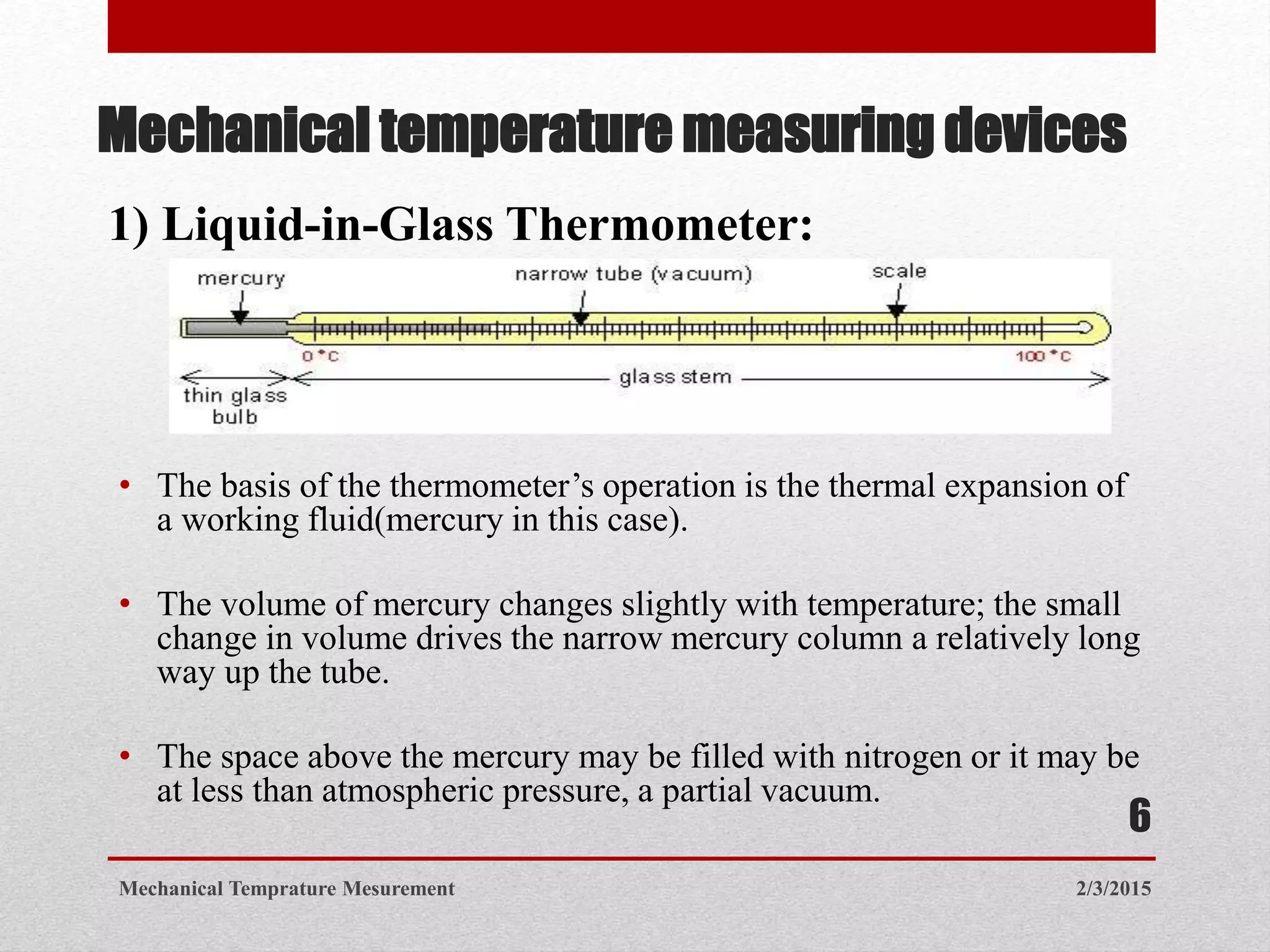

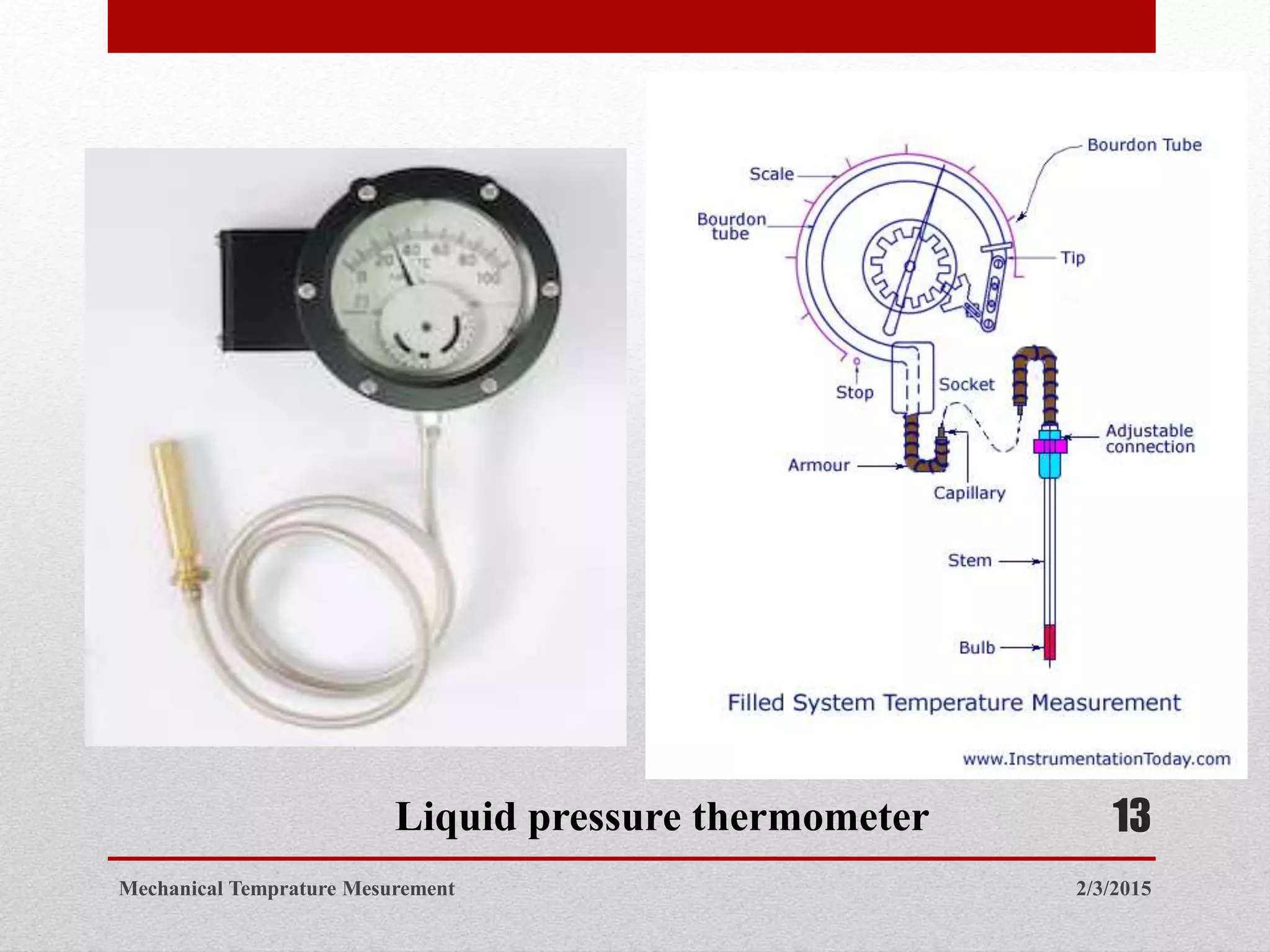

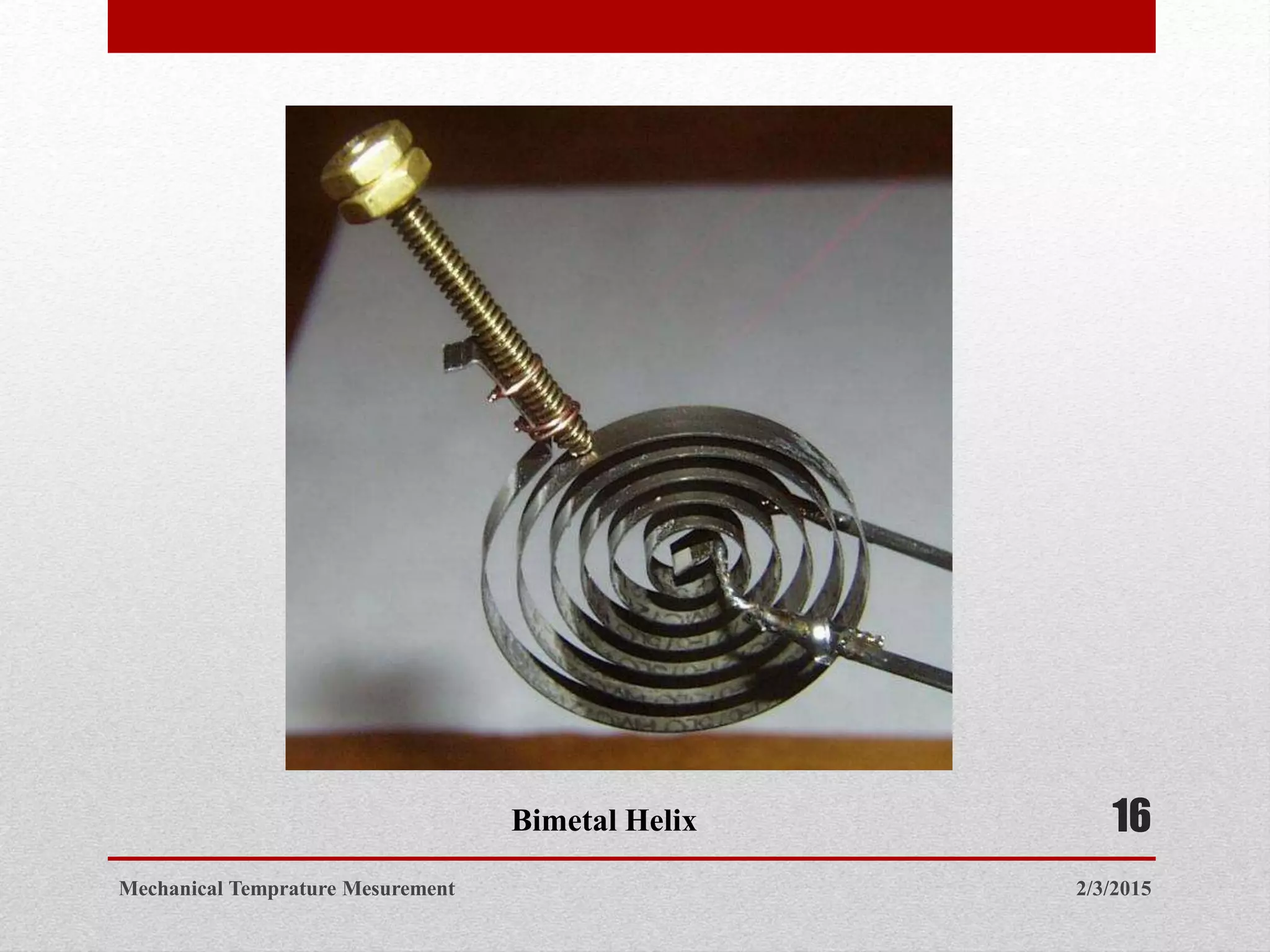

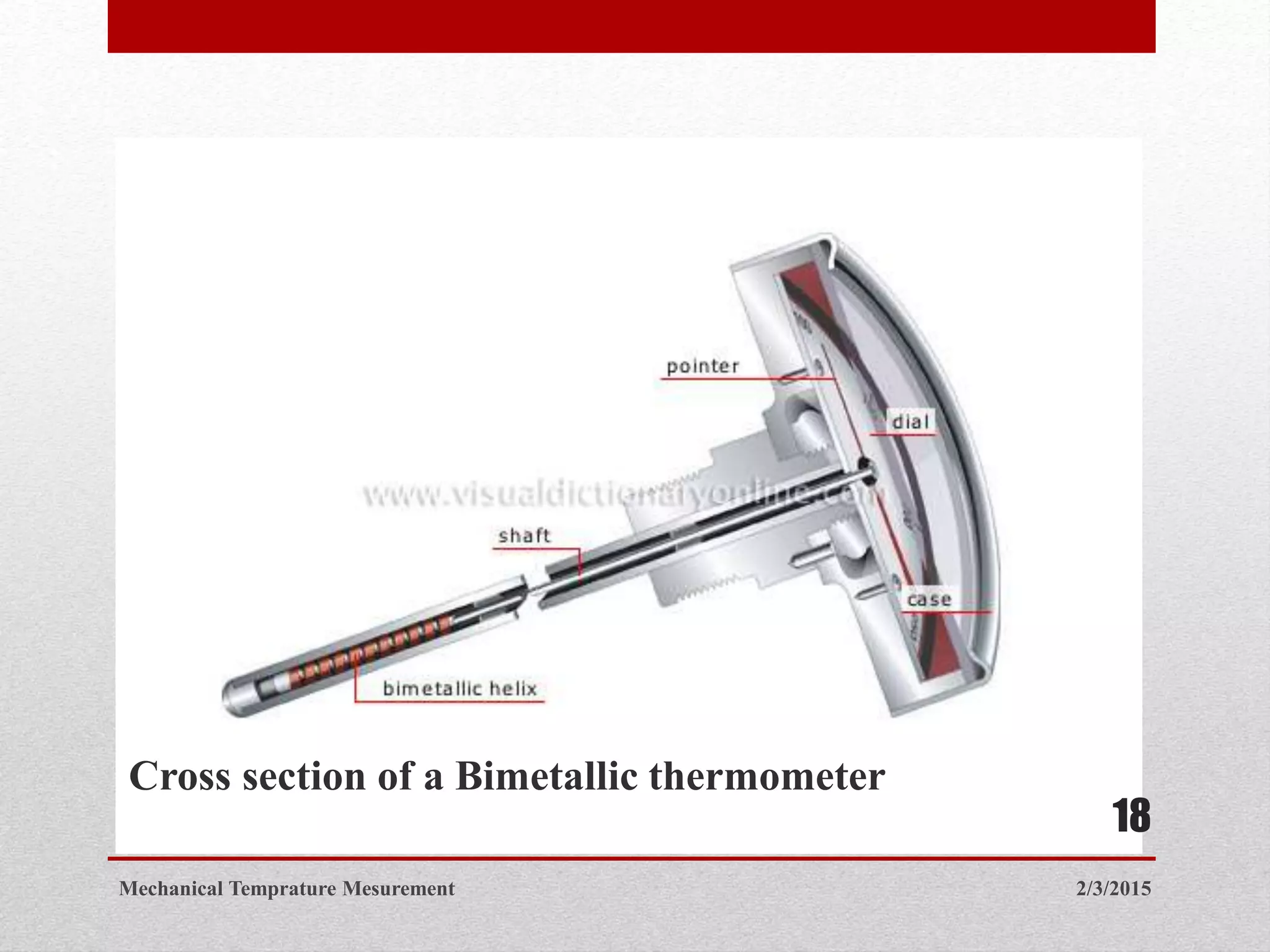

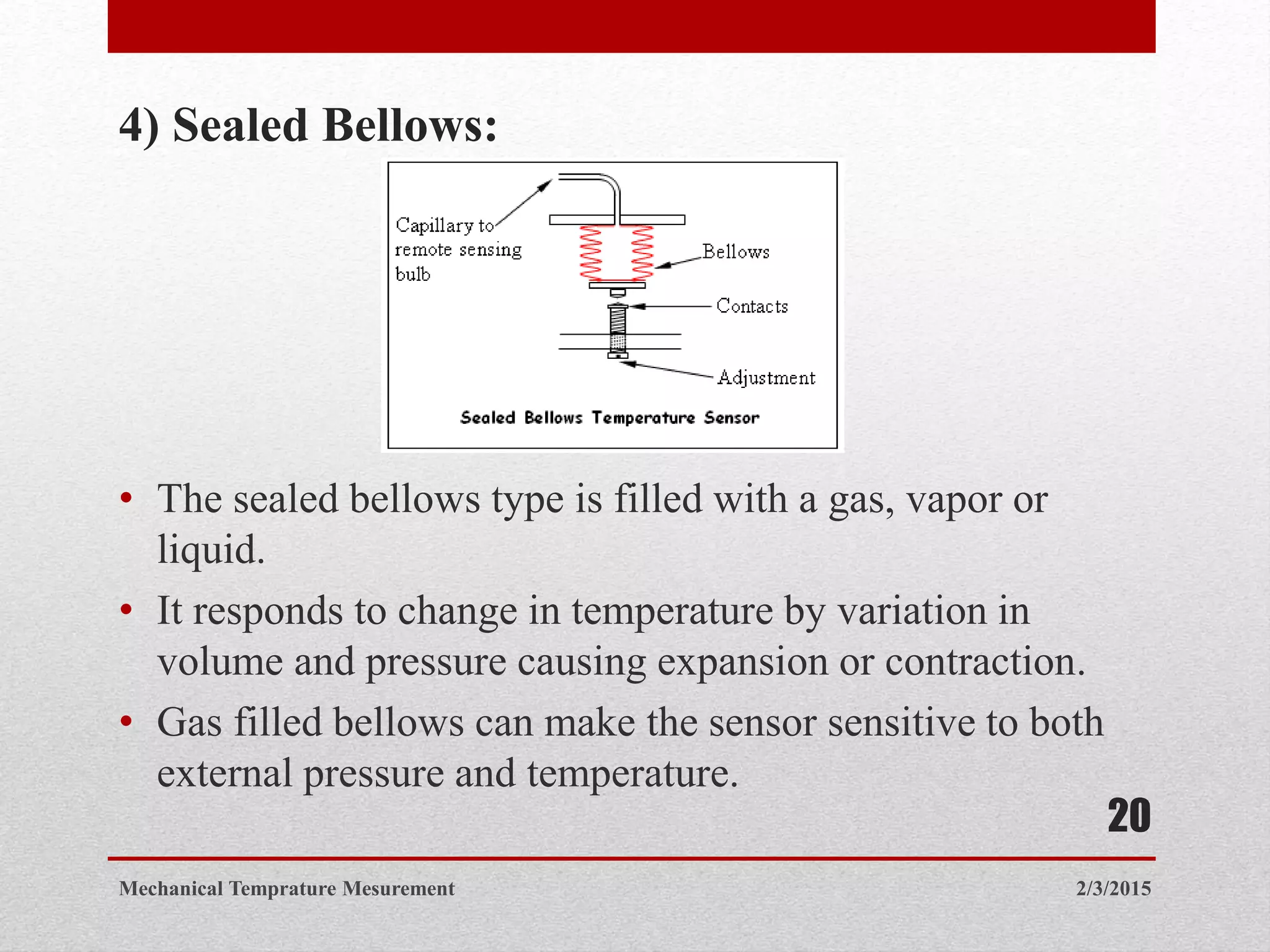

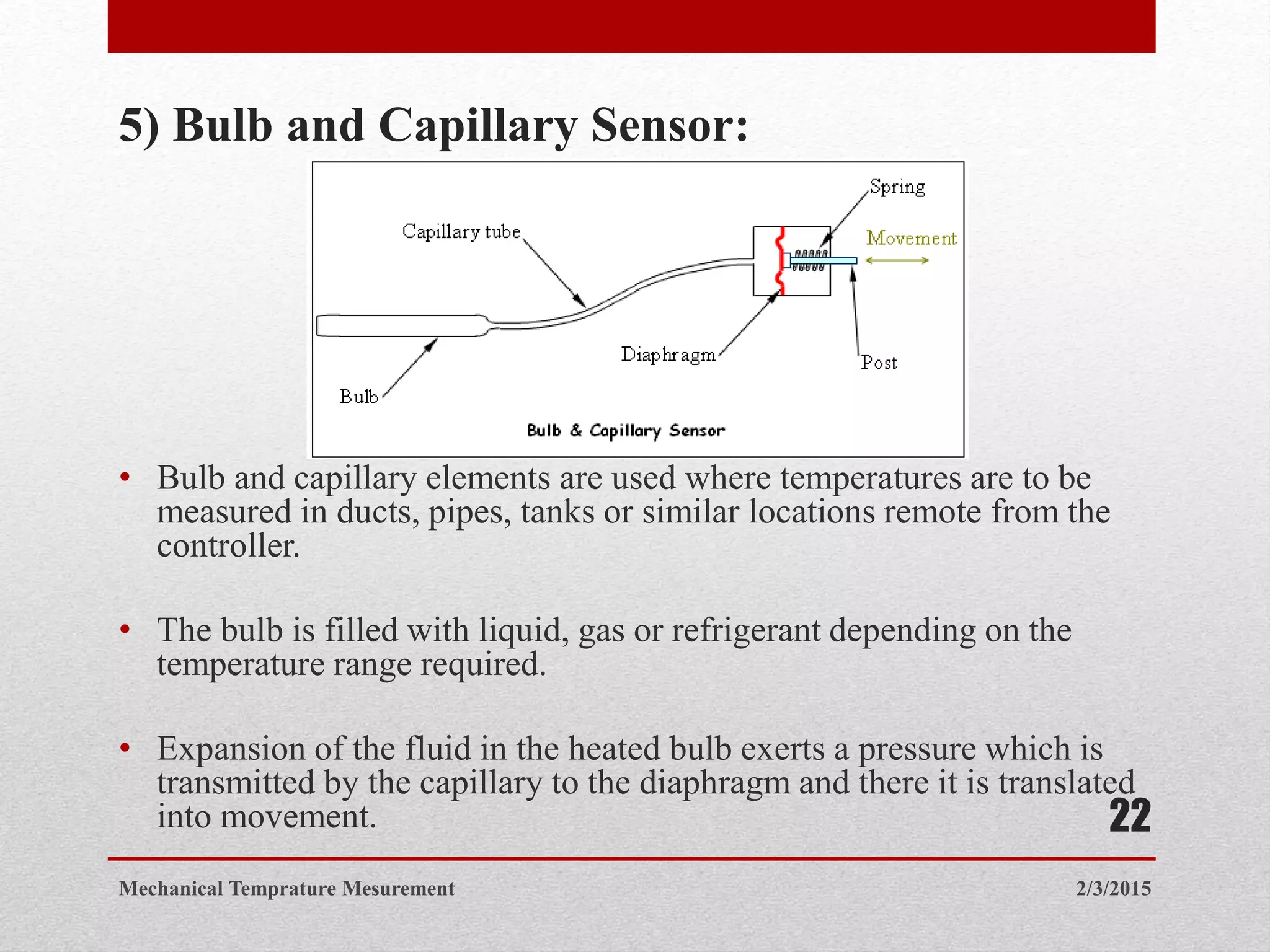

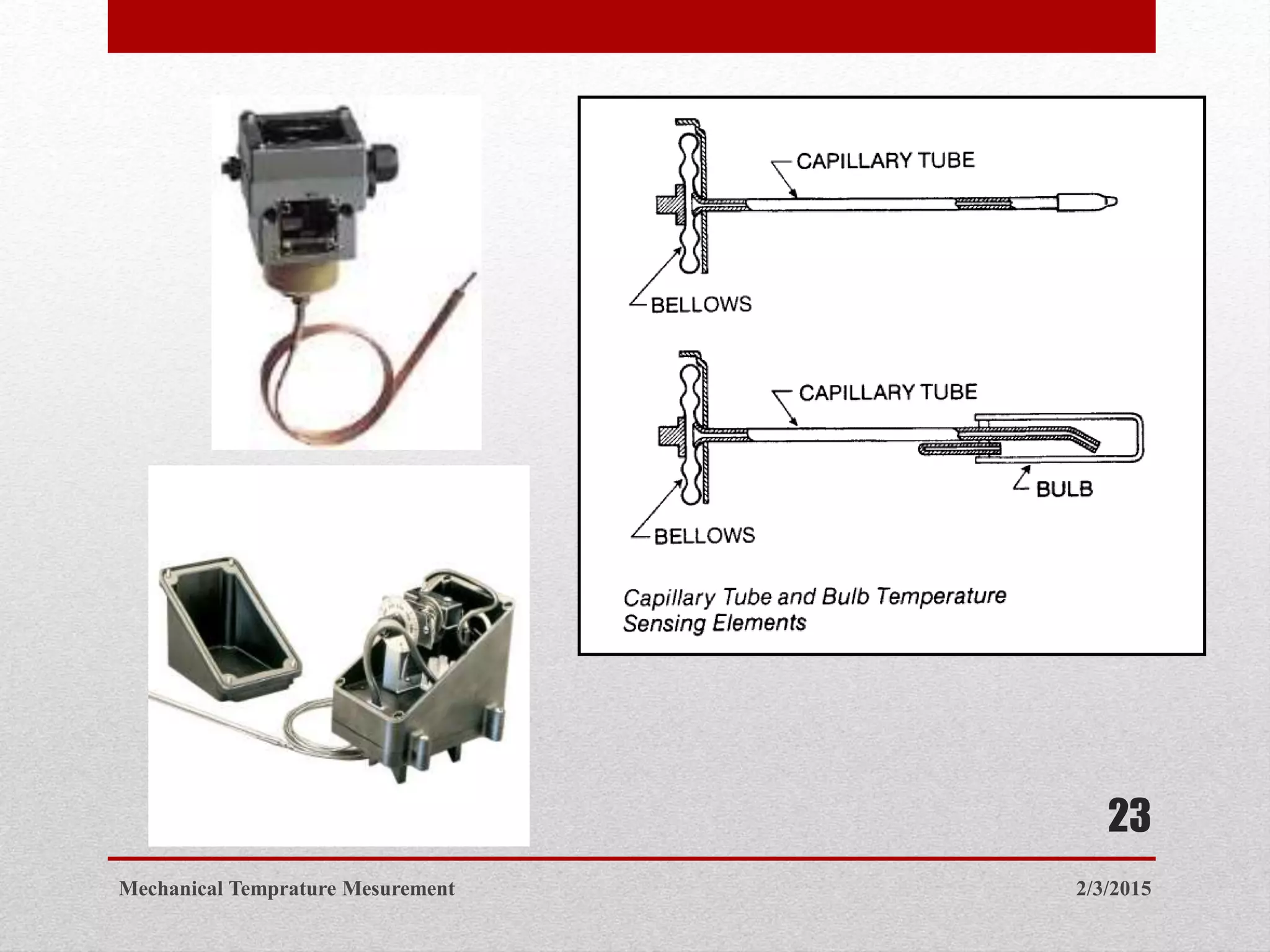

The document discusses various mechanical temperature measurement devices. It describes five main types: liquid-in-glass thermometers, pressure thermometers, bimetallic thermometers, sealed bellows, and bulb and capillary sensors. Each type uses the mechanical effects of thermal expansion to infer temperature changes by measuring volume, pressure, or motion. While some devices like thermometers are centuries old, mechanical sensors remain widely used for their reliability, cost-effectiveness, and ability to function without external power sources.