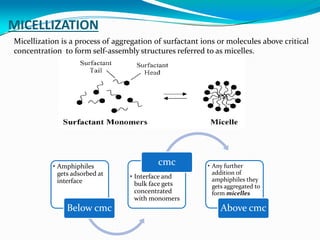

Micellization is the process where surfactant molecules spontaneously self-assemble into aggregates called micelles above a critical concentration known as the critical micellar concentration (CMC). Micelles form to minimize contact between the surfactant hydrophobic tails and water. The CMC and micelle size are affected by factors like the surfactant chain length and head group, counter ion type, temperature, and presence of additives. Micelles can incorporate hydrophobic drugs to improve their solubility and stability for drug delivery applications.

![SURFACTANTS

They are low to moderate molecular weight compounds

with a hydrophobic part and a hydrophilic part

[amphiphile].

Based on the nature of polar head groups they are

classified as

Anionic surfactants

Cationic surfactants

Non ionic surfactants

Zwitter ionic surfactants](https://image.slidesharecdn.com/surfactntschristy-170826170814/85/Surfactnts-3-320.jpg)

![MICELLE STRUCTURE [ionic, zwitter ionic ]

•Liquid core-

formed by the n

number

hydrocarbon chains

•Stern layer- ionic

head groups + (1-

alpha) n counter

ions

•Diffusion layer or

gouy Chapman

layer- alpha n

counter ions

Location of

interface is

0.08nm above the

alpha carbon of

alkyl chains](https://image.slidesharecdn.com/surfactntschristy-170826170814/85/Surfactnts-11-320.jpg)

![MICELLE STRUCTURE[non ionic]

Typical example of

non ionic micelles is

those formed by

polyoxyethylated

surfactants. Its main

components are

Core

Palisade layer

Core is surrounded

by a layer of

polyoxyethylene

chains to which

solvent molecules

may be hydrogen

bonded. This region

of micelle is called

palisade layer.](https://image.slidesharecdn.com/surfactntschristy-170826170814/85/Surfactnts-13-320.jpg)