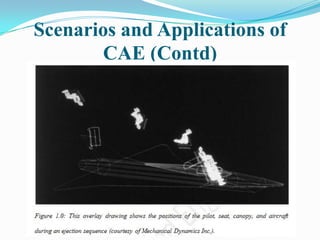

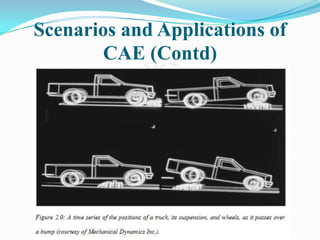

Computer-aided engineering (CAE) uses computer software to analyze product designs and improve engineering processes. It allows engineers to evaluate designs through simulation rather than physical testing, saving time and money. The goals of CAE include improved product quality and safety, reduced engineering time through fewer design iterations, and reduced costs. Common CAE applications include finite element analysis, mechanism analysis, and fluid dynamics simulation. CAE provides significant benefits to production such as earlier problem identification and reduced warranty exposure.