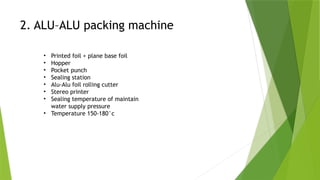

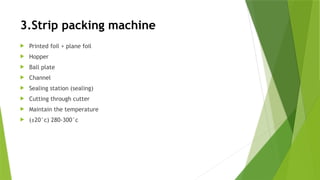

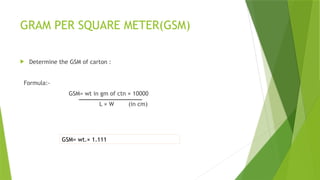

The document discusses pharmaceutical packaging, detailing its importance for product protection, identification, and promotion. It covers various materials used in packaging such as glass, plastics, and packaging types like blister and strip packages, including their advantages and disadvantages. Additionally, it describes different packaging machines used for packing pharmaceuticals and the testing methods for packaging integrity.