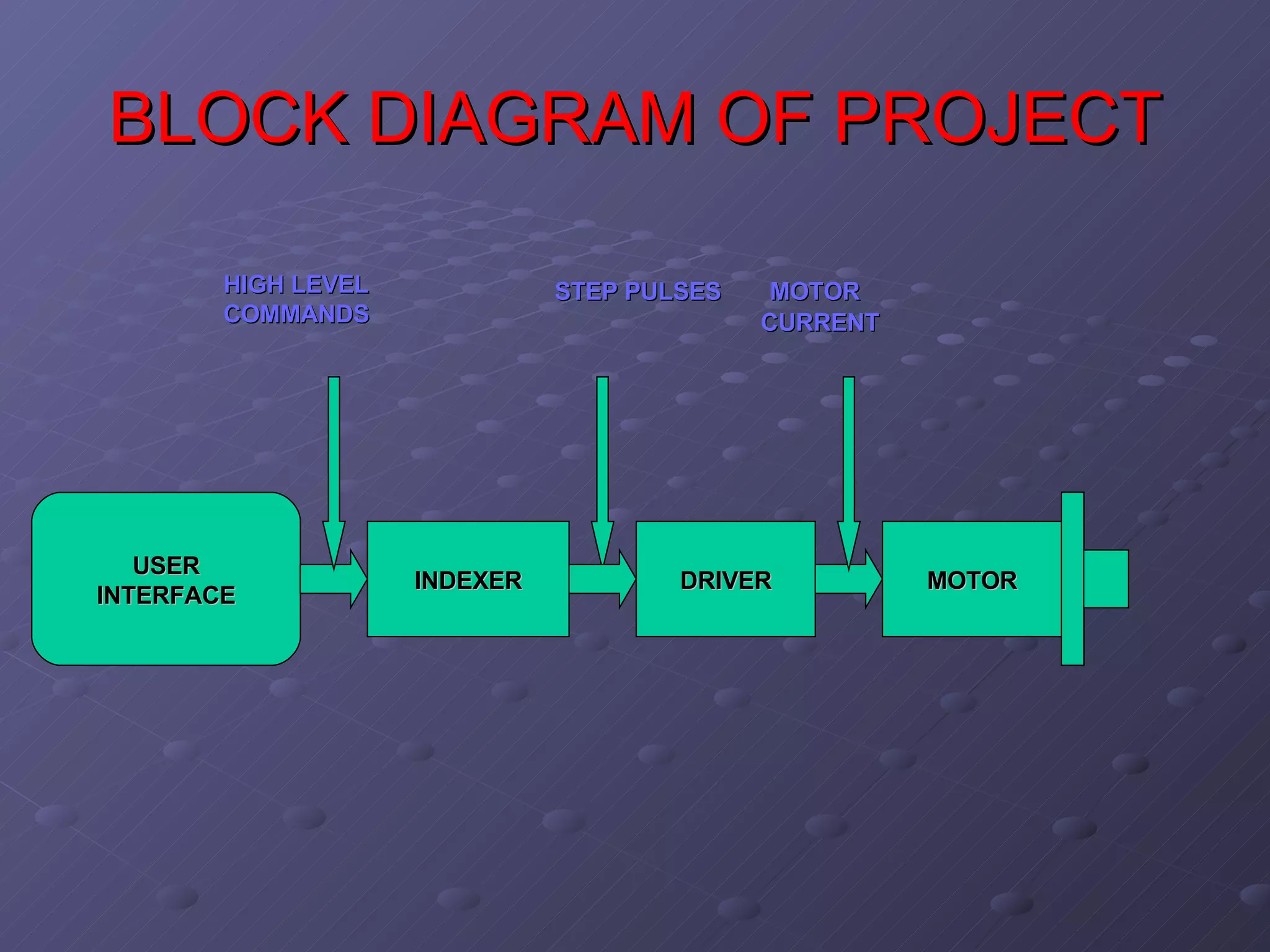

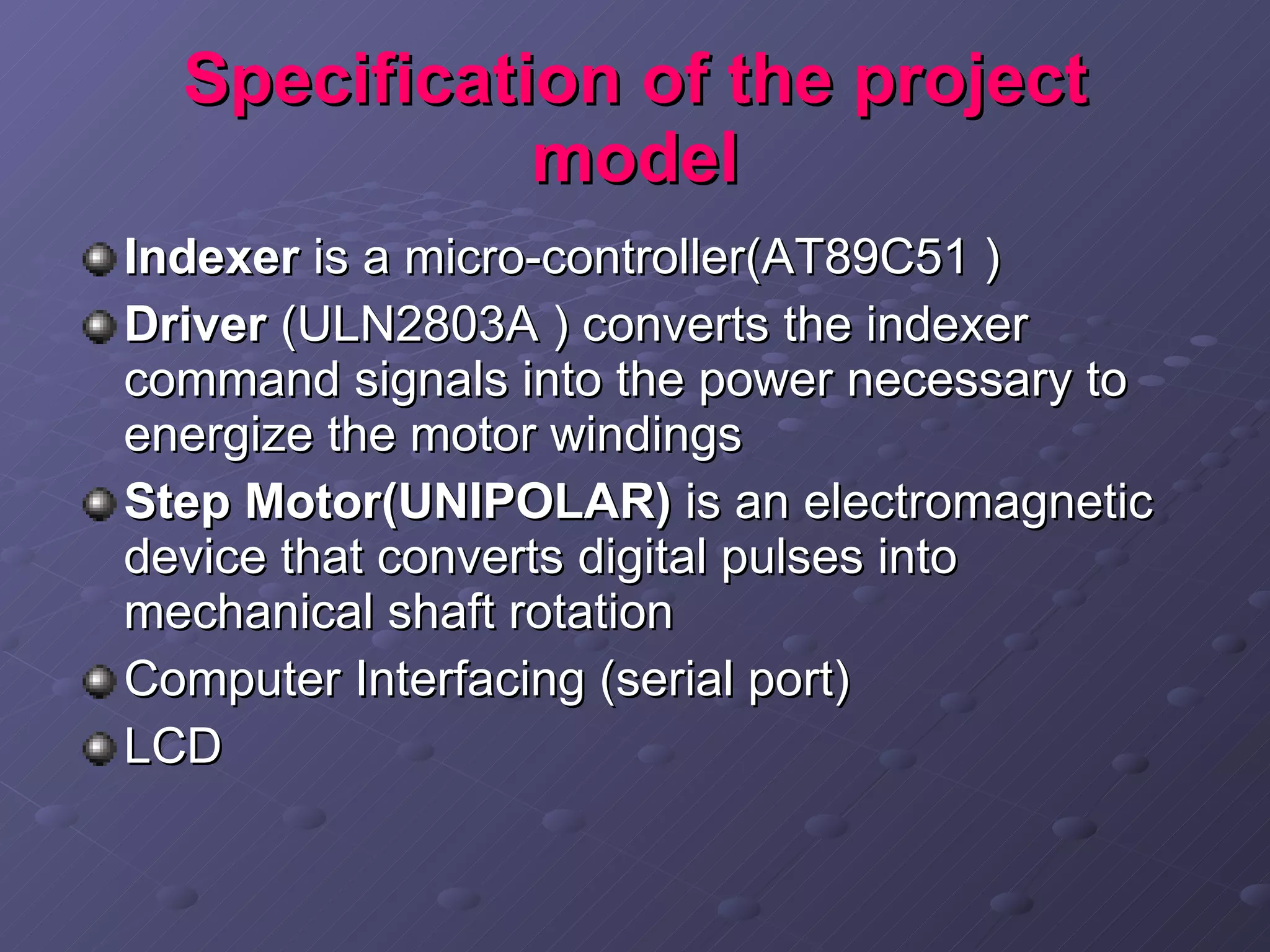

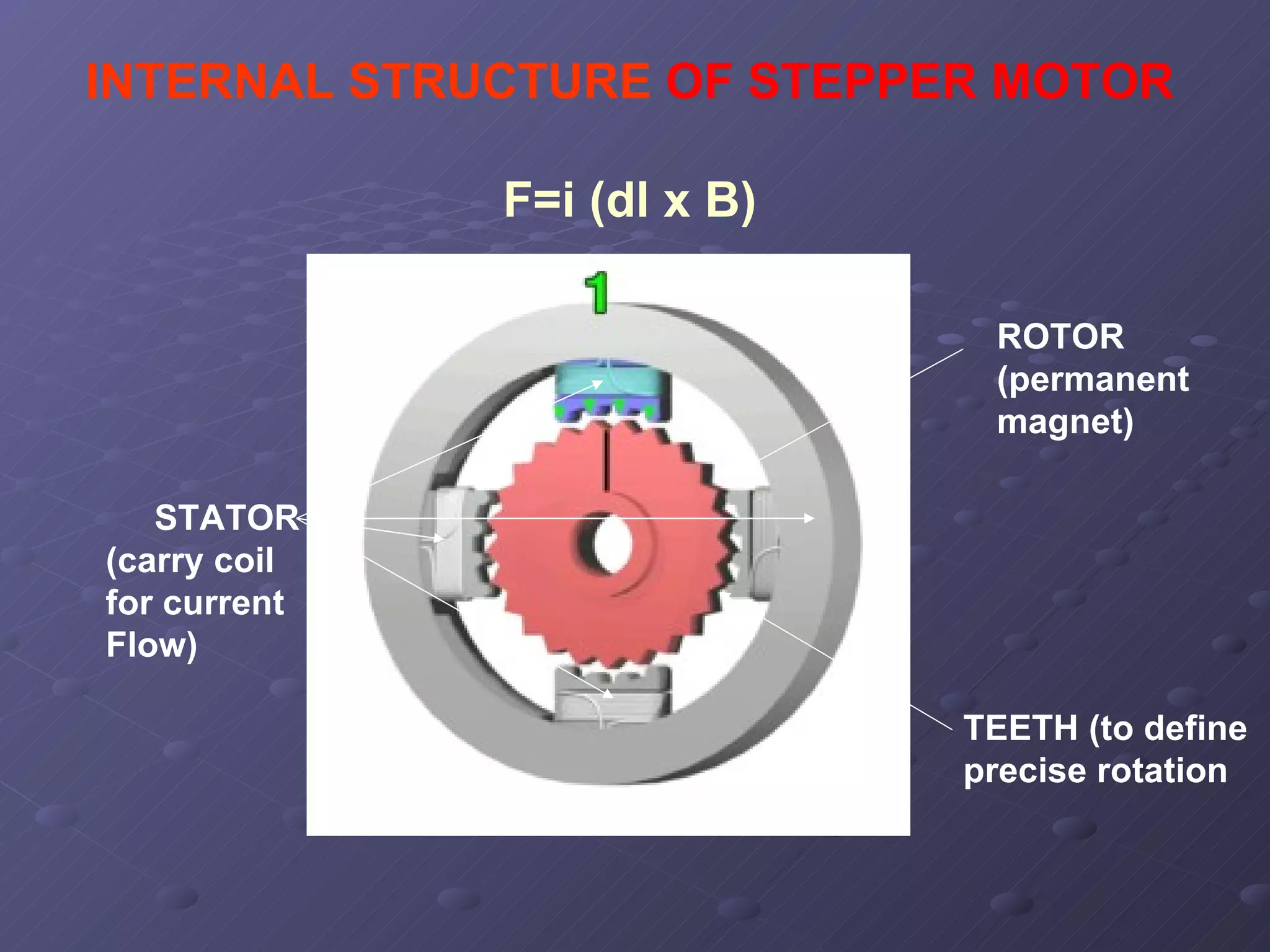

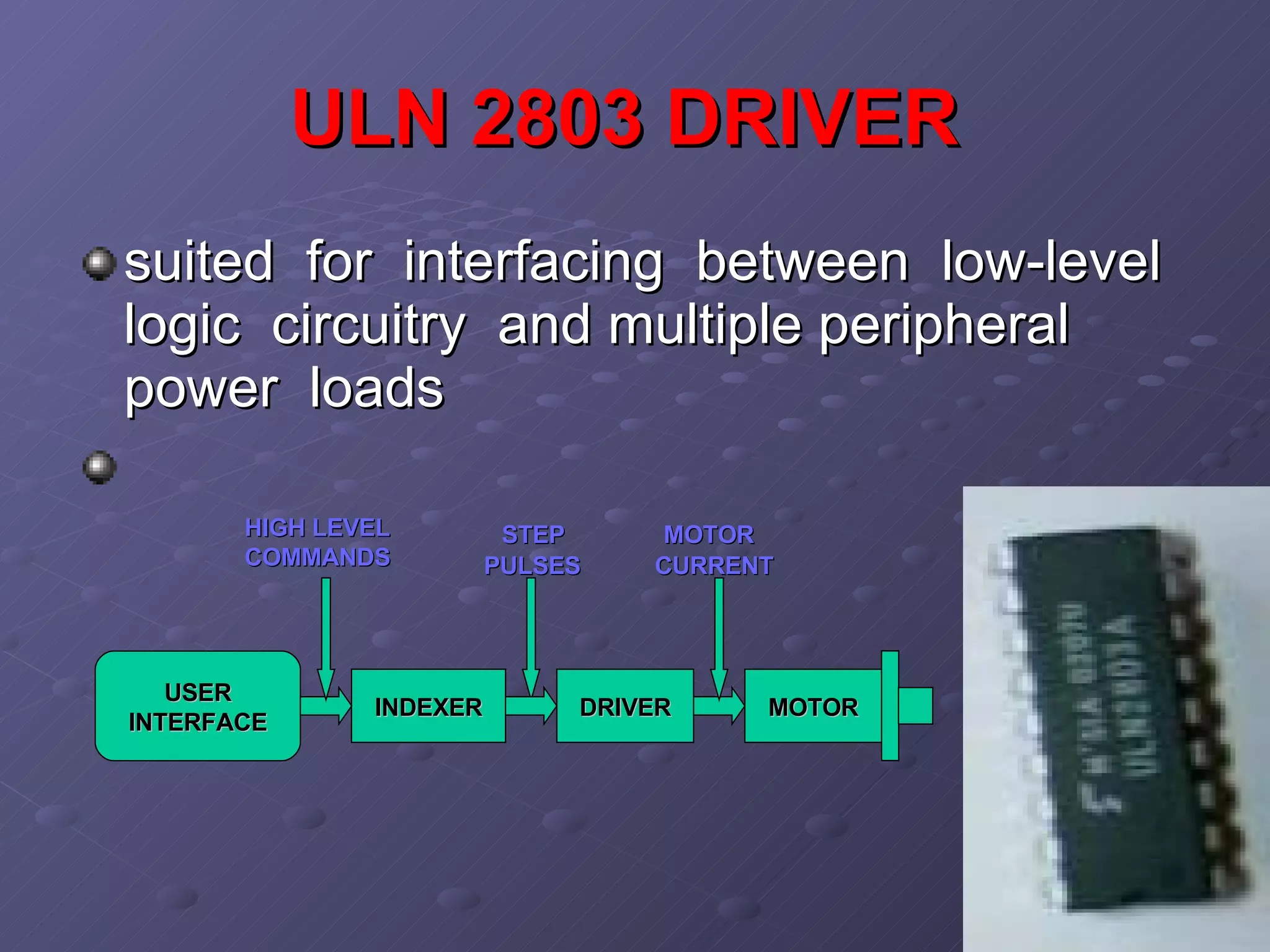

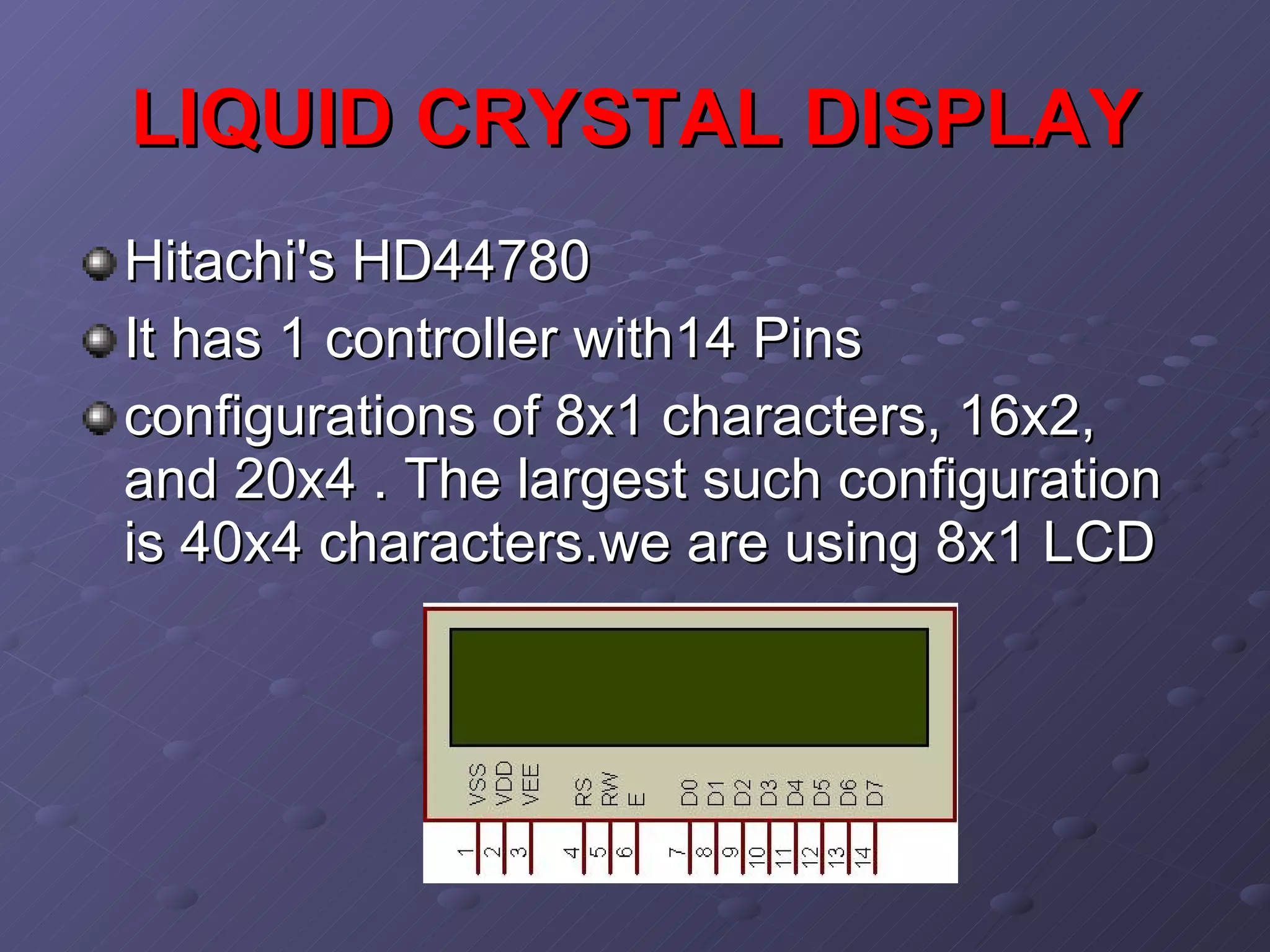

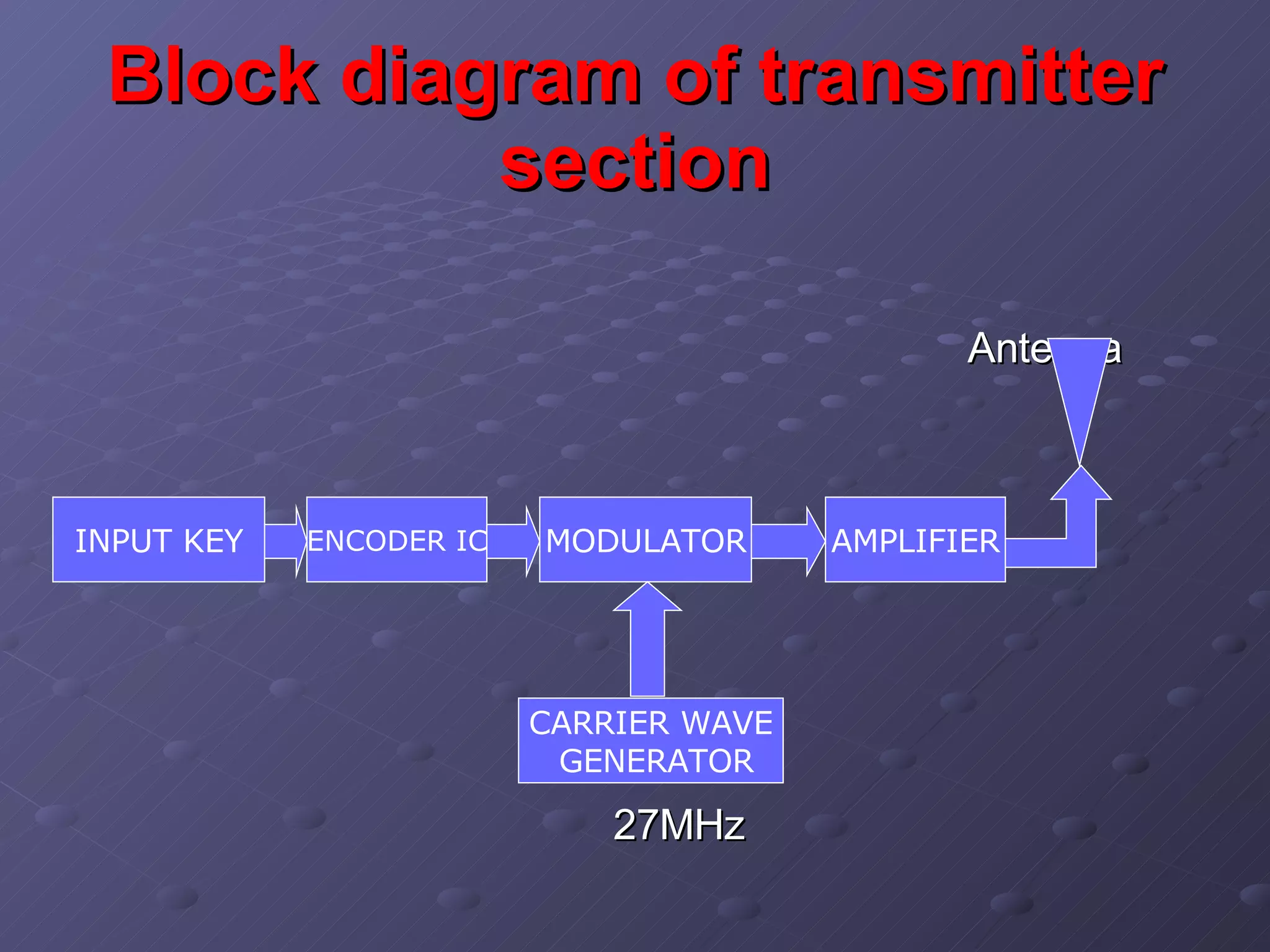

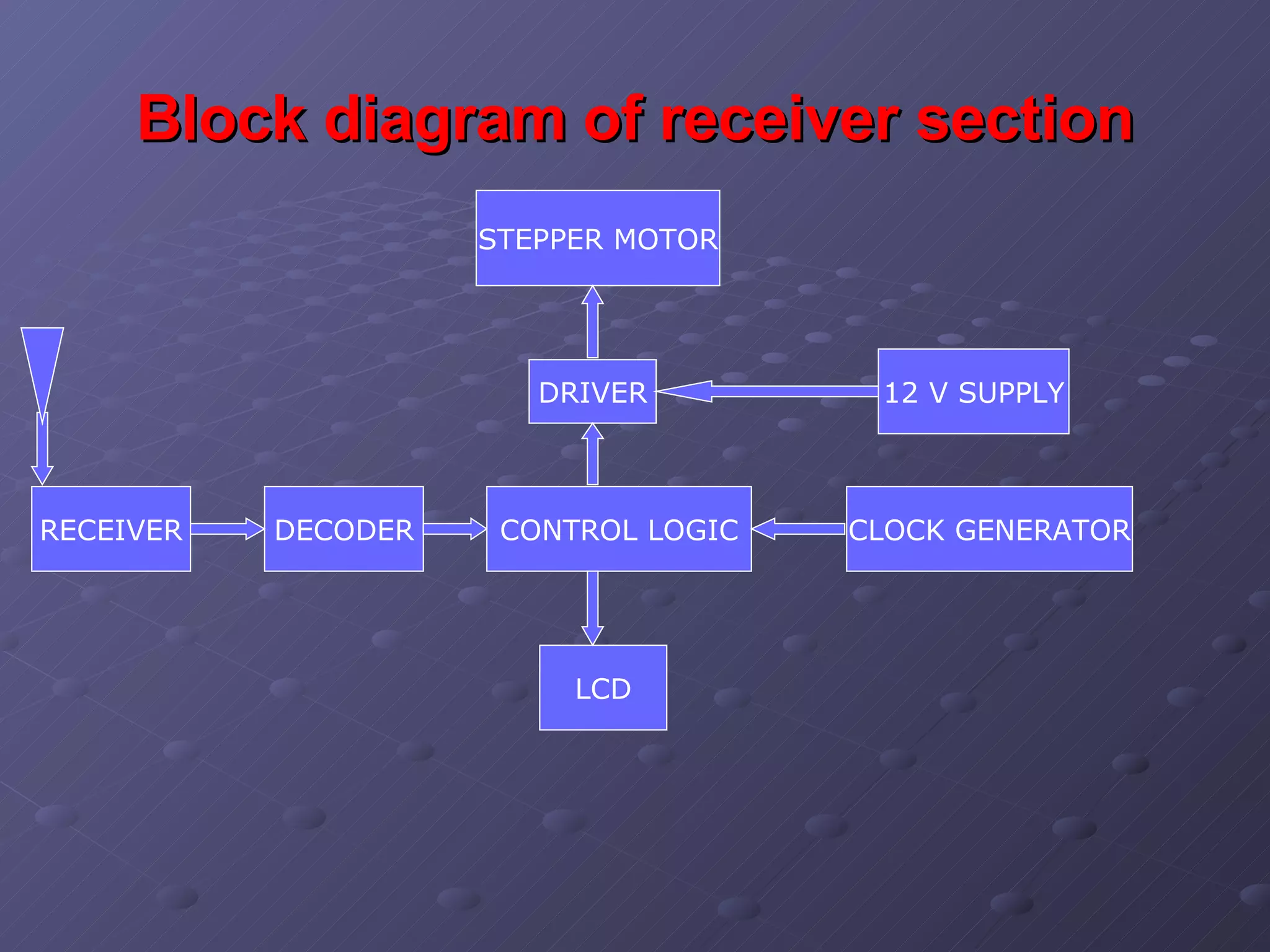

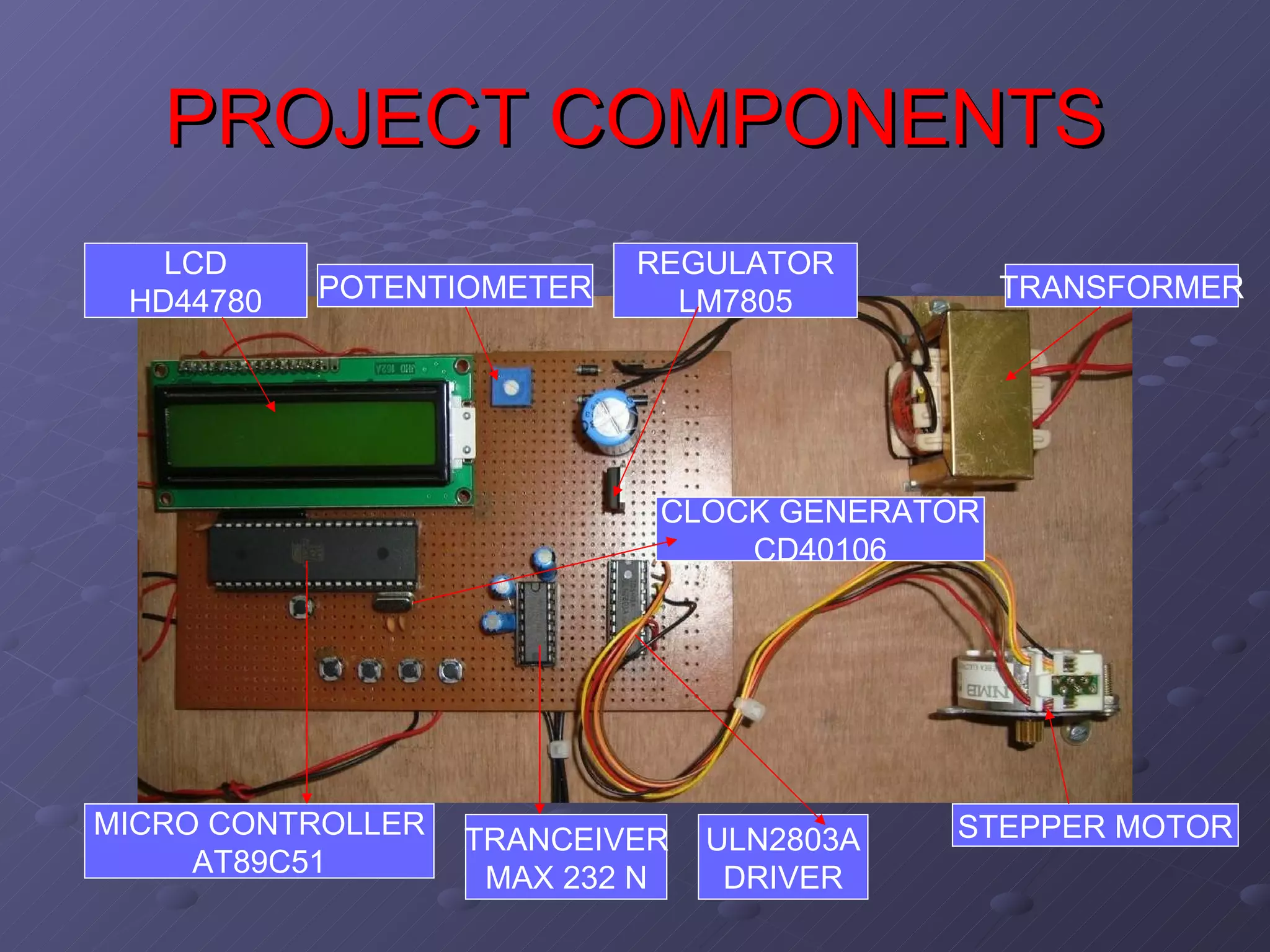

This document summarizes a student project to control a stepper motor through wireless transmission. The project uses a microcontroller to send step pulses to a driver circuit connected to a stepper motor. Commands can be sent from a computer serial port or wireless interface to control the motor speed displayed on an LCD screen. The system aims to provide precise digital control of the stepper motor position through simple wireless operation.