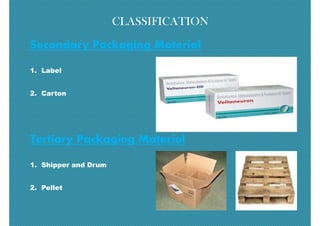

This document discusses packaging materials for pharmaceutical products. It begins by outlining factors to consider when selecting packaging, such as the product's characteristics, protective needs, and marketing requirements. It then describes the necessary characteristics of packaging materials, including protecting the product from environmental conditions while meeting regulations. The document categorizes packaging as primary, secondary, tertiary, or ancillary. It provides examples of materials used for different pharmaceutical dosage forms and packaging levels. Finally, it discusses quality control testing and tamper-resistant packaging options.