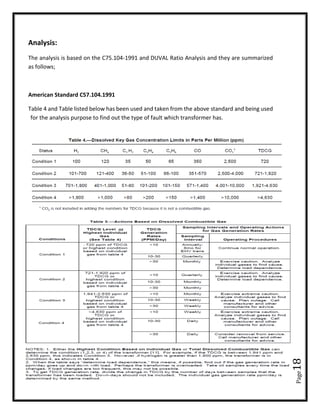

This document provides a diagnostic test report of a 22kV/0.4kV transformer. It includes the results of various tests performed on the transformer such as insulation resistance, magnetic balance, vector group, impedance, winding resistance, and SFRA tests. The document finds that the transformer is in critical condition based on dissolved gas, moisture content, and partial discharge analysis. It recommends taking the transformer out of service, performing oil filtration and retrofitting with new protections before putting it back in service.

![Page8

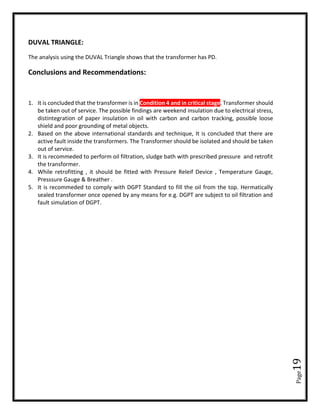

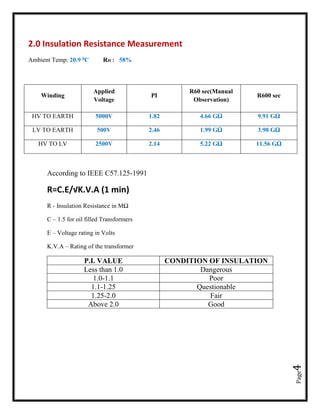

9.0 Tan Delta and Capacitance Measurement:

Oil temp= 22°C RH%= 58.0% K Value – 0.97

Sr.

No

Capacitance

being

measured

Test

Mode

Measured

capacitance

(nF)

Insulation

P.F (%)

Insulatio

n P.F

(%)

Amp.

Temp˚C

Humidity

( RH) %

1 HV-E GST G 1.034 0.317 0.307 21.6 58

2 HV-LV UST Y 2.583 0.532

0.516

21.6 58

3 HV-LV+E GST YG 3.618 0.474

0.459

21.6 58

4 LV-E GST G 6.638 0.564

0.547

21.6 58

5 LV-HV UST Y 2.584 0.525

0.509

21.6 58

6 LV-HV+E GST YG 9.220 0.546

0.529

21.6 58

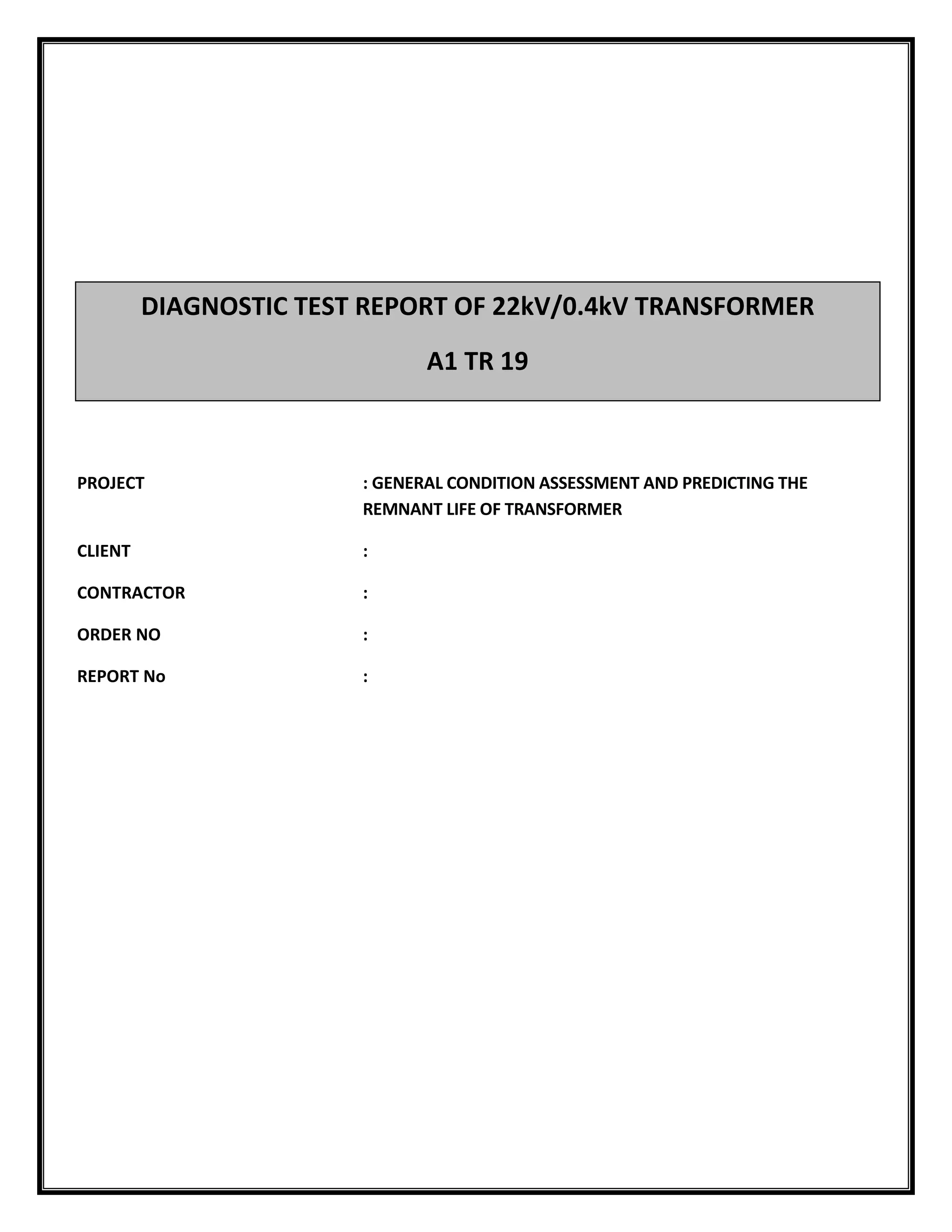

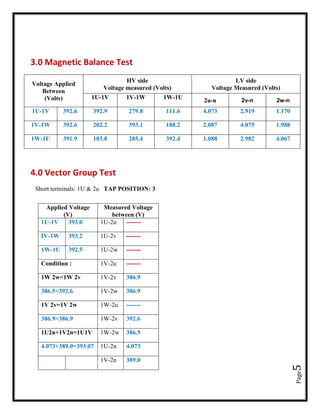

10.0 SFRA ANALYSIS:

1U-1V (LV OPEN)

-20

-30

-40

-50

-60

-70

-80

-90

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H1-H2 [open]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-8-320.jpg)

![Page9

1V-1W(LV OPEN)

1W-1U(LV OPEN)

1U,1V,1W(LV OPEN)

-10

-20

-30

-40

-50

-60

-70

-80

-90

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H2-H3 [open]]

-10

-20

-30

-40

-50

-60

-70

-80

-90

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H3-H1 [open] (1)]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-9-320.jpg)

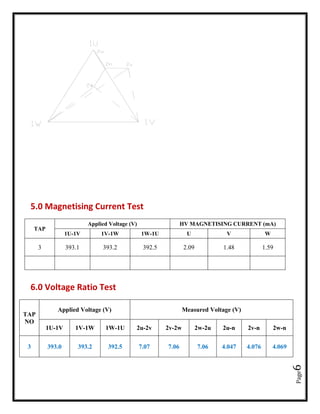

![Page10

X1-X0

X2-X0

-10

-20

-30

-40

-50

-60

-70

-80

-90

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H1-H2 [open]] [H2-H3 [open]] [H3-H1 [open] (1)]

0

-5

-10

-15

-20

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[X1-X0 [open]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-10-320.jpg)

![Page11

X3-X0

0

-5

-10

-15

-20

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[X2-X0 [open]]

0

-5

-10

-15

-20

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[X3-X0 [open]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-11-320.jpg)

![Page12

X1-X0,X2-X0,X3-X0

1U-1V (LV SHORT)

1V – 1W(LV SHORT)

0

-5

-10

-15

-20

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[X1-X0 [open]] [X2-X0 [open]] [X3-X0 [open]]

-10

-20

-30

-40

-50

-60

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H1-H2 [short X1-X2-X3]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-12-320.jpg)

![Page13

1W-1U (LV SHORT)

1U-1V,1V-1W,1W-1U (LV SHORT)

-10

-20

-30

-40

-50

-60

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H2-H3 [short X1-X2-X3]]

-10

-20

-30

-40

-50

-60

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H3-H1 [short X1-X2-X3]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-13-320.jpg)

![Page14

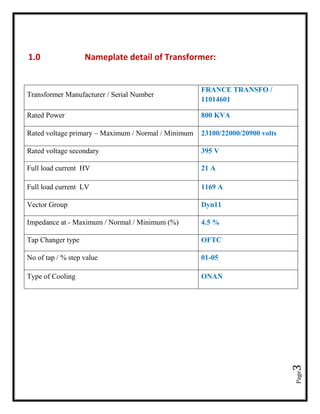

11.0 DFRA ANALYSIS:

Measured Graphs Vs Frequency (Attached Graphs)

✓ Oil Conductivity

✓ Polarisation Depolaraisation

✓ Tan Delta & Capacitance

✓ Tan Delta

✓ Powerfactor

✓ Impedance

-10

-20

-30

-40

-50

-60

Magnitude(dB)

100 1 k 10 k 100 k 1 M

Frequency (Hz)

[H1-H2 [short X1-X2-X3]] [H2-H3 [short X1-X2-X3]] [H3-H1 [short X1-X2-X3]]](https://image.slidesharecdn.com/trfsamplereport-190309151014/85/TRANSFORMER-SAMPLE-REPORT-DGA-PHYSICAL-CONDITION-14-320.jpg)