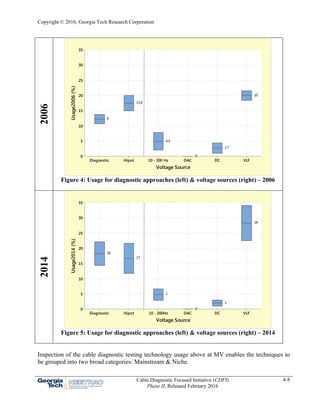

This document provides guidance on selecting the most appropriate cable diagnostic program for a medium voltage cable system. It discusses the evolution of cable diagnostics from 2006 to 2014 based on surveys of over 100 utilities. The use of some techniques, such as very low frequency withstand tests, has increased in that time period due to improvements in equipment and knowledge. The document provides a five-step process called SAGE for selecting diagnostic techniques in a transparent manner and offers information and considerations to help users choose techniques that best suit their needs and risk tolerance.