Embed presentation

Downloaded 227 times

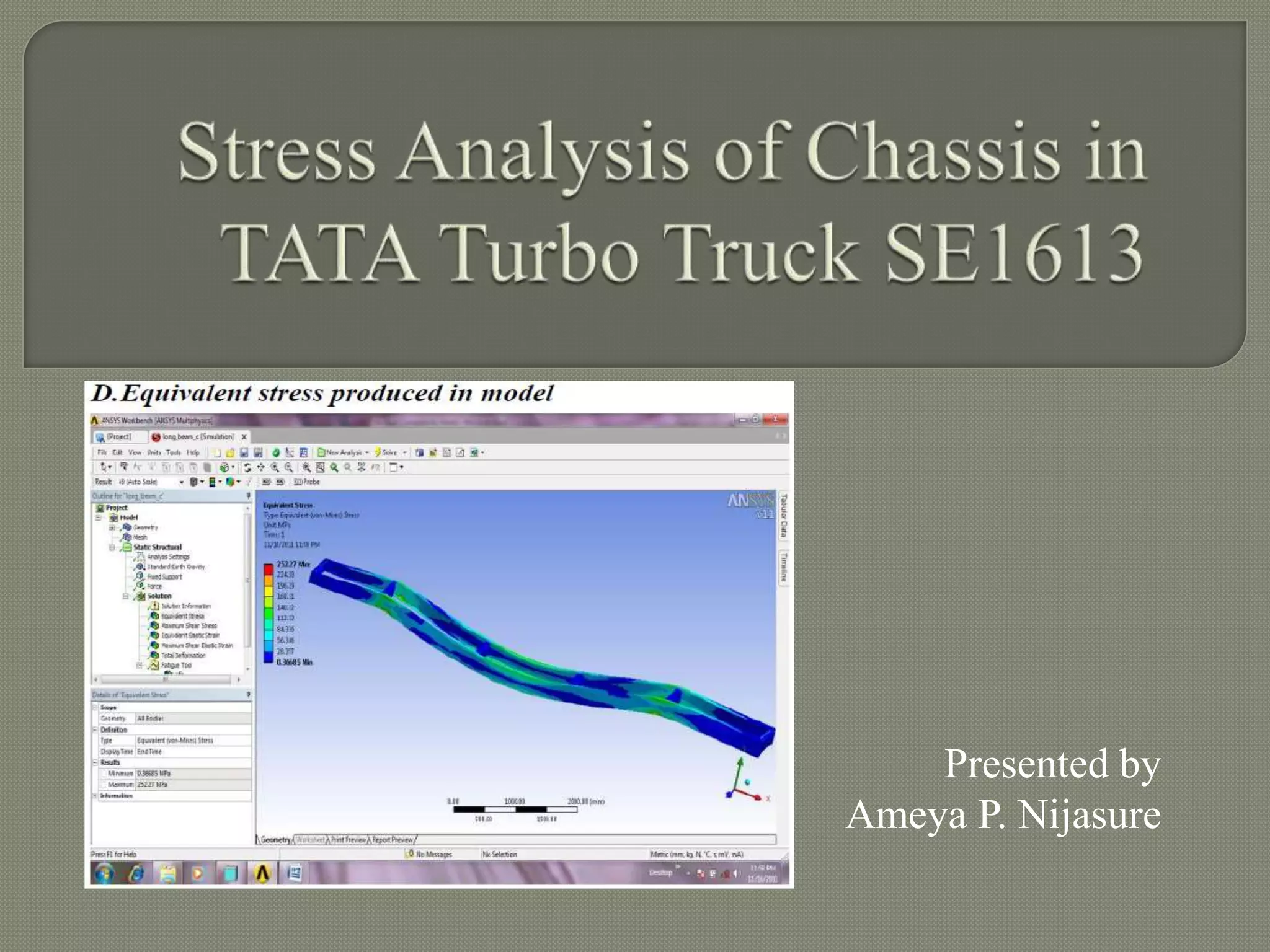

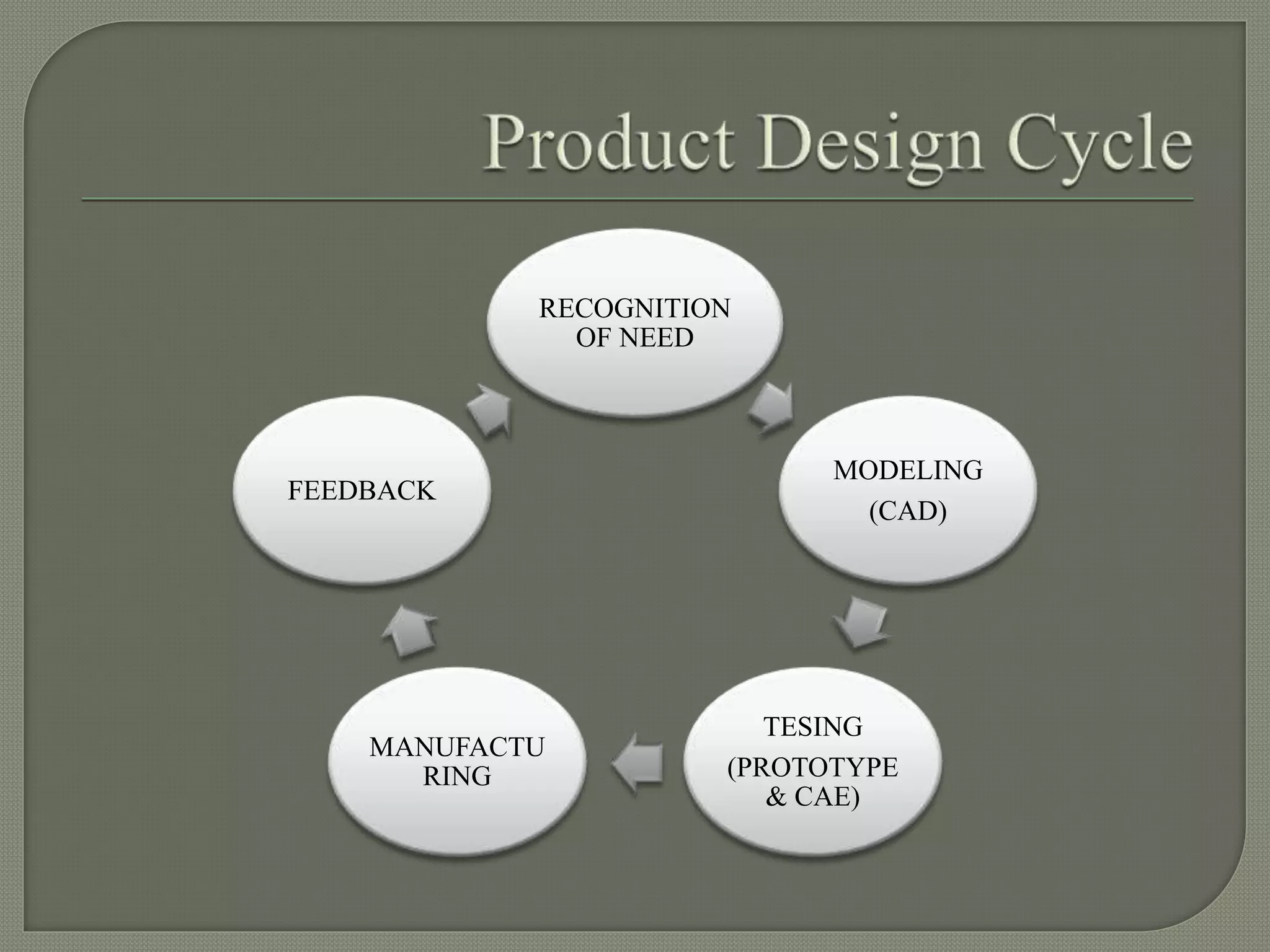

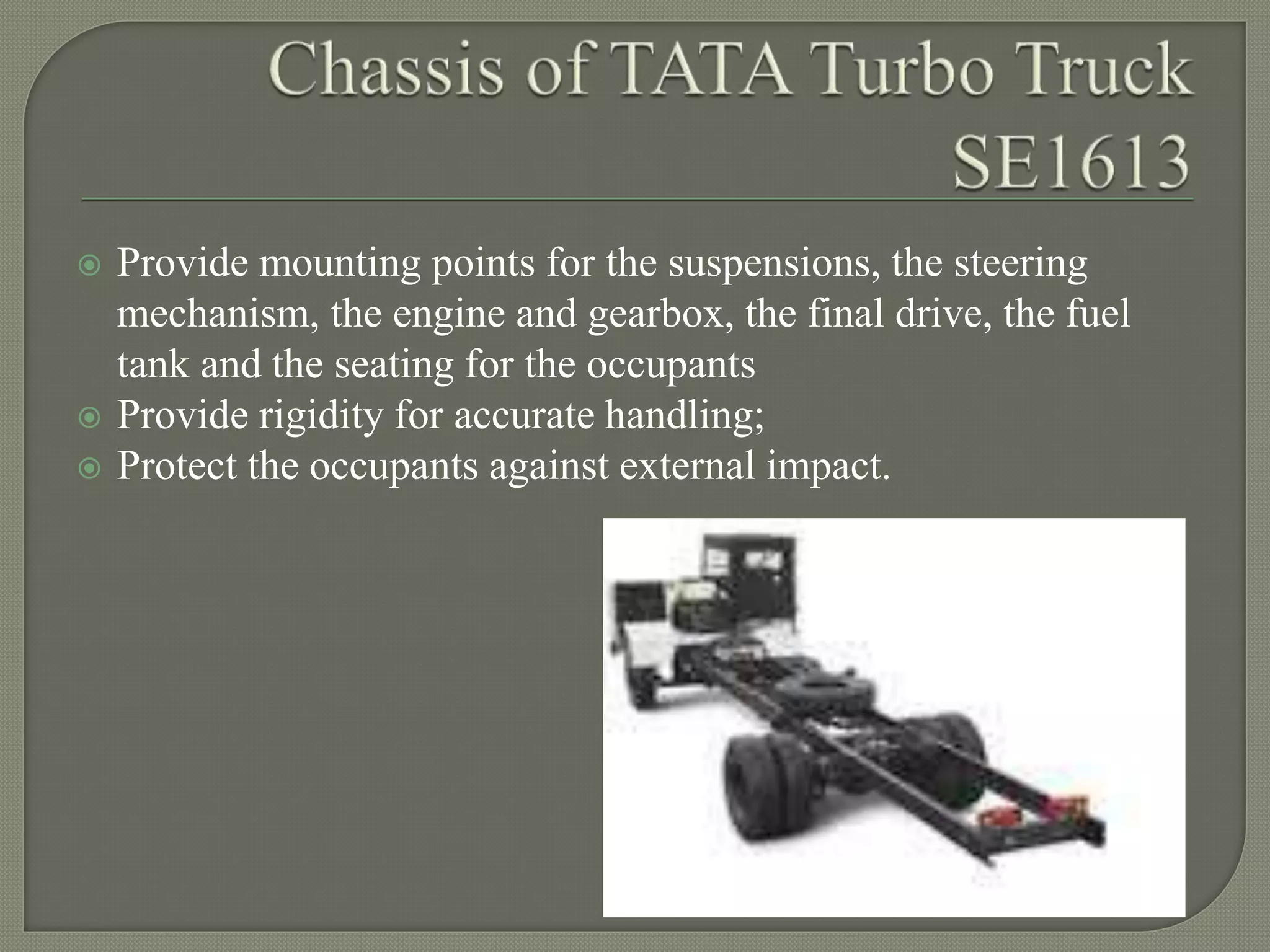

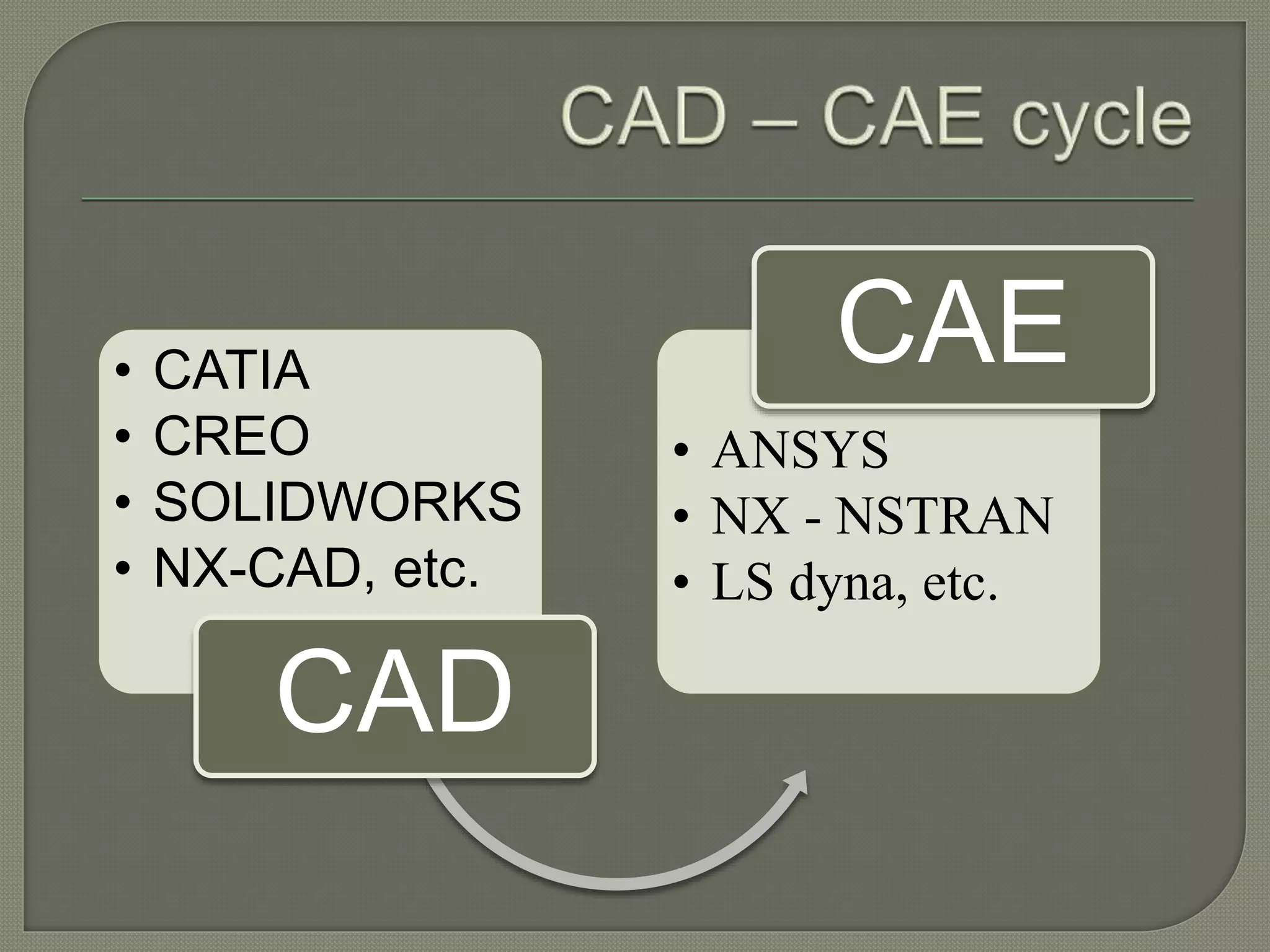

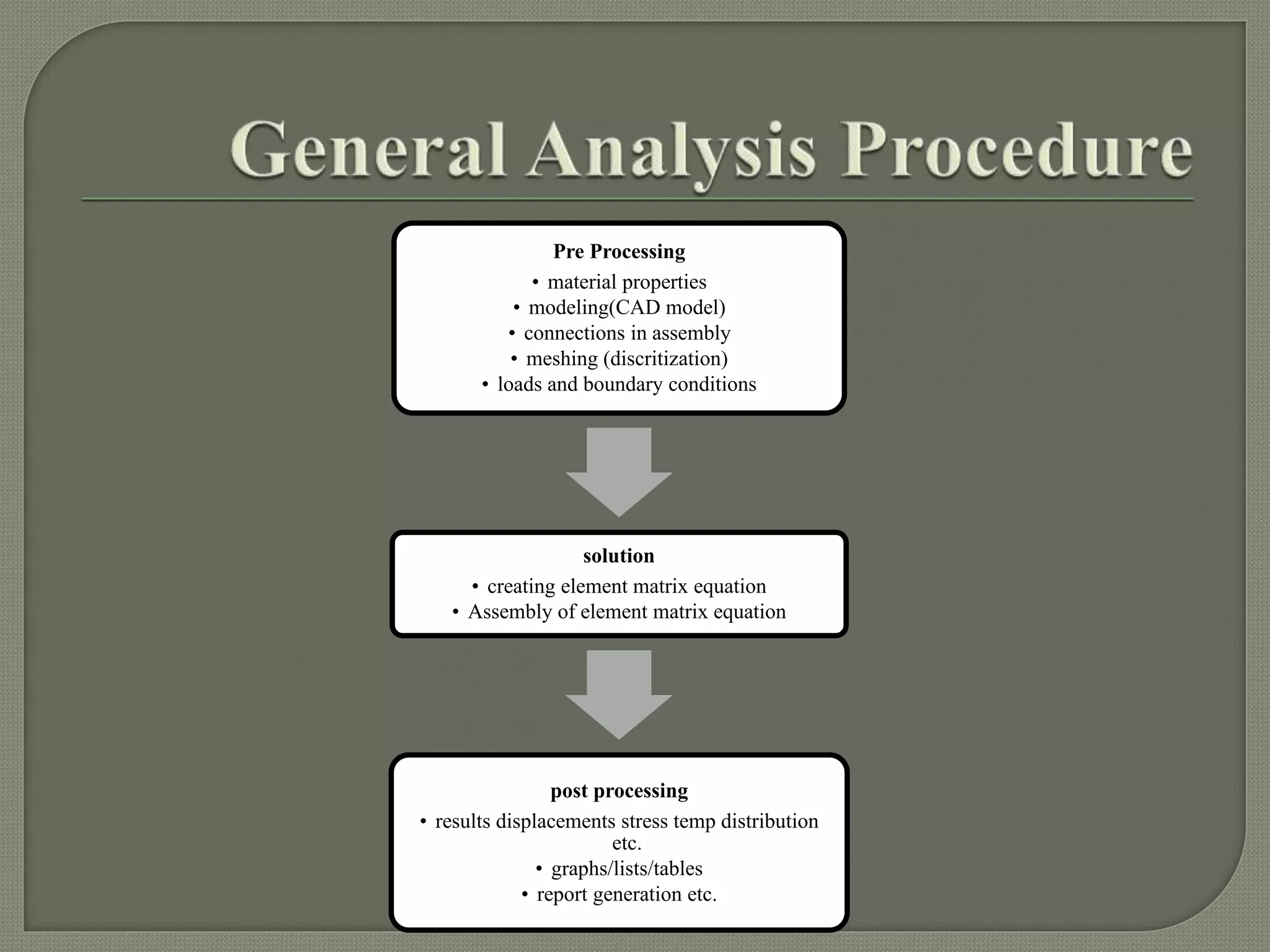

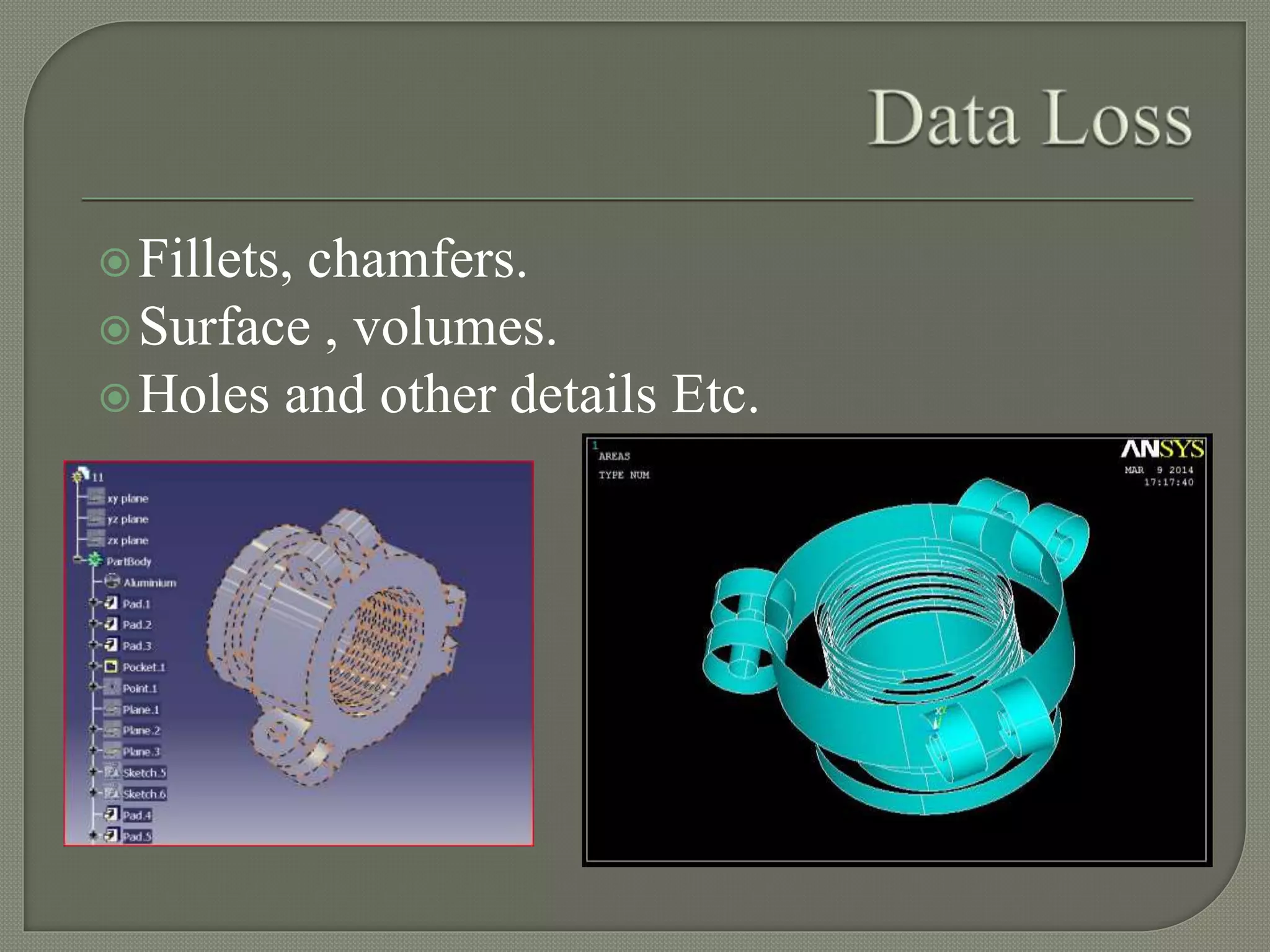

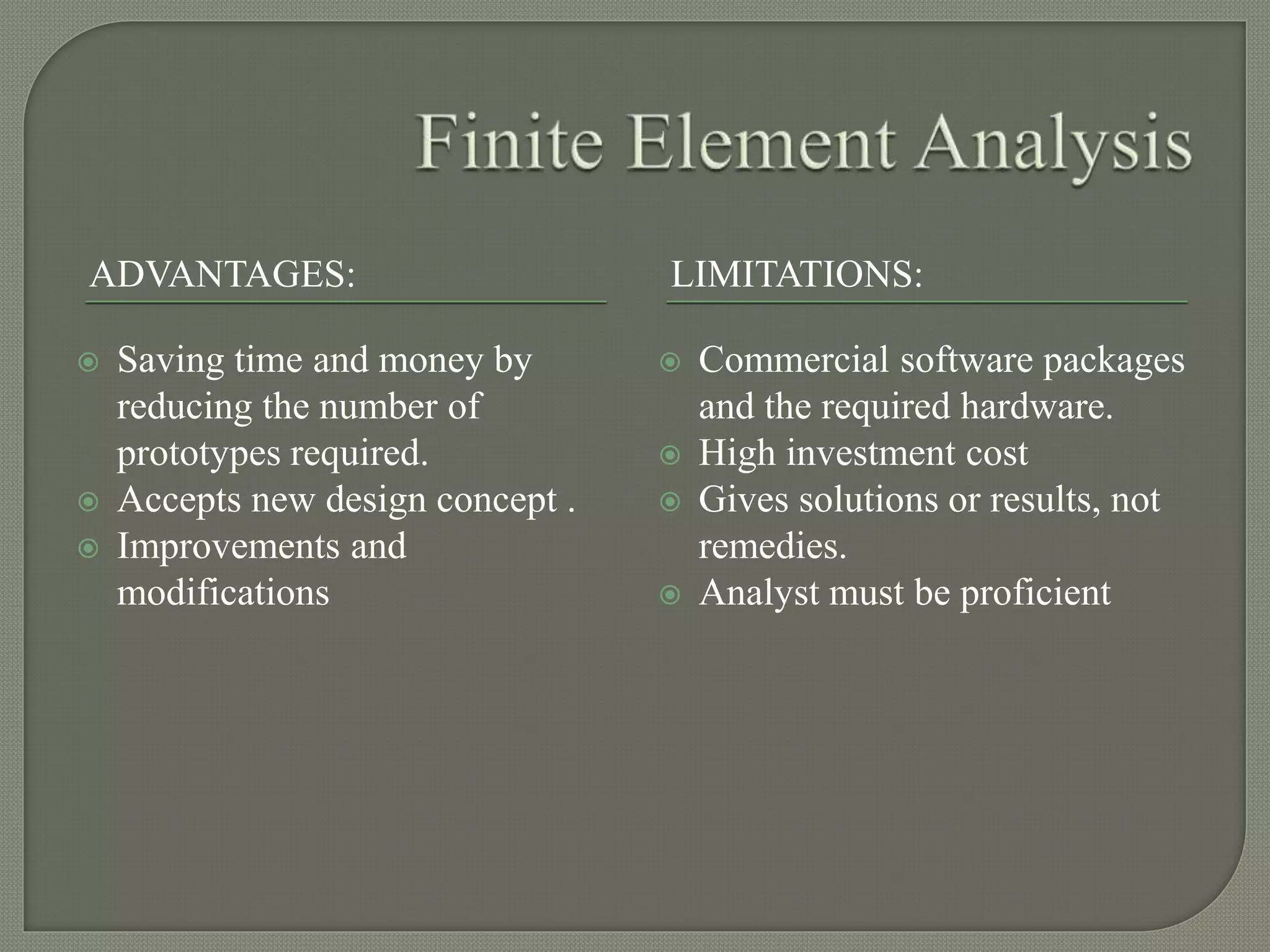

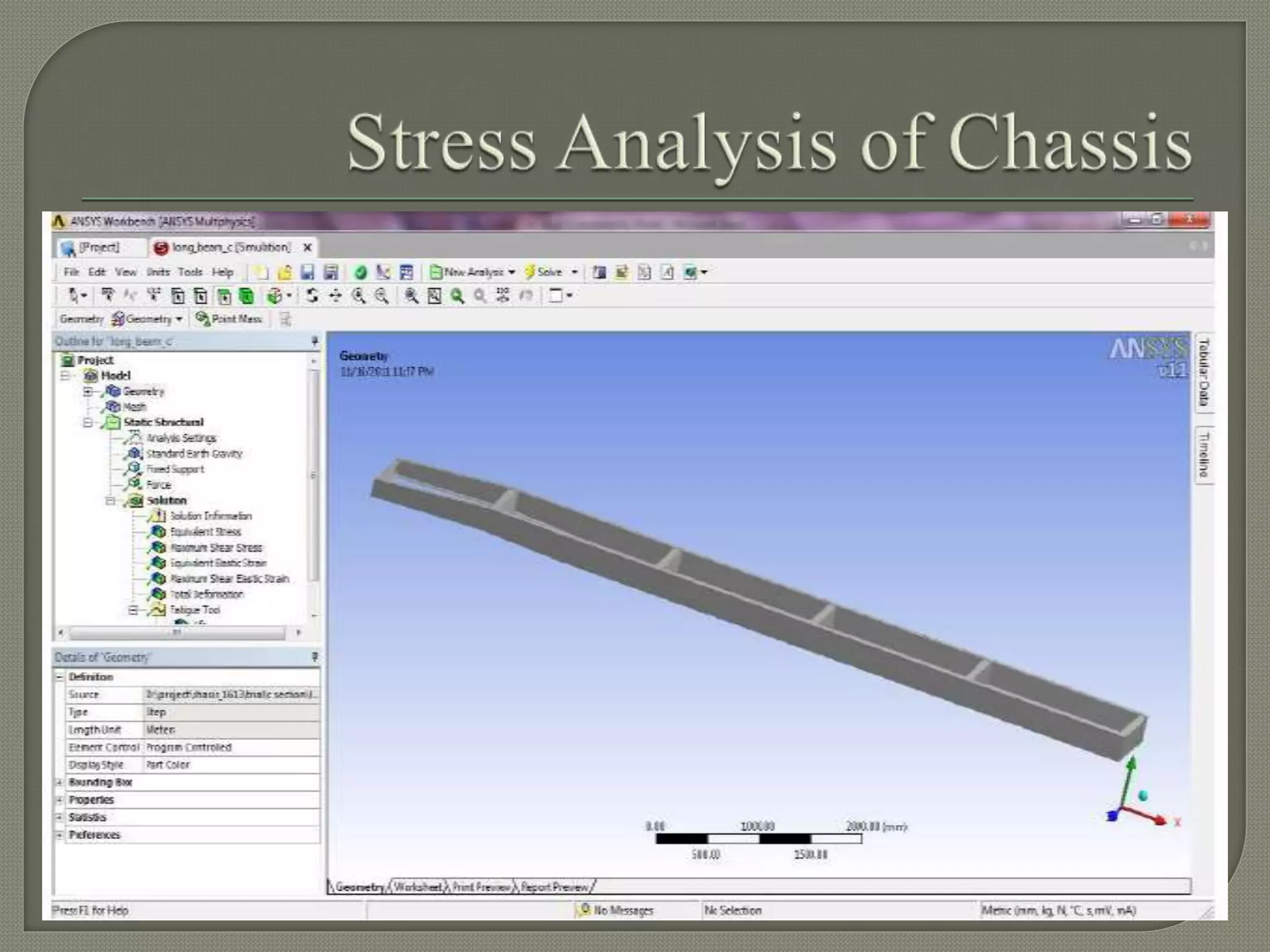

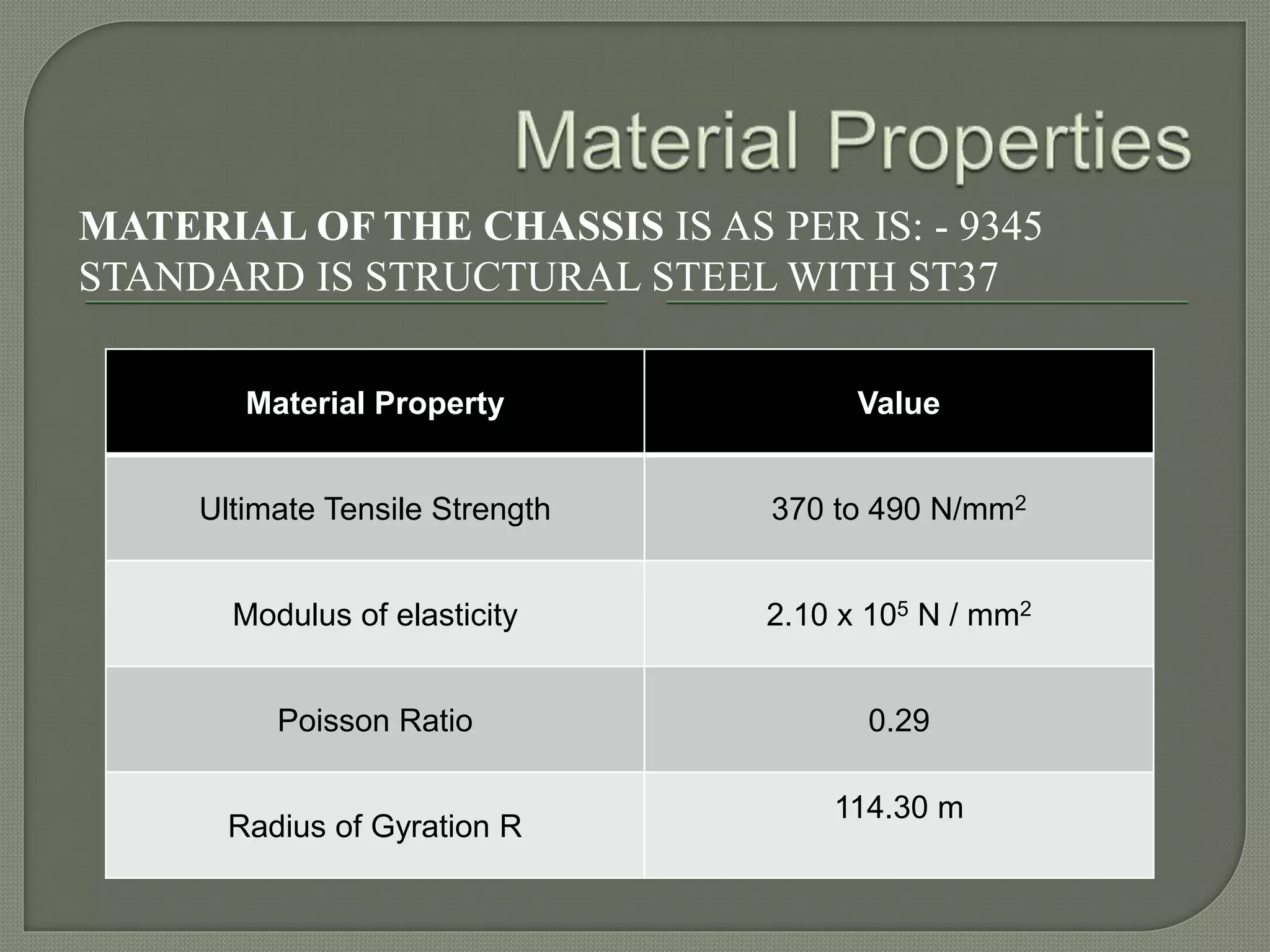

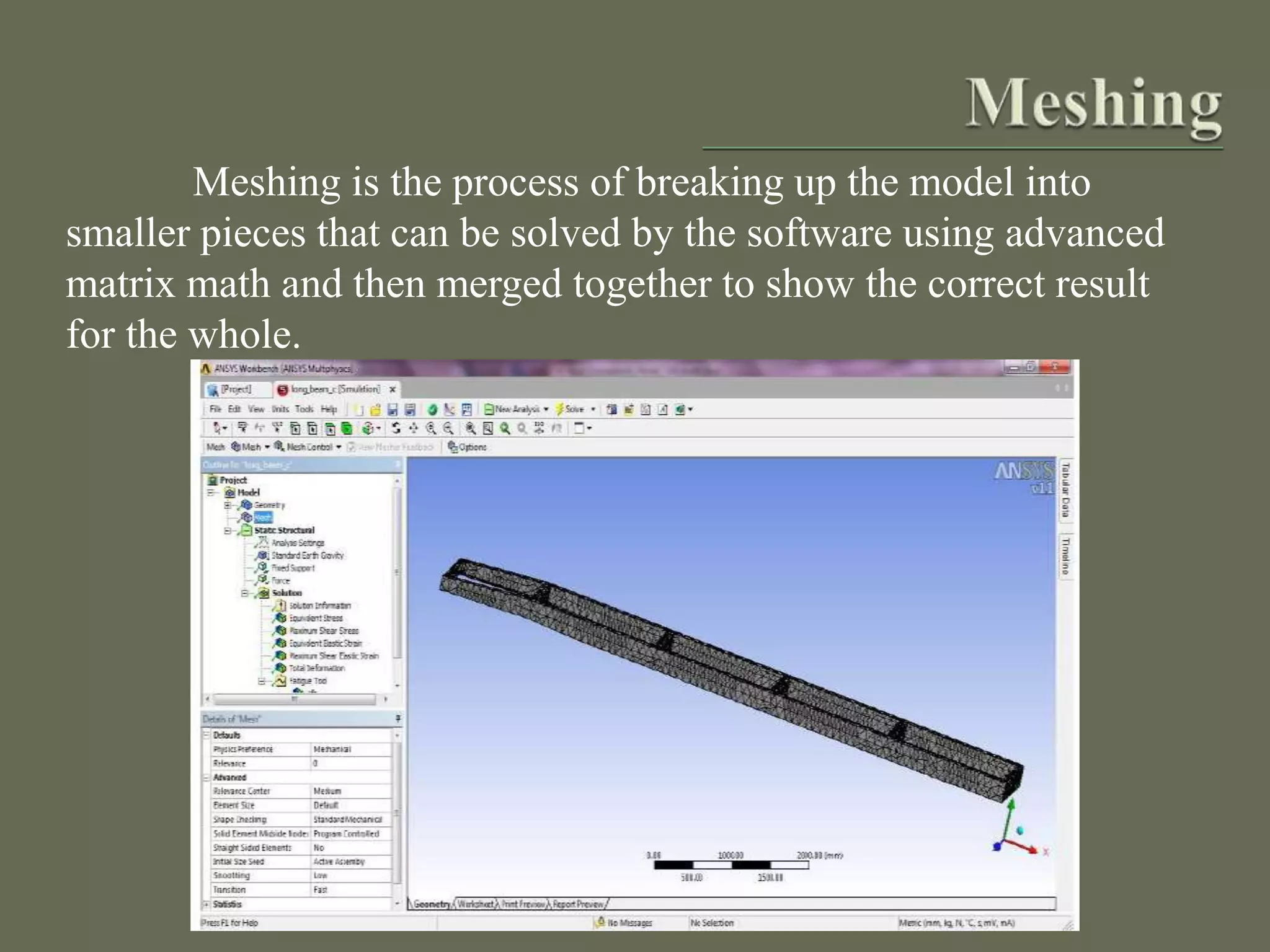

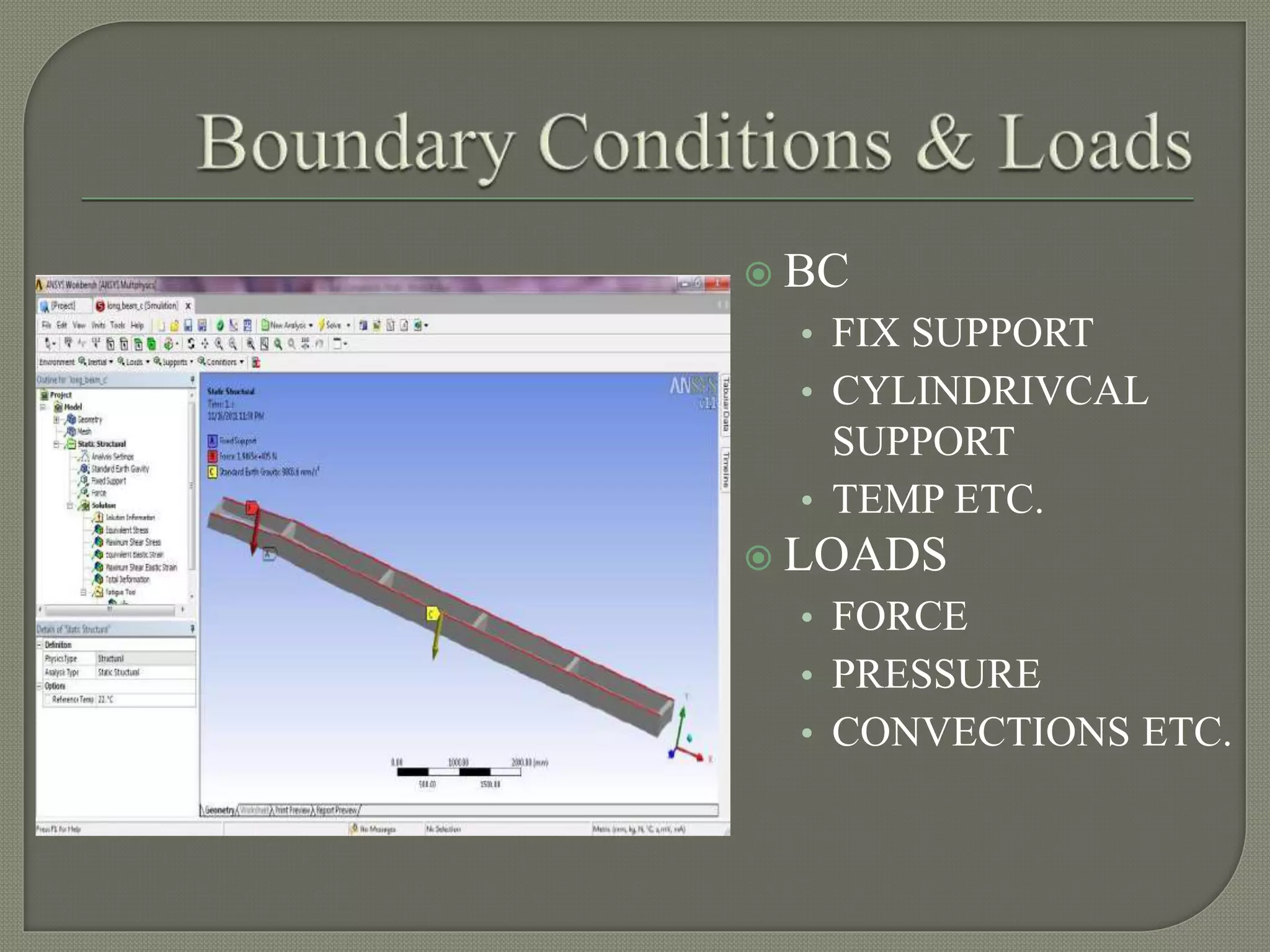

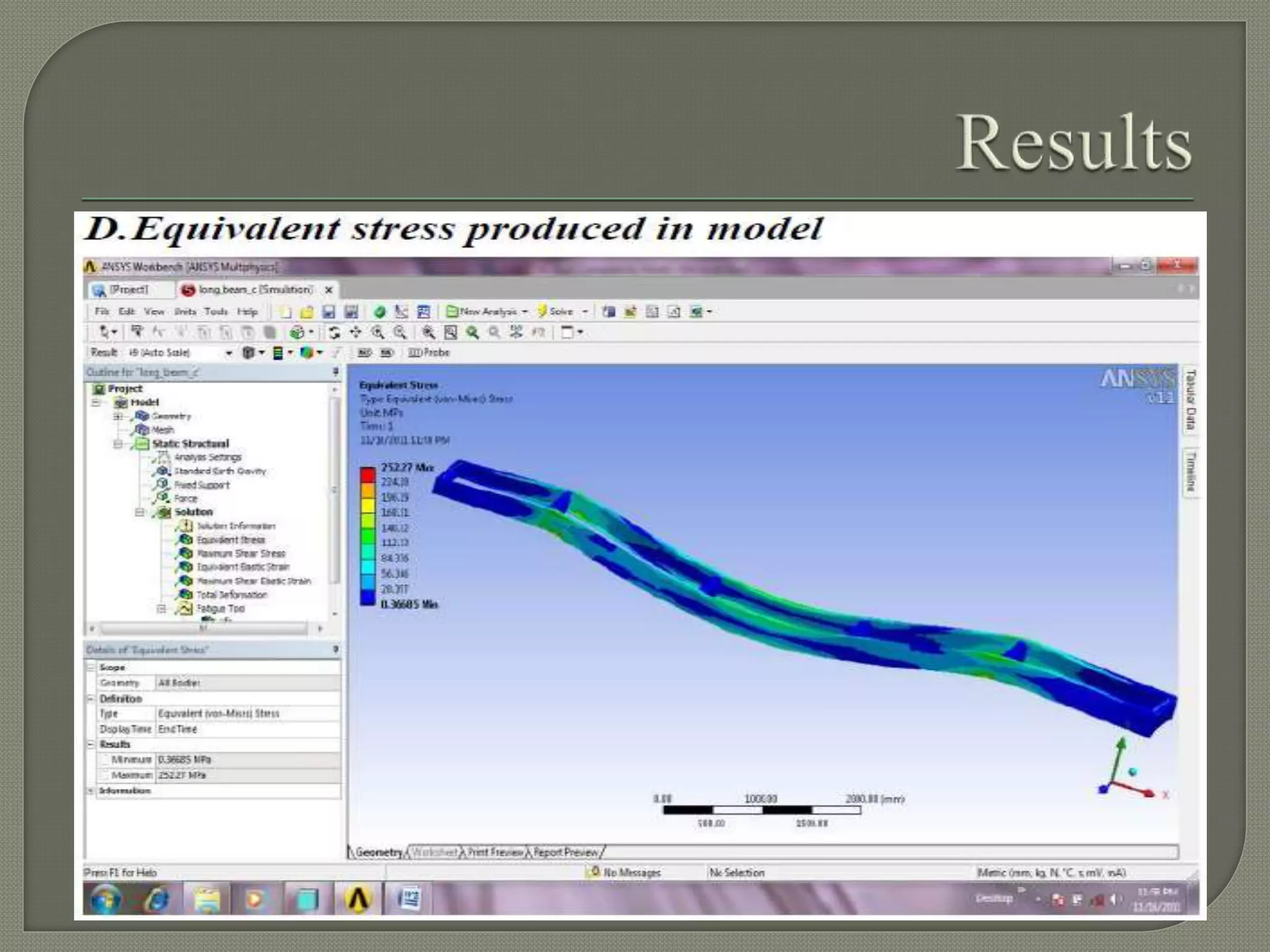

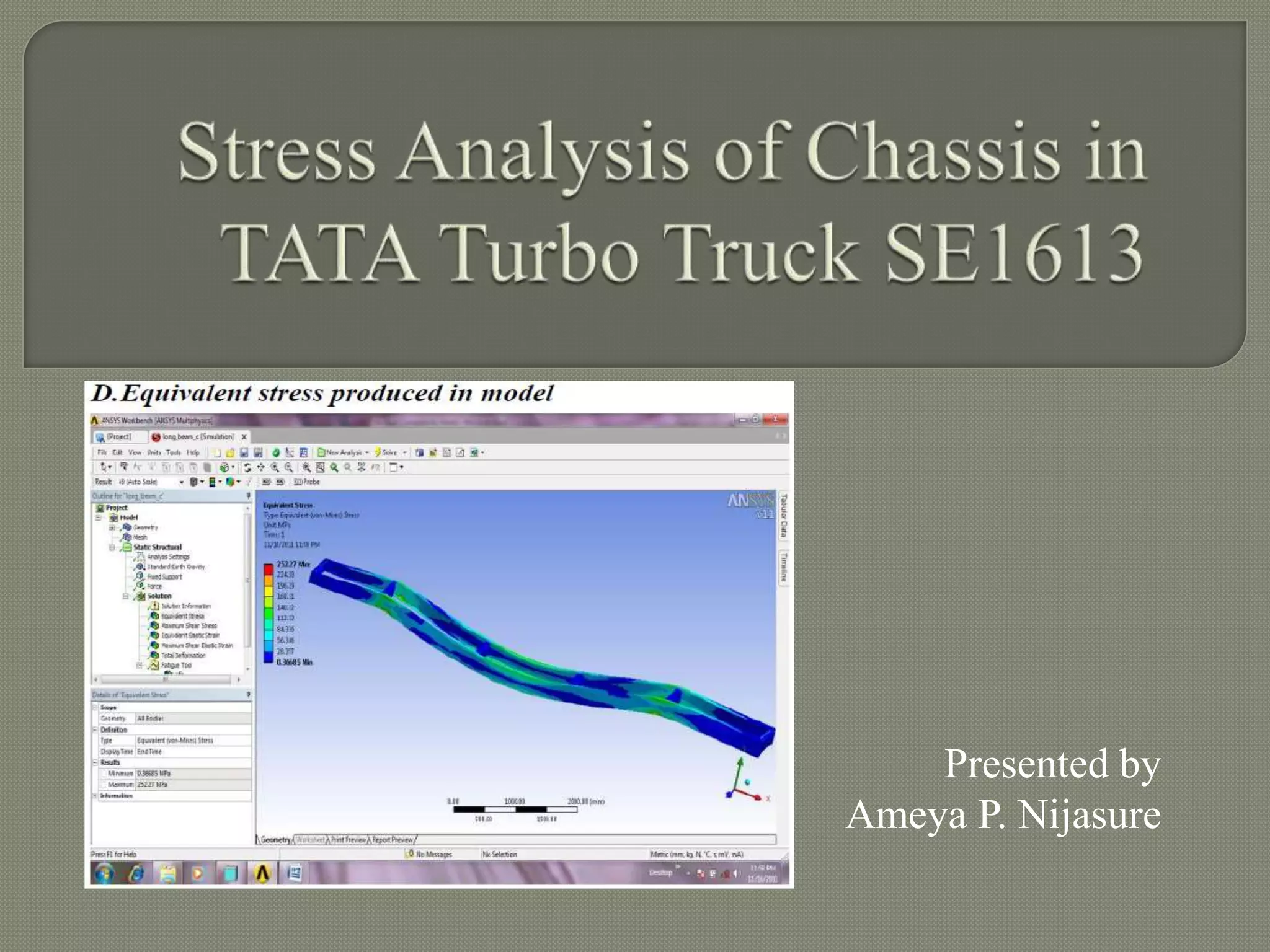

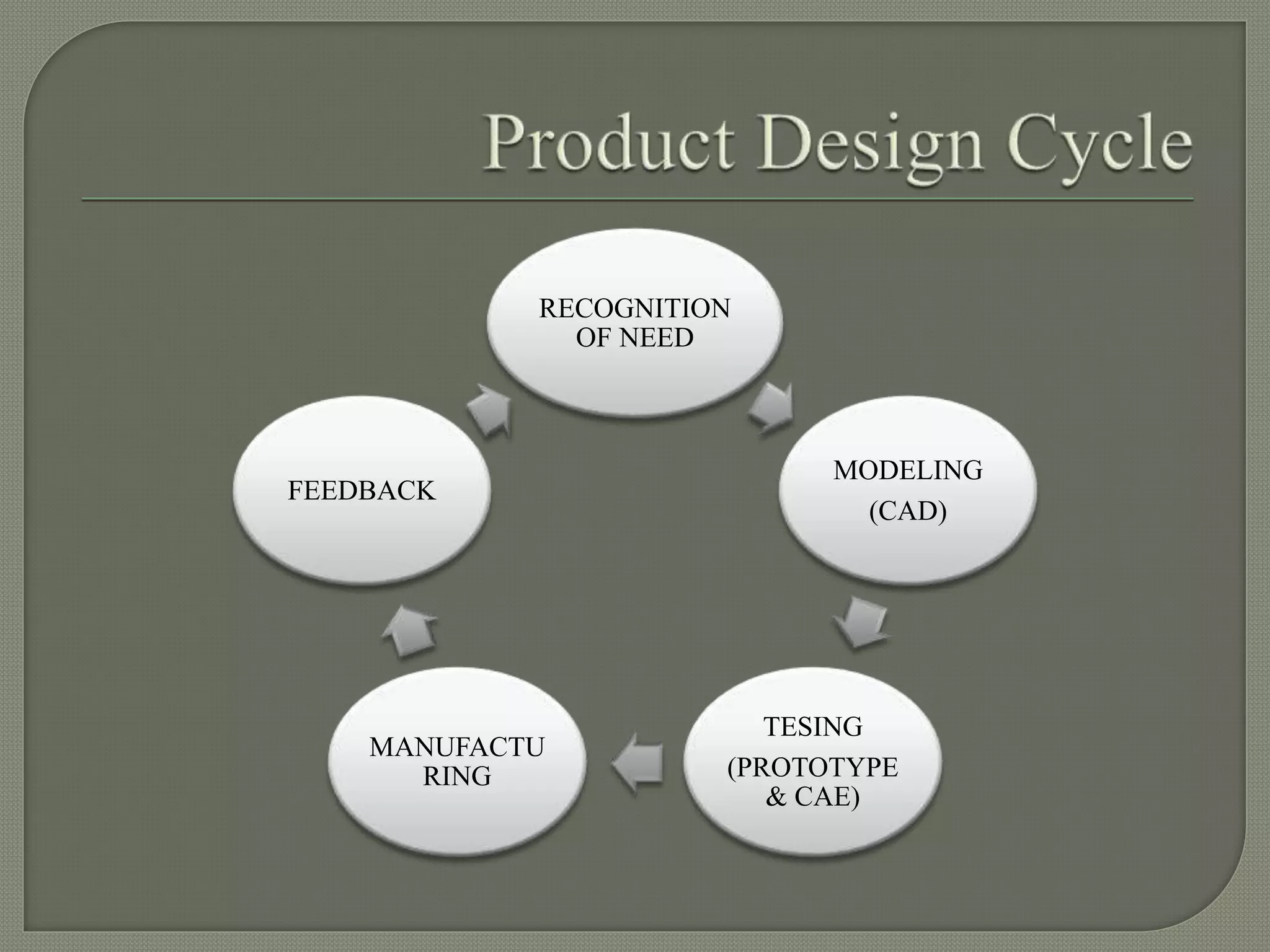

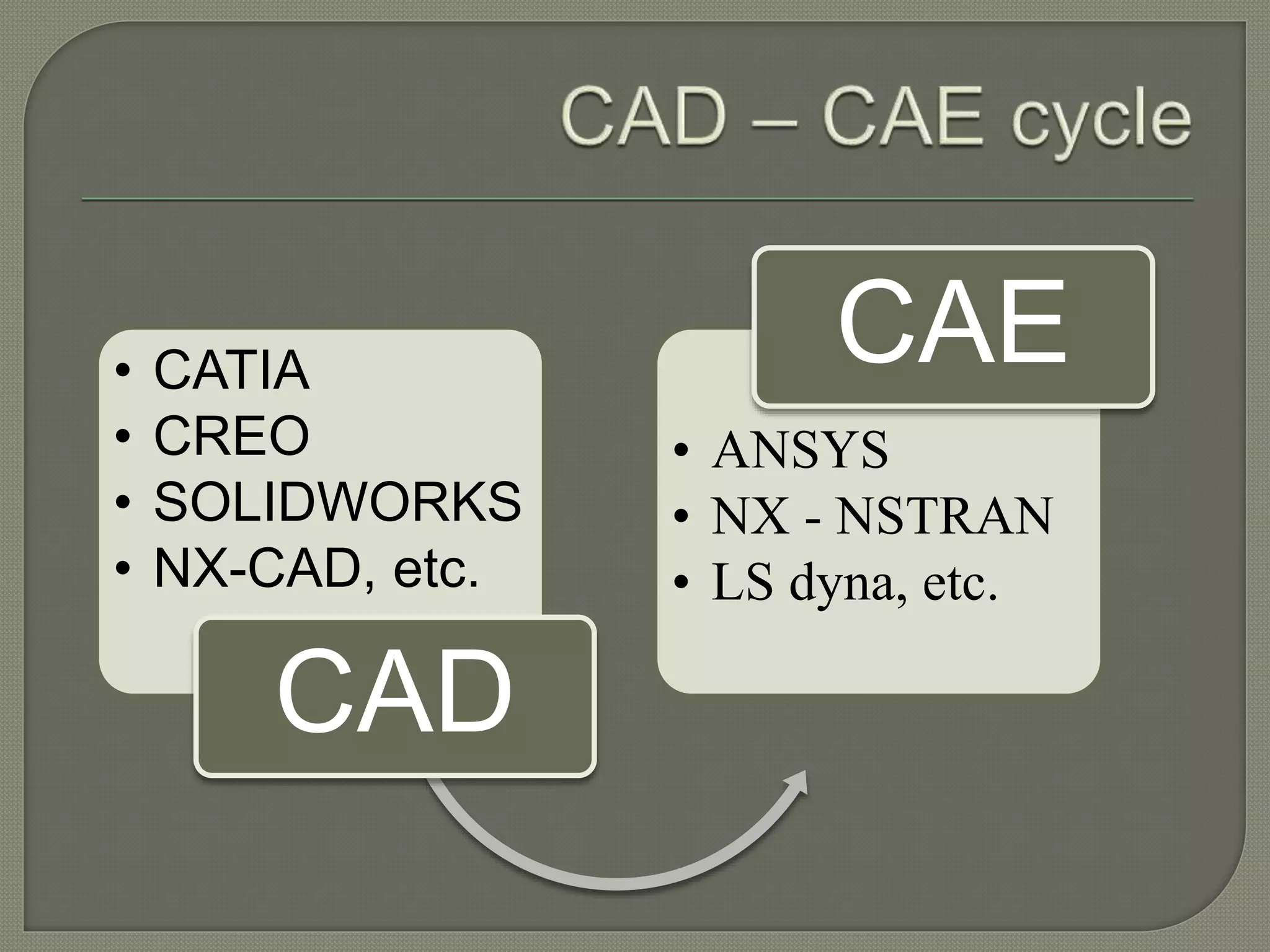

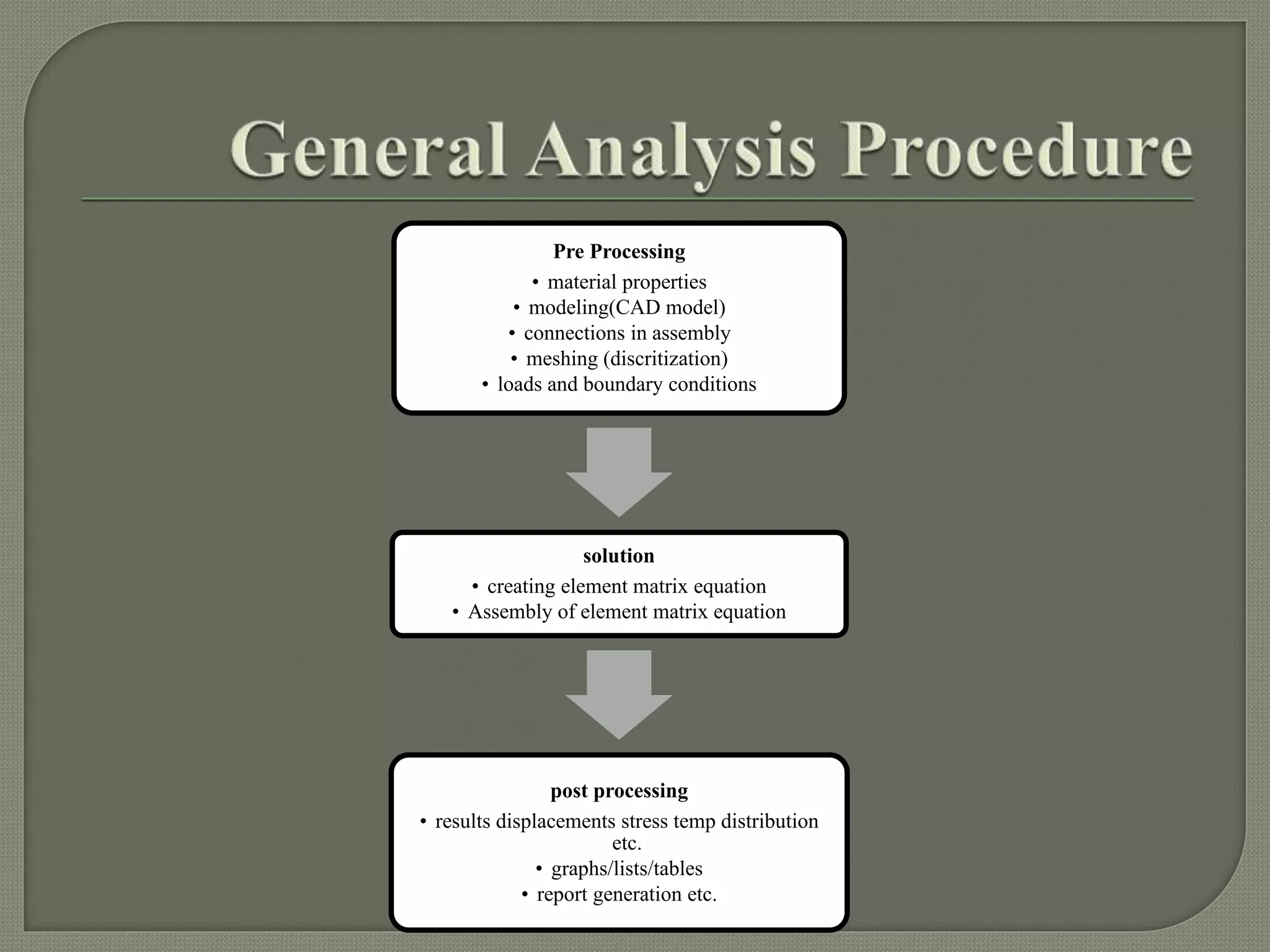

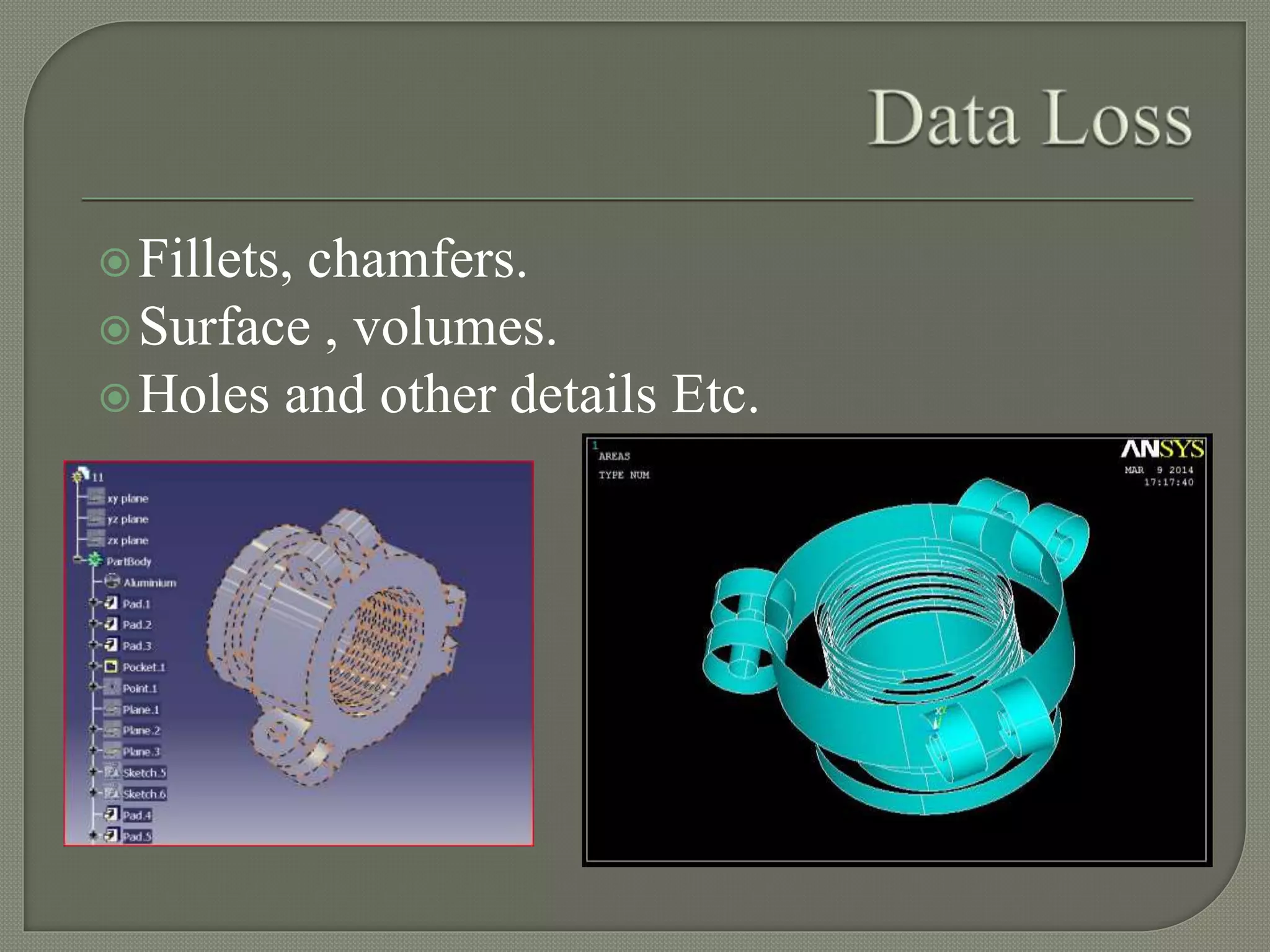

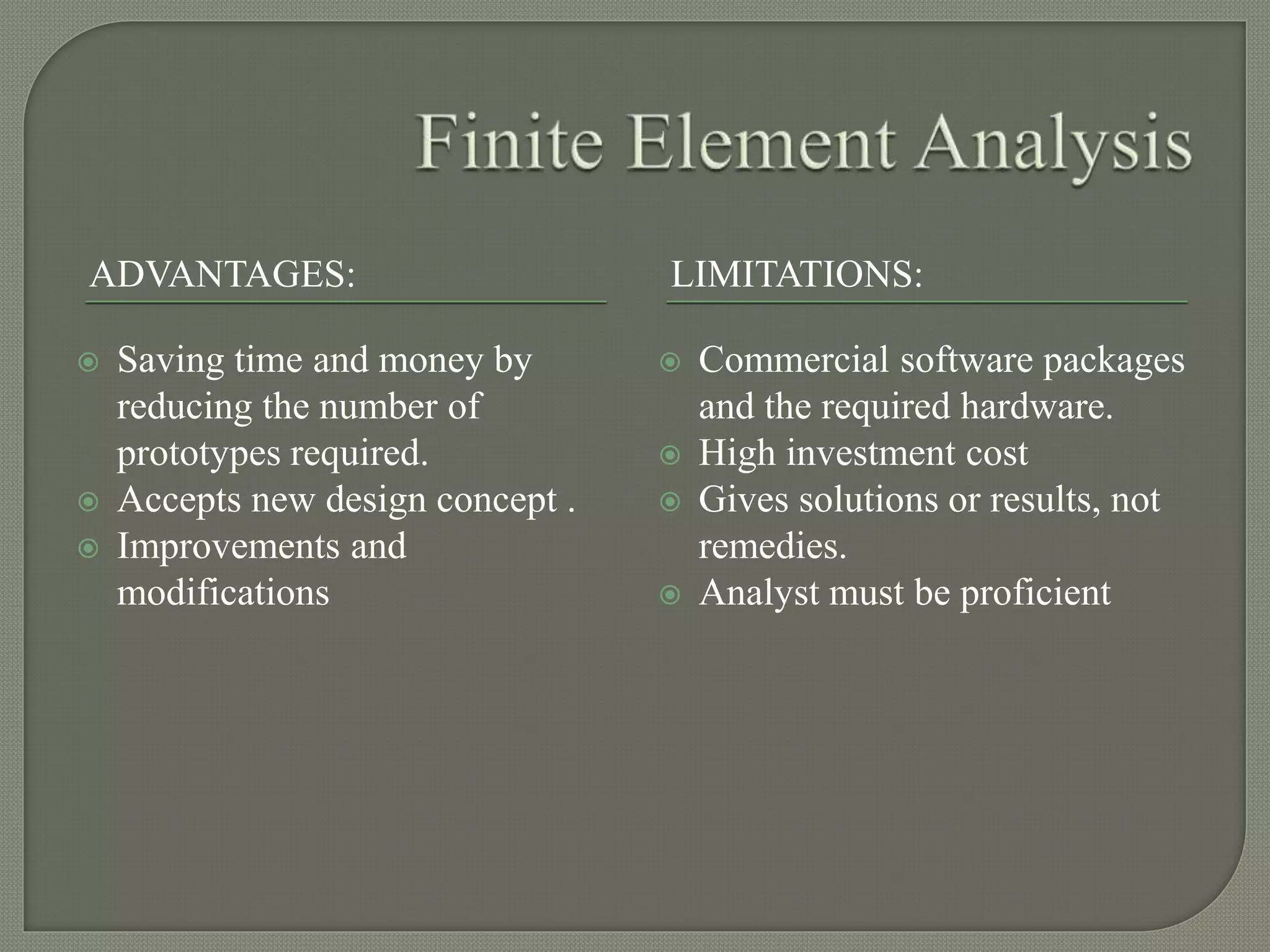

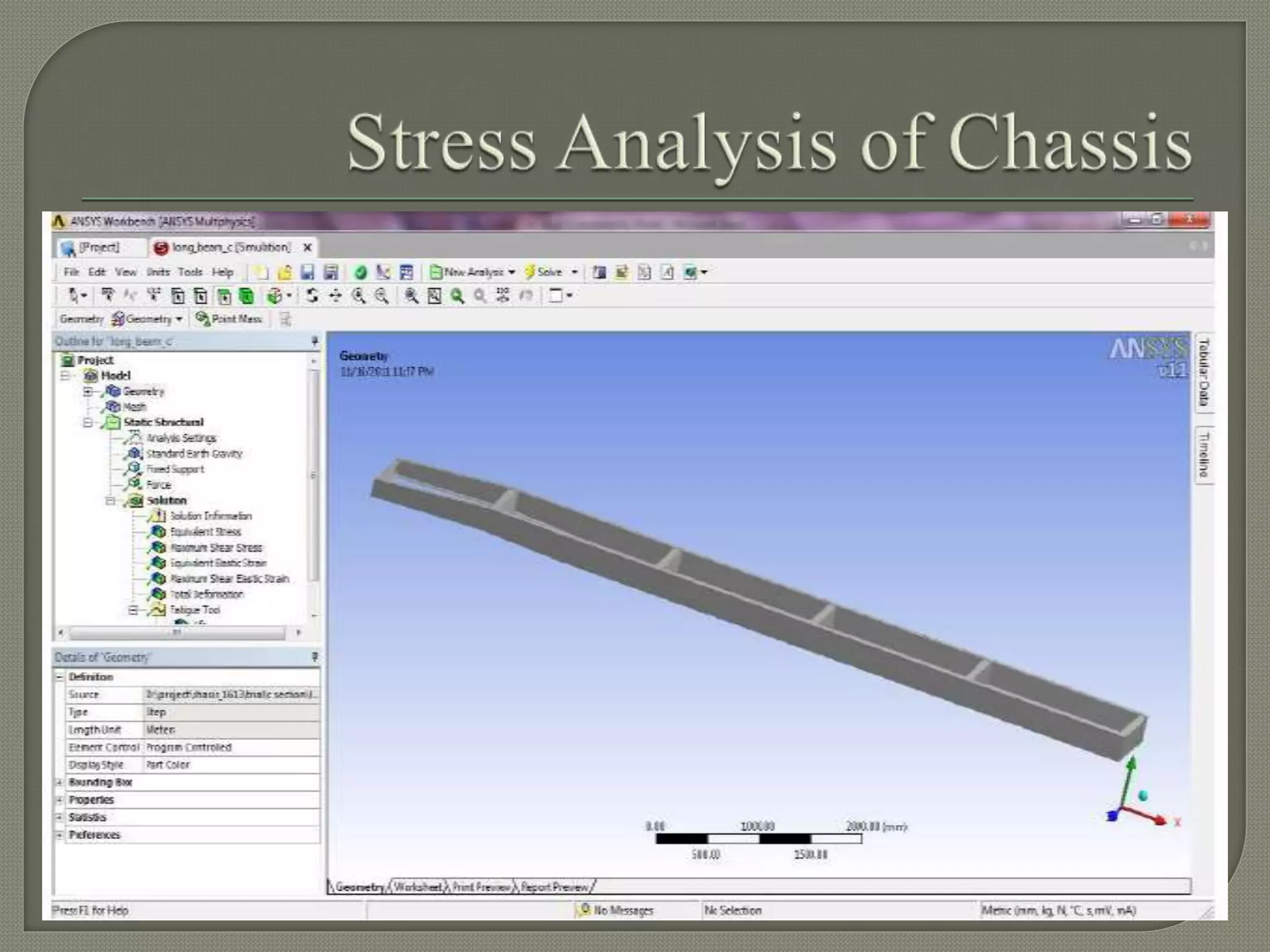

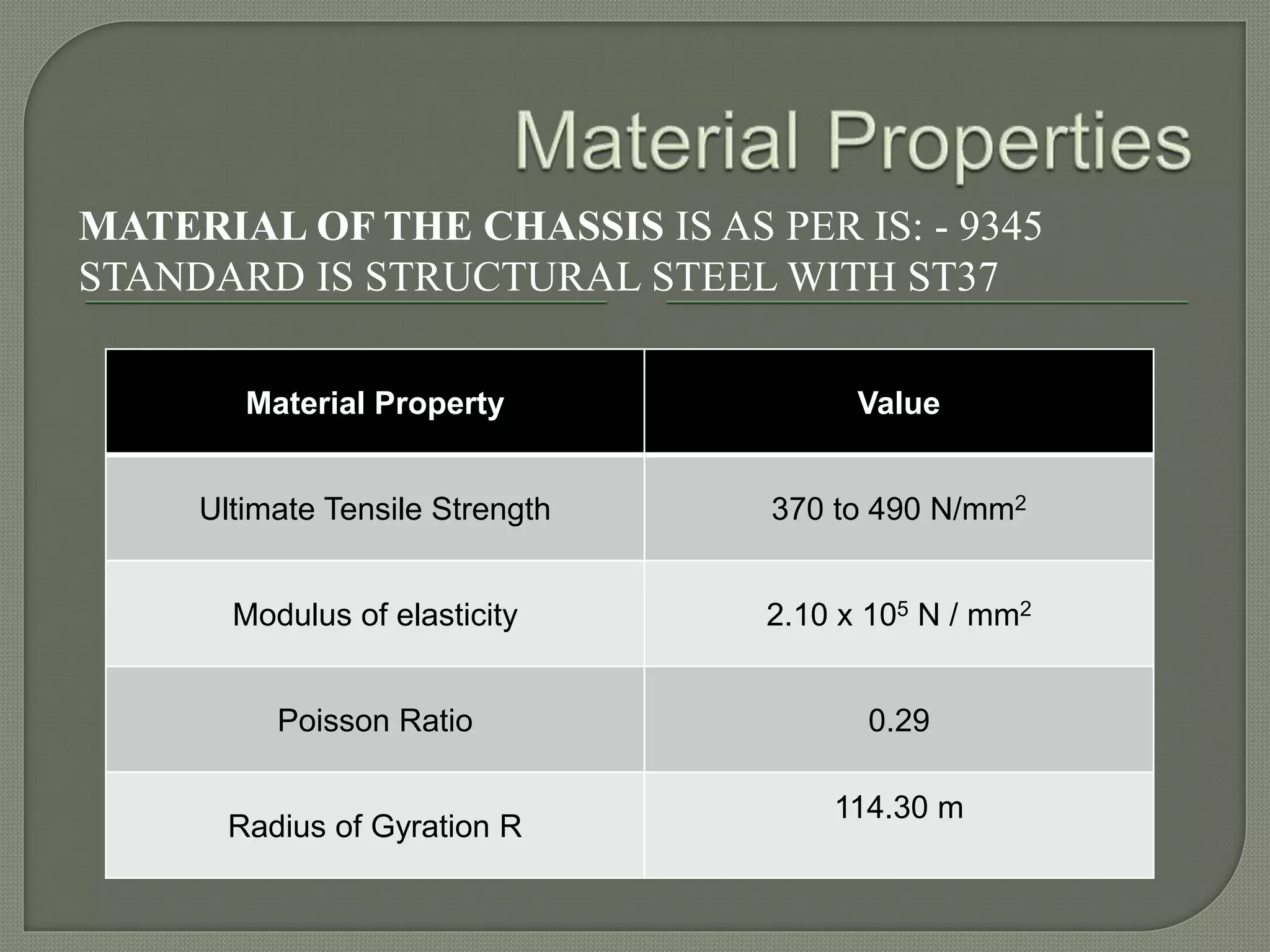

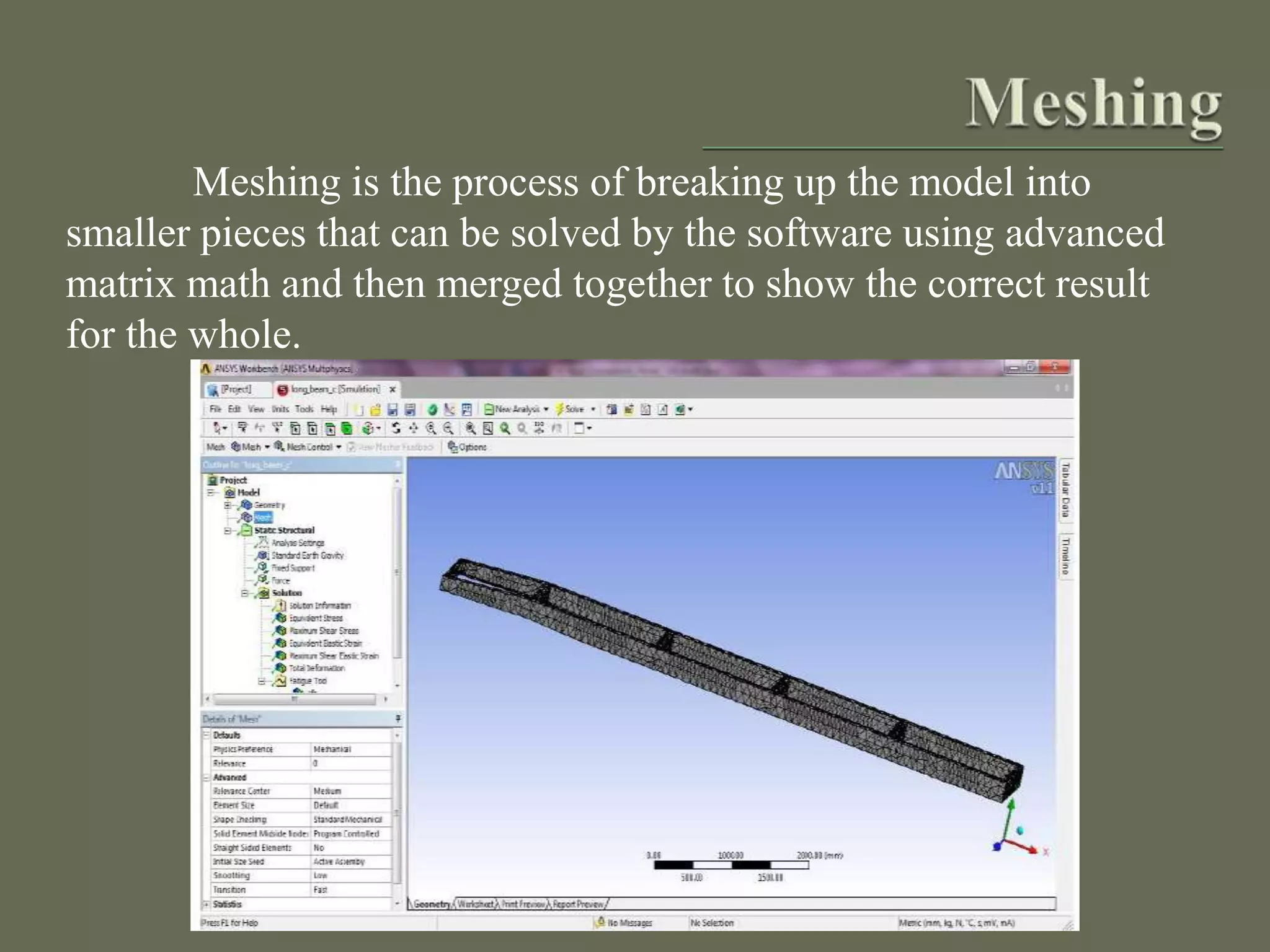

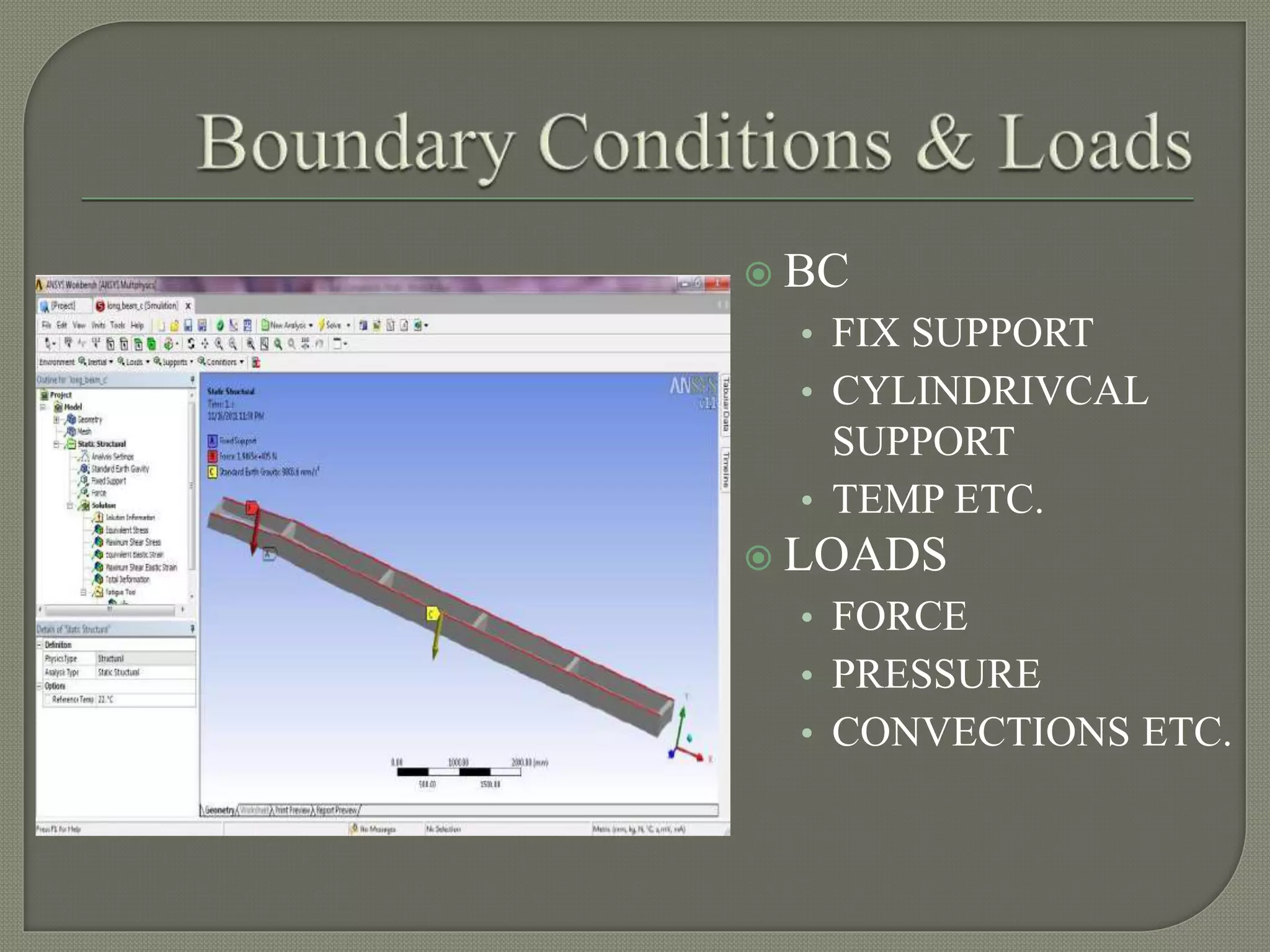

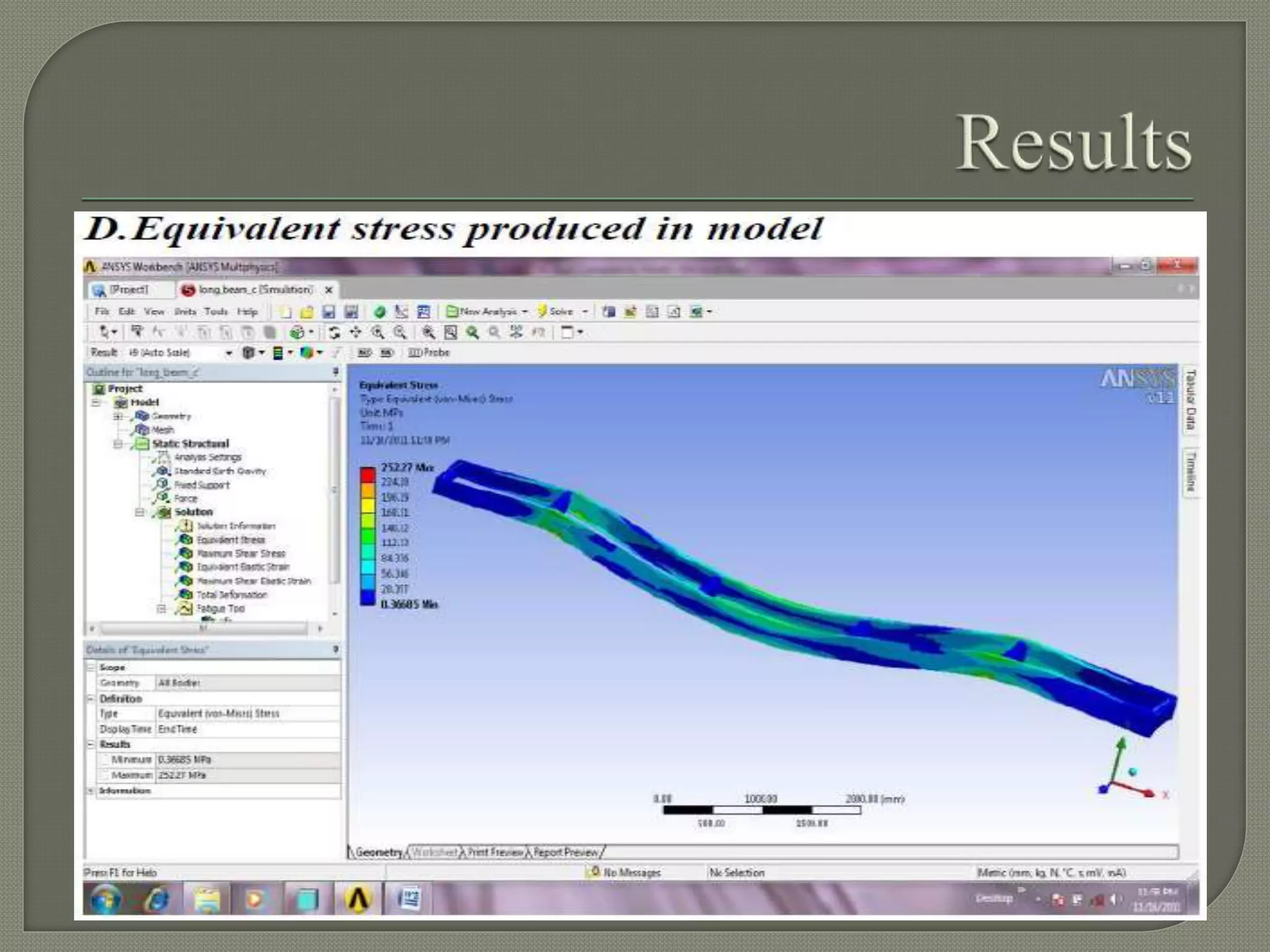

The document discusses the chassis design process which includes modeling, testing, and manufacturing. It provides details on: 1) The key functions of a vehicle chassis which are to provide mounting points for components, rigidity for handling, and occupant protection. 2) Common CAD and CAE software used for modeling and testing including CATIA, CREO, SOLIDWORKS, ANSYS, and LS-Dyna. 3) The CAE analysis process of pre-processing, solution, and post-processing to simulate and optimize chassis design virtually before manufacturing. 4) Manufacturing considerations for the chassis including details, fillets, holes, and the material selection of structural steel ST37.