This document describes the design and analysis of a truck chassis. The chassis was modeled in CAD software including AutoCAD and CATIA. Finite element analysis was then performed on the chassis model in ANSYS to evaluate stresses and deflections. The objectives were to study chassis principles, investigate potential problems, create 3D models, and suggest design improvements through FEA. The chassis was meshed and simulated under static and dynamic loading conditions to determine high stress areas and optimize the chassis design.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 06 Issue: 04 | Apr 2019 www.irjet.net p-ISSN: 2395-0072

© 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2912

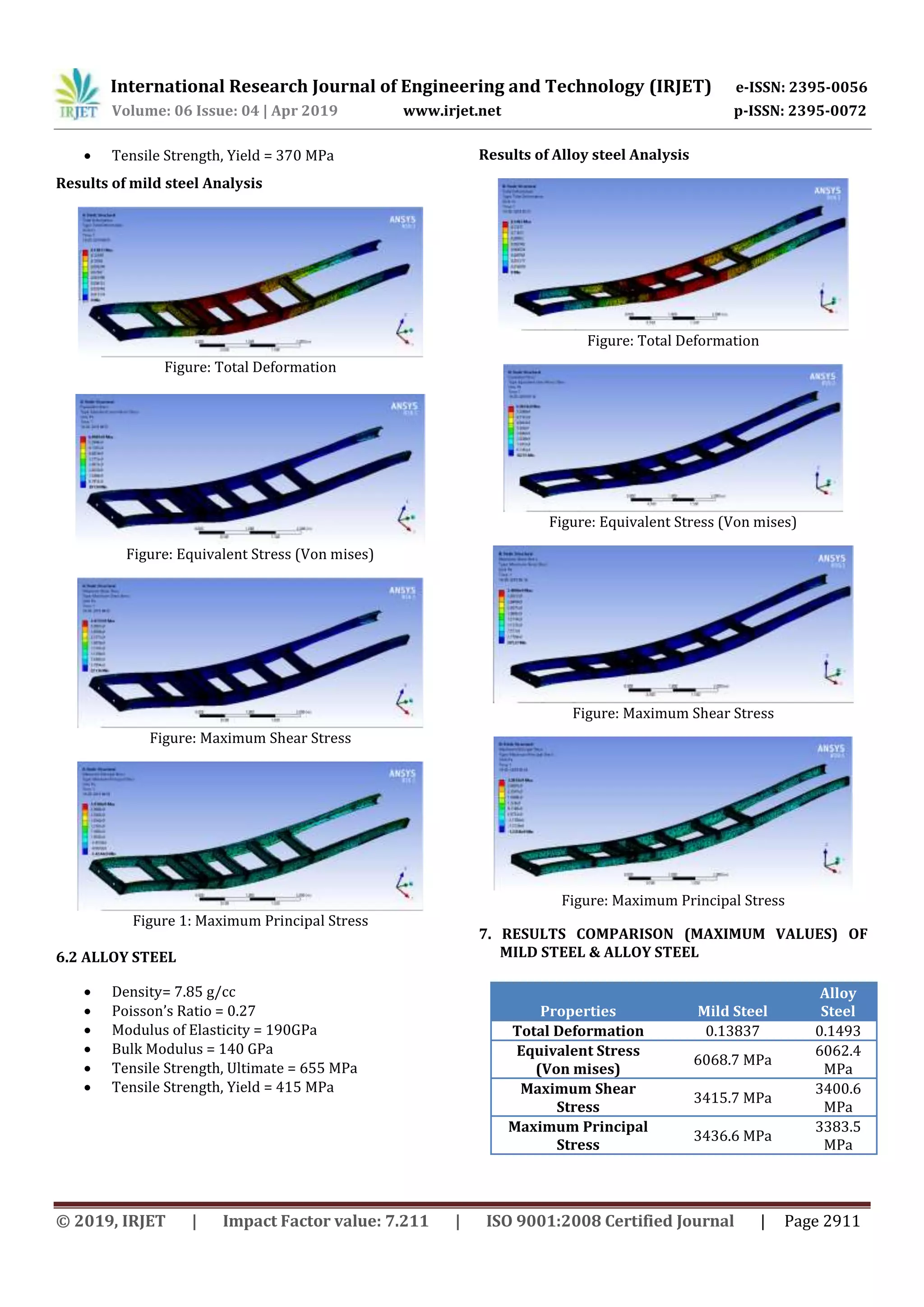

DISCUSSION

In this analysis we have studied the MILD STEEL properties

are greater than as compare to ALLOY STEEL. For making a

chassis of MILD STEEL is a suitable material for carry 40

Tonnes load.

8. CONCLUSONS

From above Study it is conclude that for chassis mild steel is

best material than alloy steel material aspertheAnsysresult

obtained. In order to examine the performance

characteristics of thechassis,Structural andthermal analysis

were conducted. The following conclusion was obtained.

1. For chassis the maximum shear stress that produce for

mild steel material is 34157 Mpa which is greater than

the for Alloy steel i.e. 3400.6 Mpa. Also as per theweight

and cost comparison the mildsteel material ispreferred.

2. For chassis the Equivalent and produced is 6068.7 Mpa

for mild steel material which is greater than value

obtained by using Alloy steel material i.e. 6062.4 Mpa.

Also as per weight and cost comparison the Mild steel

Material is preferred

REFERENCES

[1] Tanveer Ahamed Bankapur,Lohitesh Jaga

Kumar,Dr.Irfan G,“Design and Analysis of Dual plate

Check Valve”,IJIET volume 07, Issue 01,June 2016,pp

422-426

[2] Design of machine elements II by Prof. J.B.K.DasandP.L.

Srinivasa Murthy, Sapna book house (P) Ltd., 2010

[3] Company, Houghton Mifflin Harcourt Publishing. "The

American Heritage Dictionary entry:

chassis". Www.ahdictionary.com.Retrieved 2017-05-21.

[4] "Chassis definition and meaning | Collins English

Dictionary". Www.collinsdictionary.com.Retrieved 2017-

05-21.

[5] Association of Licensed Automobile Manufacturers (U.S.)

(1922). Official Handbook of Automobiles. National

Automobile Association. p. 180. OCLC 6360726.

Retrieved 10 September2010.

BIOGRAPHIES

Ansari Mohd Abuzar Mohd Naeem

Student, Dept of mechanical engg,

Padm. Dr.V.B.Kolte college of

engineering Malkapur 443101

Ghulam Tausif Ghulam Younus

Student, Dept of mechanical engg,

Padm. Dr.V.B.Kolte college of

engineering Malkapur 443101

Mohd Ismail Zainulabedin

Student, Dept of mechanical engg,

Padm. Dr.V.B.Kolte college of

engineering Malkapur 443101

M Tausif M Sharif

Student, Dept of mechanical engg,

Padm. Dr.V.B.Kolte college of

engineering Malkapur 443101

Tanveer Baig Naseer Baig

Student, Dept of mechanical engg,

Padm. Dr.V.B.Kolte college of

engineering Malkapur 443101](https://image.slidesharecdn.com/irjet-v6i4619-190706095729/75/IRJET-Chassis-Design-Analysis-5-2048.jpg)