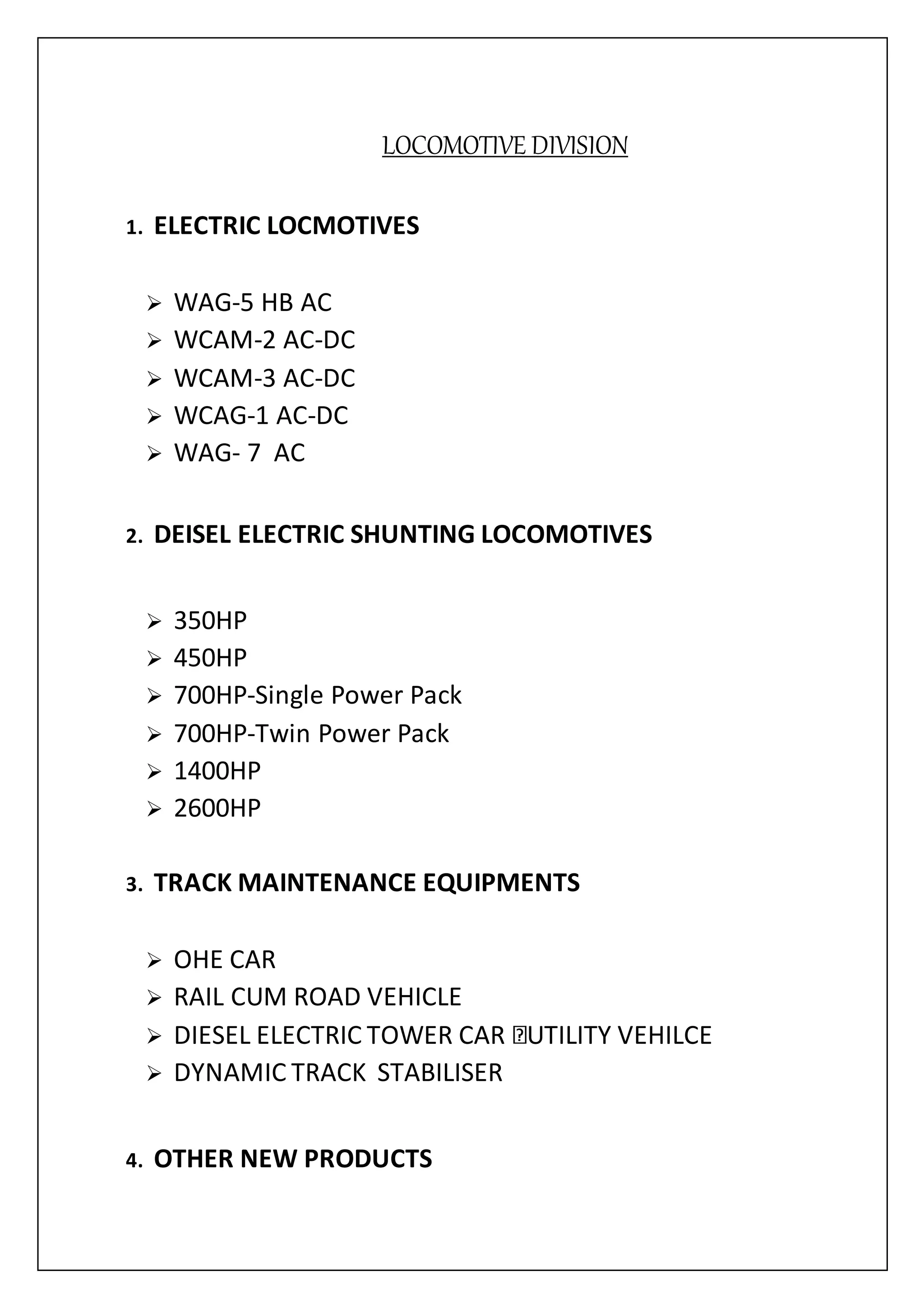

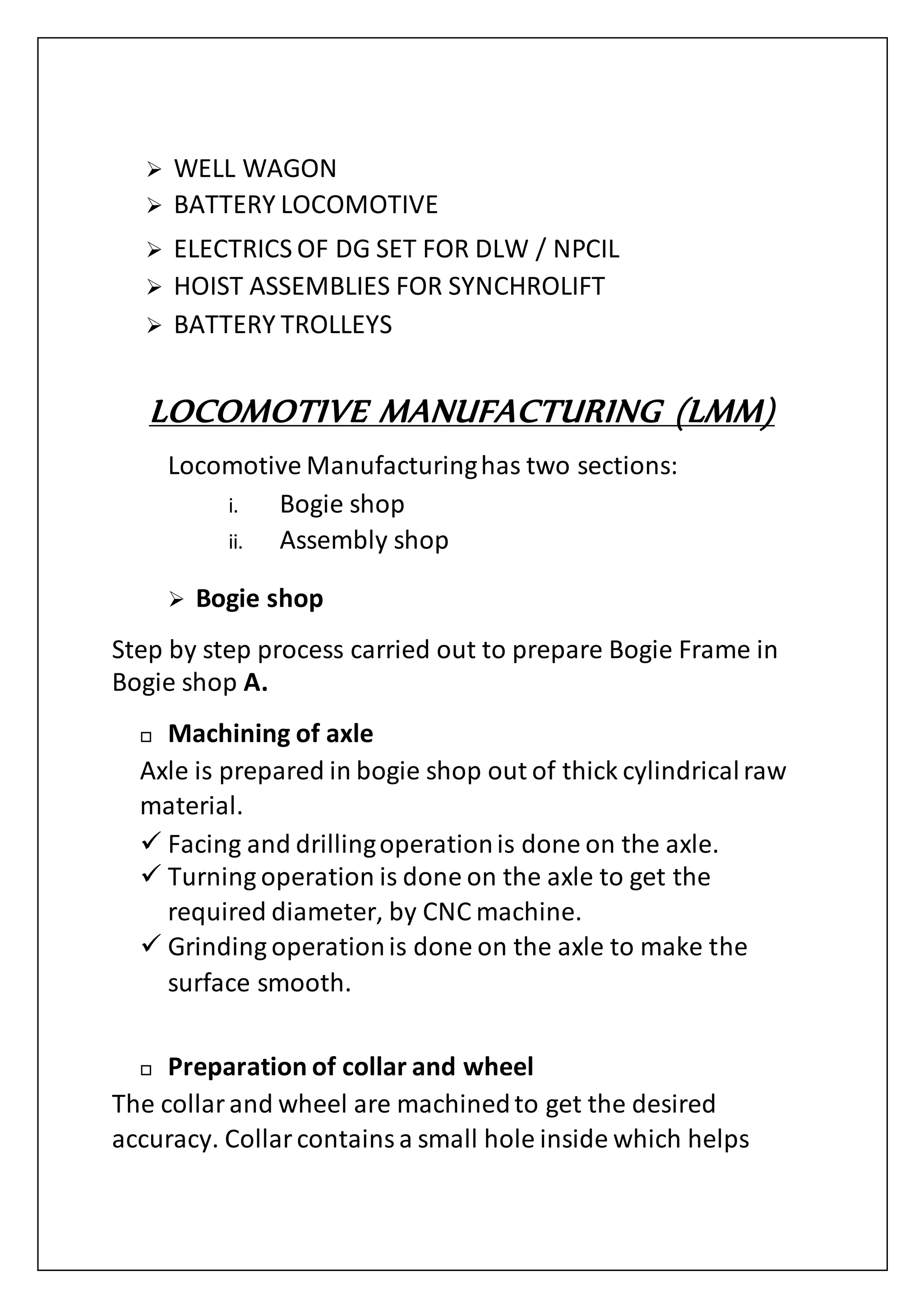

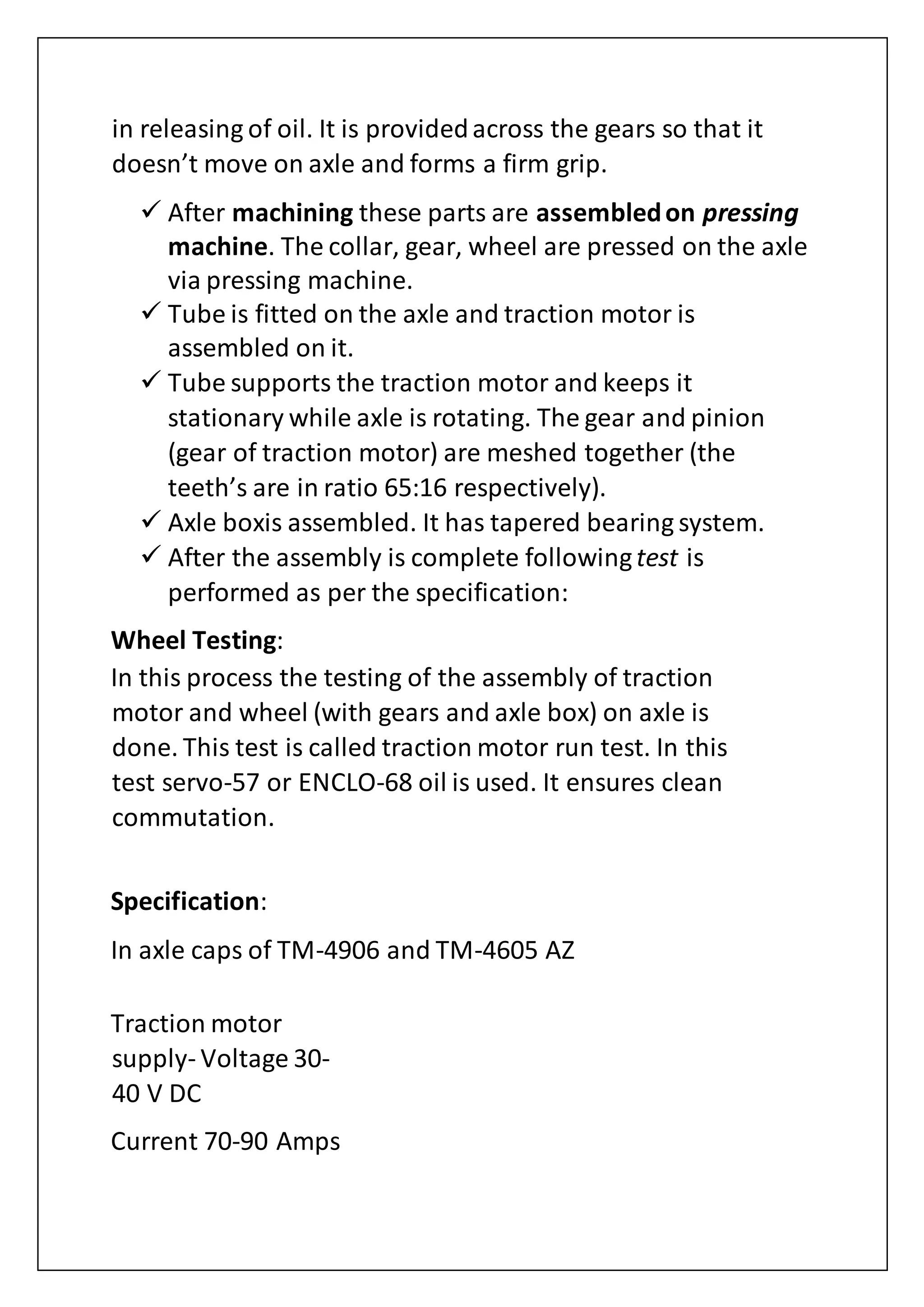

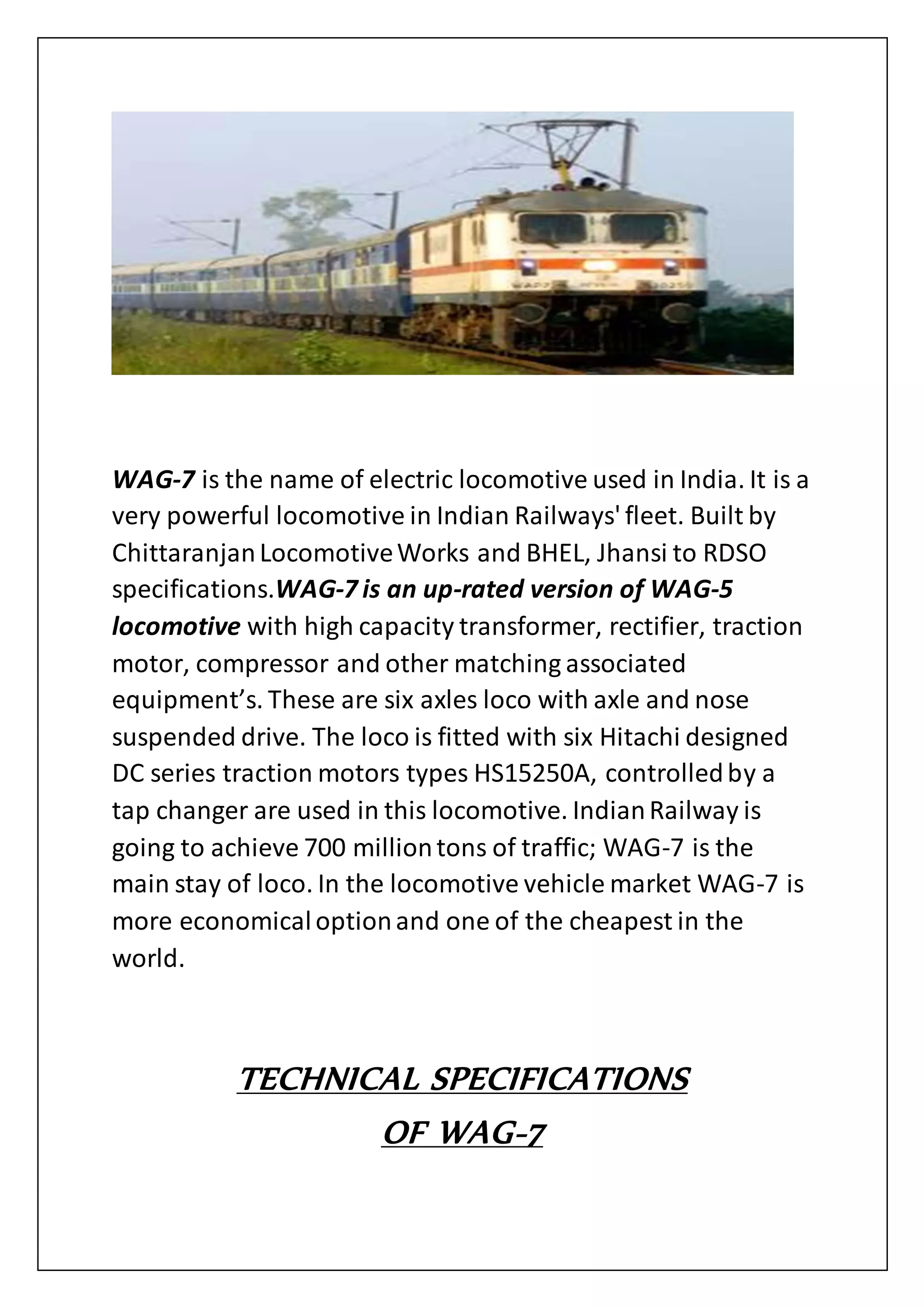

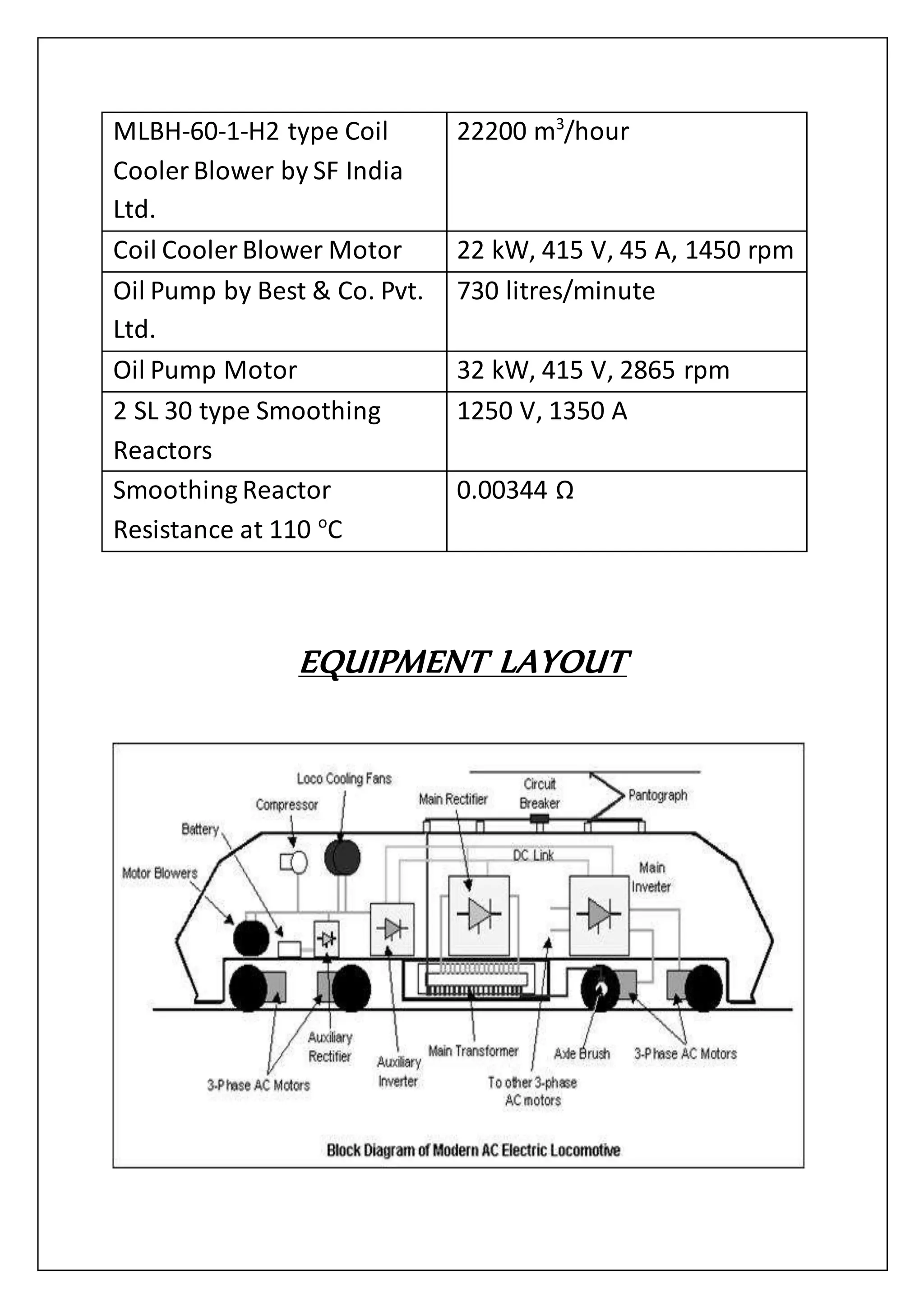

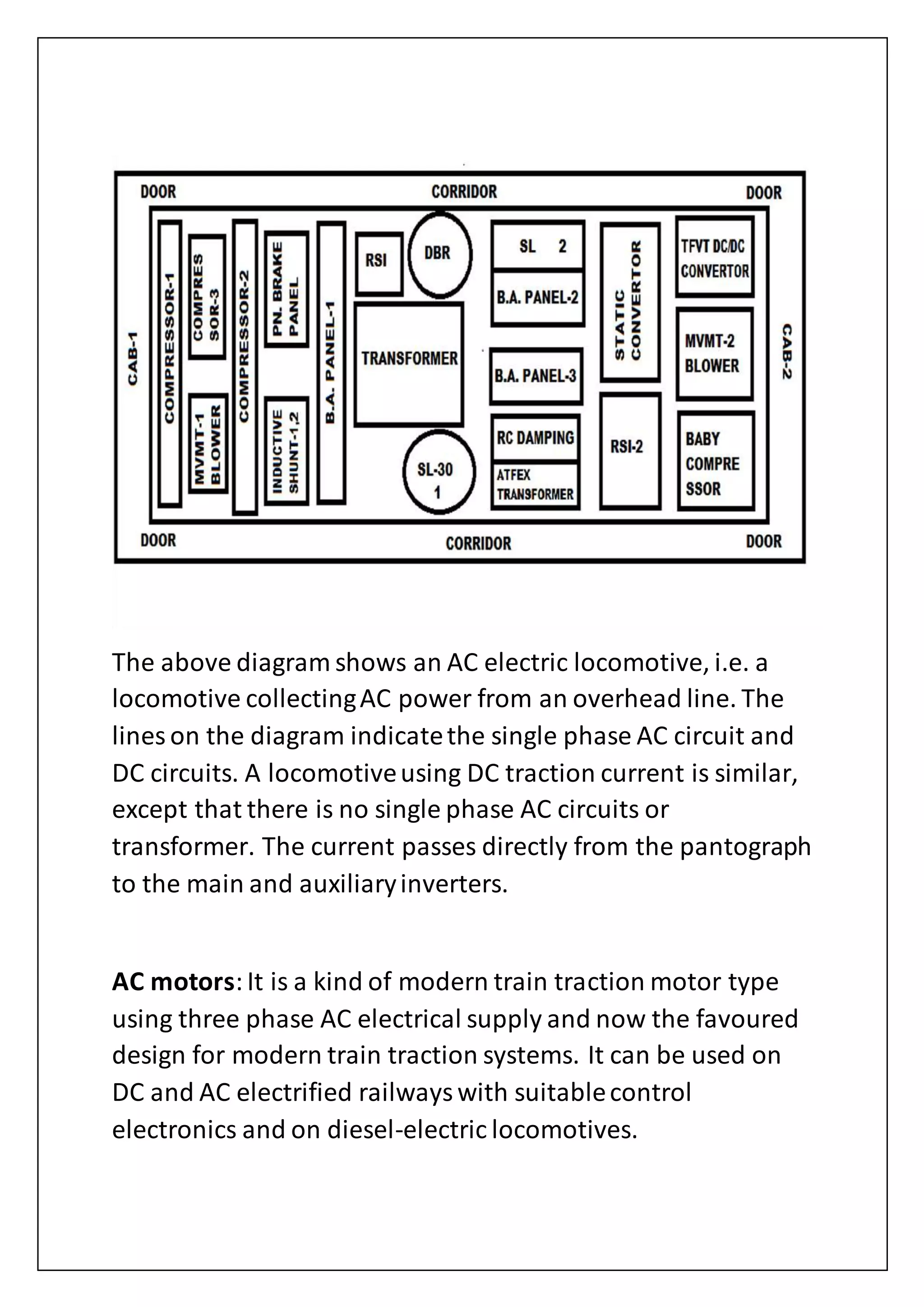

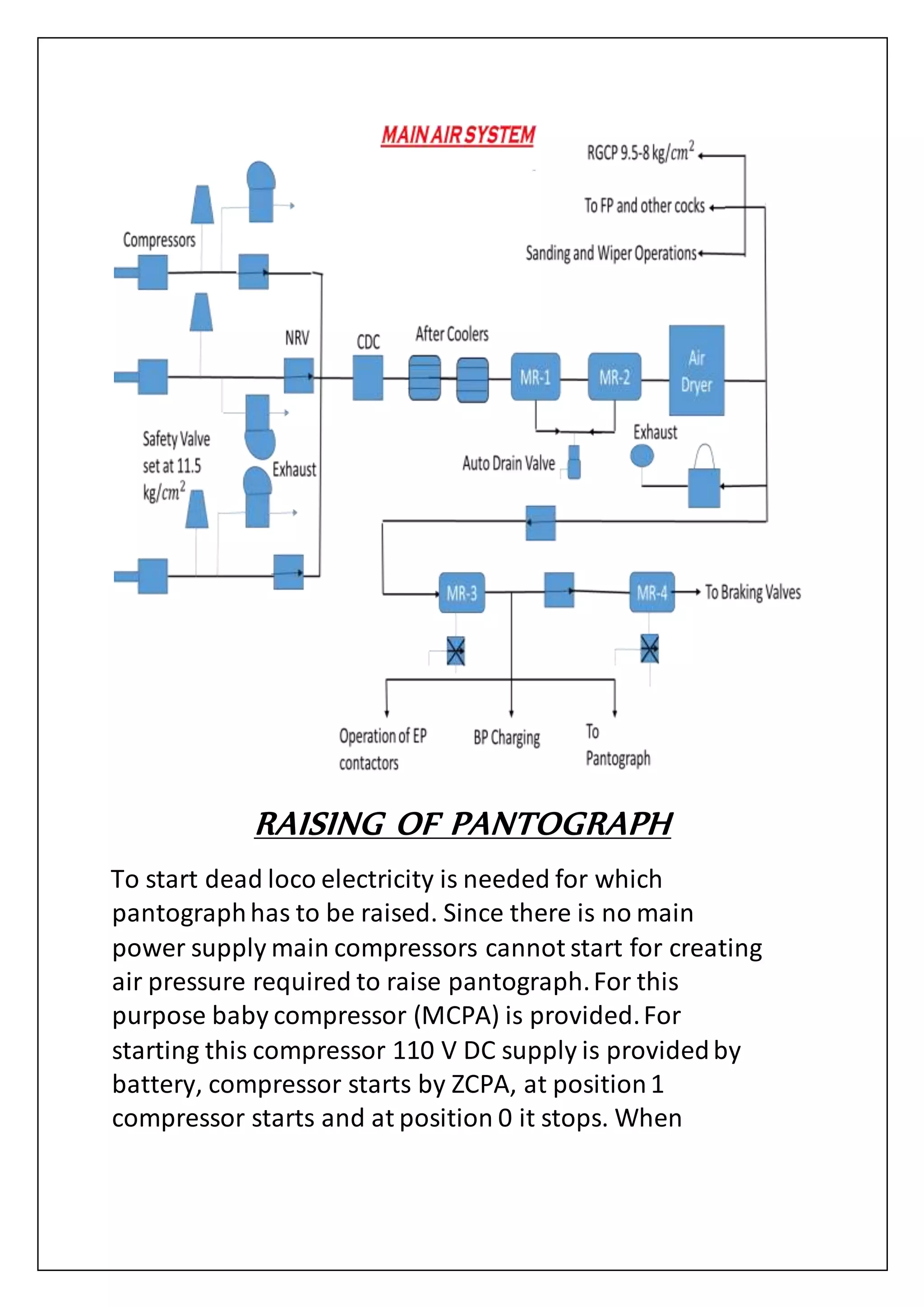

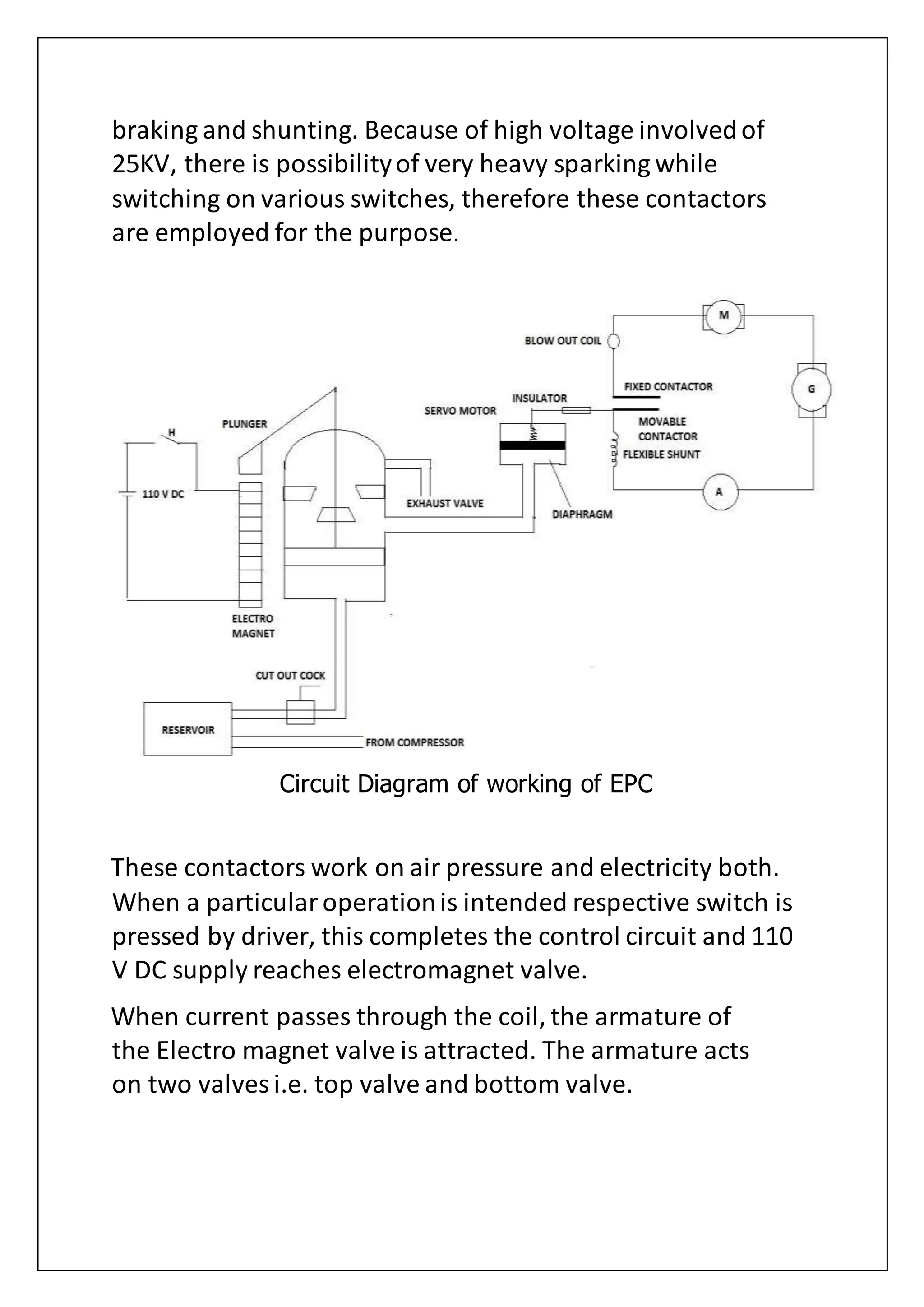

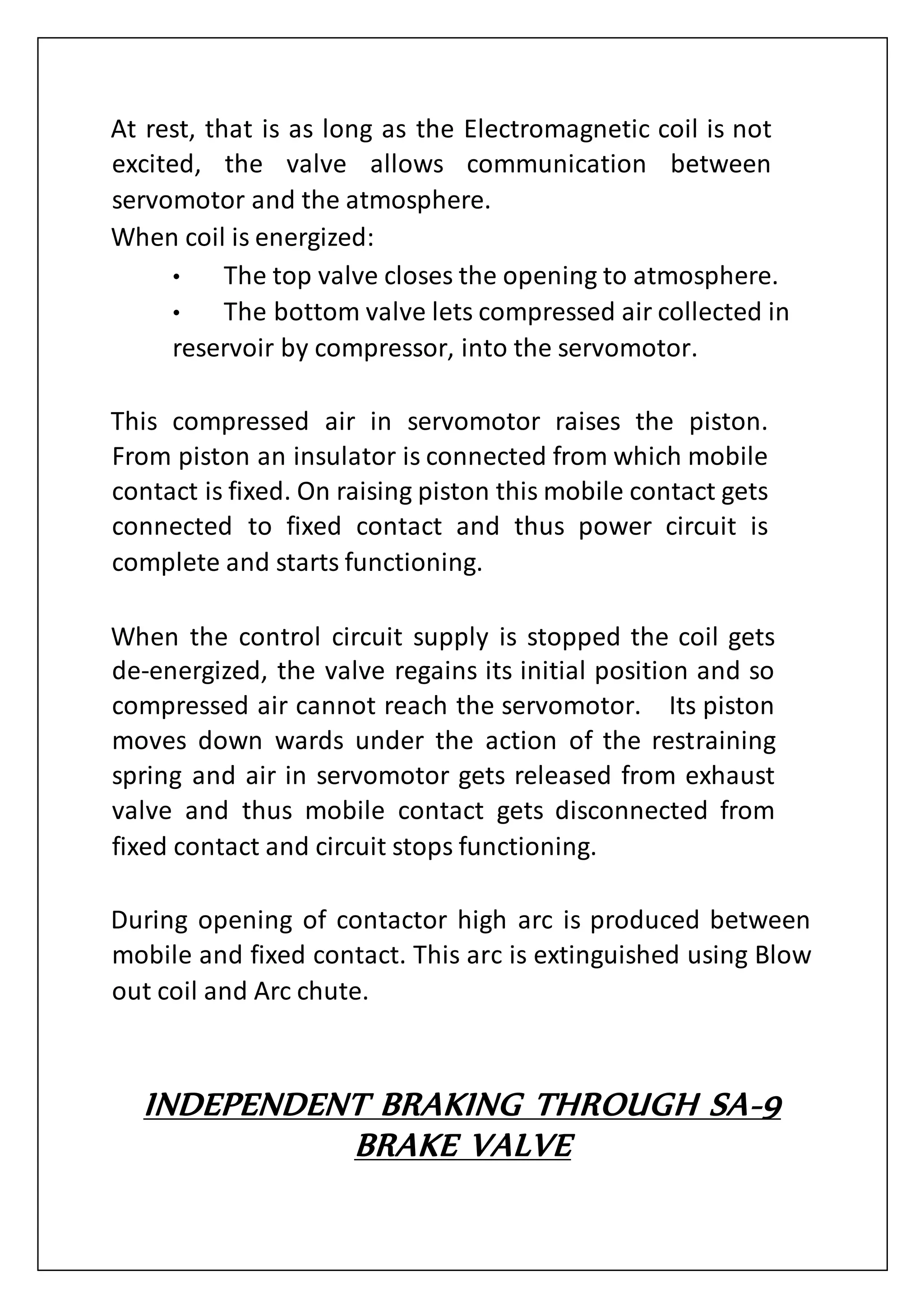

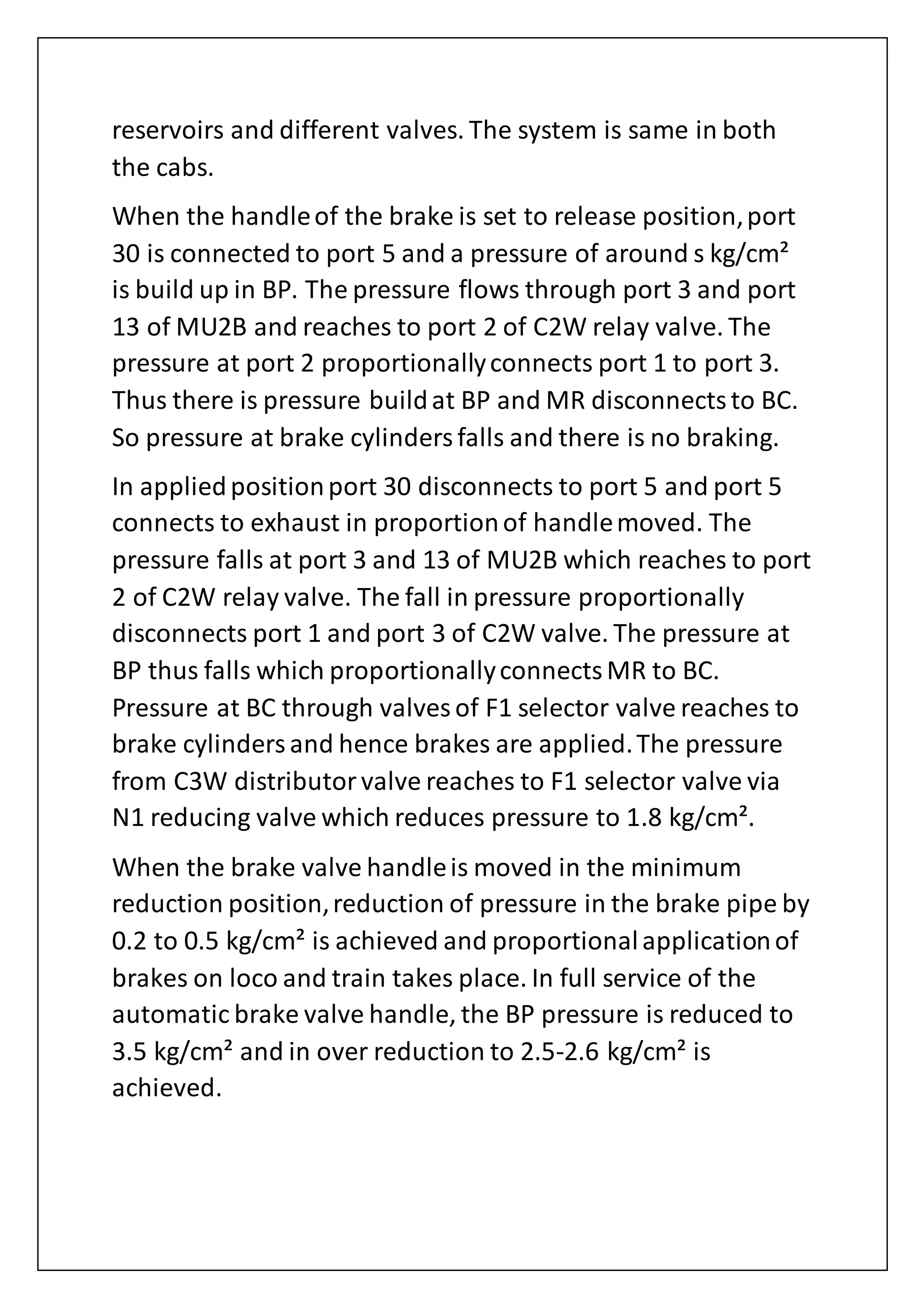

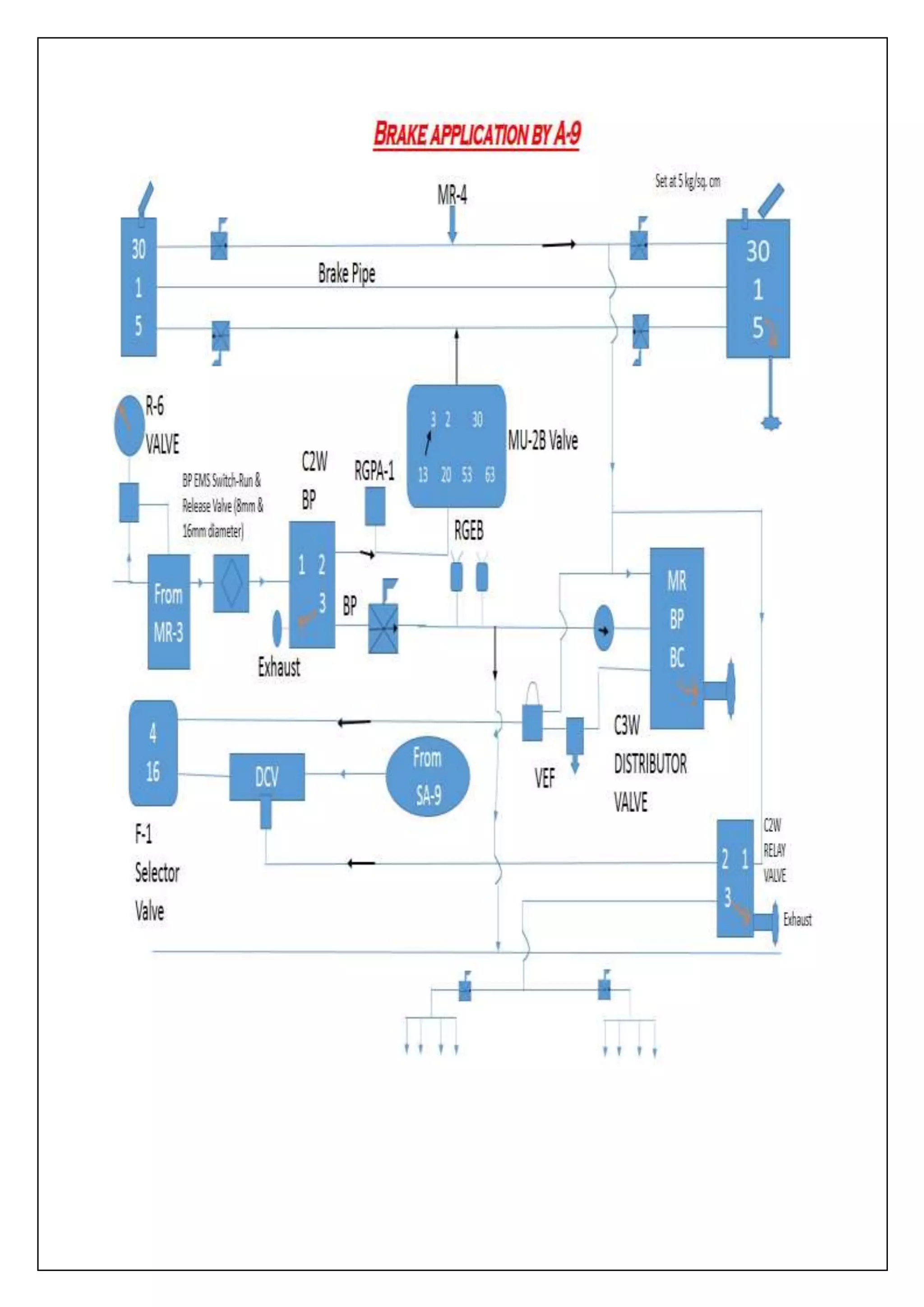

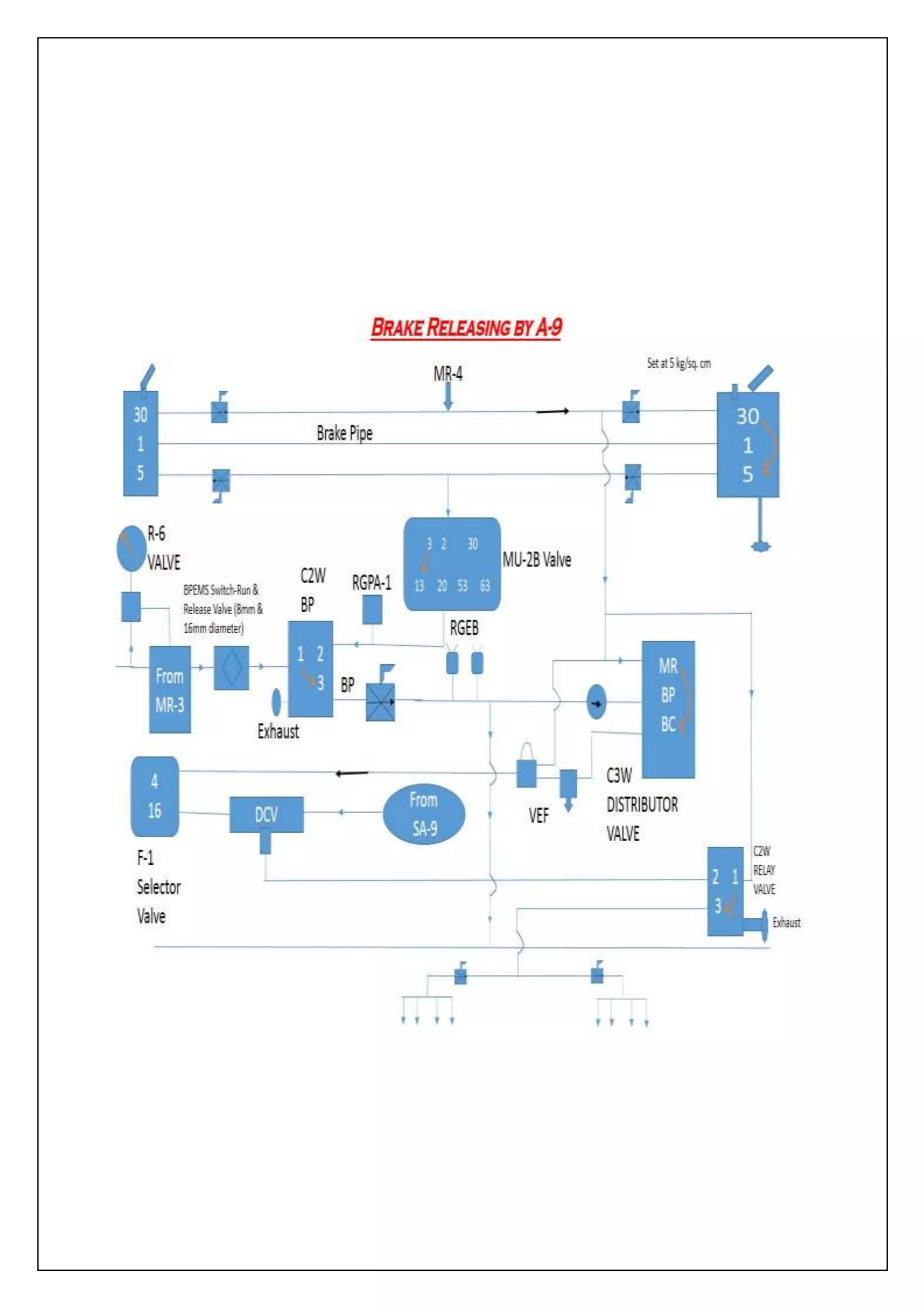

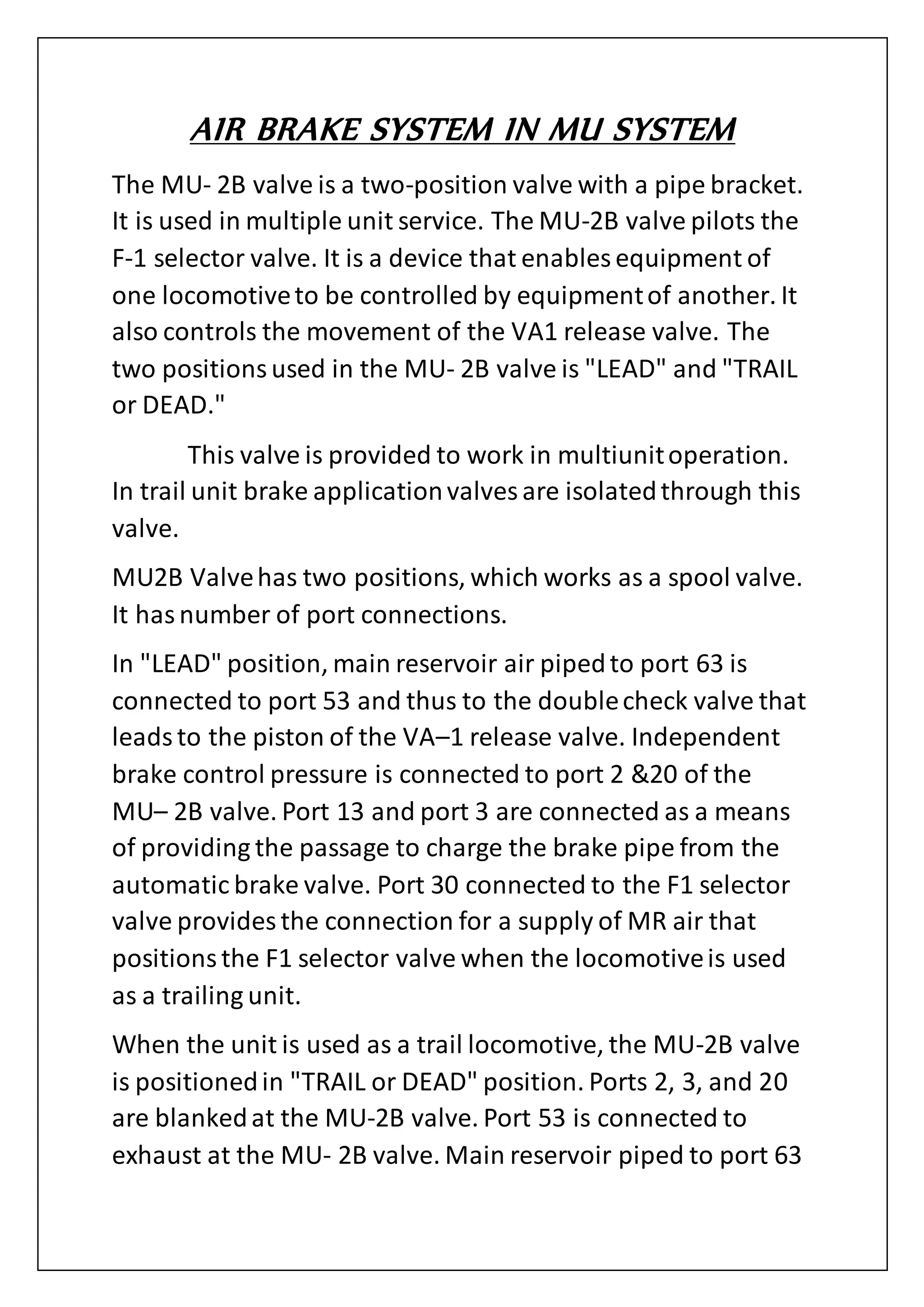

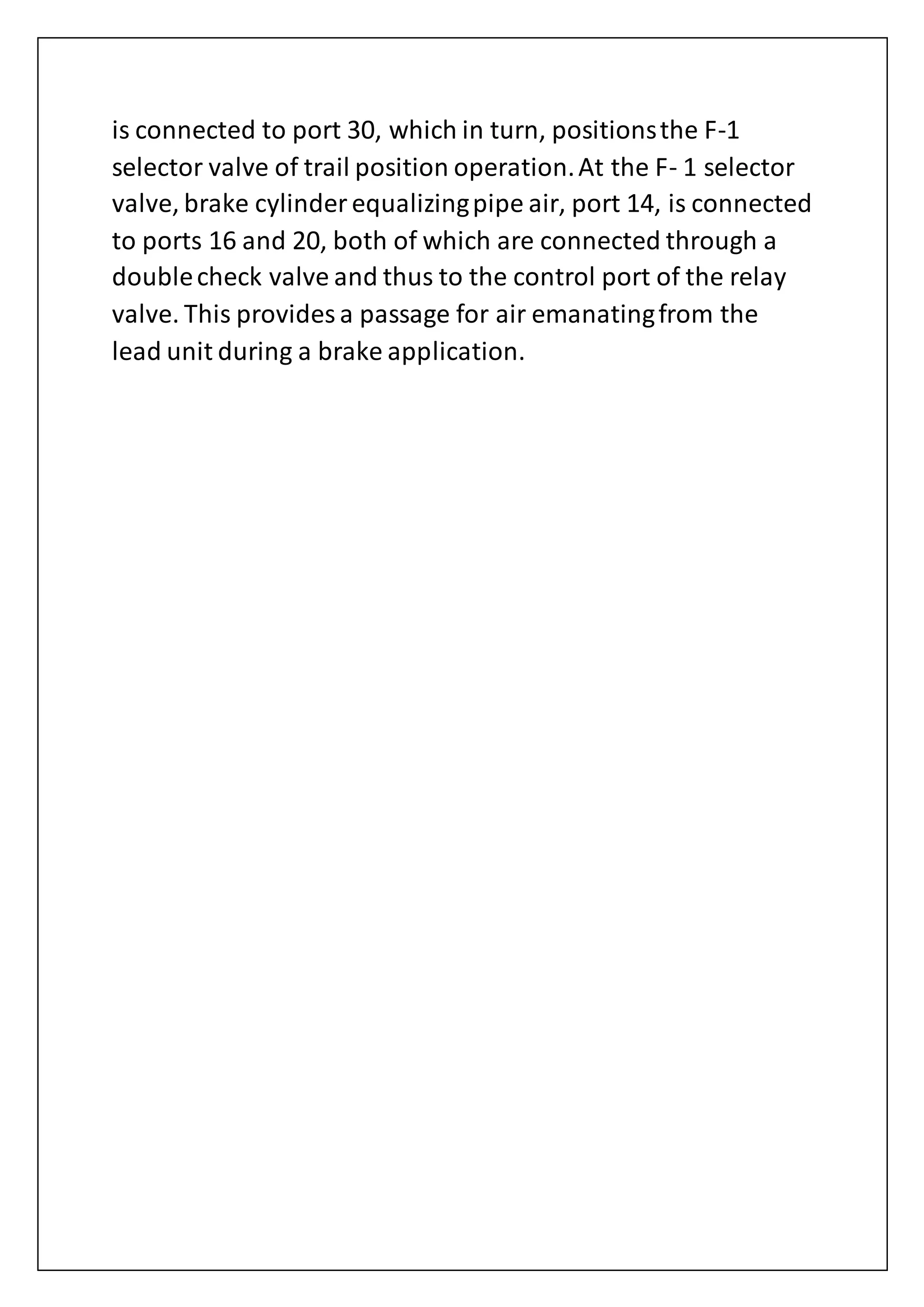

This document provides an overview of the pneumatic systems used in WAG-7 locomotives produced by Bharat Heavy Electricals Limited (BHEL). It first introduces BHEL as one of India's largest engineering companies and discusses its vision, mission and values. It then focuses on BHEL's Locomotive Manufacturing Division and describes the various pneumatic functions, equipment, types of brakes and air brake systems used in WAG-7 locomotives.