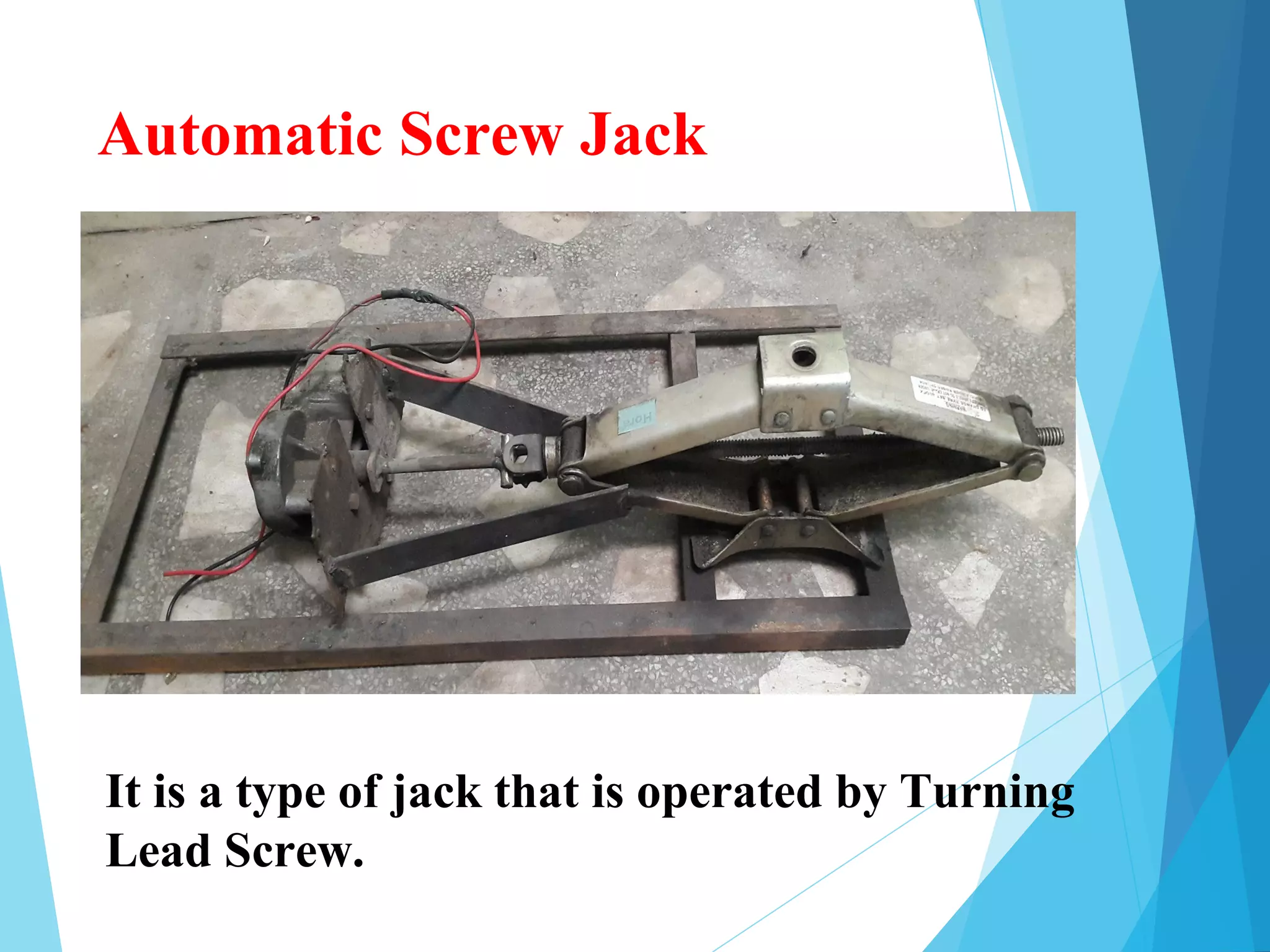

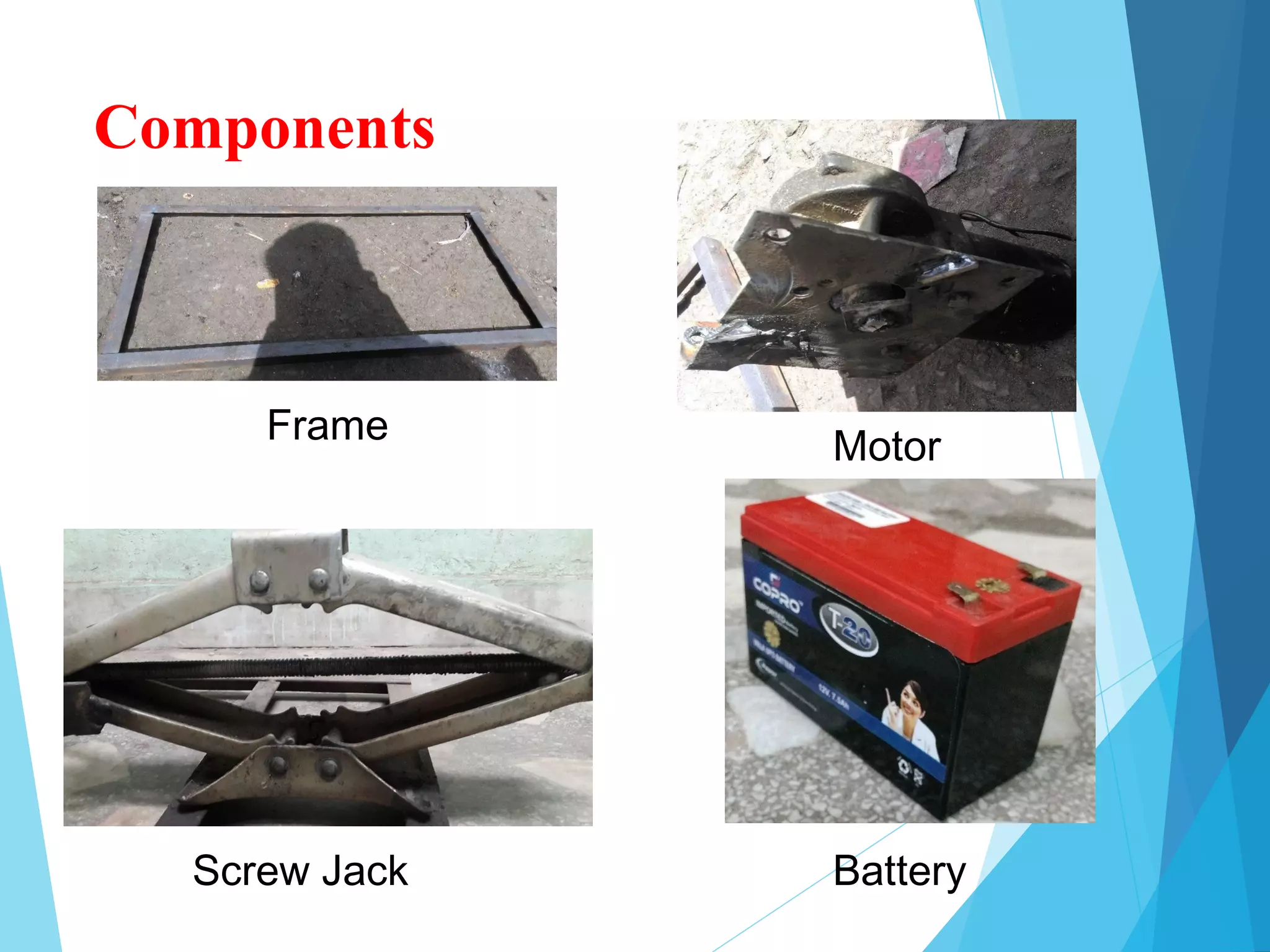

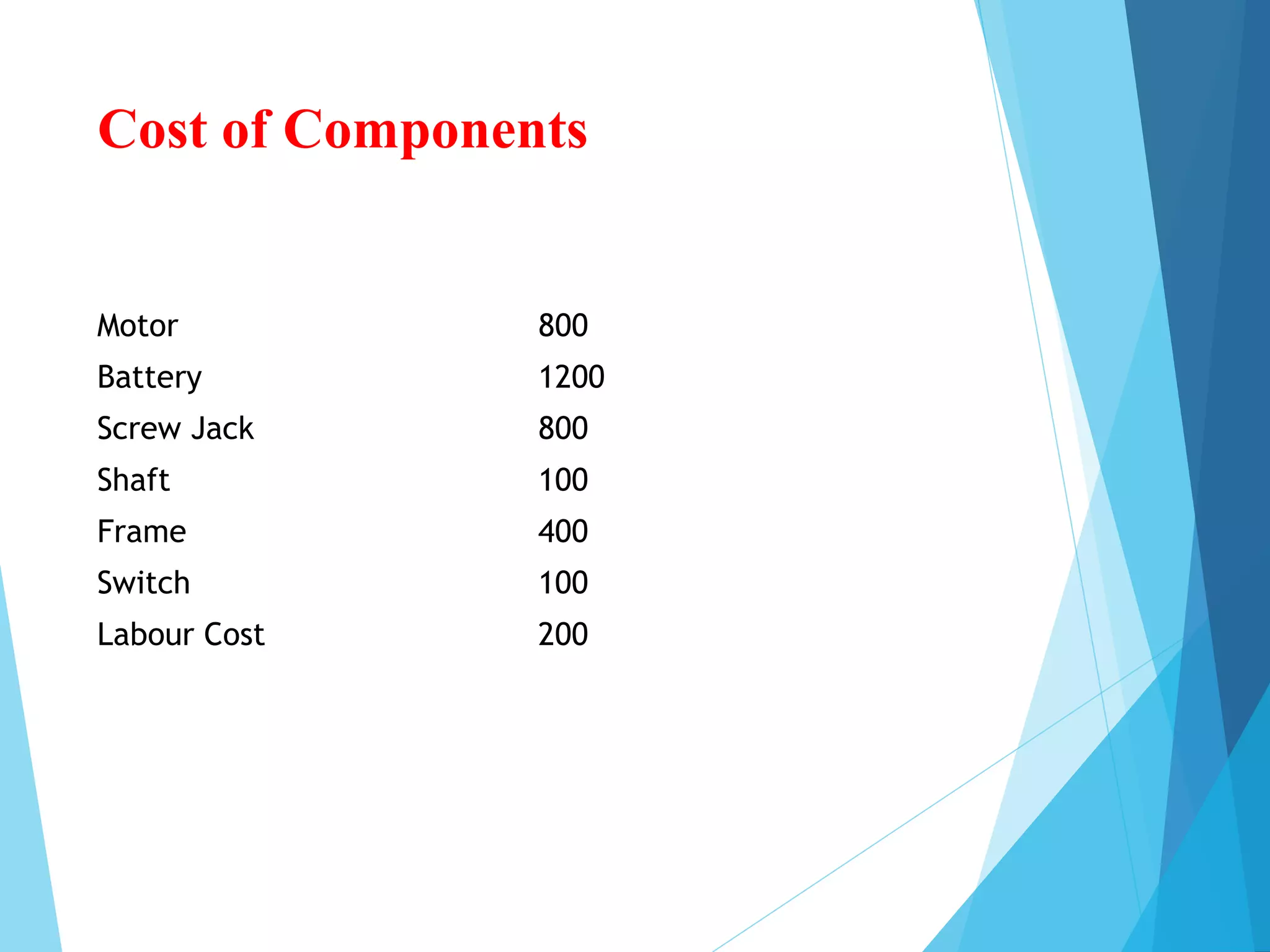

This document is a project report on an automatic screw jack for light vehicles. It describes the components of the automatic screw jack, which include a frame, motor, shaft, and battery and switches. The motor transmits rotary motion to lift the screw jack and can lift weights up to 3 tonnes. It also provides the costs of the components and advantages of the automatic screw jack over traditional car jacks, such as not requiring physical labor or manpower to lift vehicles.