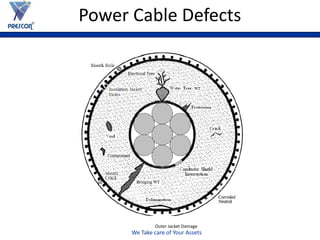

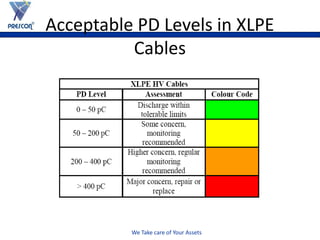

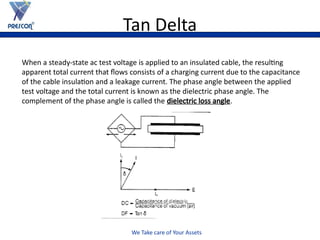

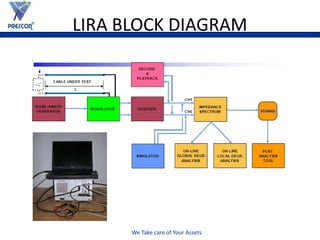

The document discusses various defects and conditions affecting power cables, including manufacturing imperfections, poor workmanship, environmental damage, and overheating, which can lead to reduced dielectric strength and increased aging. It outlines assessment techniques for evaluating cable conditions, such as insulation resistance, time domain reflectometry (TDR), partial discharge testing, tan delta measurements, and line impedance resonance analysis (LIRA), emphasizing the effectiveness, accuracy, and clarity of these methods. Key standards for cable installation and testing are also mentioned, such as IEC 62067 and IEEE 400 series.