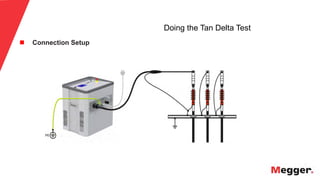

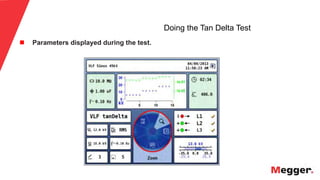

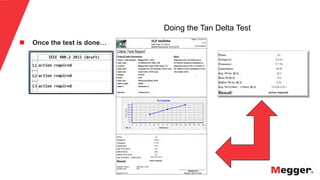

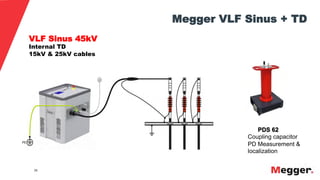

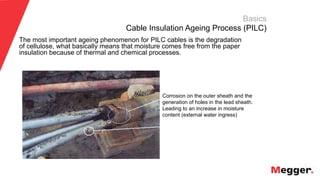

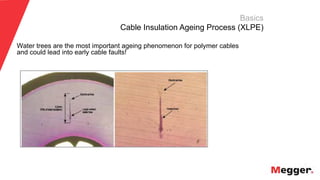

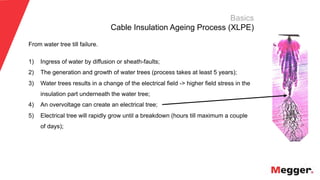

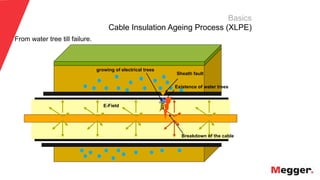

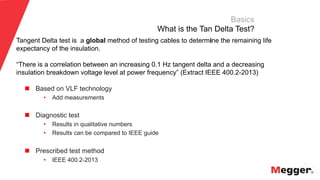

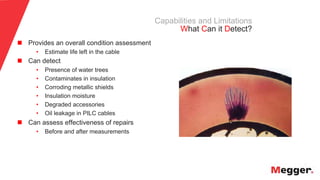

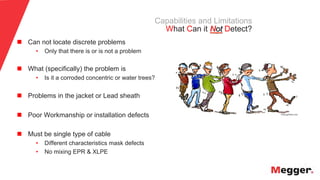

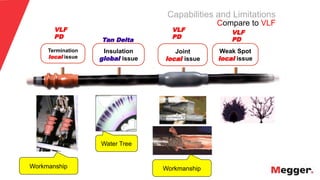

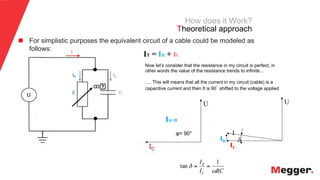

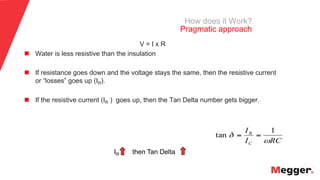

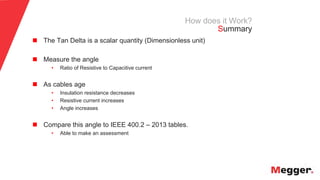

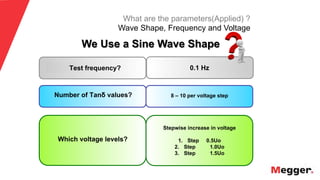

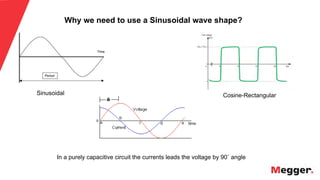

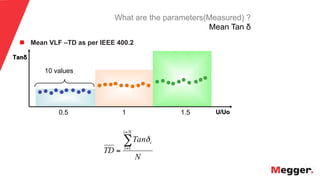

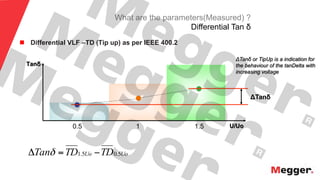

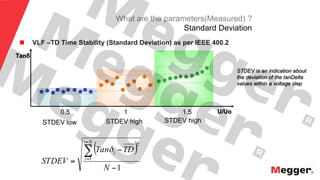

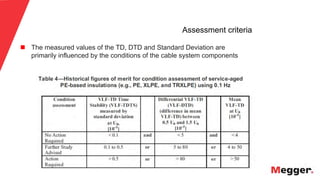

The document discusses Tan Delta testing of medium voltage cables. It provides basics on cable insulation aging processes, defines Tan Delta as a measurement of the ratio of resistive to capacitive current in a cable, and explains that increasing Tan Delta values indicate worsening cable insulation condition. The document also outlines test parameters, how to interpret results based on IEEE criteria, and how to perform a Tan Delta test.

![30

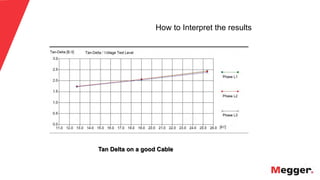

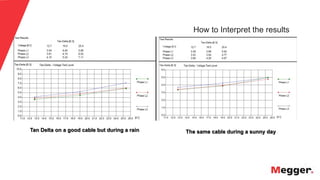

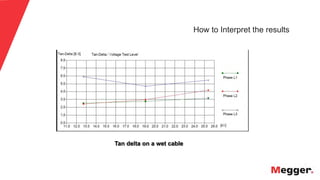

How to Interpret the results

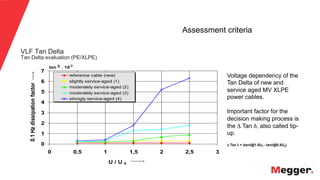

VLF Tan Delta

Tan Delta evaluation (PILC IEEE 400.2 2013)

PD in Electrical Power Apparatus; ISBN 3-8007-1760-3].

Voltage dependency of the TanDelta of a poor

and well impregnated PILC power cable.

Also in this case in addition to the absolute

TanDelta factor, the Δ Tan δ or tip-up is an

important factor in the decision making process.

Moisture ingress will also increase the tanDelta.](https://image.slidesharecdn.com/tandeltaonmvcable-191223182548/85/Tan-Delta-on-MV-Cables-Megger-29-320.jpg)