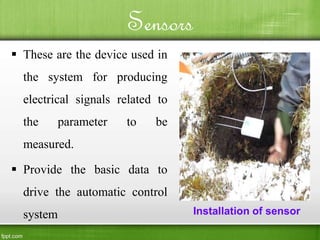

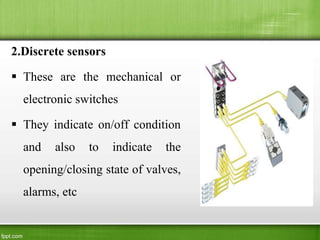

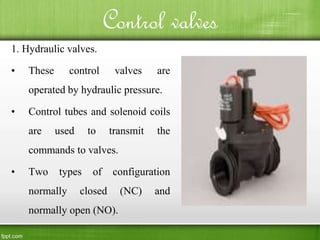

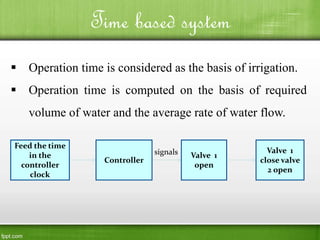

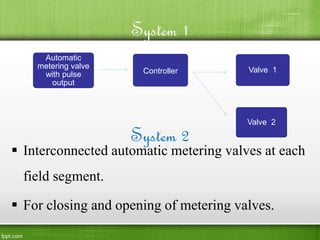

The presentation outlines the design and benefits of automated micro irrigation systems, emphasizing the transition from manual to automated operations to improve efficiency in agriculture. Key components discussed include sensors, controllers, and various automation types, alongside their advantages and limitations. The document also highlights the potential for increased crop yield, water conservation, and flexibility in irrigation management.