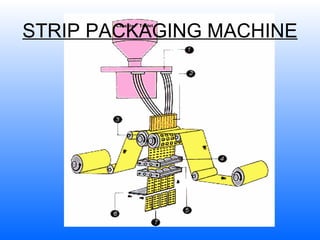

Strip packaging is an alternative form of unit dose packaging that encloses individual articles between two webs of material sealed together in separate compartments. The process involves feeding two webs of material between heated crimping rollers that form cavities to hold the articles as they drop between the webs. The webs are then heat sealed together around the contents. Common materials used include paper, aluminum foil, and plastic films that provide effective barriers and seals while allowing identification of contents. Strip packaging offers individual protection of contents, increased shelf life, and allows for printing on outer packaging.