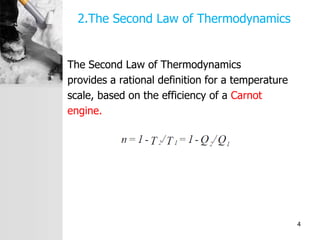

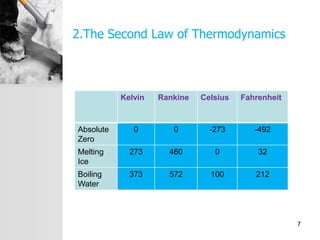

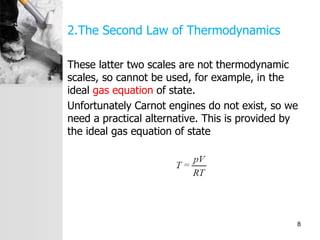

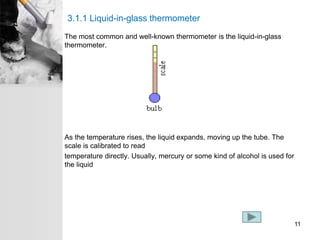

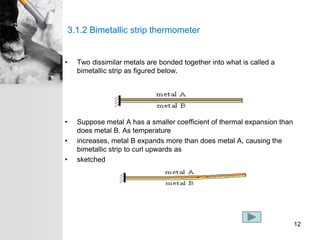

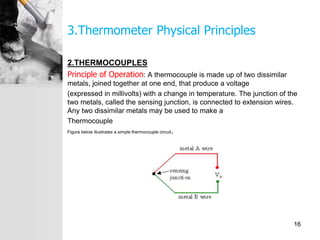

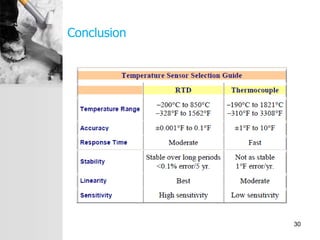

The document discusses different methods for measuring temperature. It begins by introducing temperature scales defined by fixed points like melting ice. The Second Law of Thermodynamics provides a conceptual definition of temperature. Four basic types of temperature sensors are then described: 1) Mechanical sensors like liquid-in-glass thermometers use thermal expansion, 2) Thermocouples produce voltage from dissimilar metals, 3) Thermoresistive sensors measure resistance changes in materials like RTDs and thermistors, and 4) Radiative sensors like infrared pyrometers detect emitted infrared radiation. The conclusion compares thermocouples and RTDs, noting thermocouples are cheaper while RTDs offer greater sensitivity and flexibility.