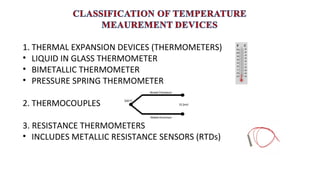

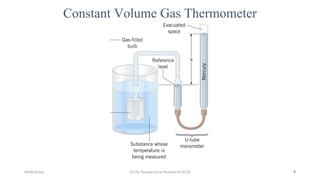

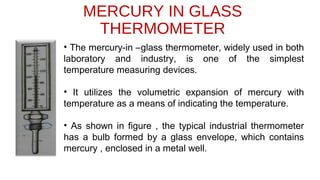

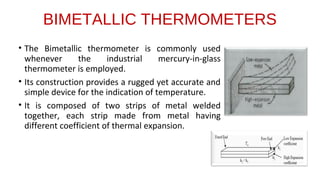

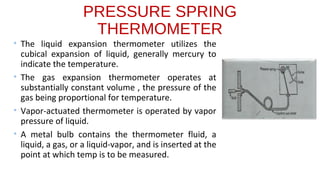

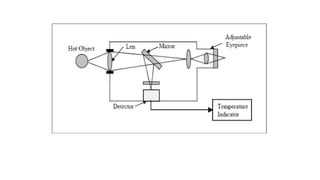

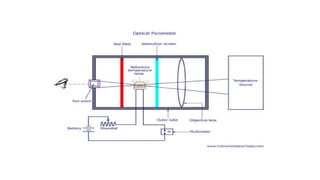

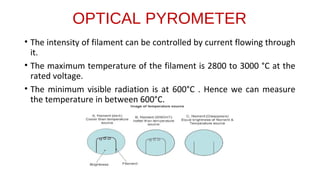

The document discusses various temperature measurement devices widely used in industrial processing, including liquid-in-glass thermometers, bimetallic thermometers, and thermocouples. It explains how these instruments operate based on physical principles such as thermal expansion and the relationship between pressure and temperature. Additionally, it highlights the use of radiation thermometers for non-contact temperature measurement and describes the function of radiation and optical pyrometers.