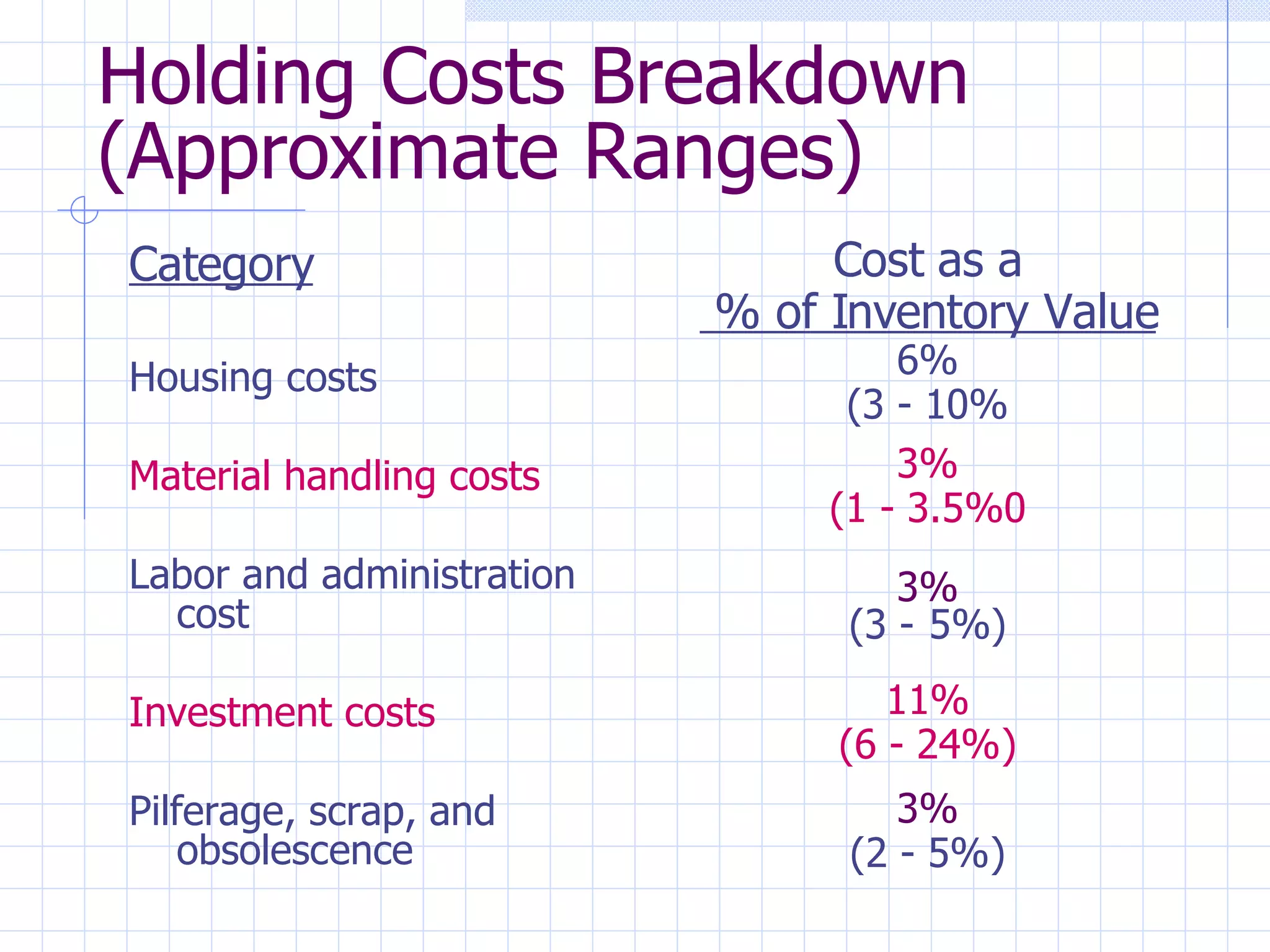

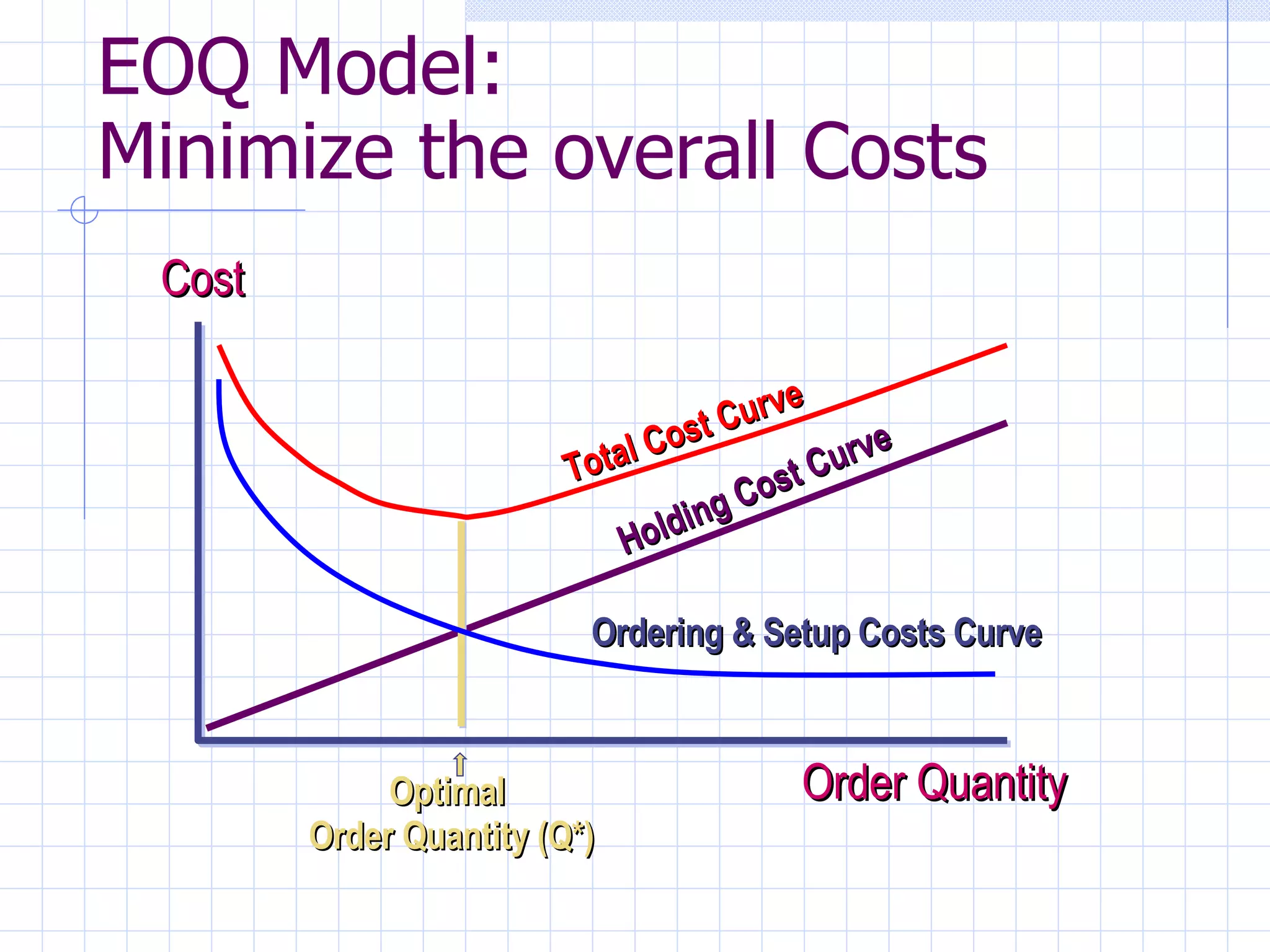

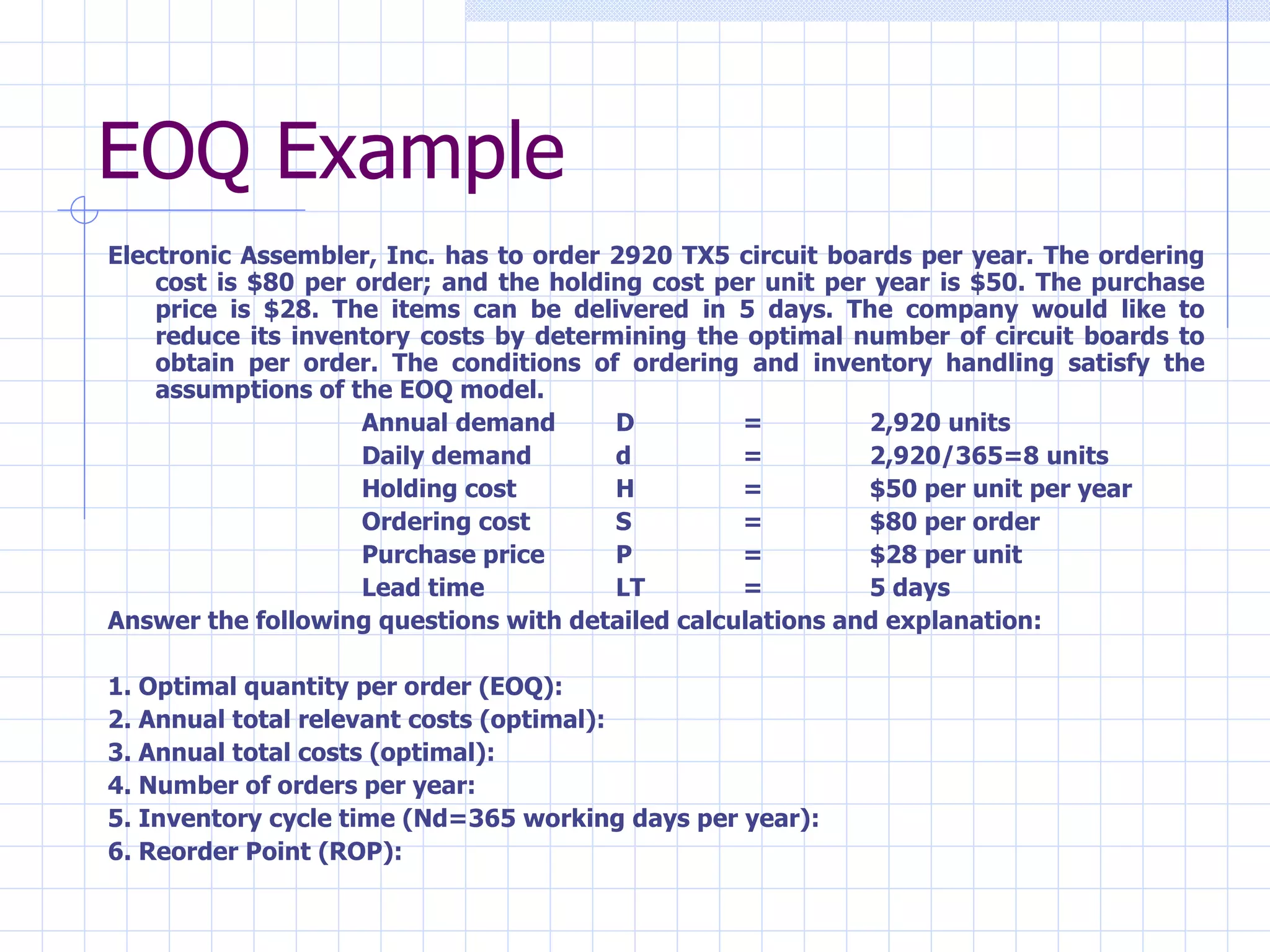

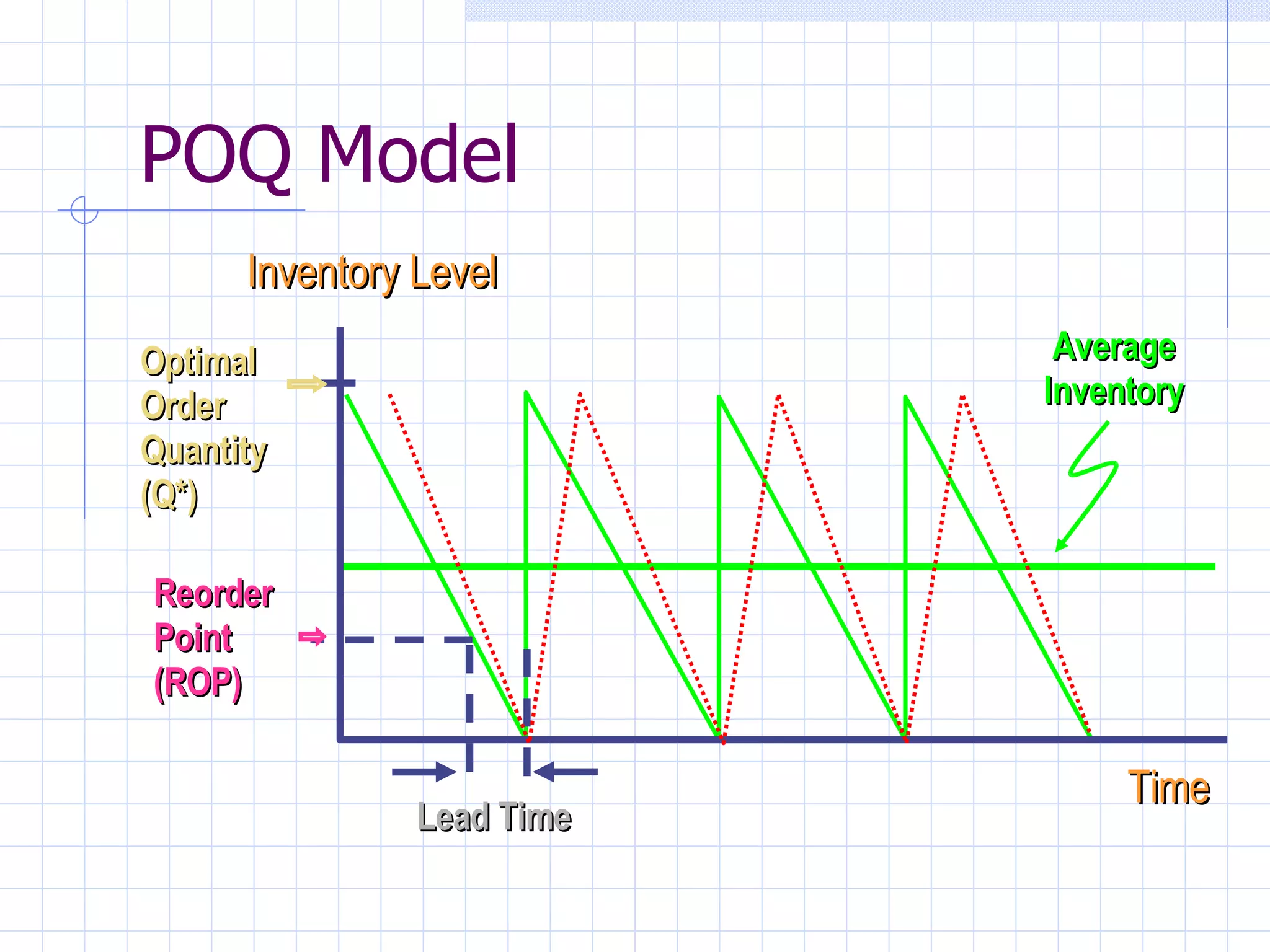

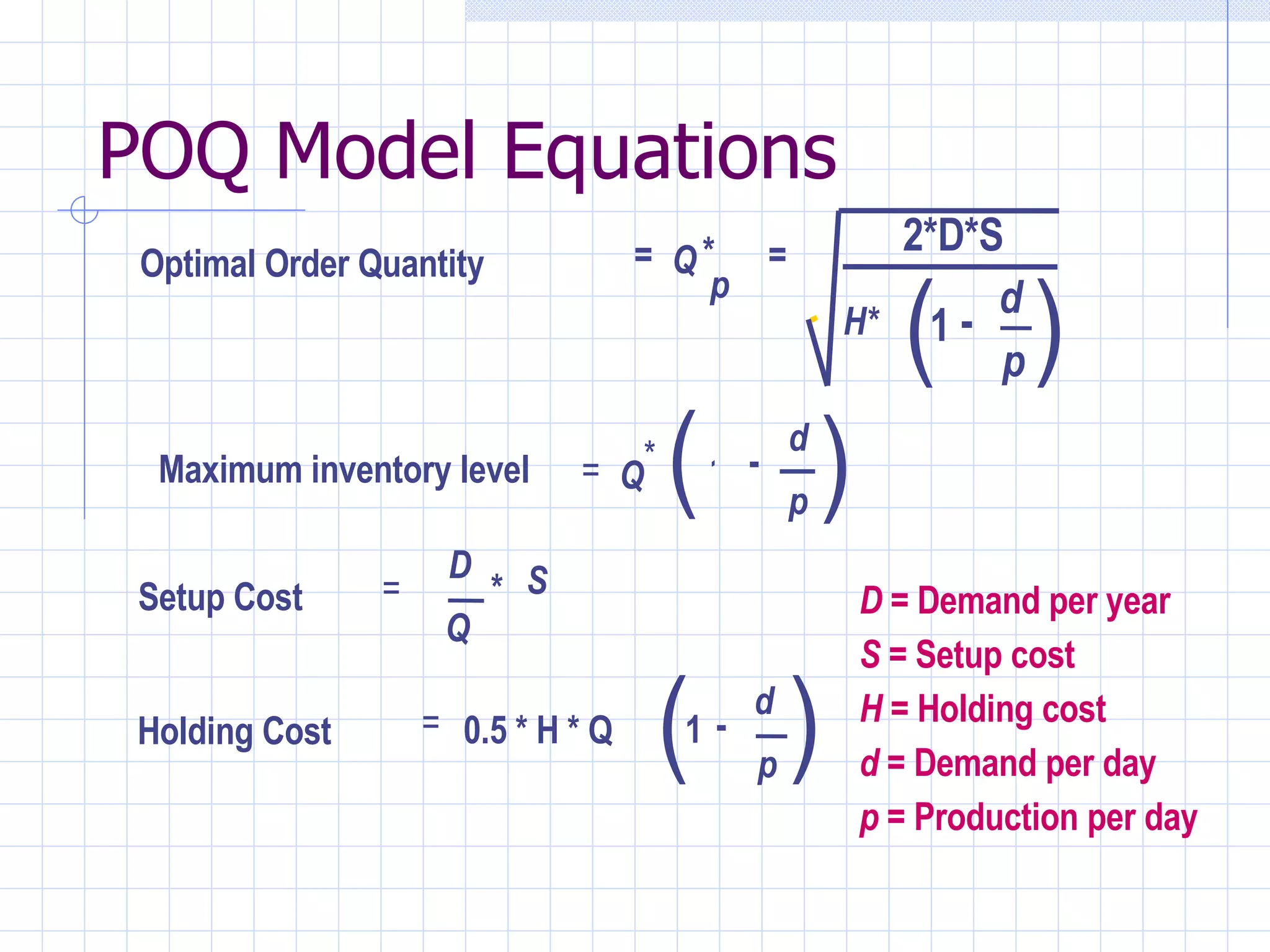

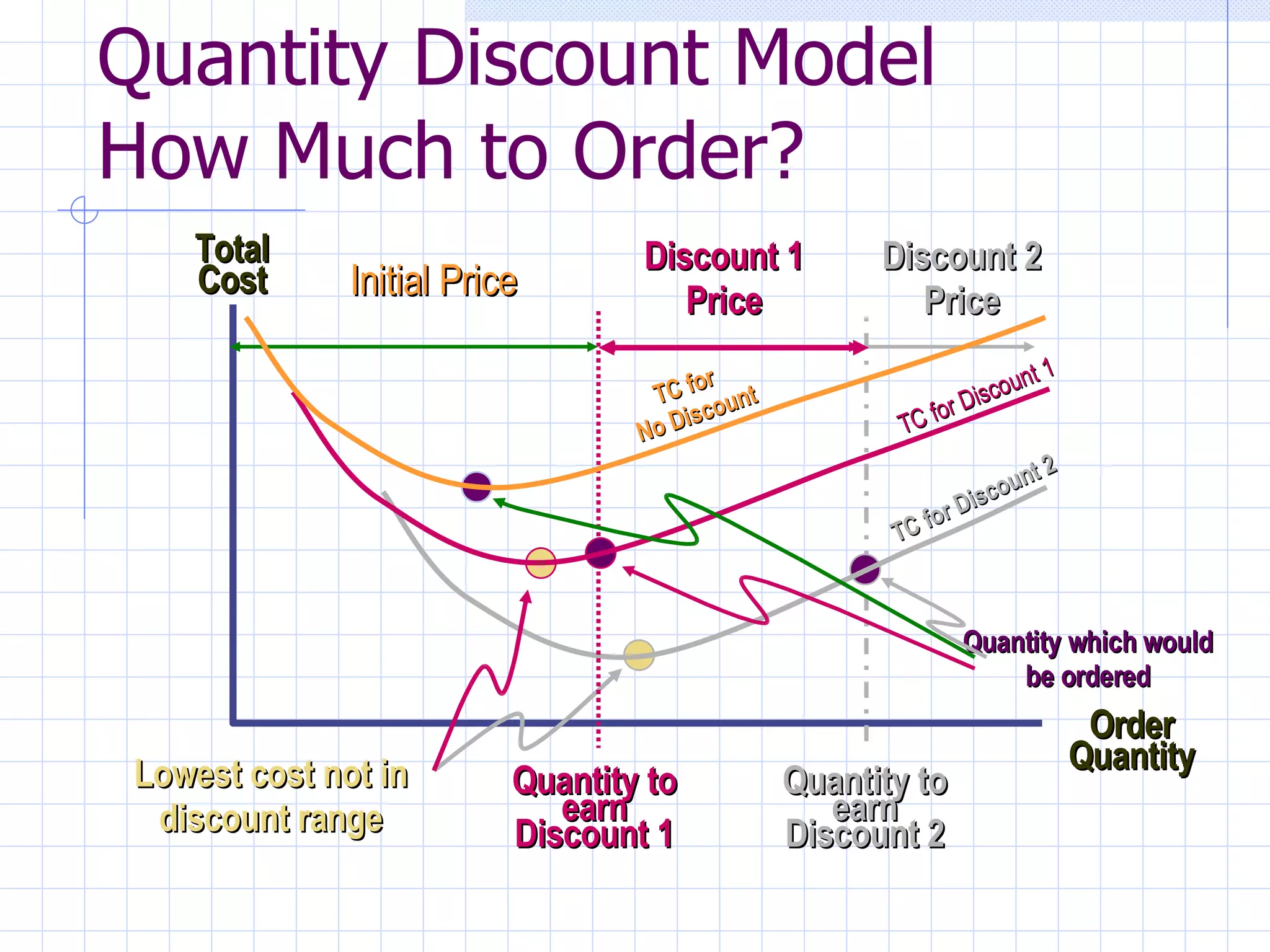

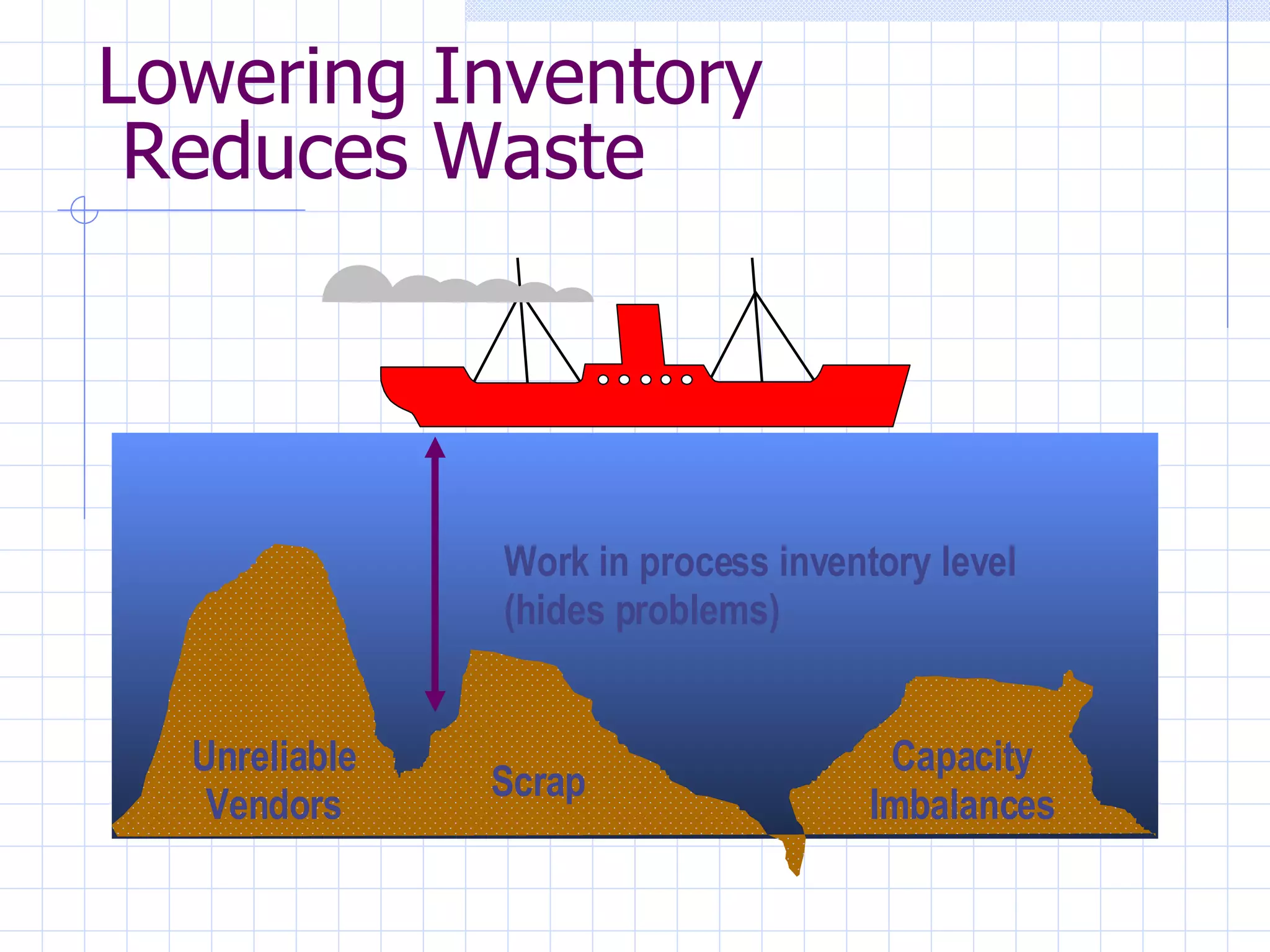

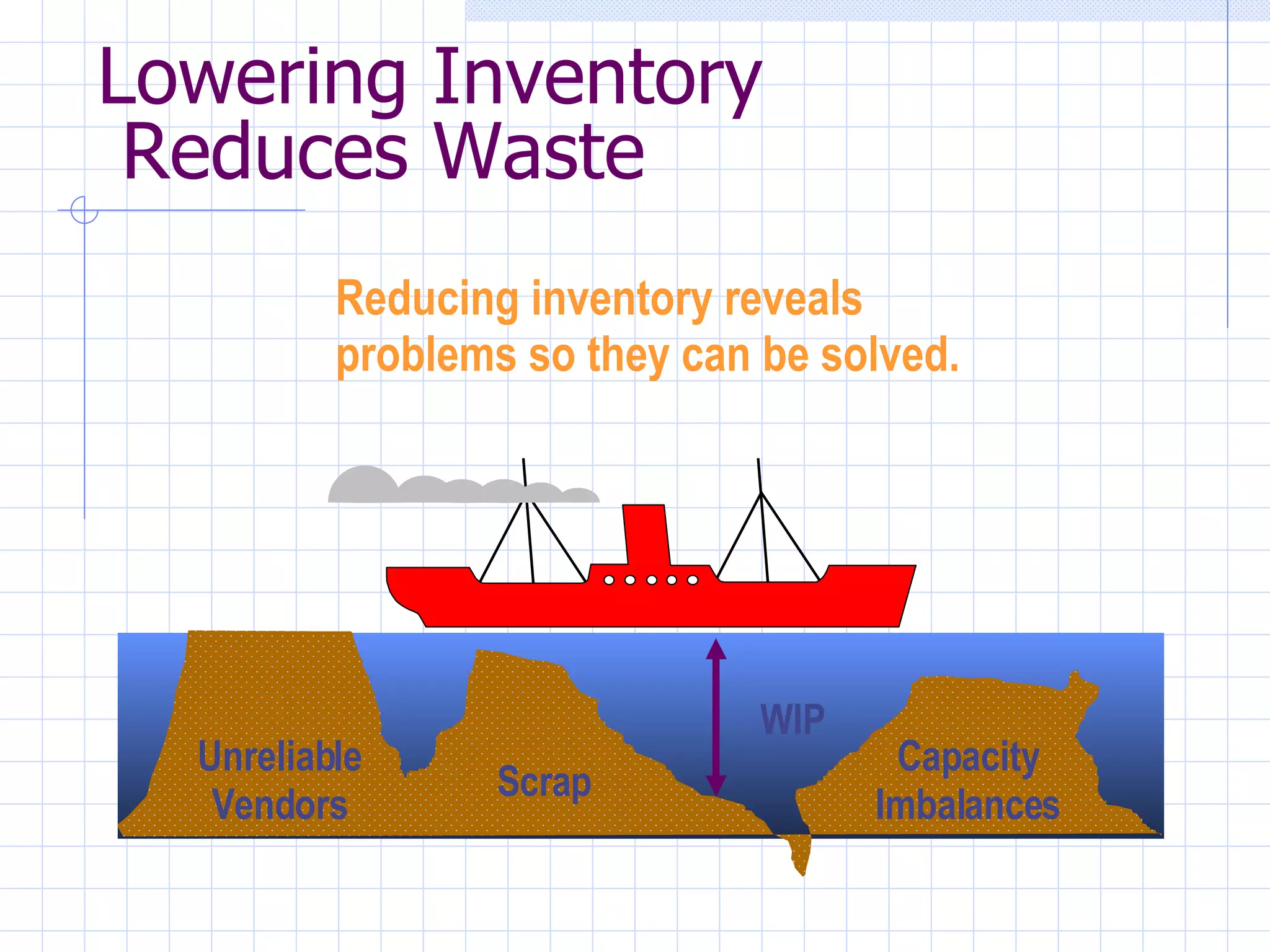

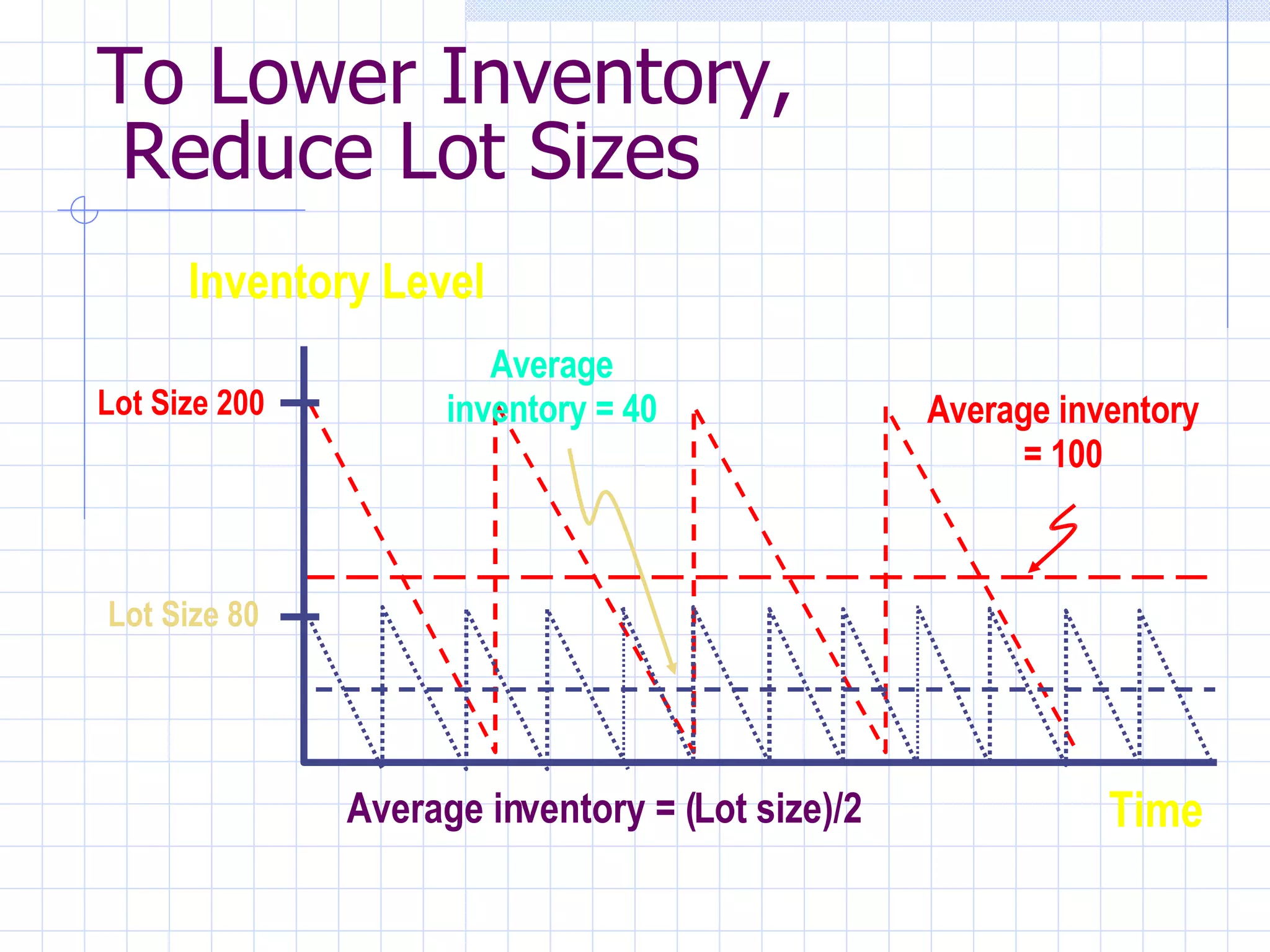

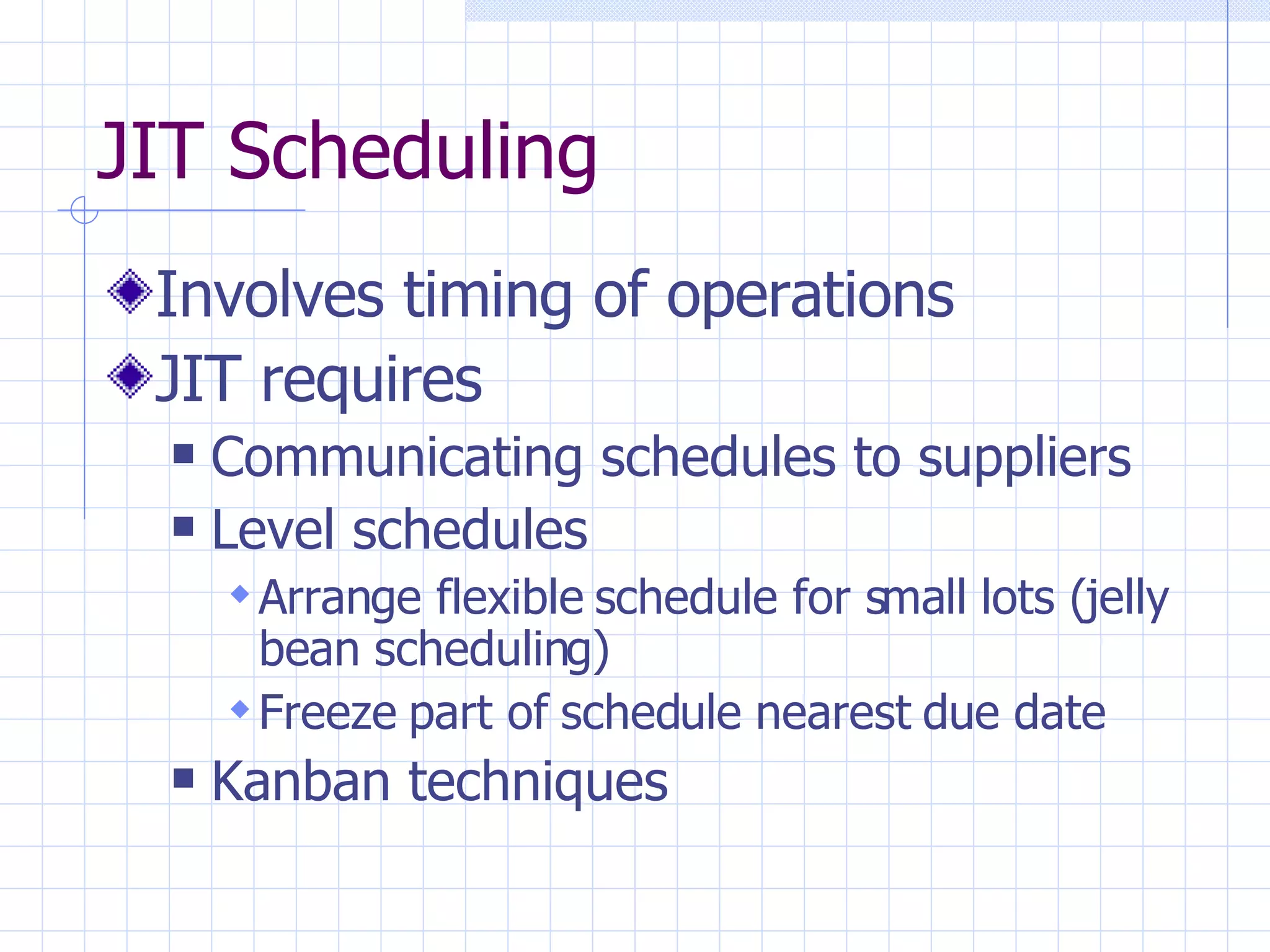

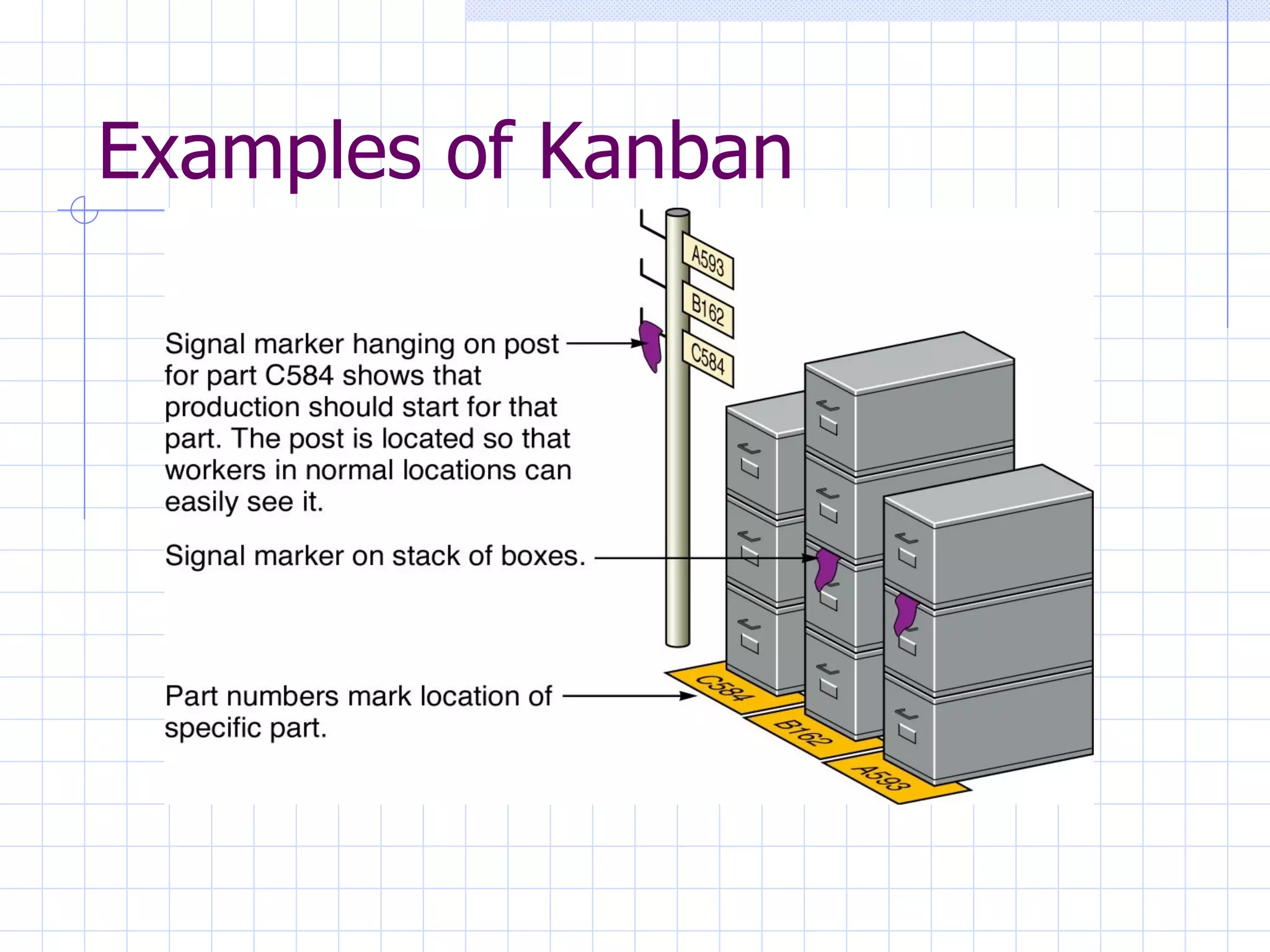

The document outlines various inventory management concepts including types of inventory, inventory classification systems, inventory models, and strategies for reducing inventory levels. It discusses direct and indirect inventory, ABC analysis, independent vs dependent demand, economic order quantity models, reorder points, probabilistic models, quantity discounts, fixed period systems, and how implementing just-in-time principles can help lower inventory through reducing lot sizes and setup times.