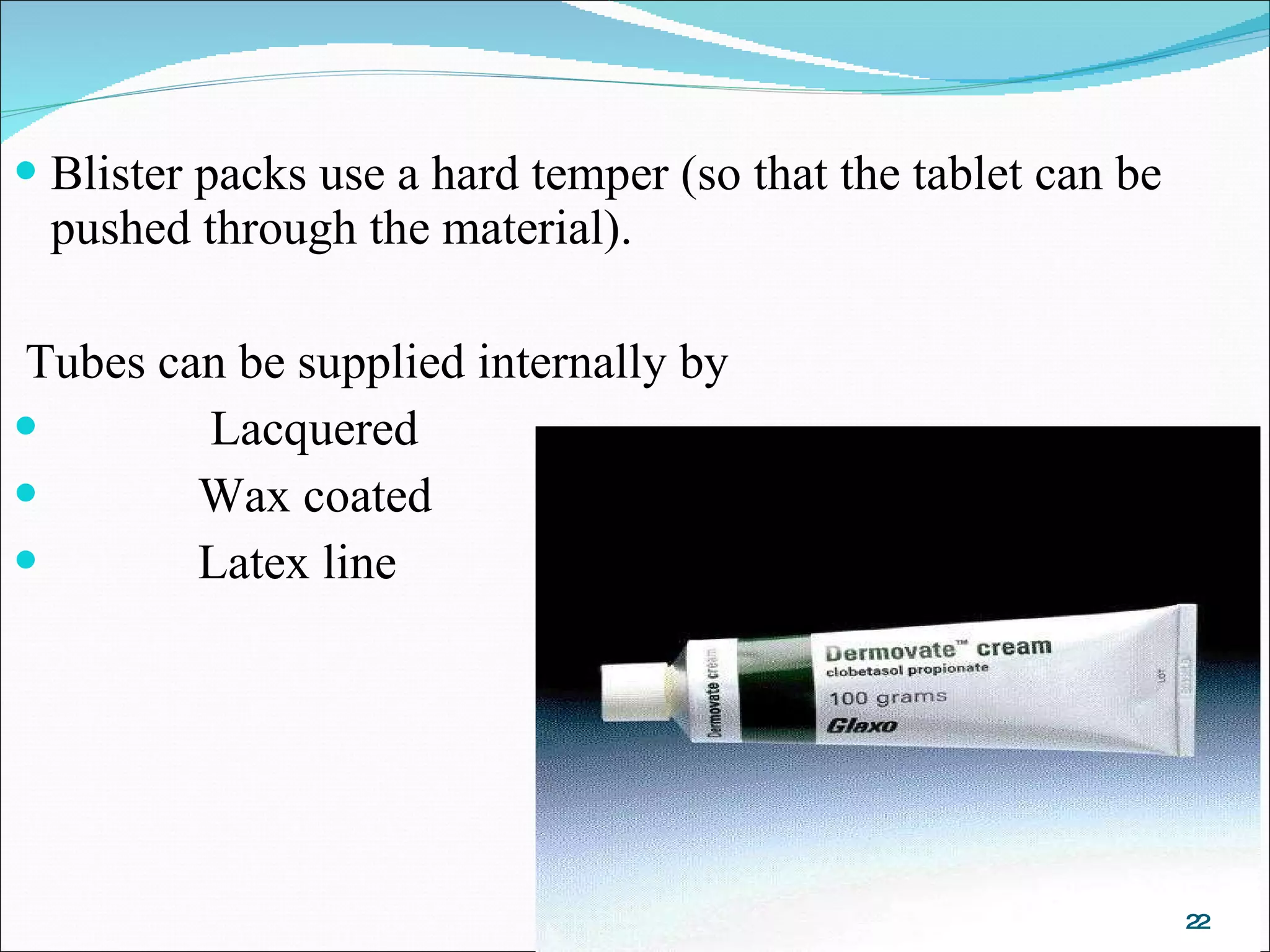

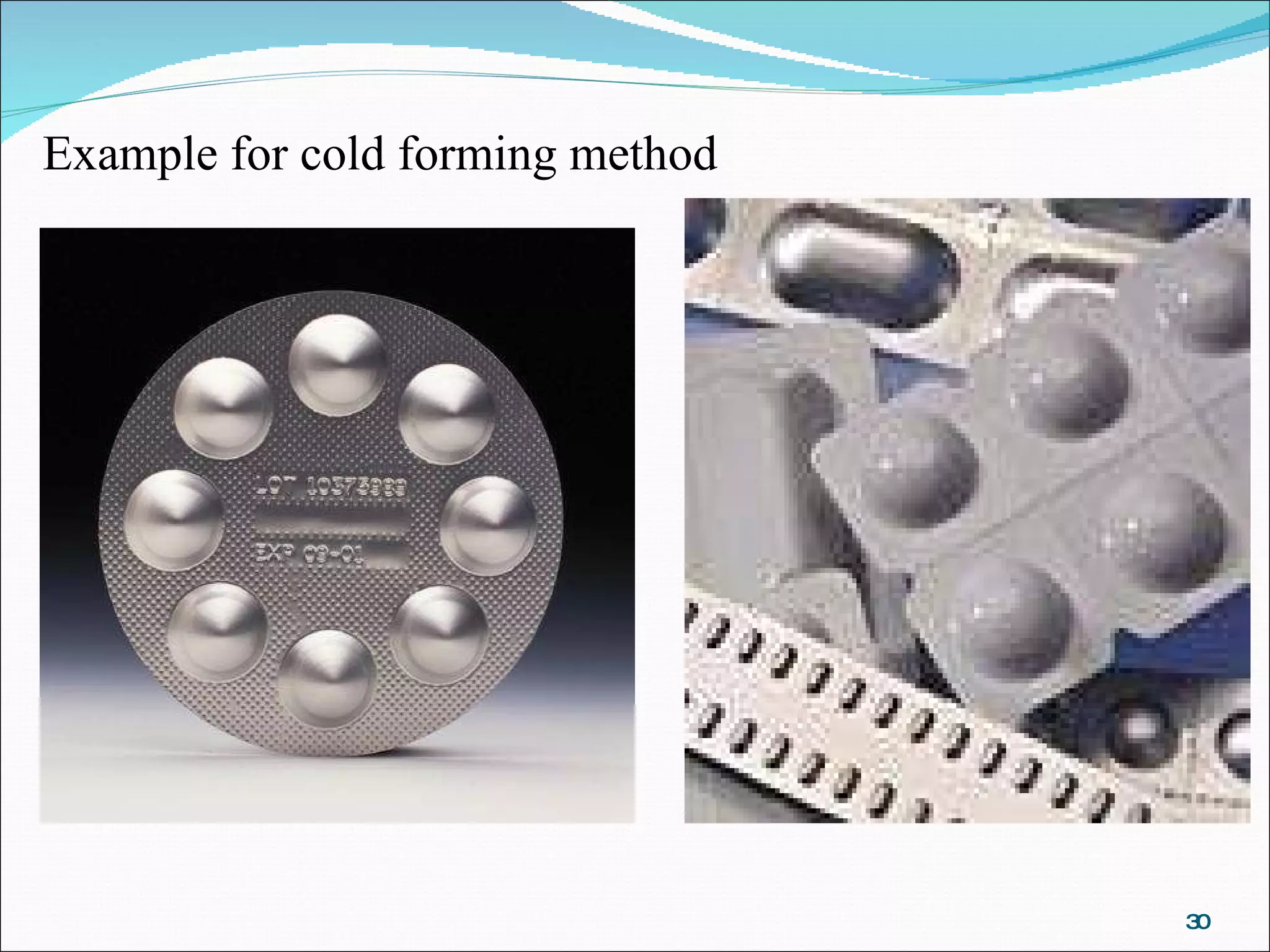

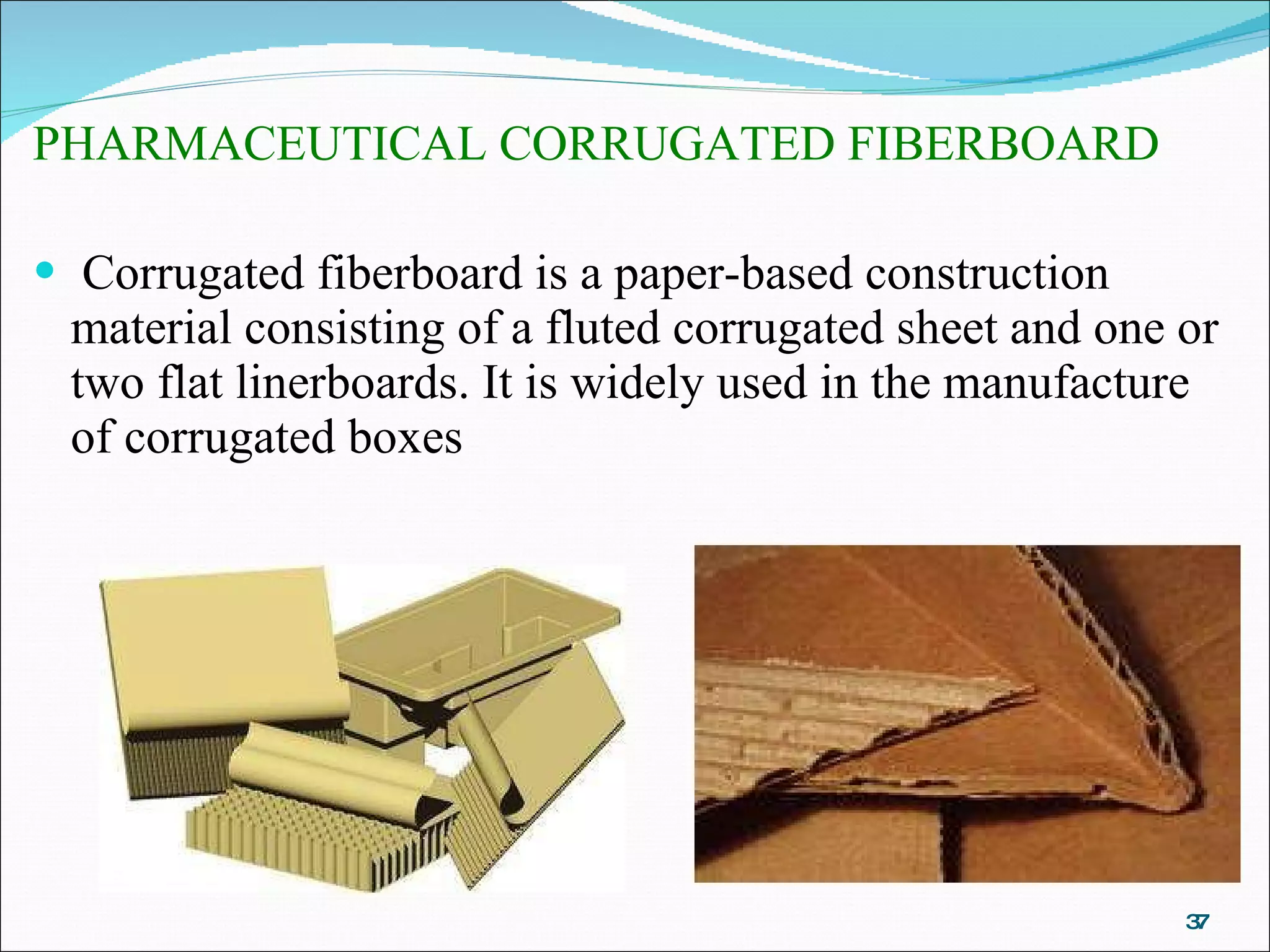

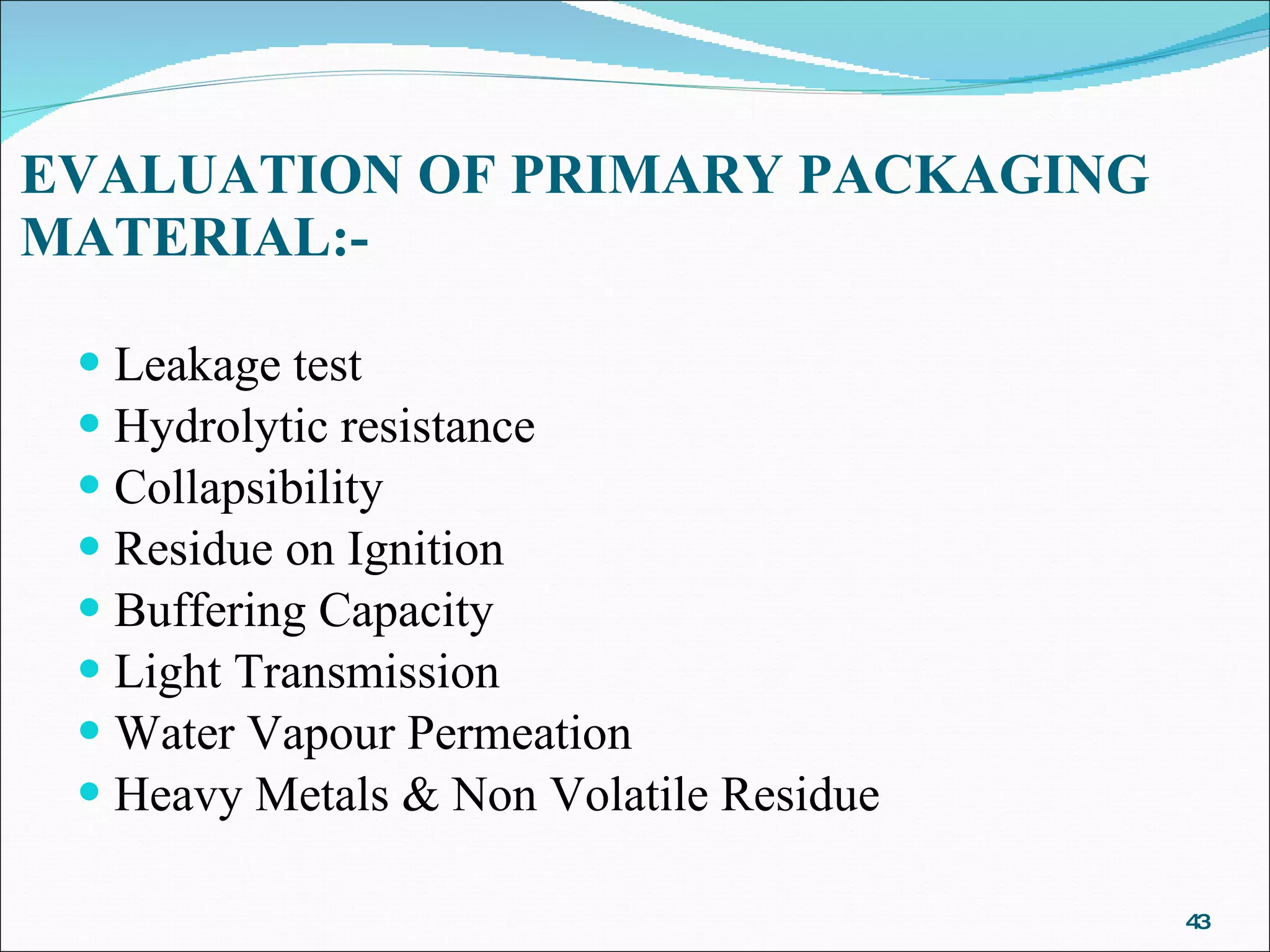

The document discusses packaging in the pharmaceutical industry, detailing the types of packaging (primary, secondary, and tertiary) and materials used, such as glass, plastics, and metals. It highlights the functions of packaging including protection, containment, and convenience, as well as the evaluation methods for packaging materials. Trends and challenges in pharmaceutical packaging are also covered, emphasizing the importance of safety, hermetic sealing, and flexibility in production.