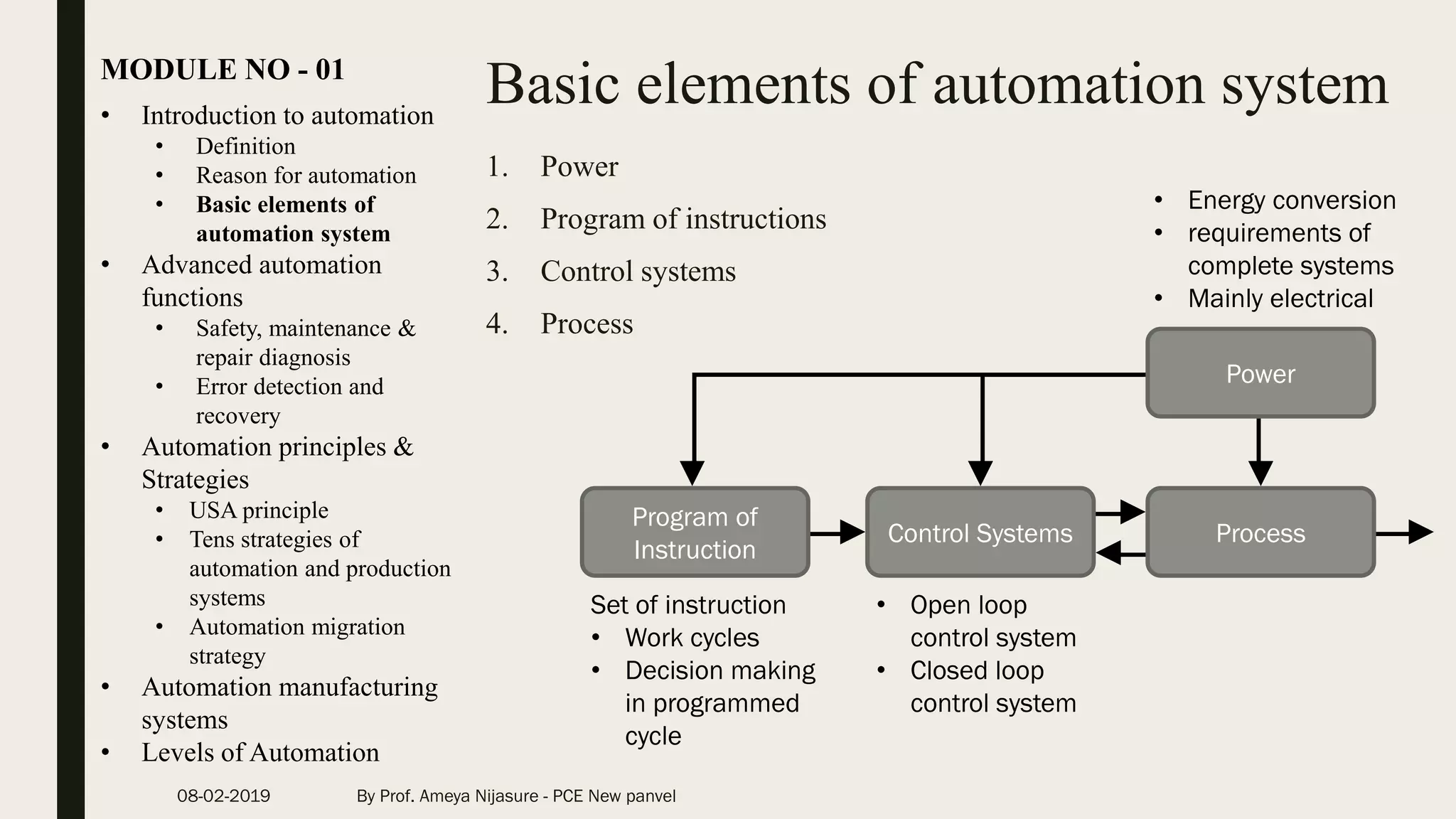

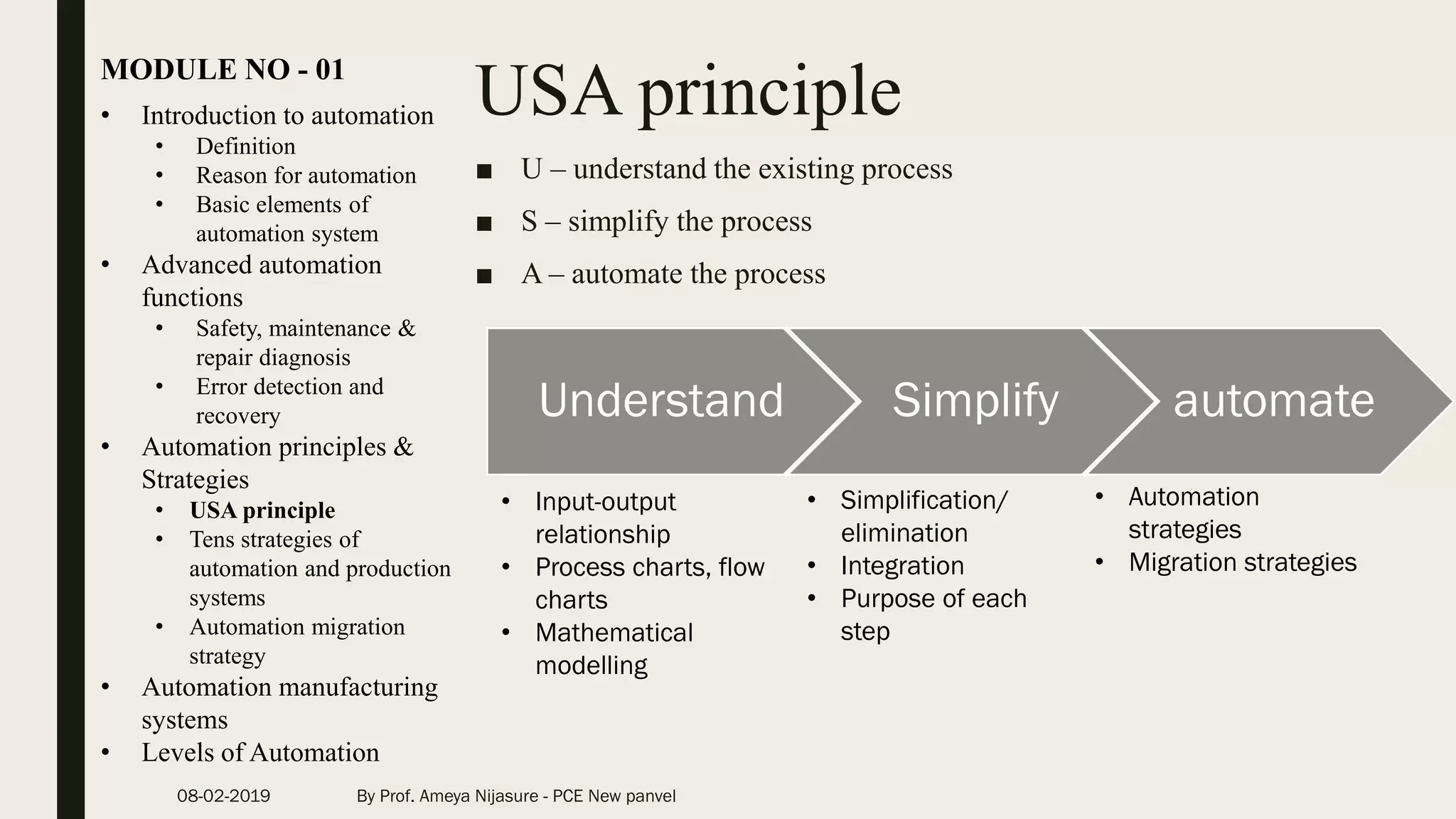

The document introduces automation, defining it as a set of technologies that allows machines and systems to operate without significant human intervention. It discusses key areas of industrial automation like controls, communication, and real-time computing. Reasons for automating include increasing productivity, reducing costs, improving quality and safety. The basic elements of an automation system are described as the program of instructions, control systems, process, and power. Advanced functions like safety monitoring, maintenance diagnostics, and error detection and recovery are also introduced.