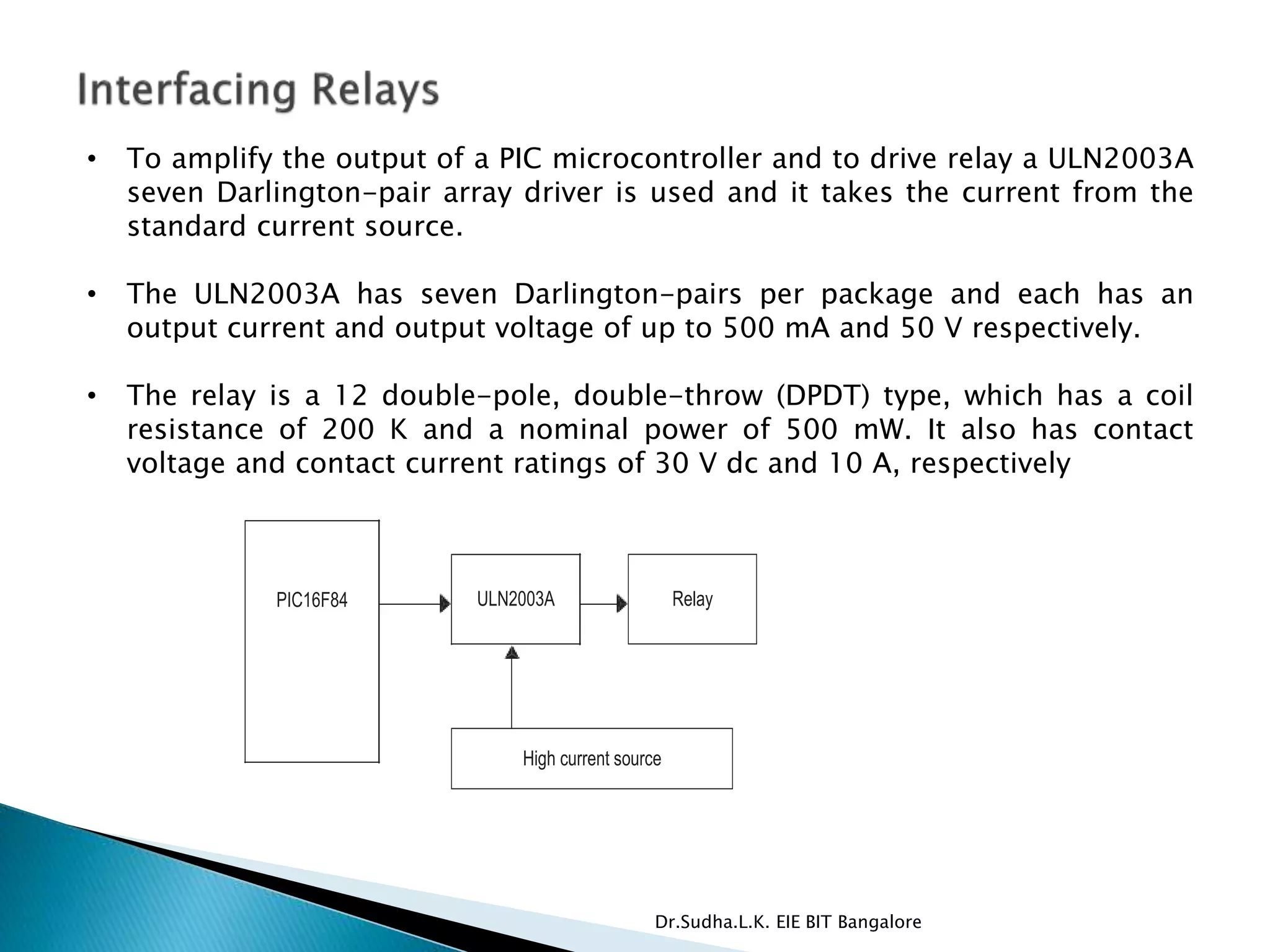

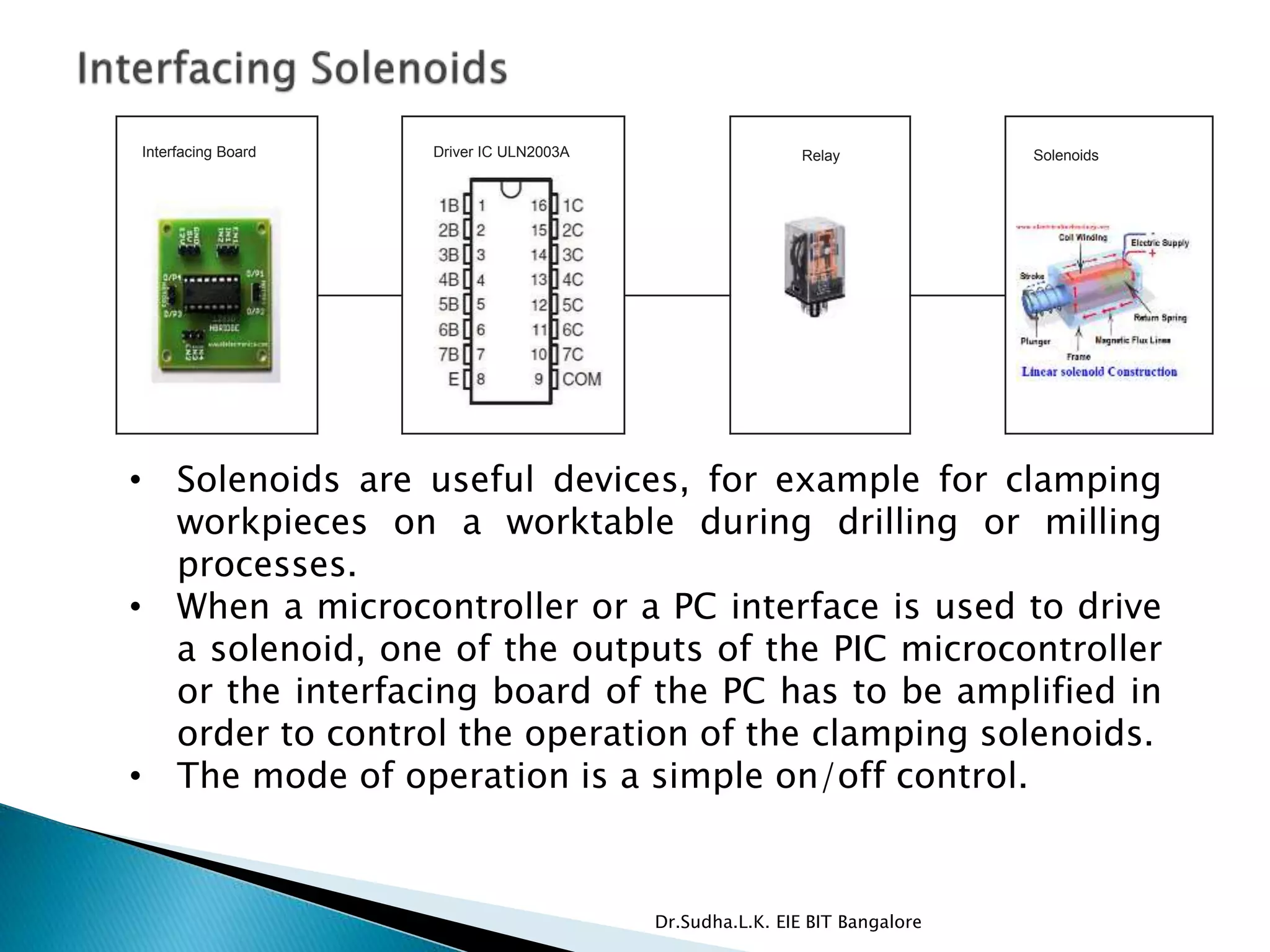

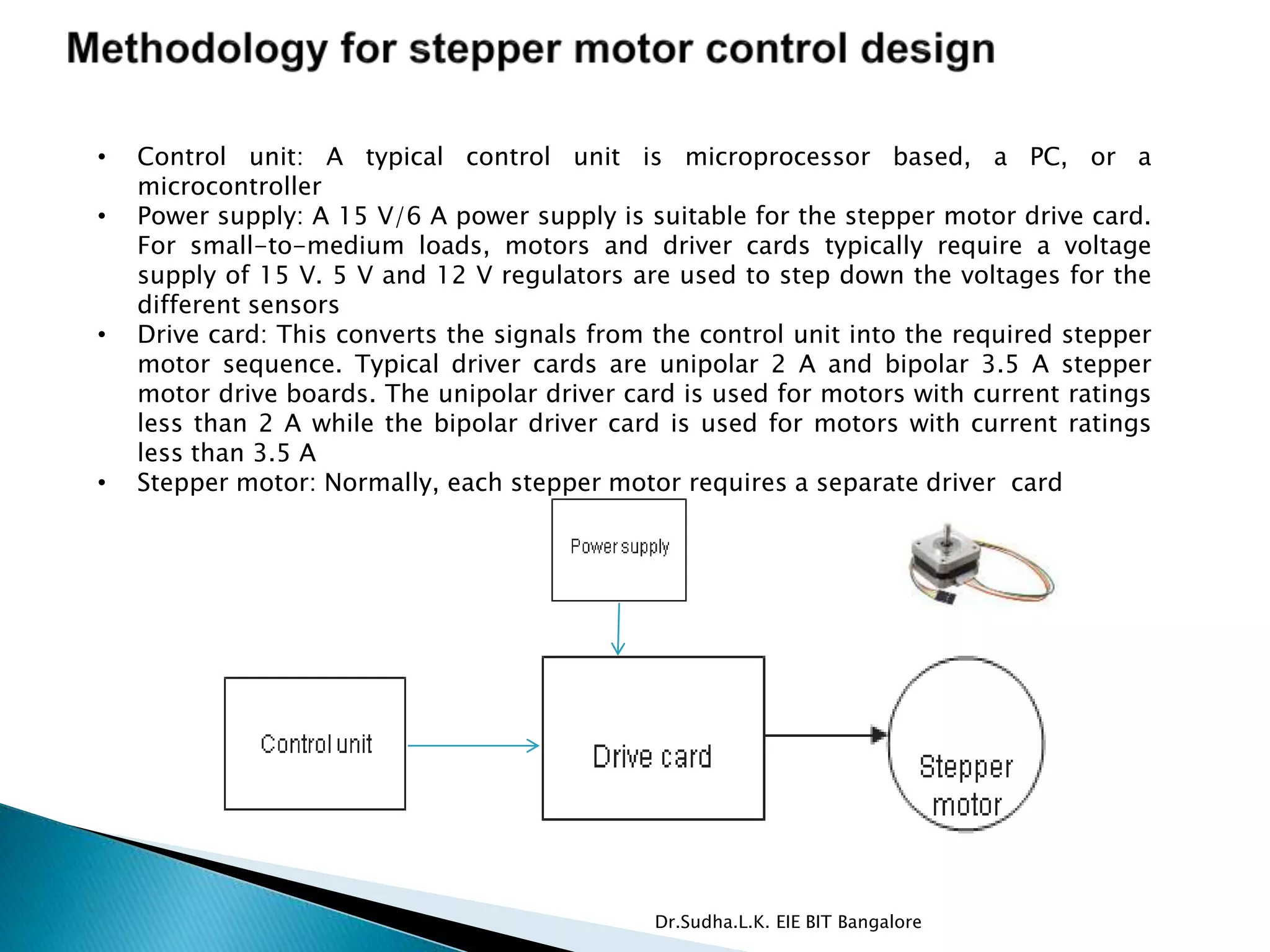

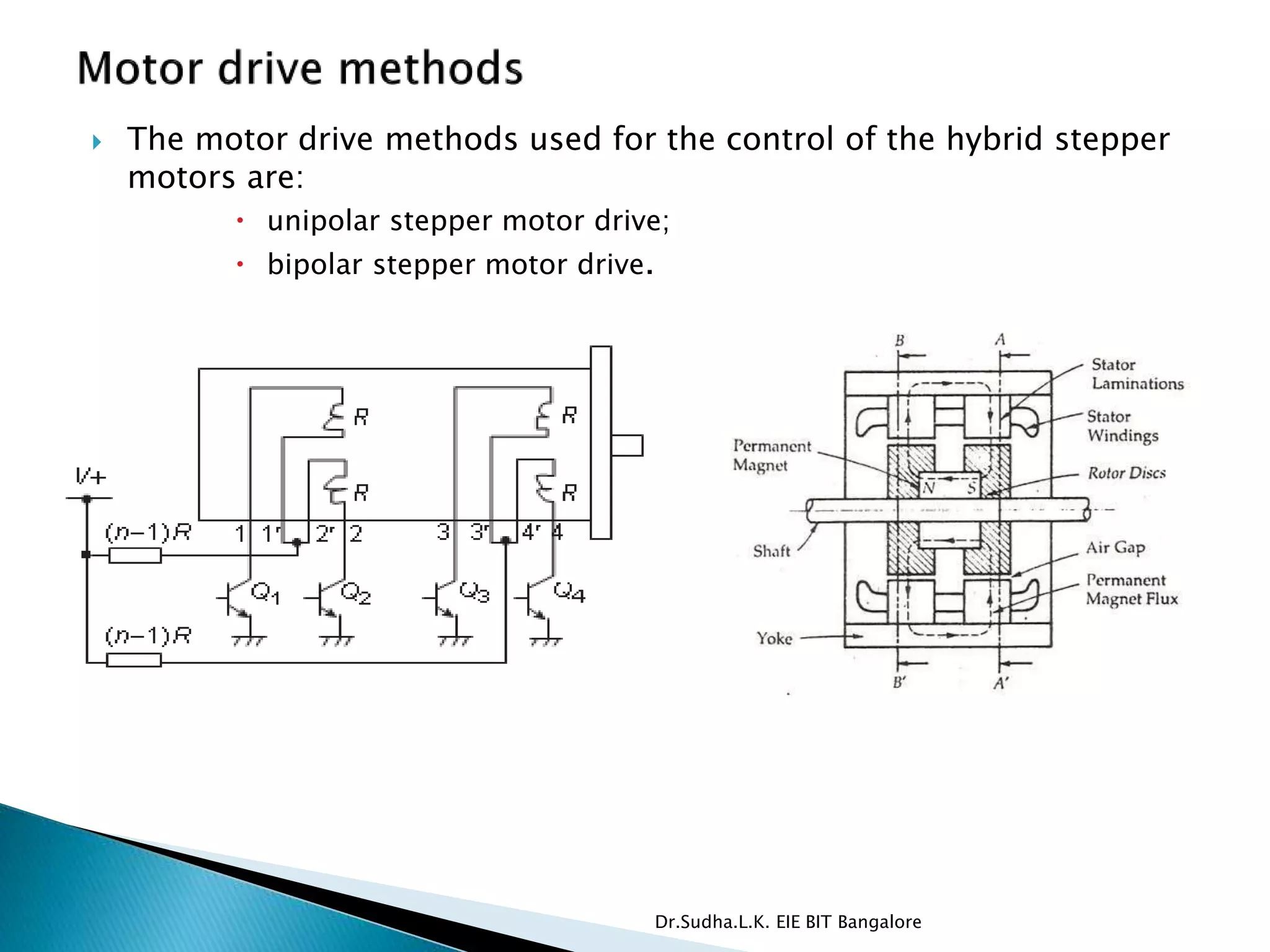

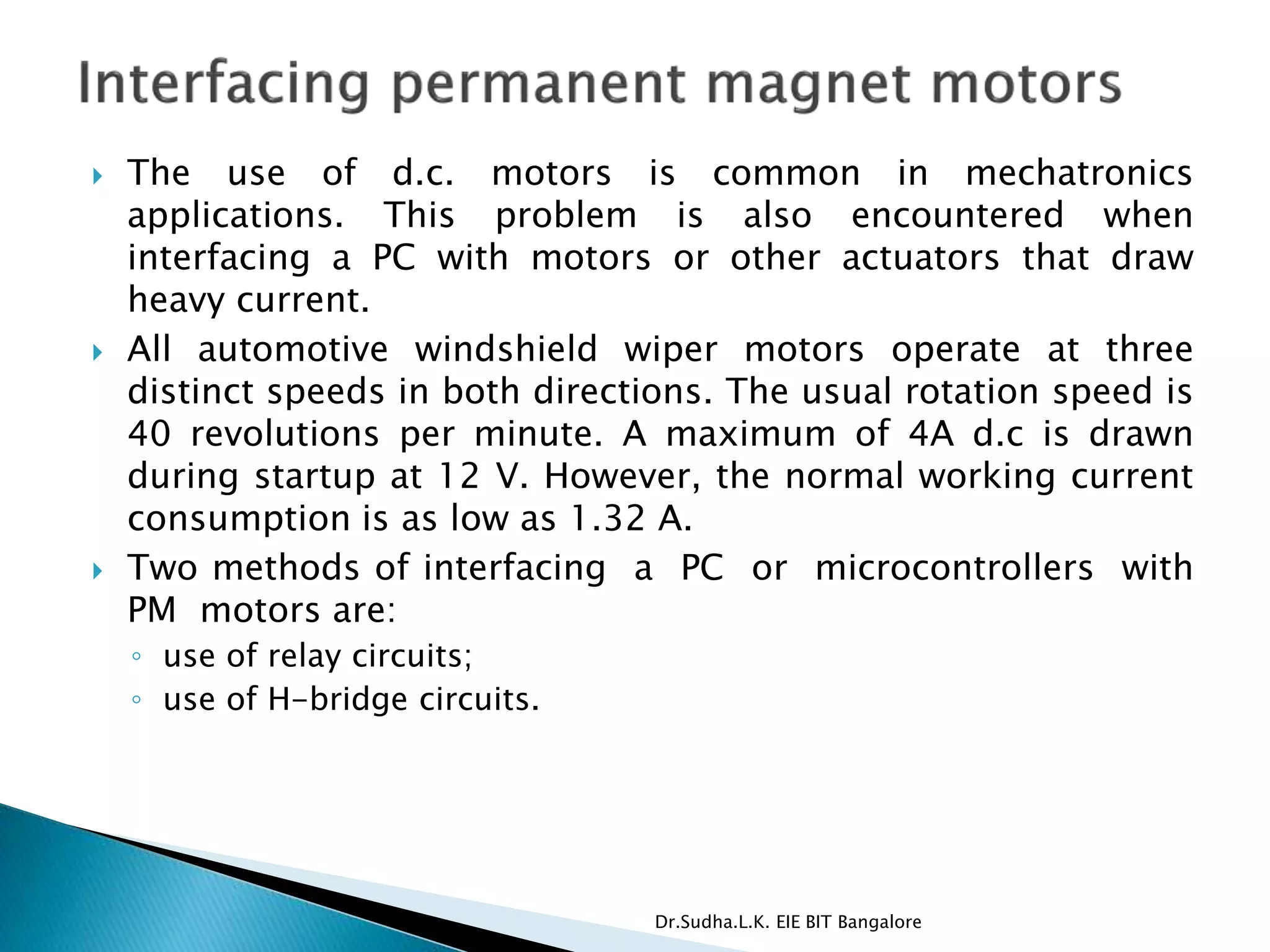

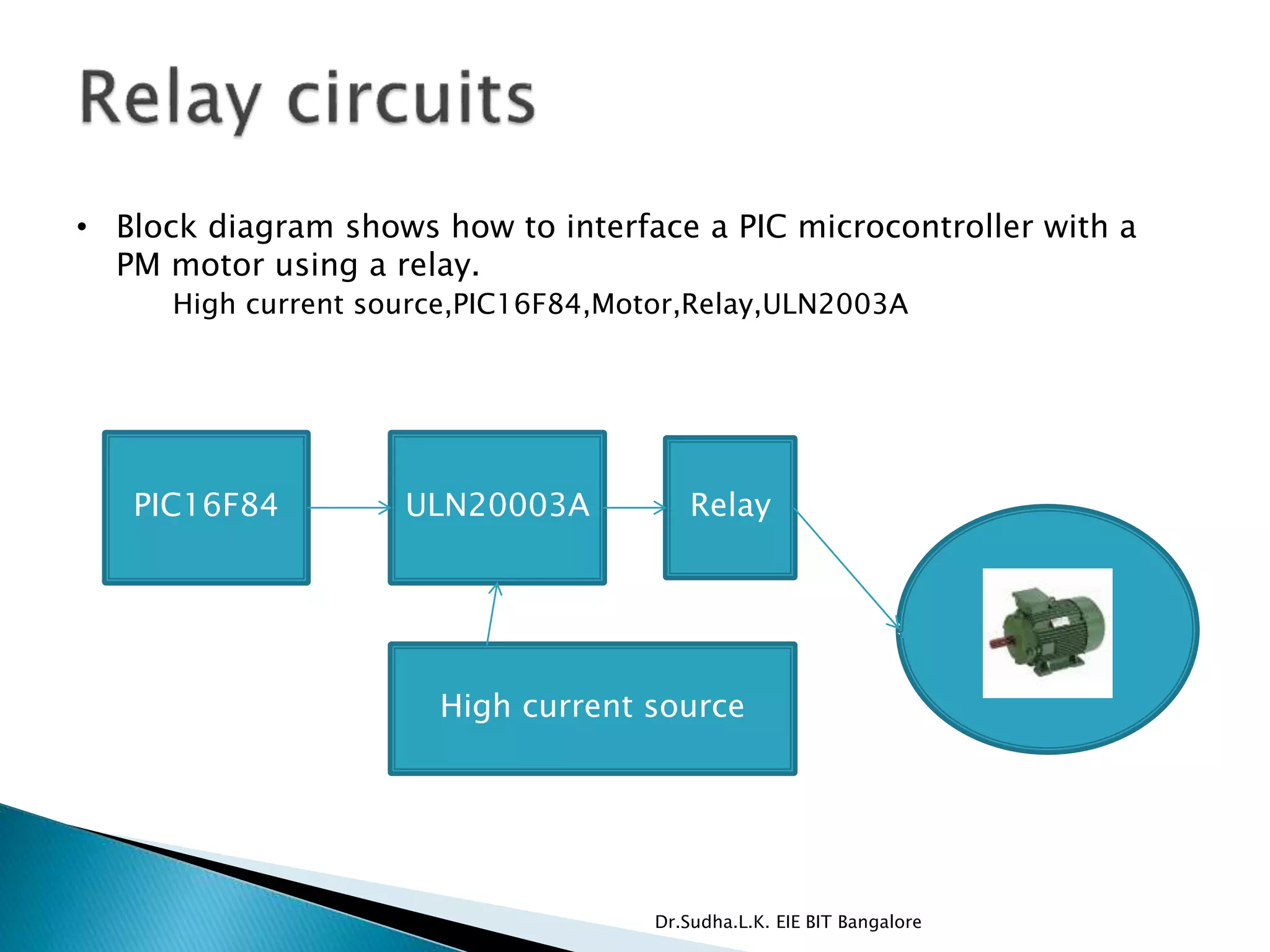

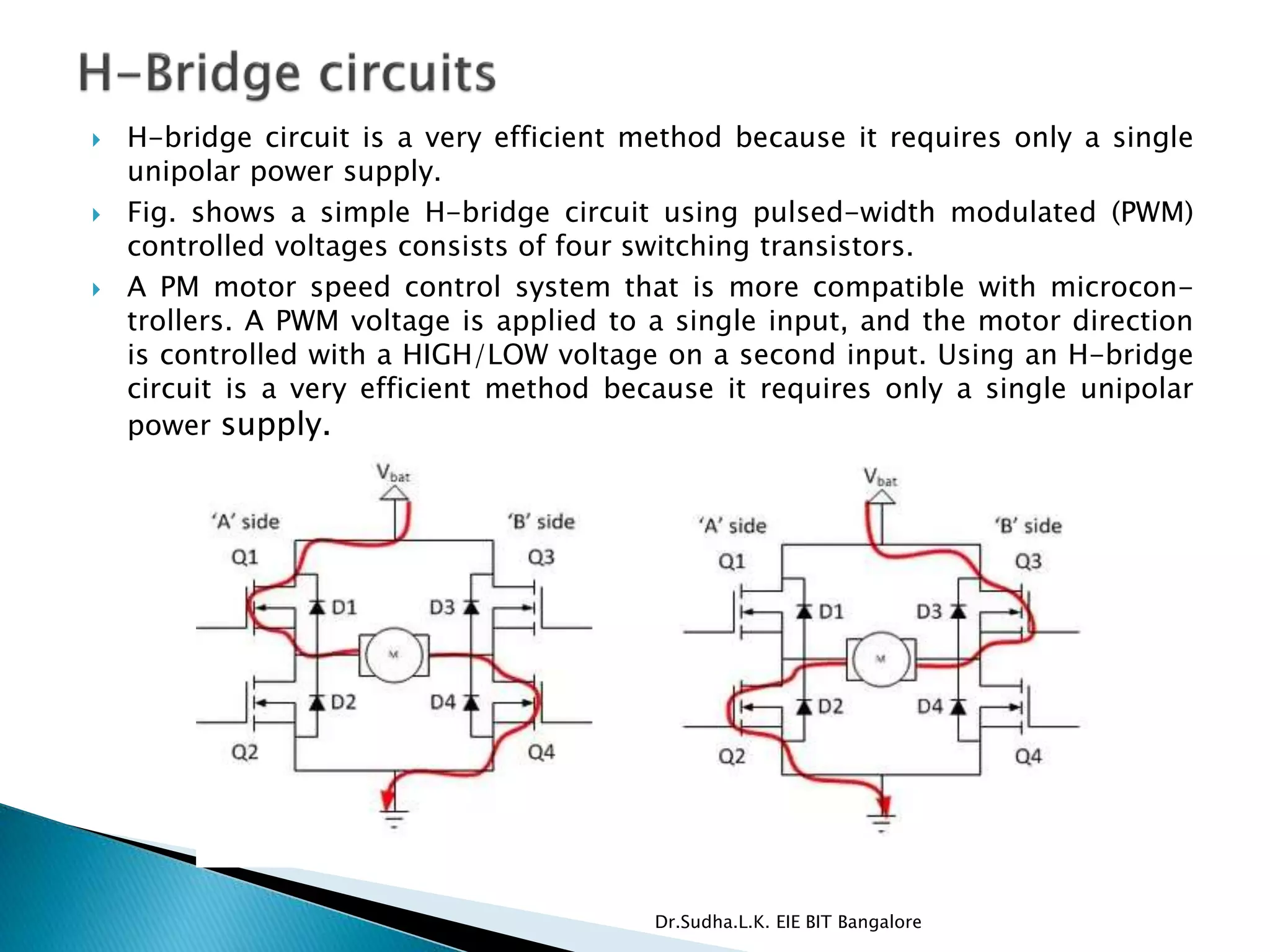

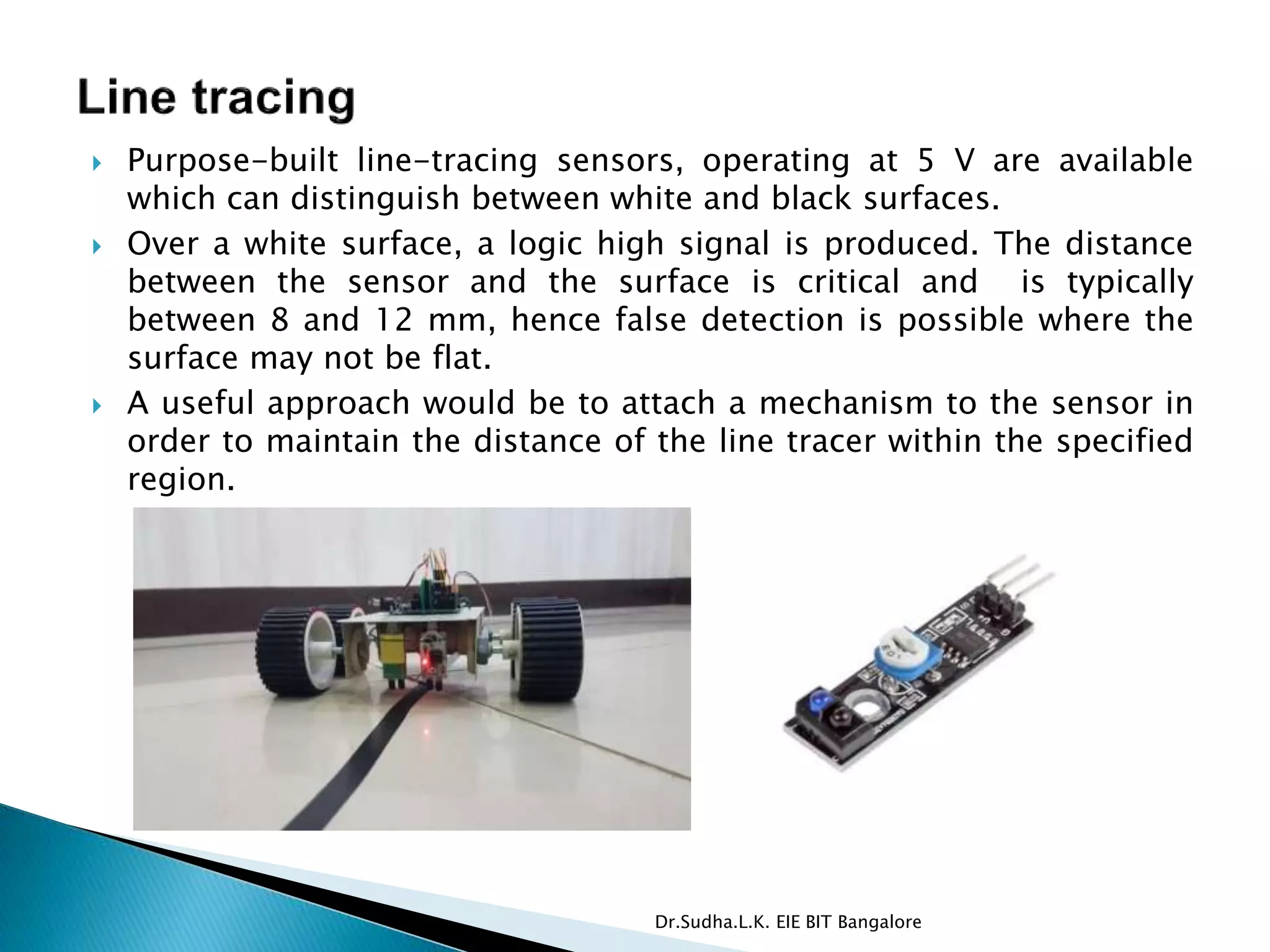

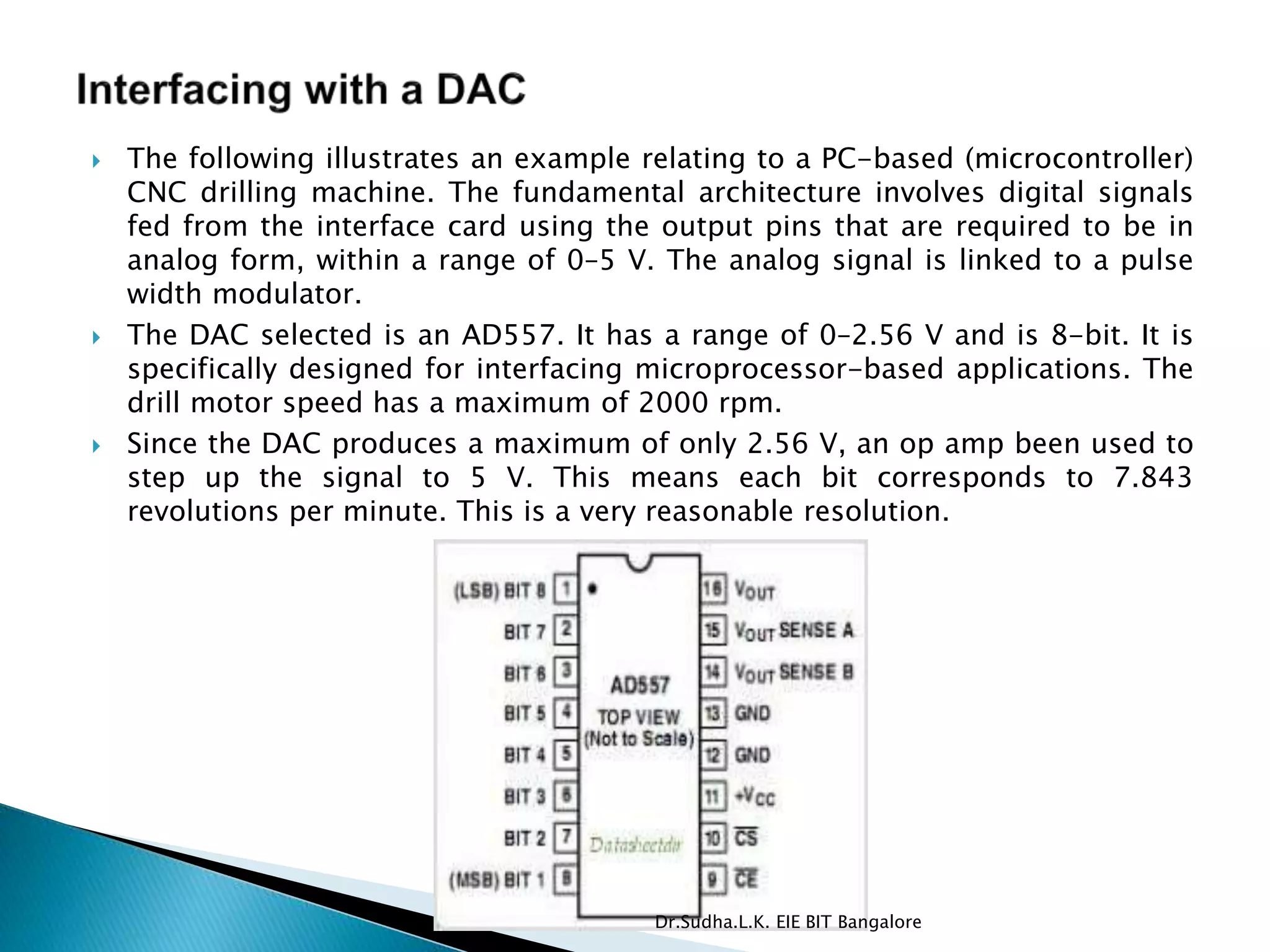

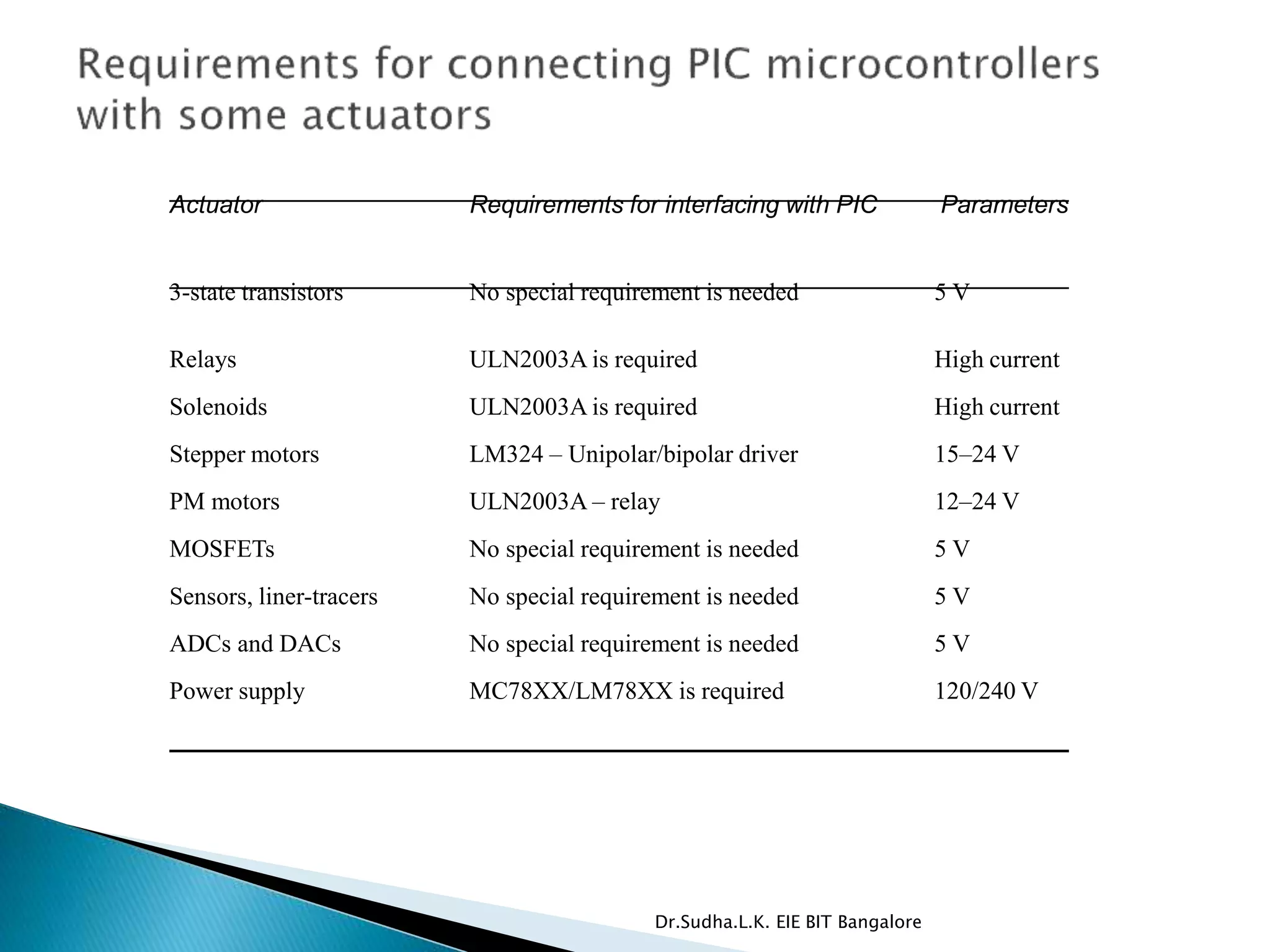

This document discusses interfacing components in mechatronic systems with microcontrollers. It describes how to interface three-state transistors, relays, solenoids, stepper motors, DC motors, and sensors using various driver integrated circuits. Common ICs used include the ULN2003A for amplifying output to drive high-current devices, and the LM324 for unipolar/bipolar stepper motor control. The document also discusses power supply requirements, with AC mains voltages needing to be converted to standardized lower DC voltages used by electronic components.