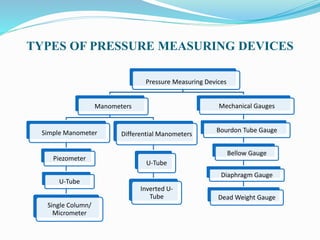

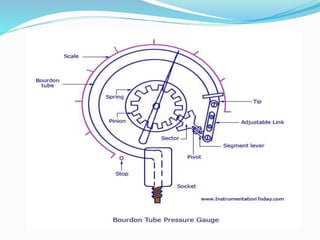

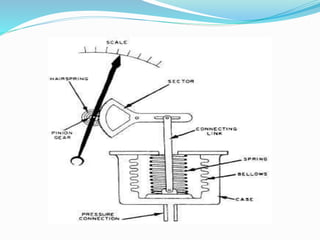

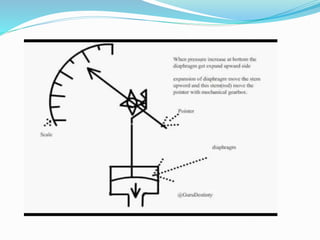

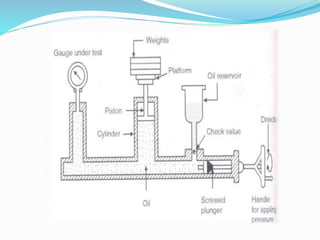

This document discusses different types of pressure measuring devices, including manometers, mechanical gauges like the Bourdon tube gauge, bellow gauge, diaphragm gauge, and dead weight gauge. It provides details on how each device works to measure fluid pressure by translating pressure into linear motion that can be read on a scale. The Bourdon tube gauge uses a coiled tube that straightens under pressure. The bellow gauge uses flexible bellows. The diaphragm gauge uses the deflection of a circular membrane. The dead weight gauge is used to calibrate other pressure gauges by applying a known pressure.