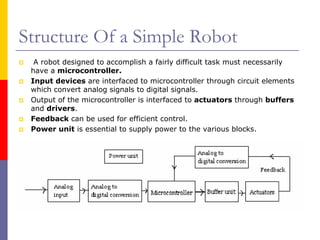

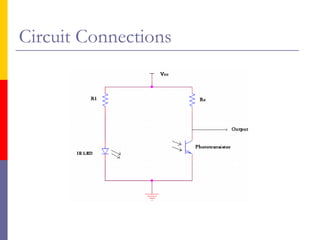

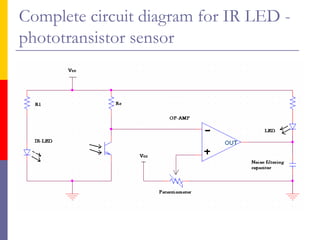

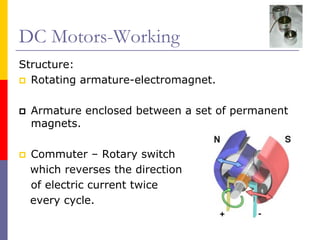

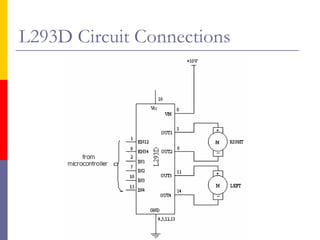

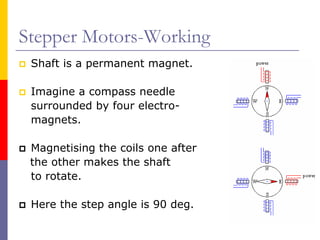

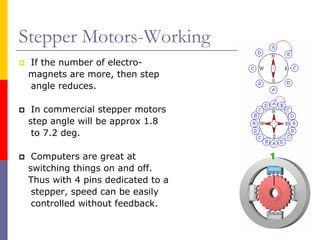

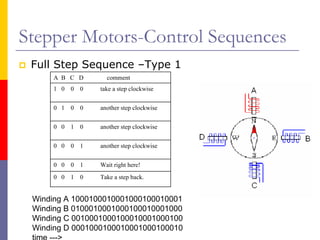

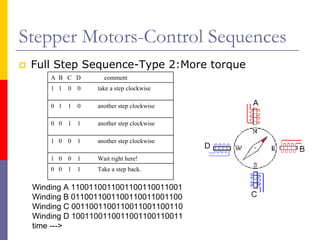

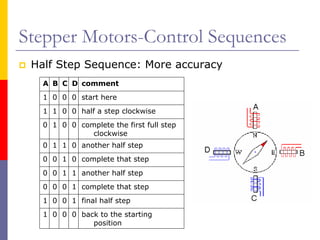

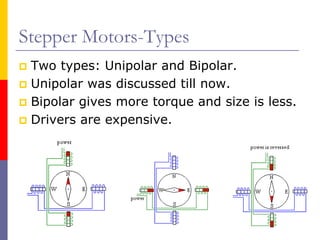

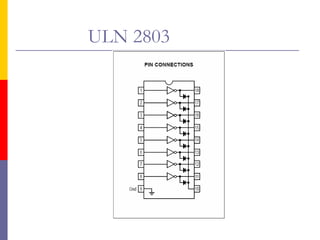

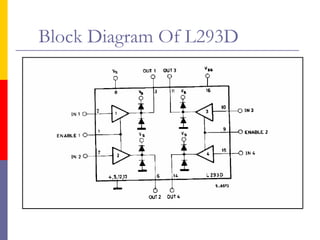

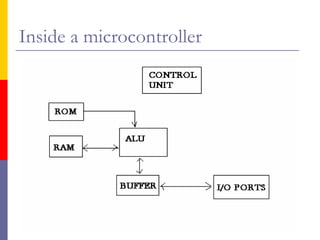

A robot requires sensors, a microcontroller, motors, and a power source. Sensors like LDRs and phototransistors provide input to the microcontroller. The microcontroller processes the input and controls actuators like DC motors through motor drivers. Stepper motors provide accurate movement but require more complex control sequences. The document discusses various sensors, motors, and motor interfaces that can be used to build an automated robot.