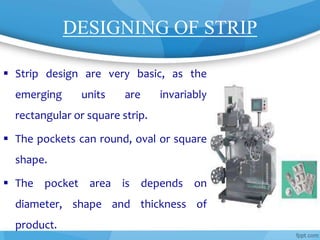

This document discusses strip packaging technology. Strip packaging involves enclosing individual articles between two webs of material sealed together in pockets by heated rollers. The process involves feeding articles and web materials between rollers with cavities to form sealed pockets around each article. Design considerations for the strips include pocket shape and size. Seal quality is inspected by heating sealed areas and checking for leaks underwater. Common materials used are foil laminates, PET, and aluminum foil for their barrier and sealing properties.