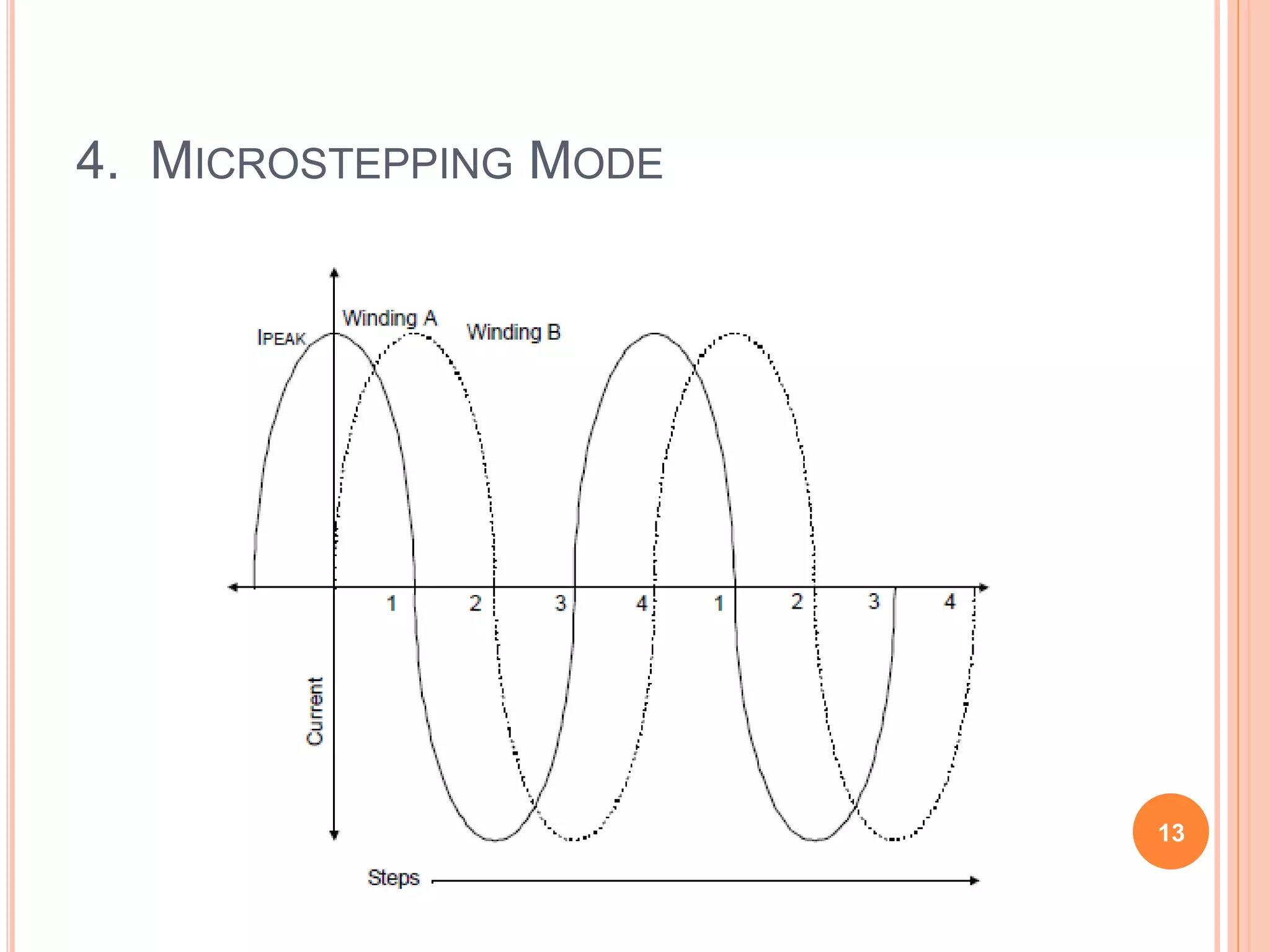

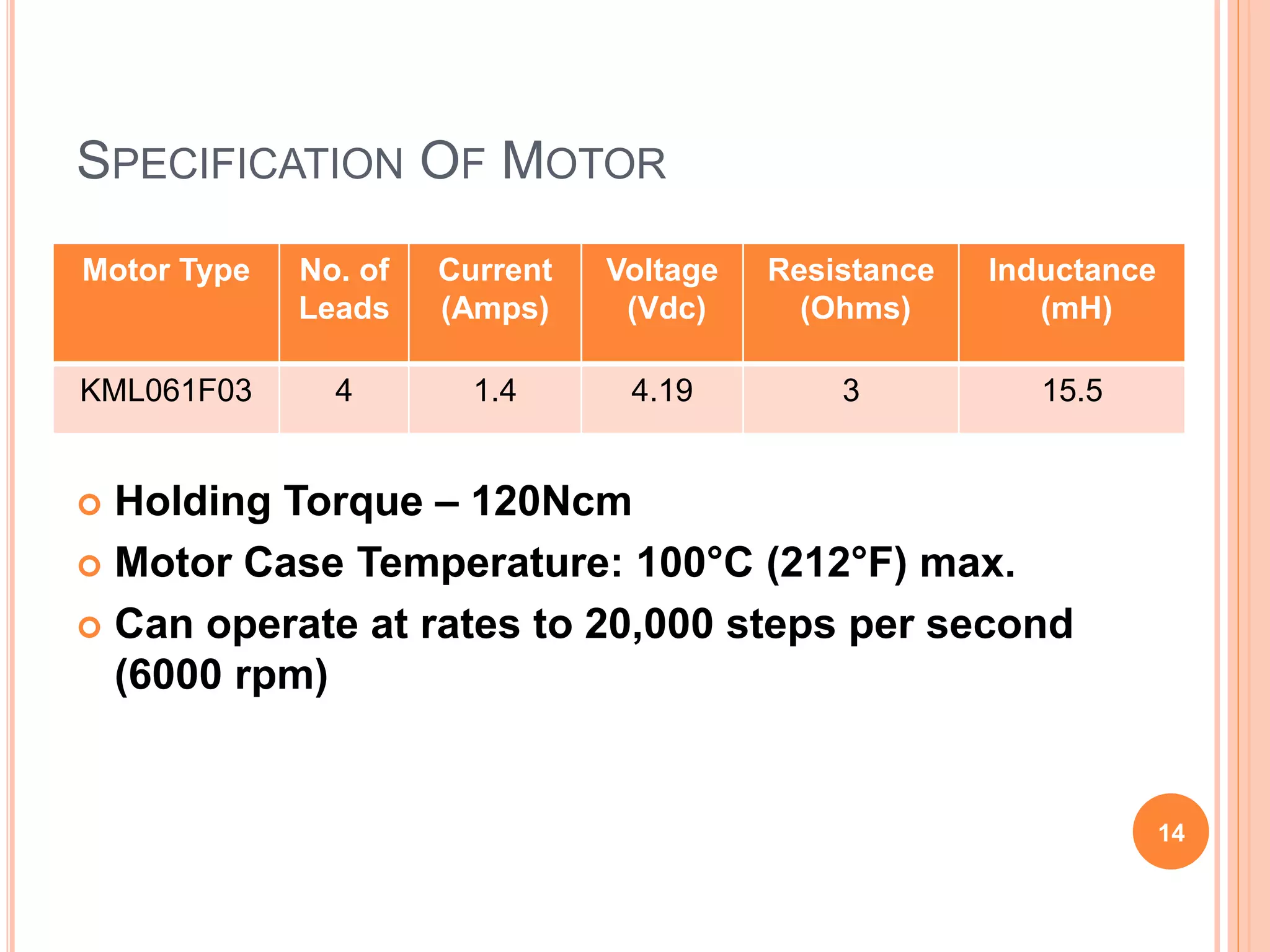

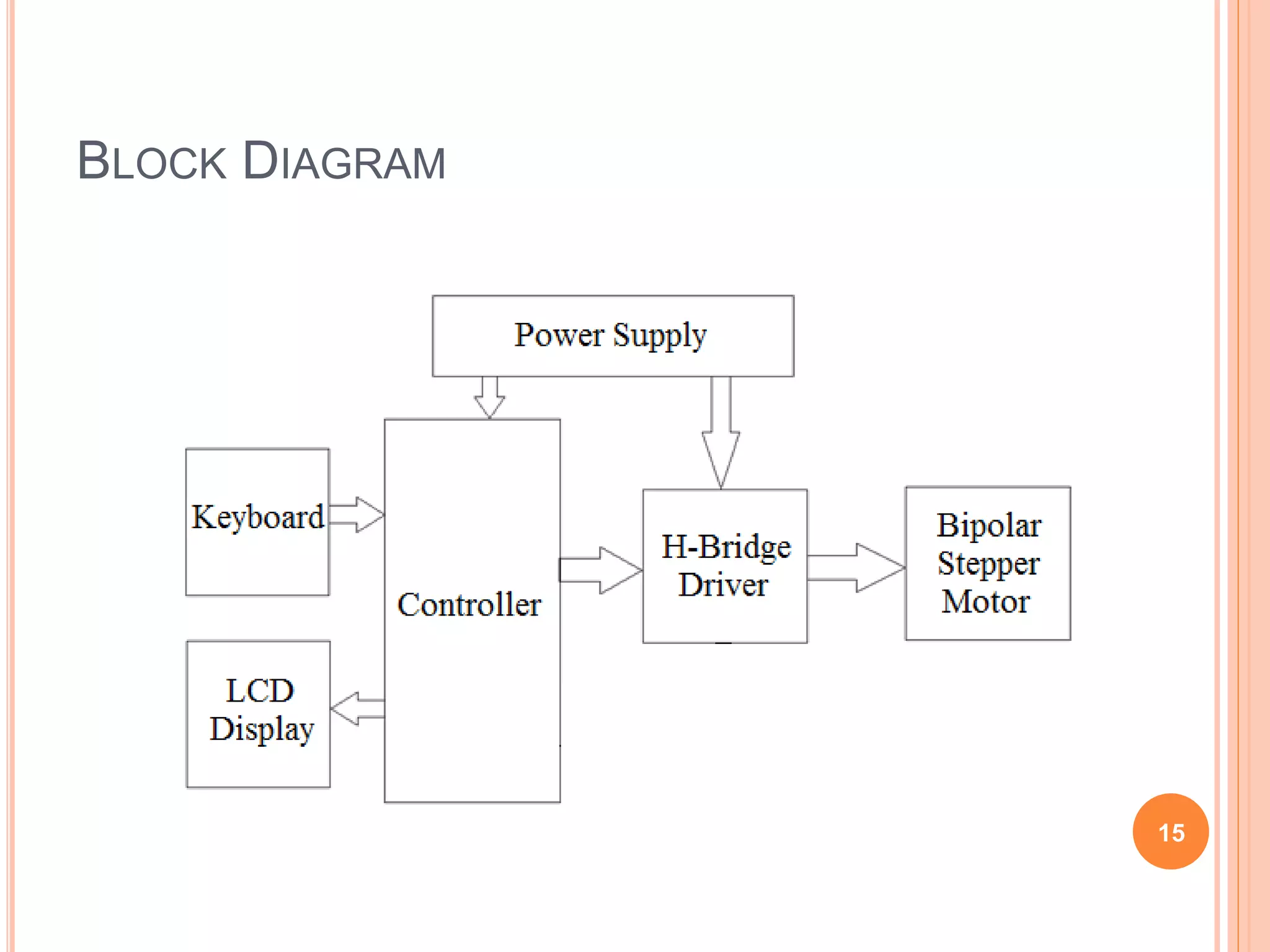

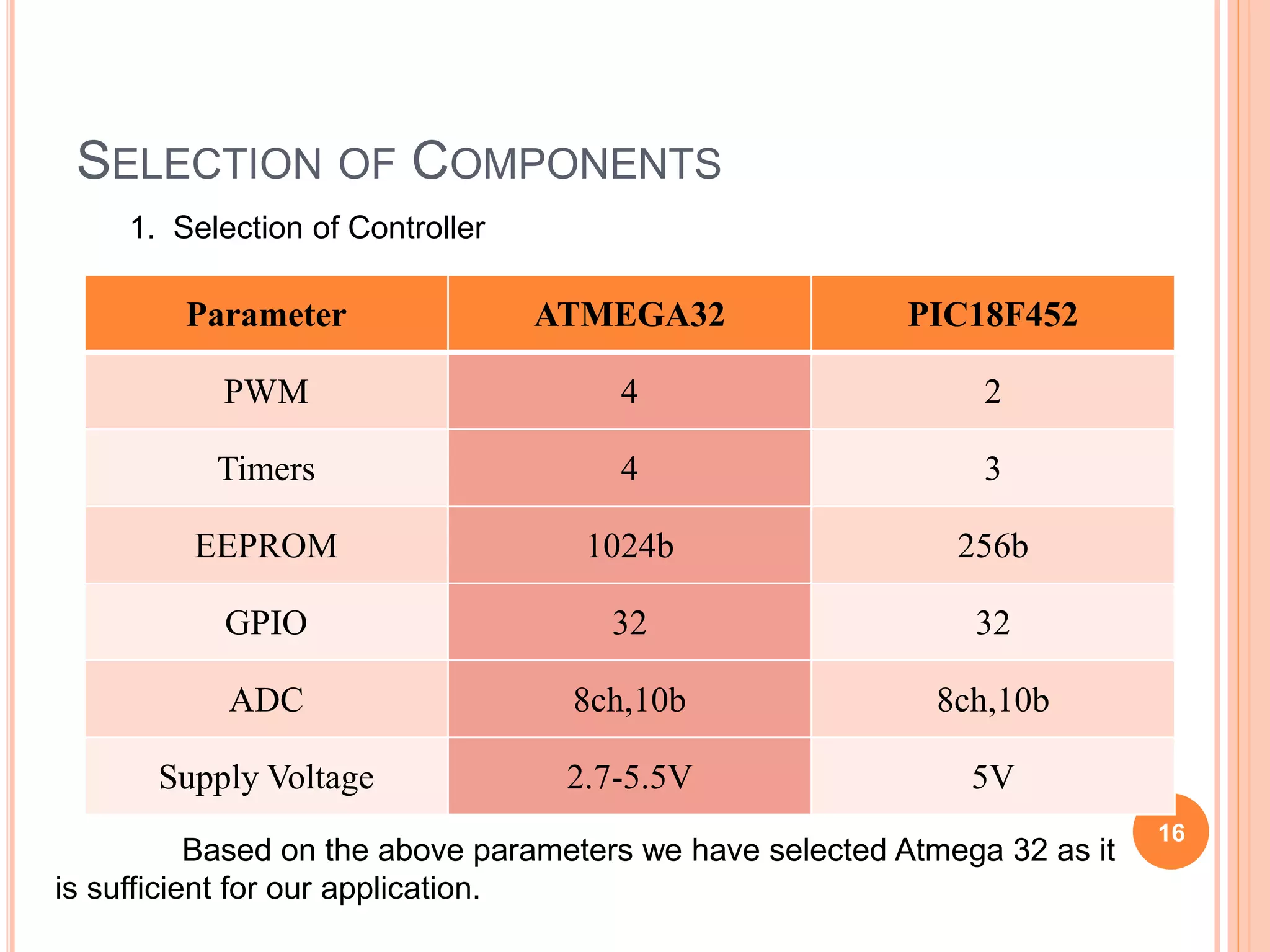

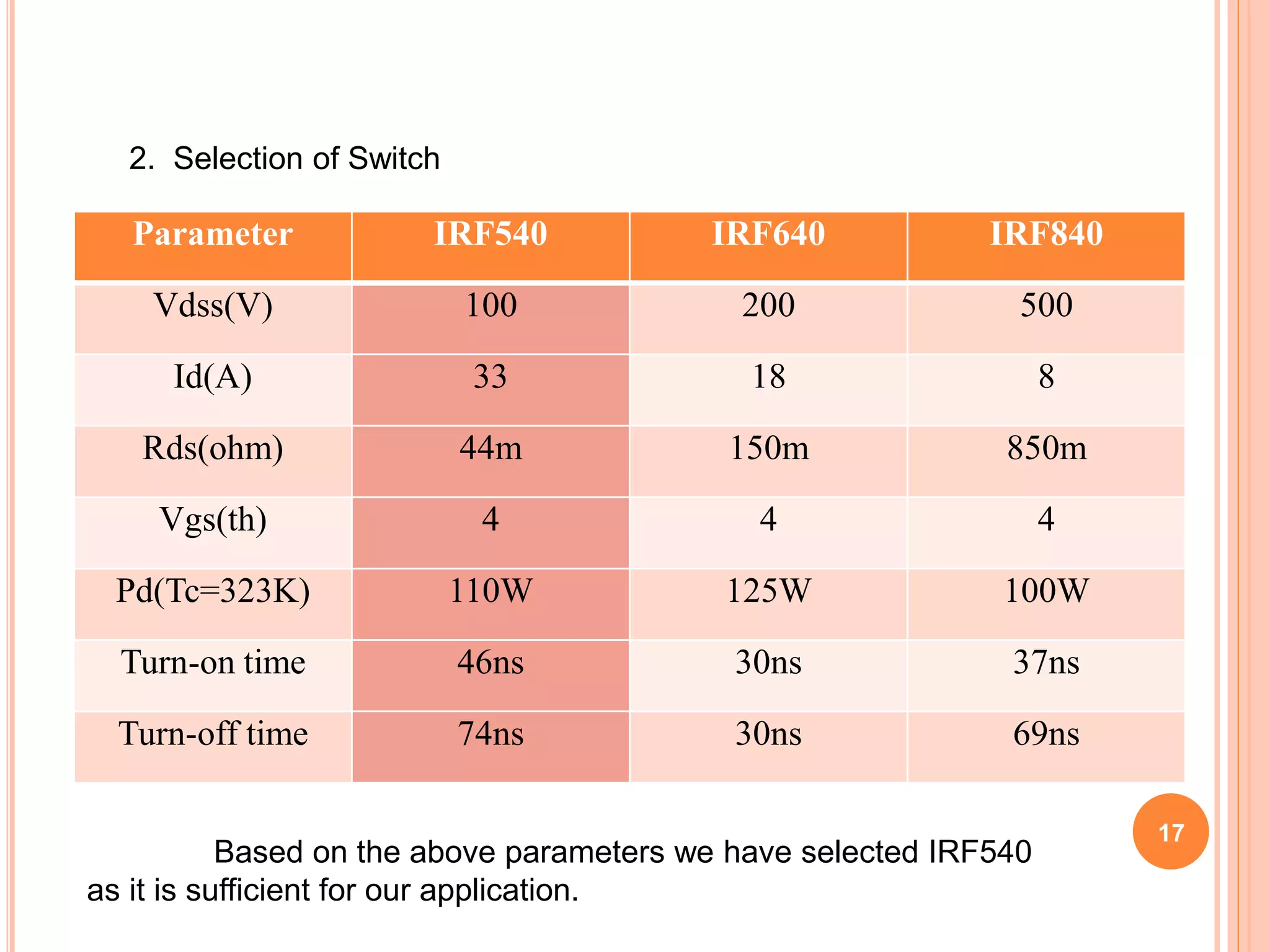

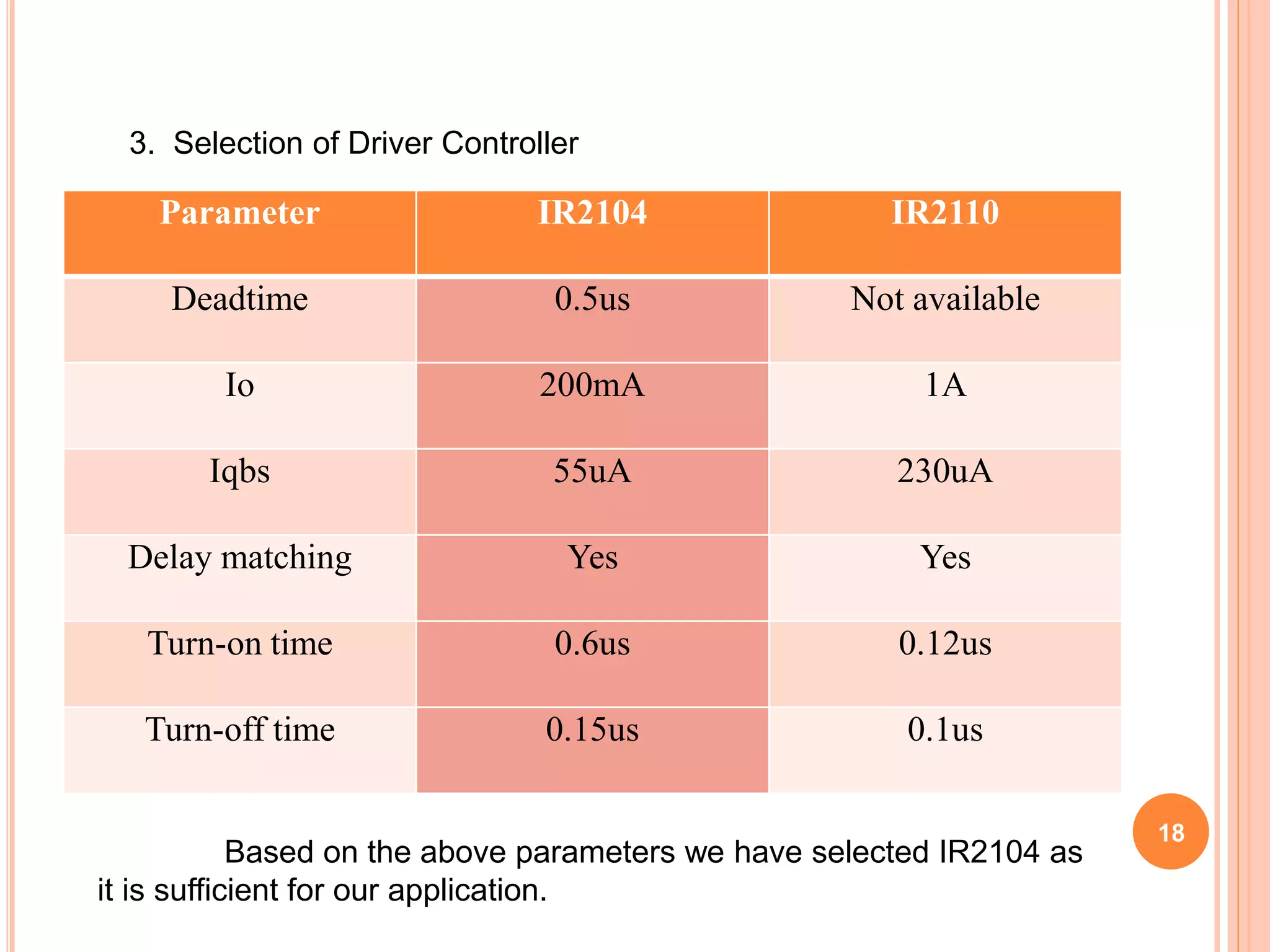

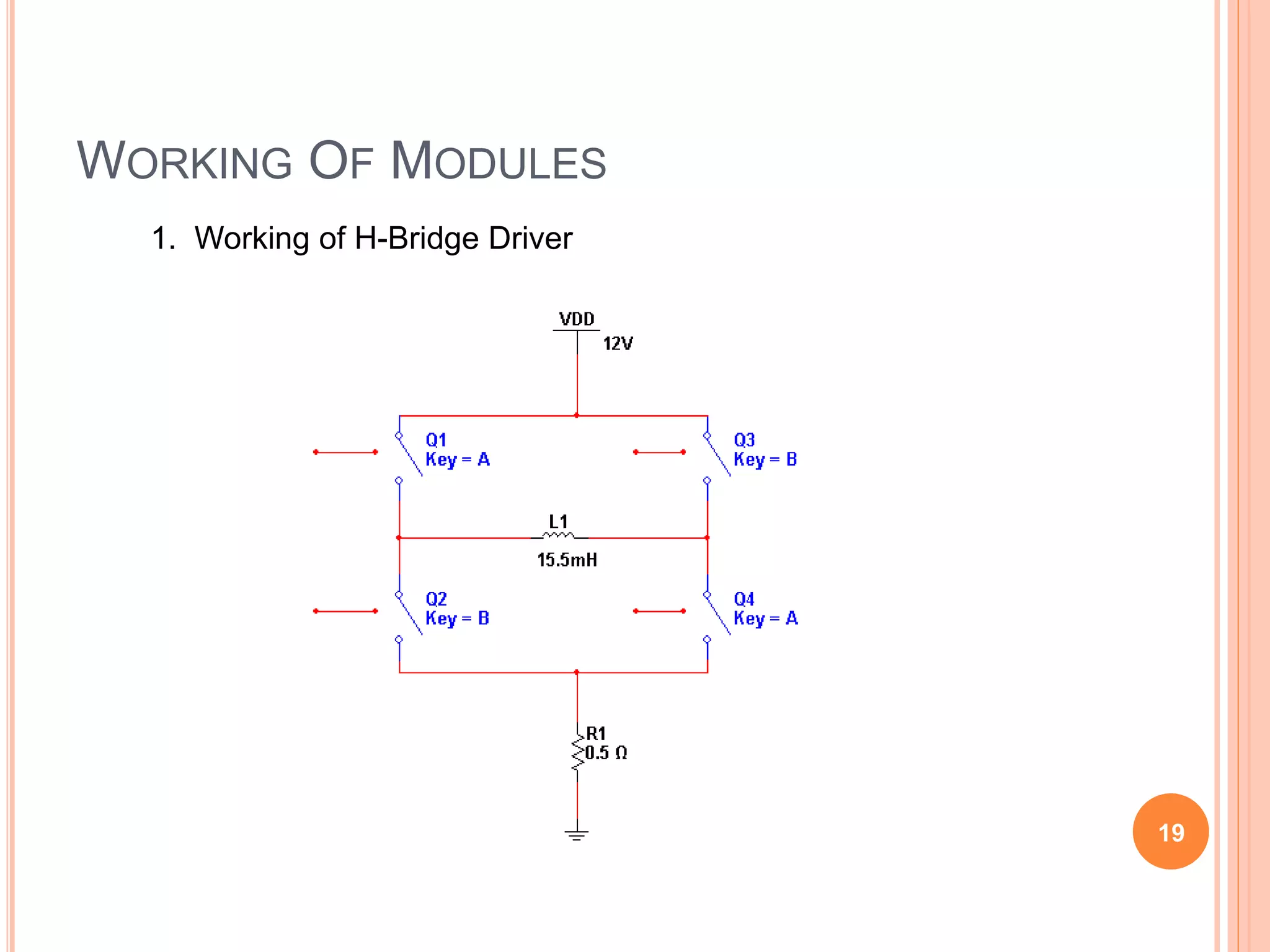

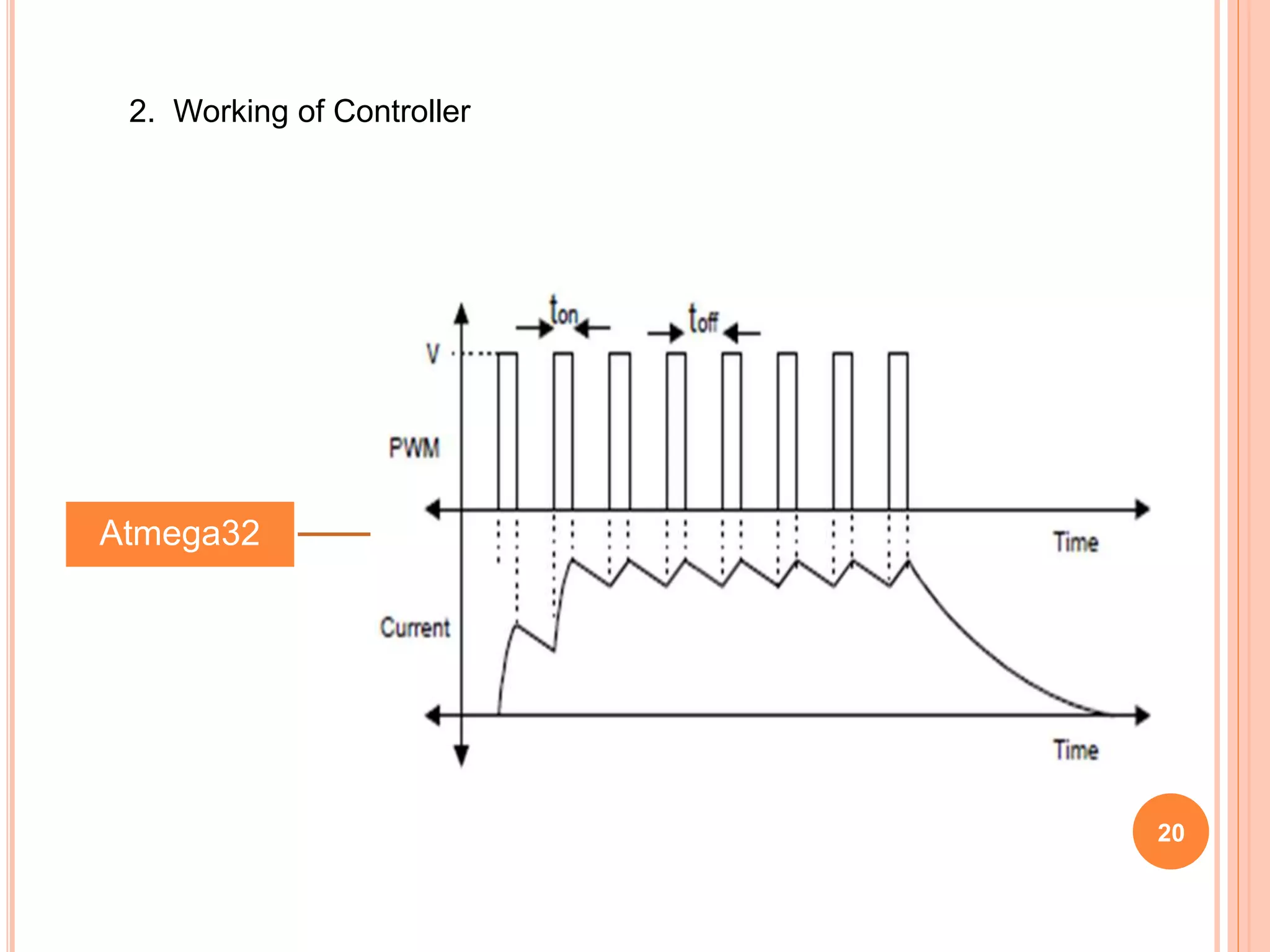

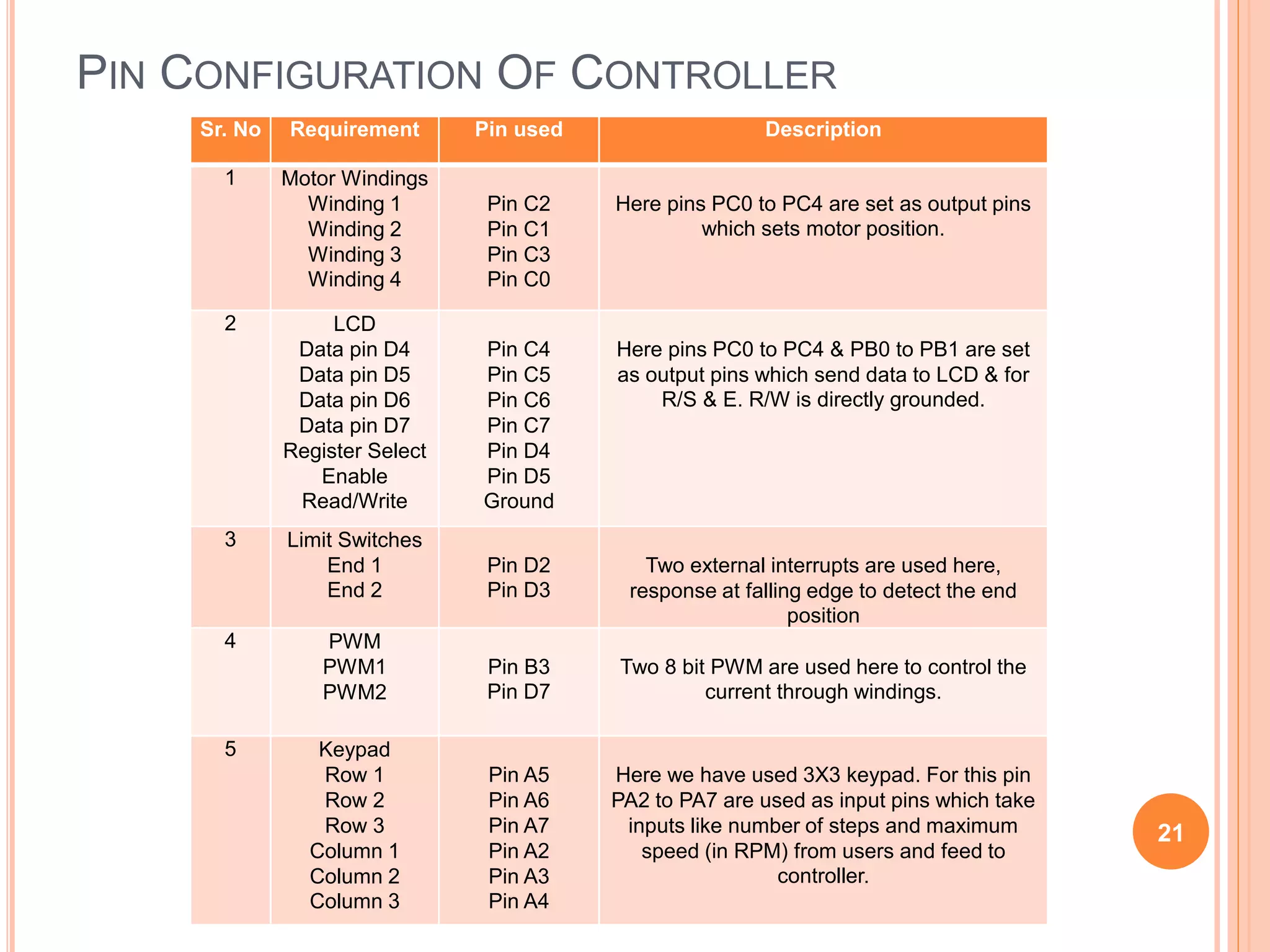

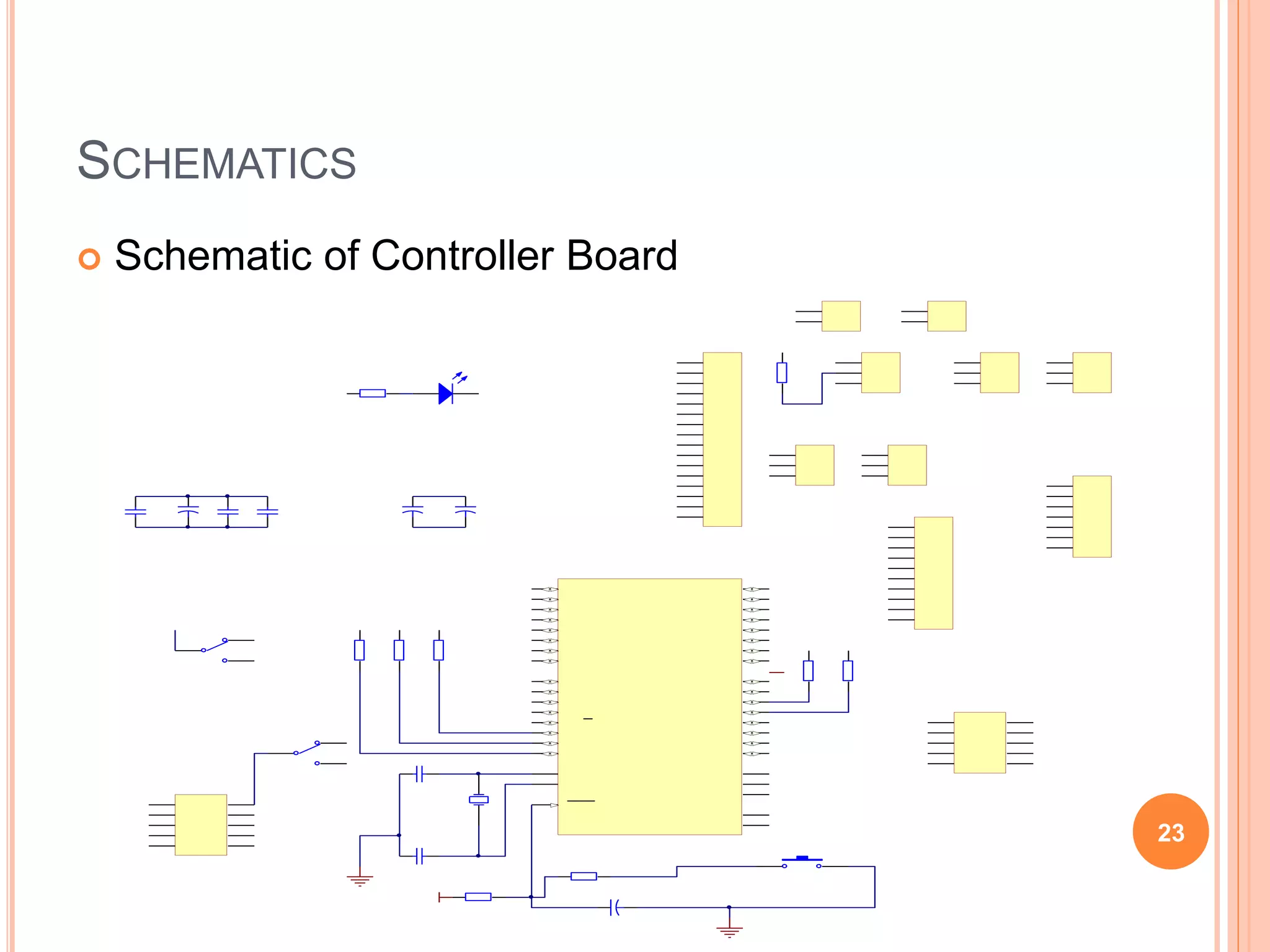

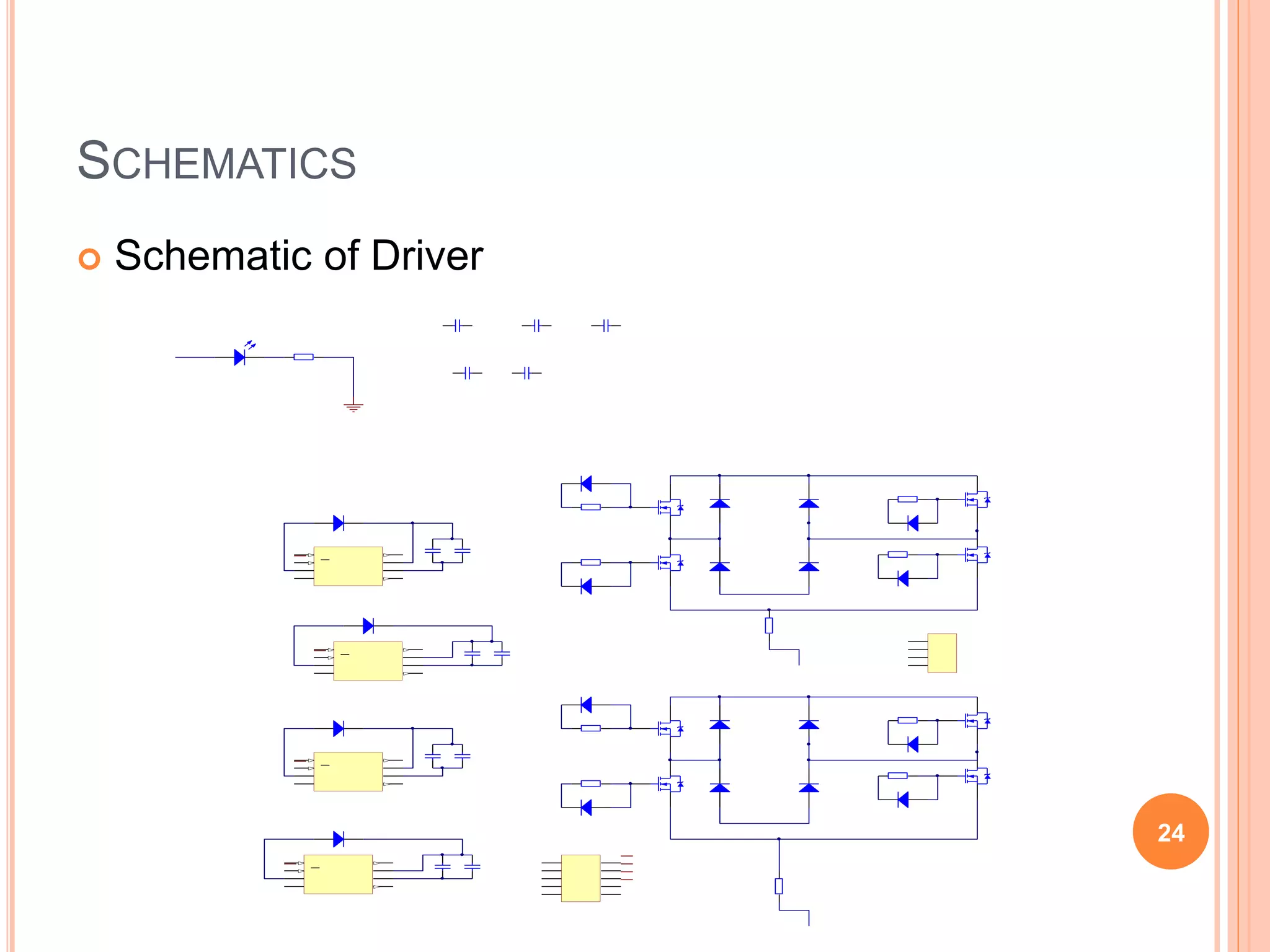

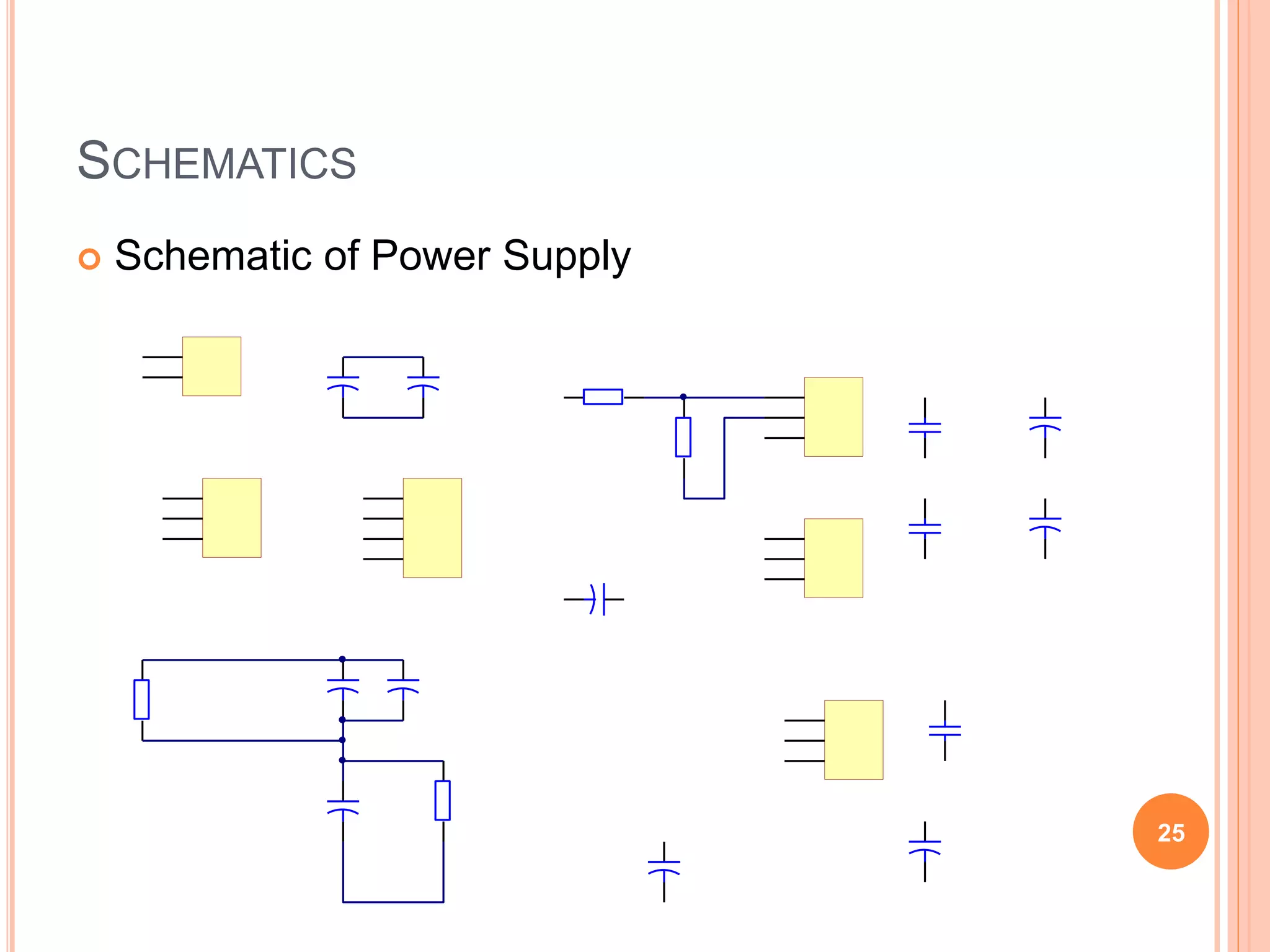

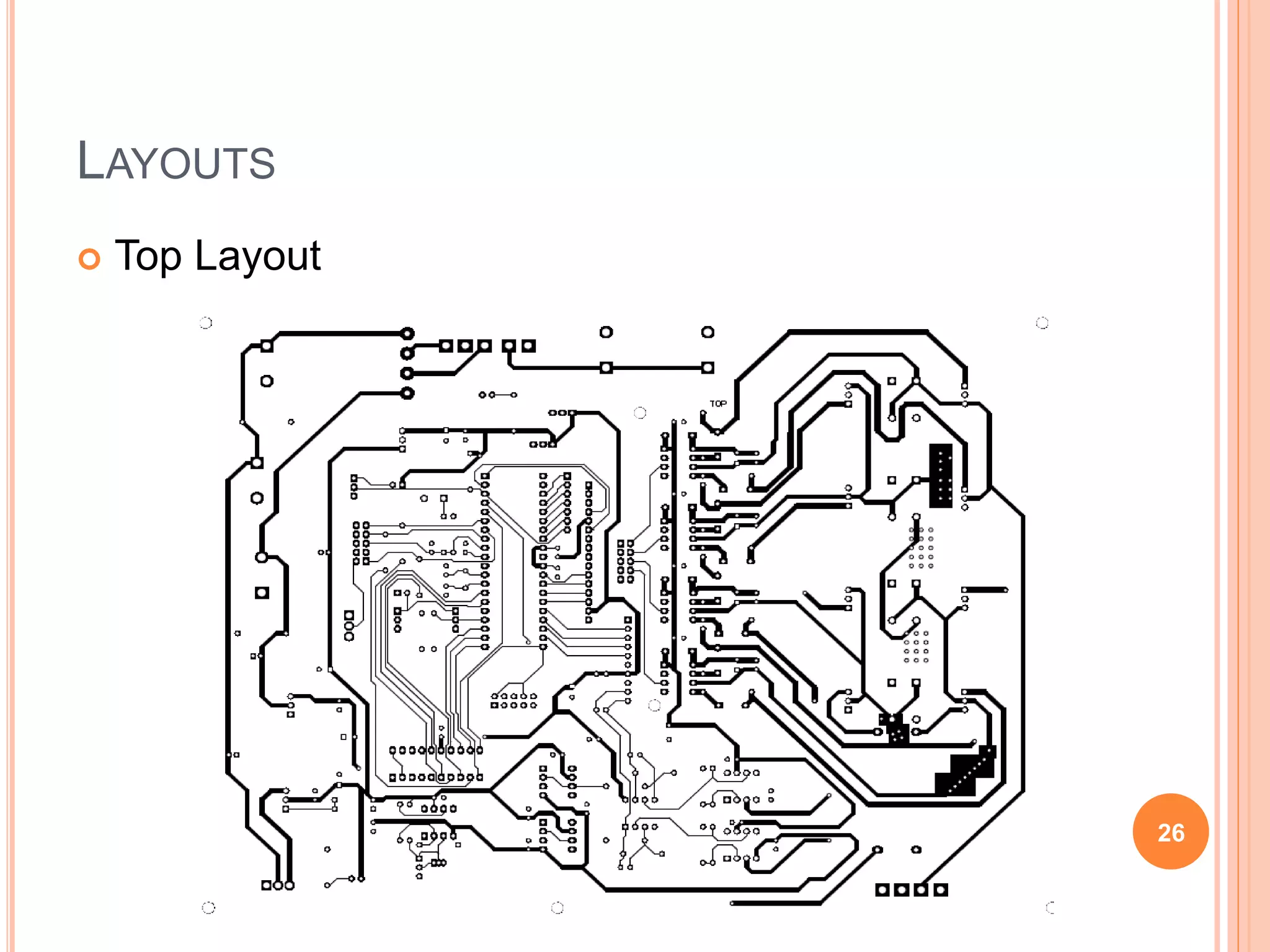

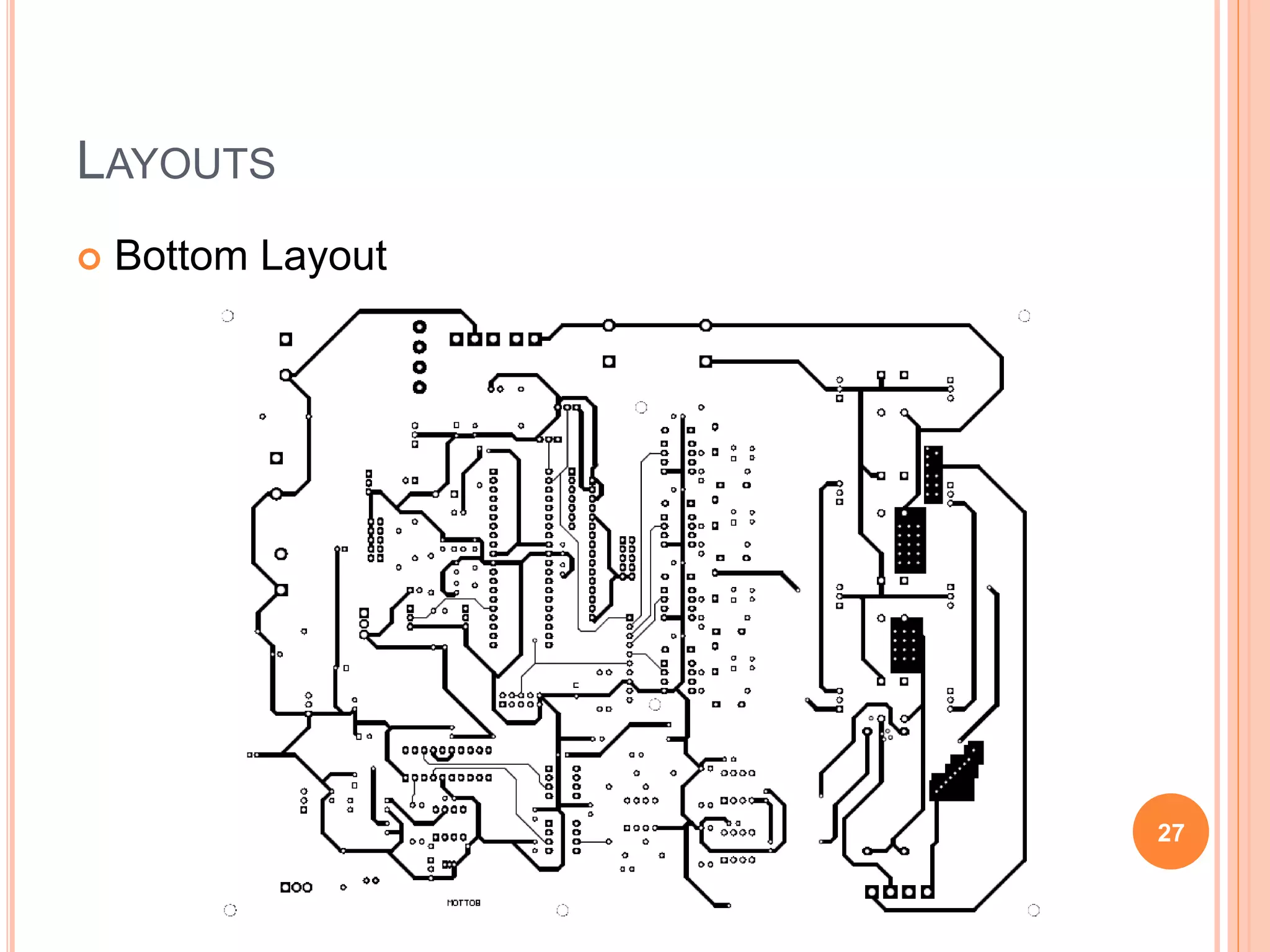

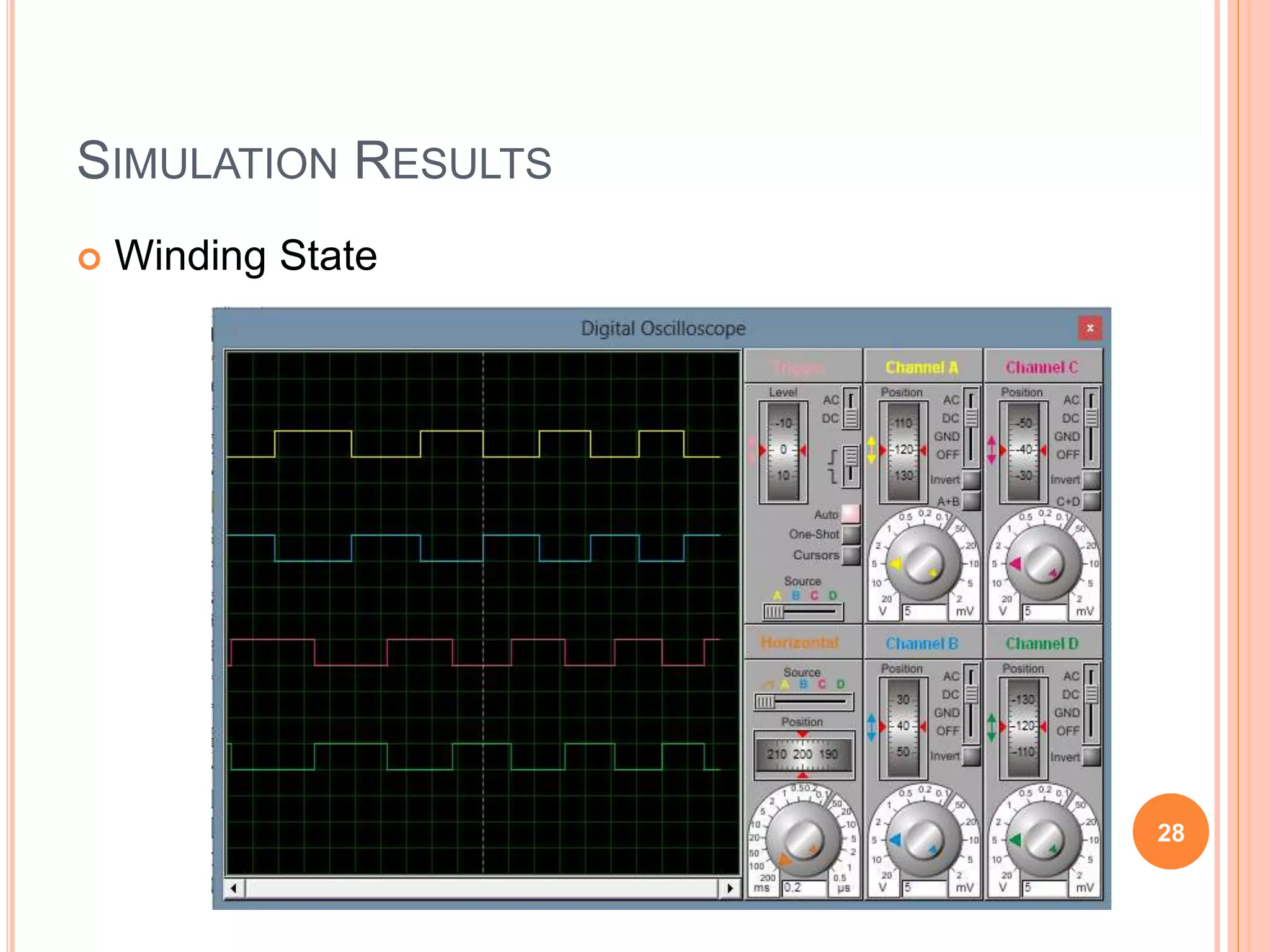

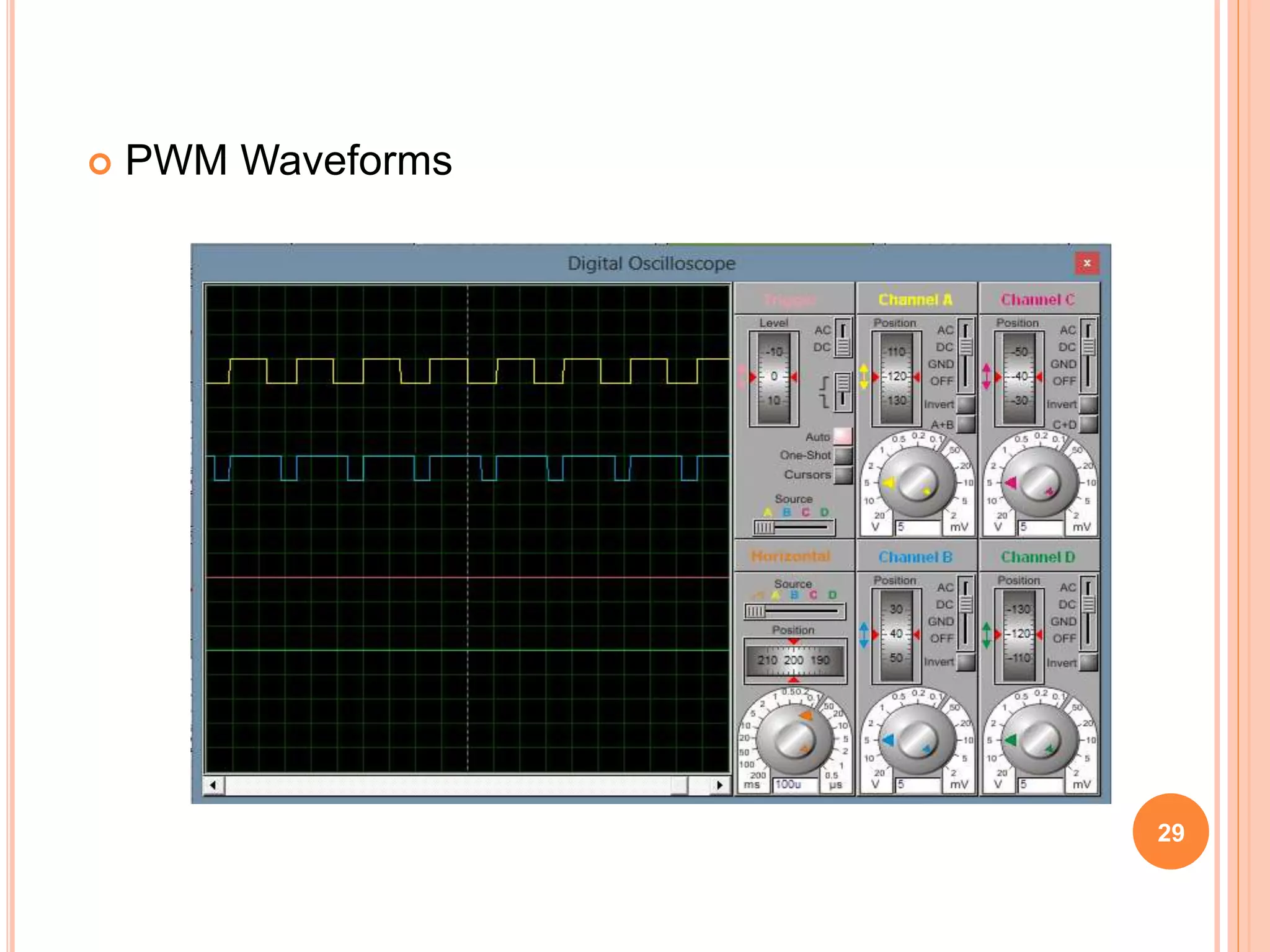

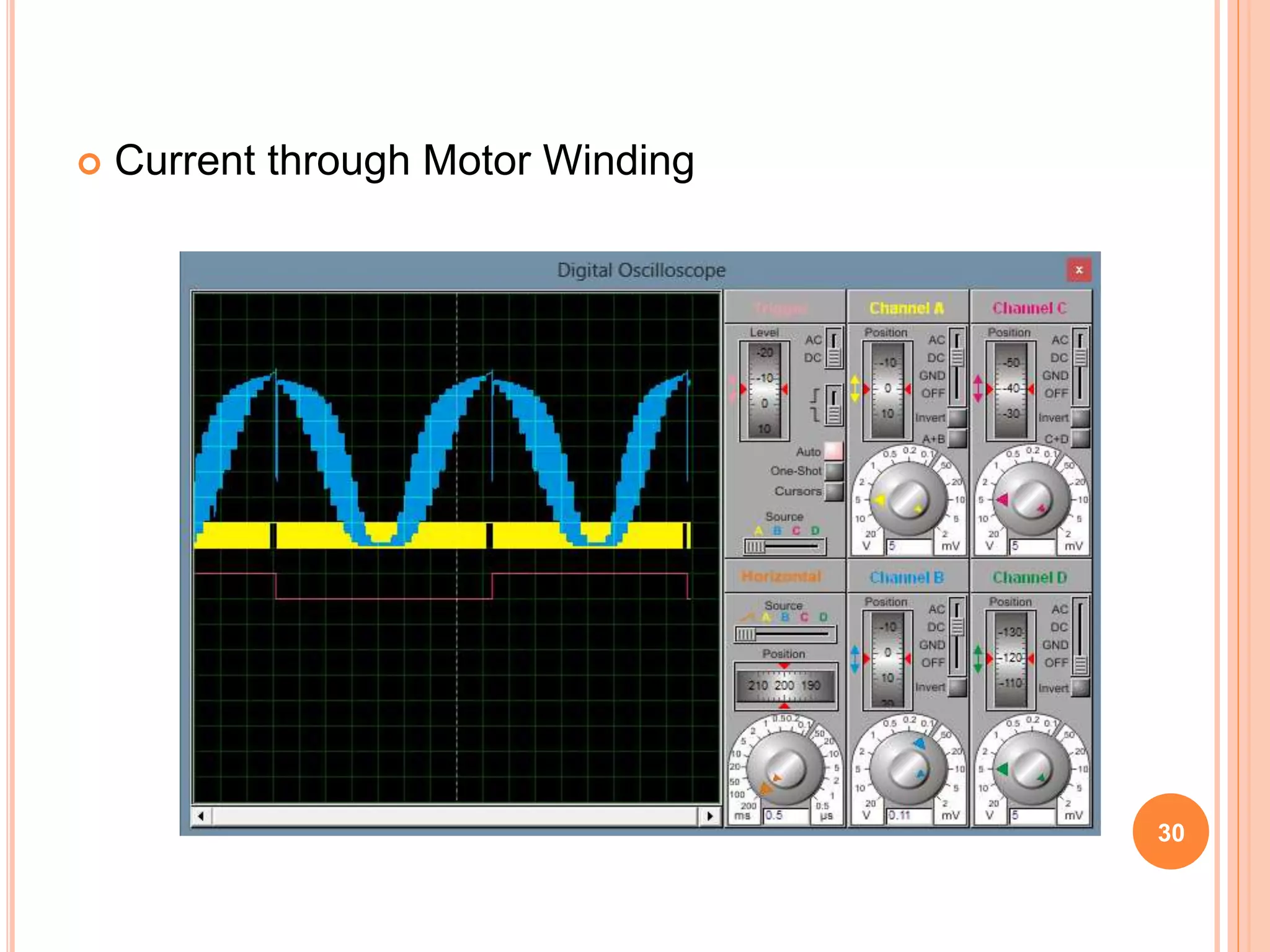

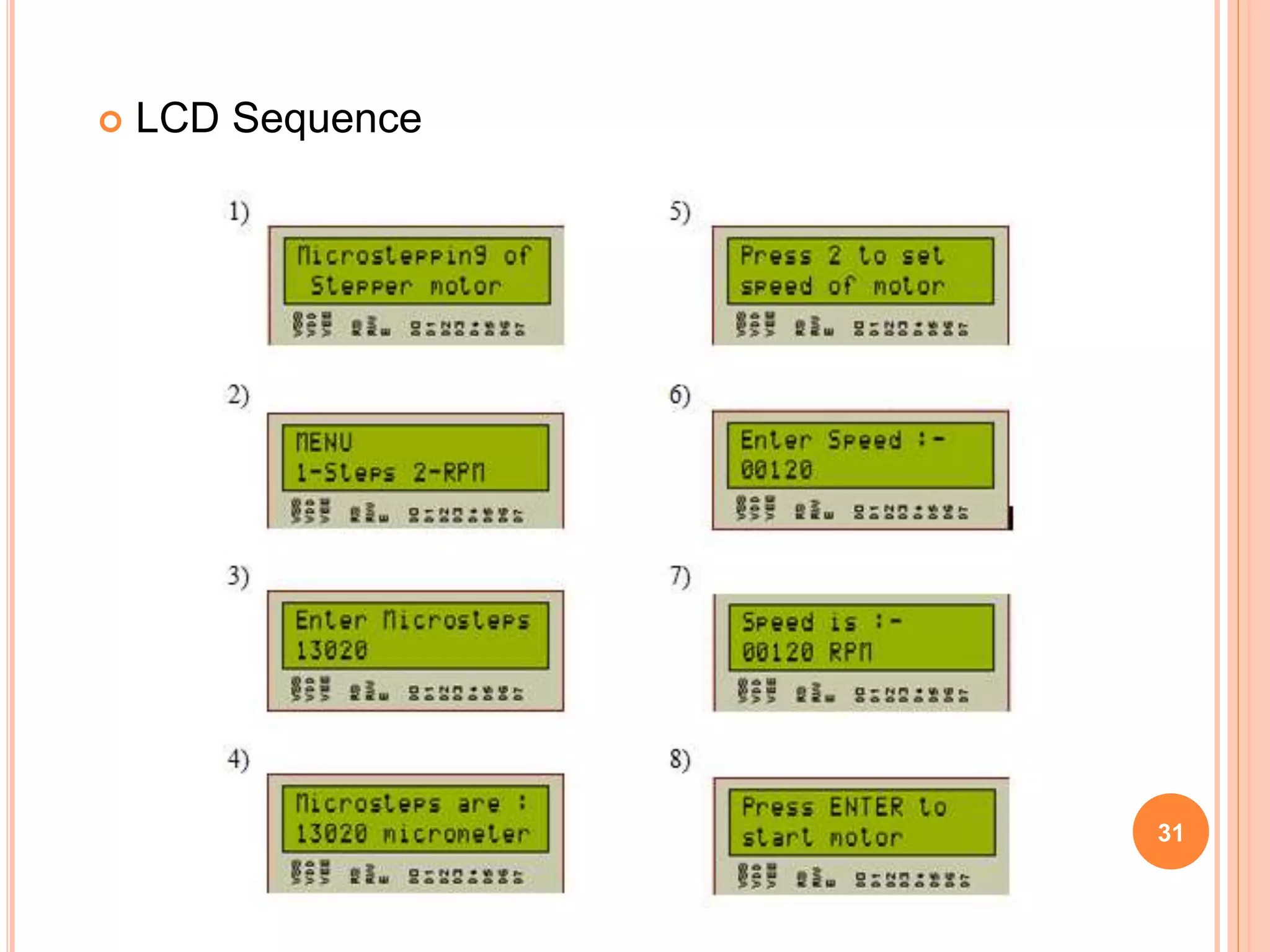

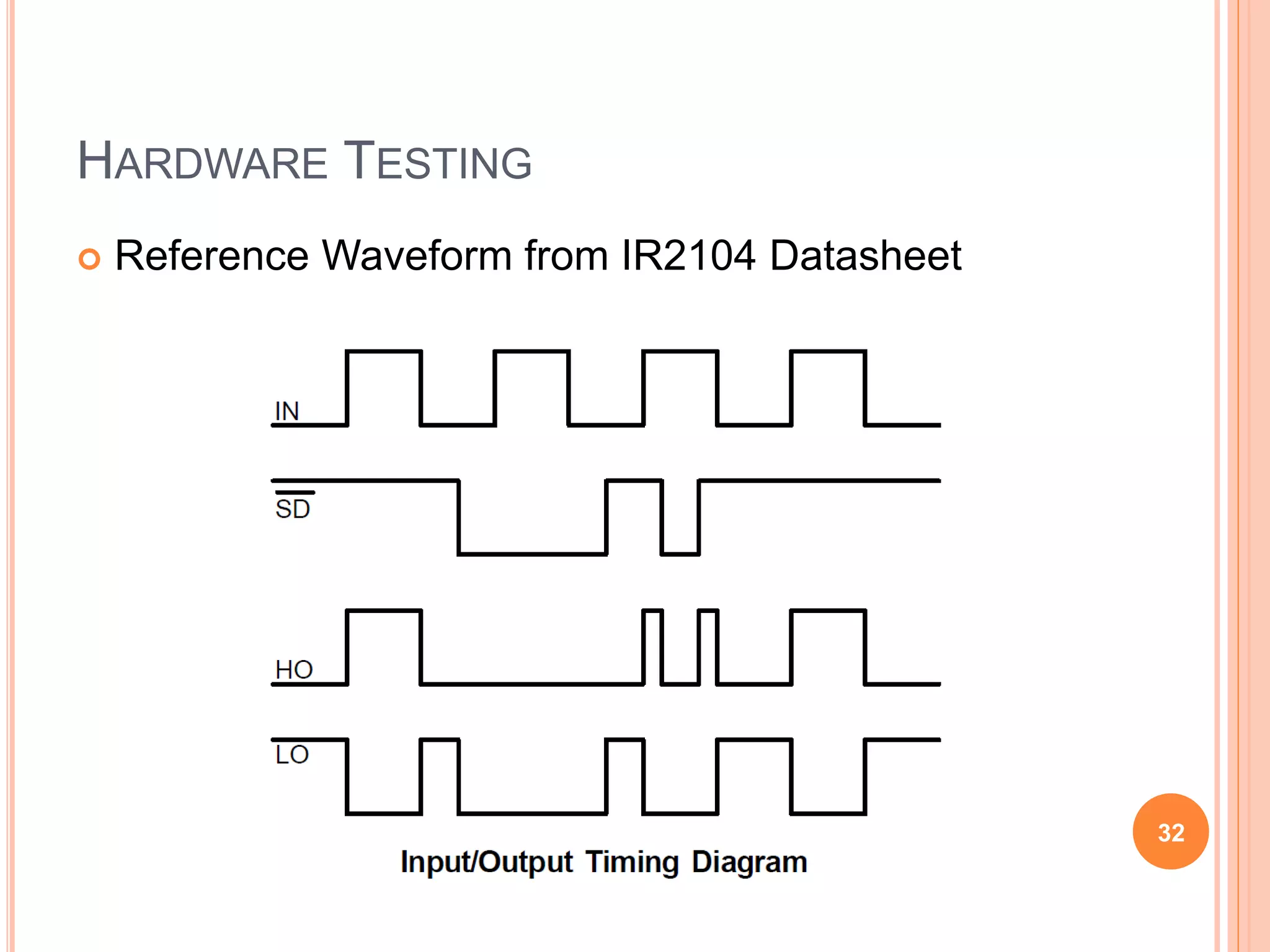

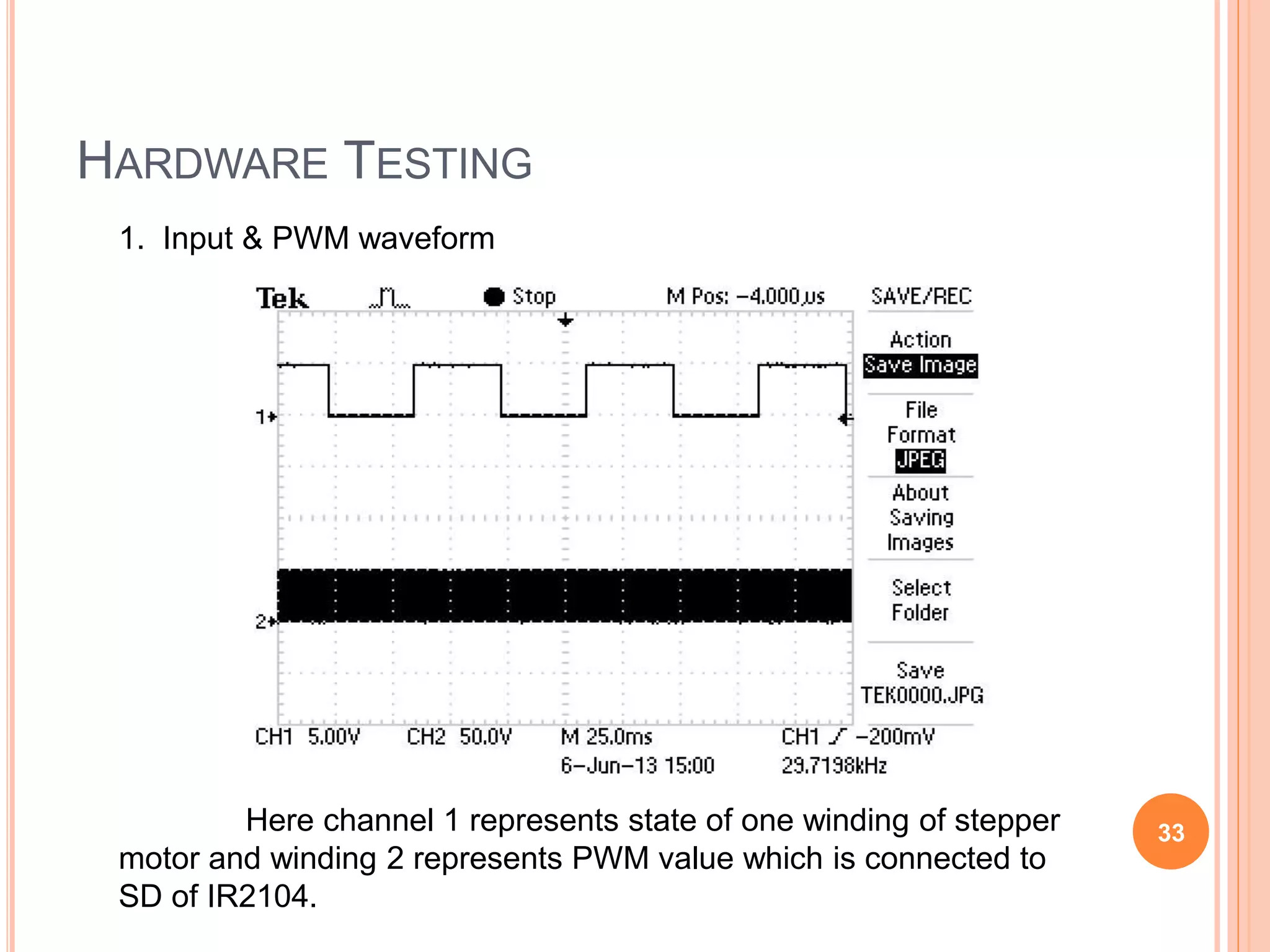

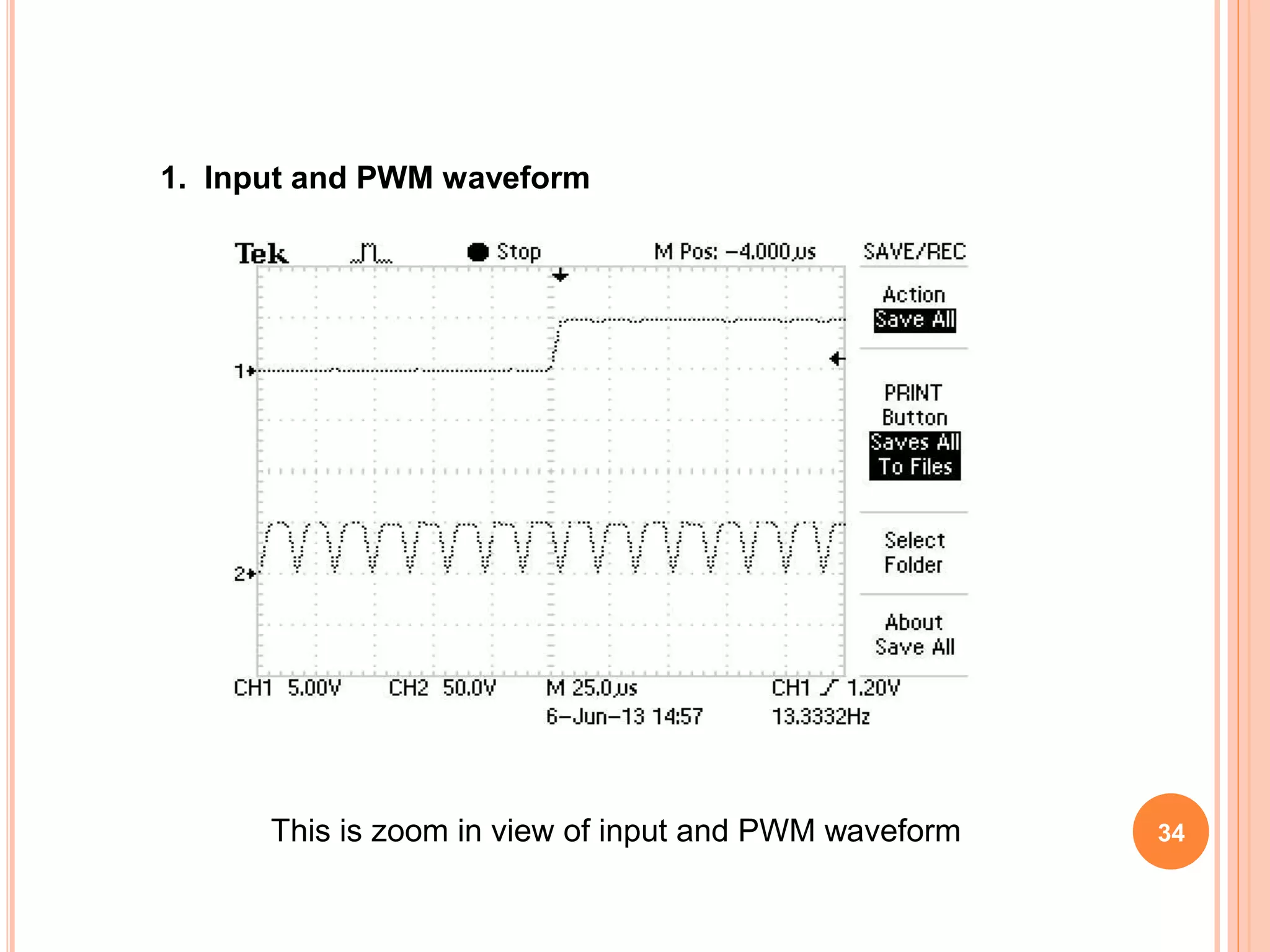

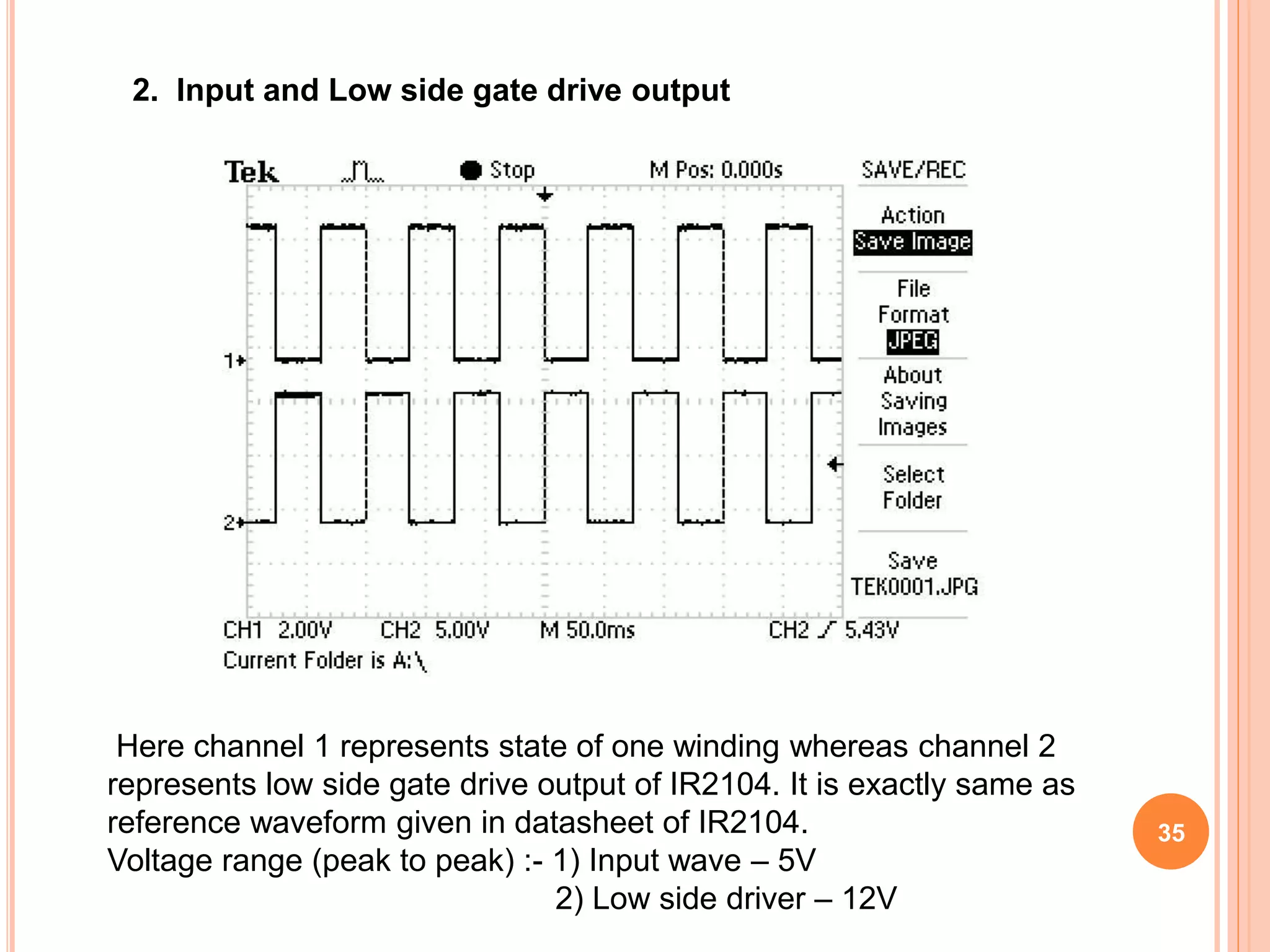

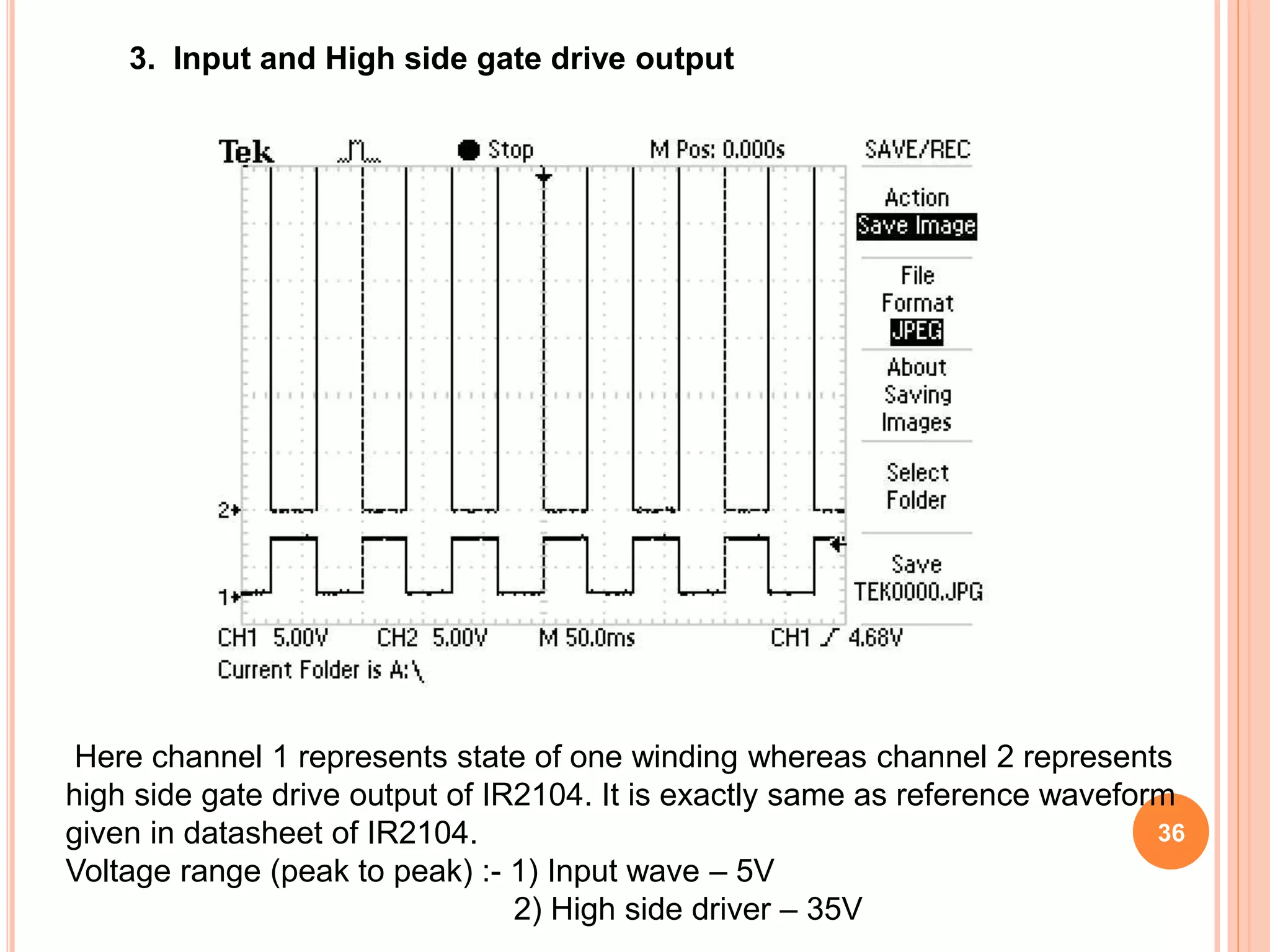

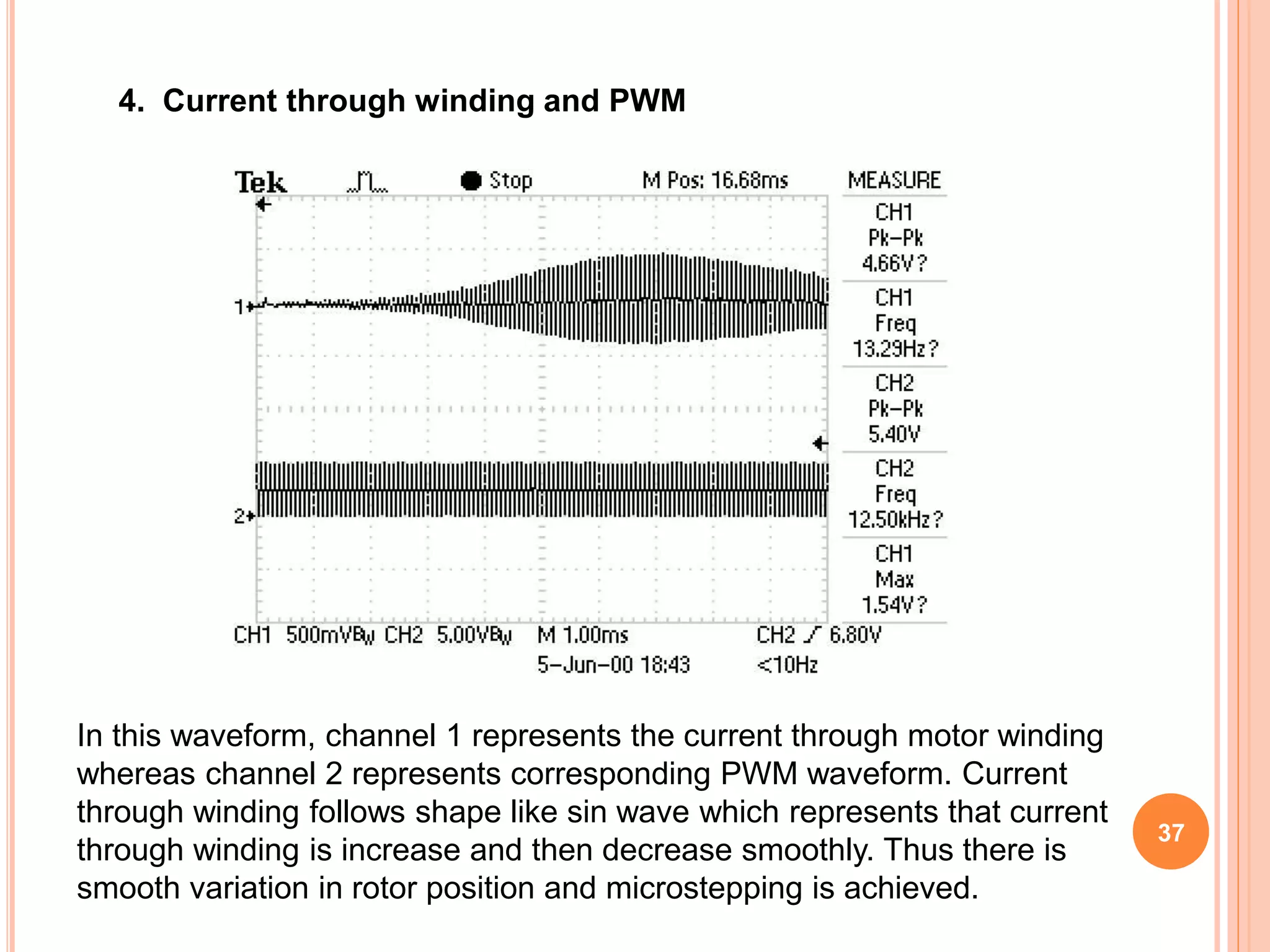

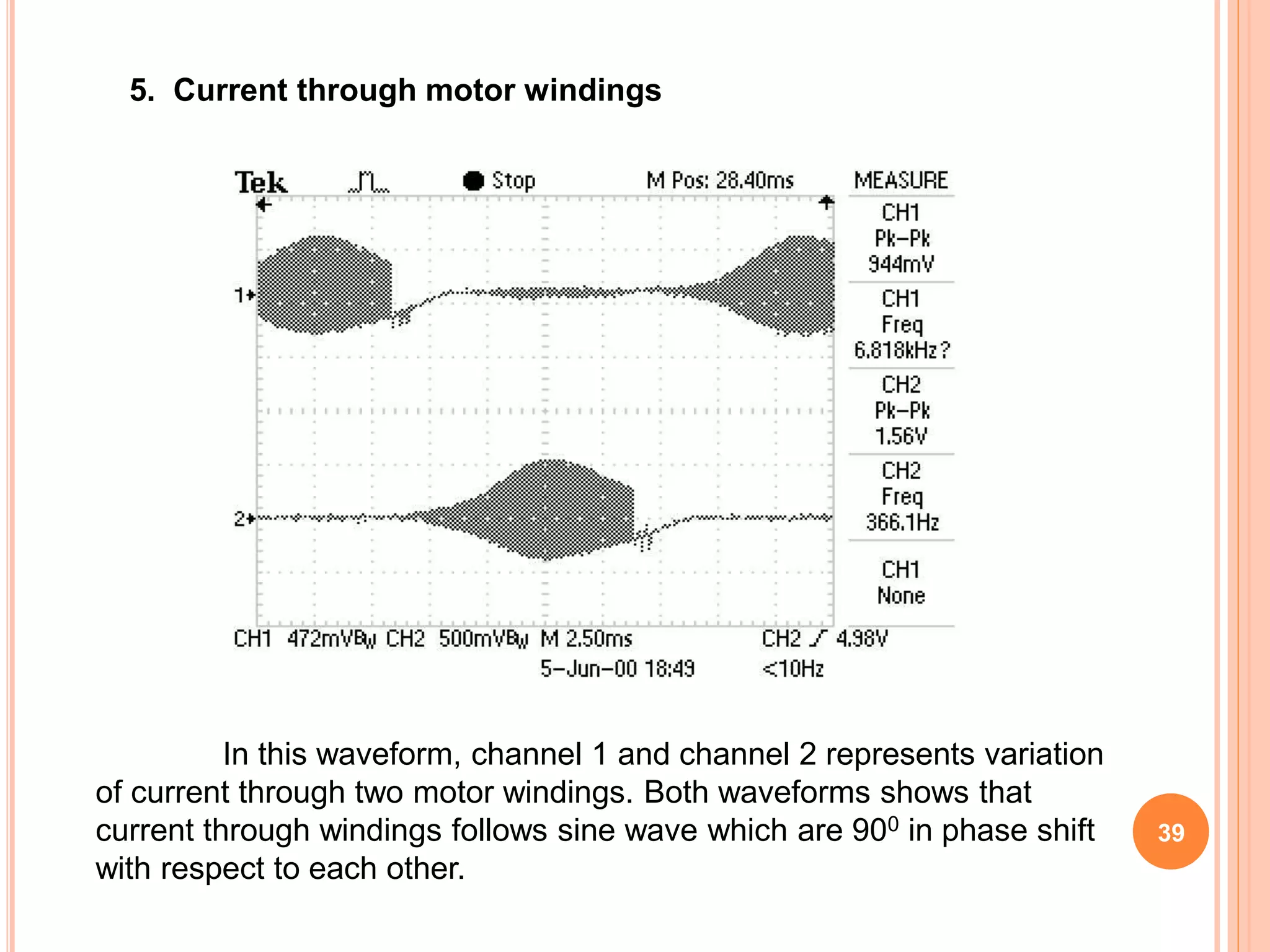

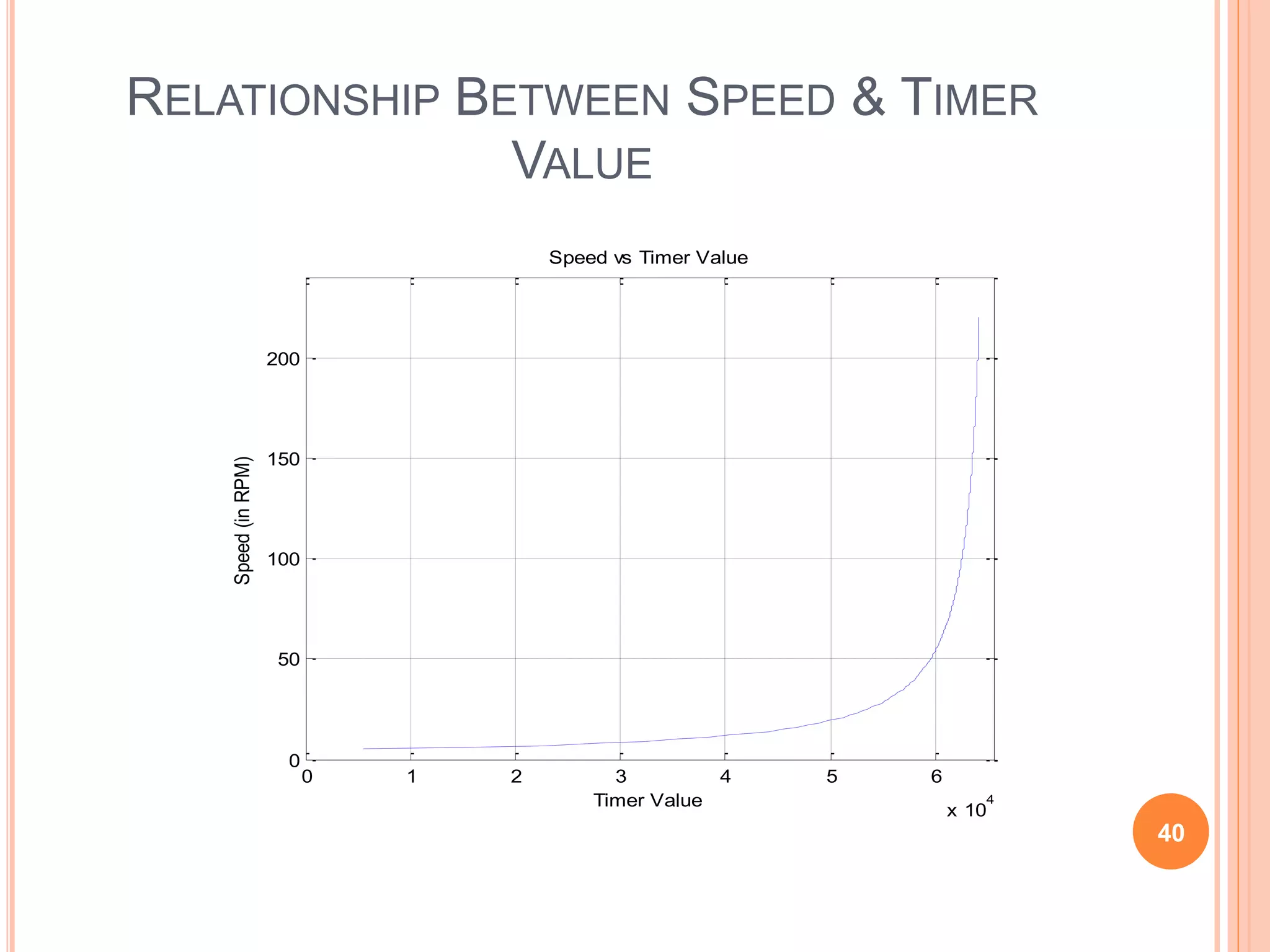

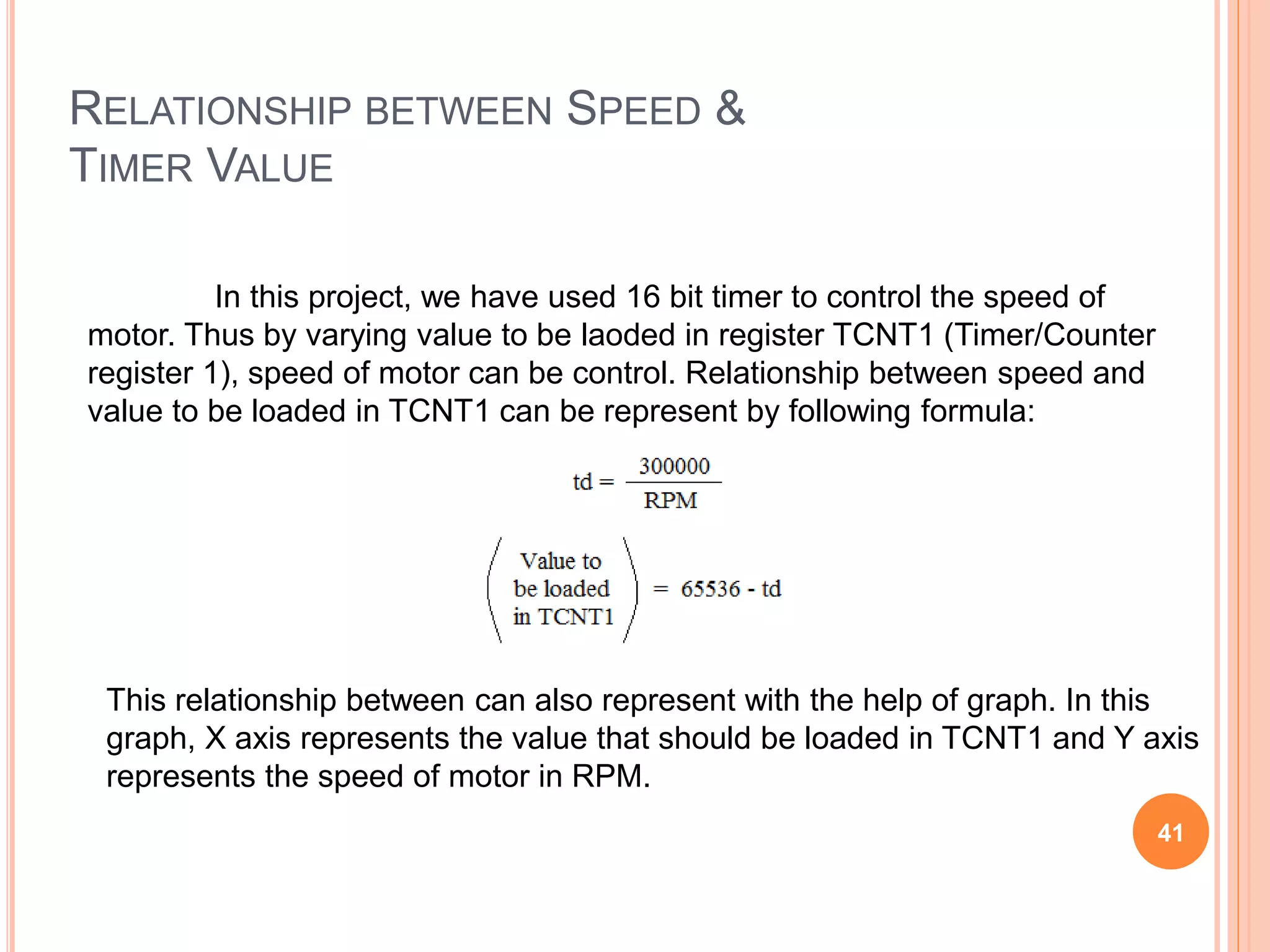

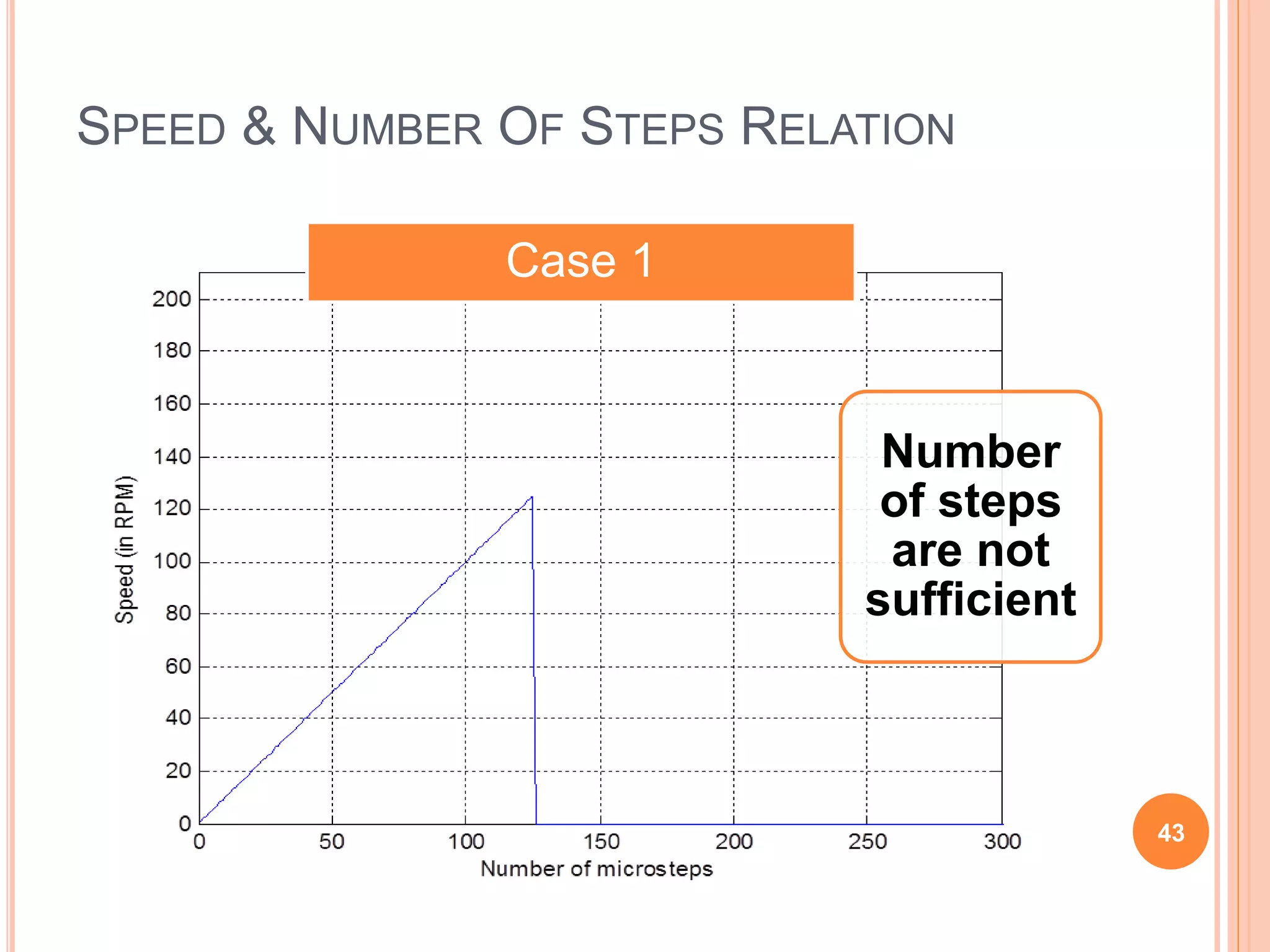

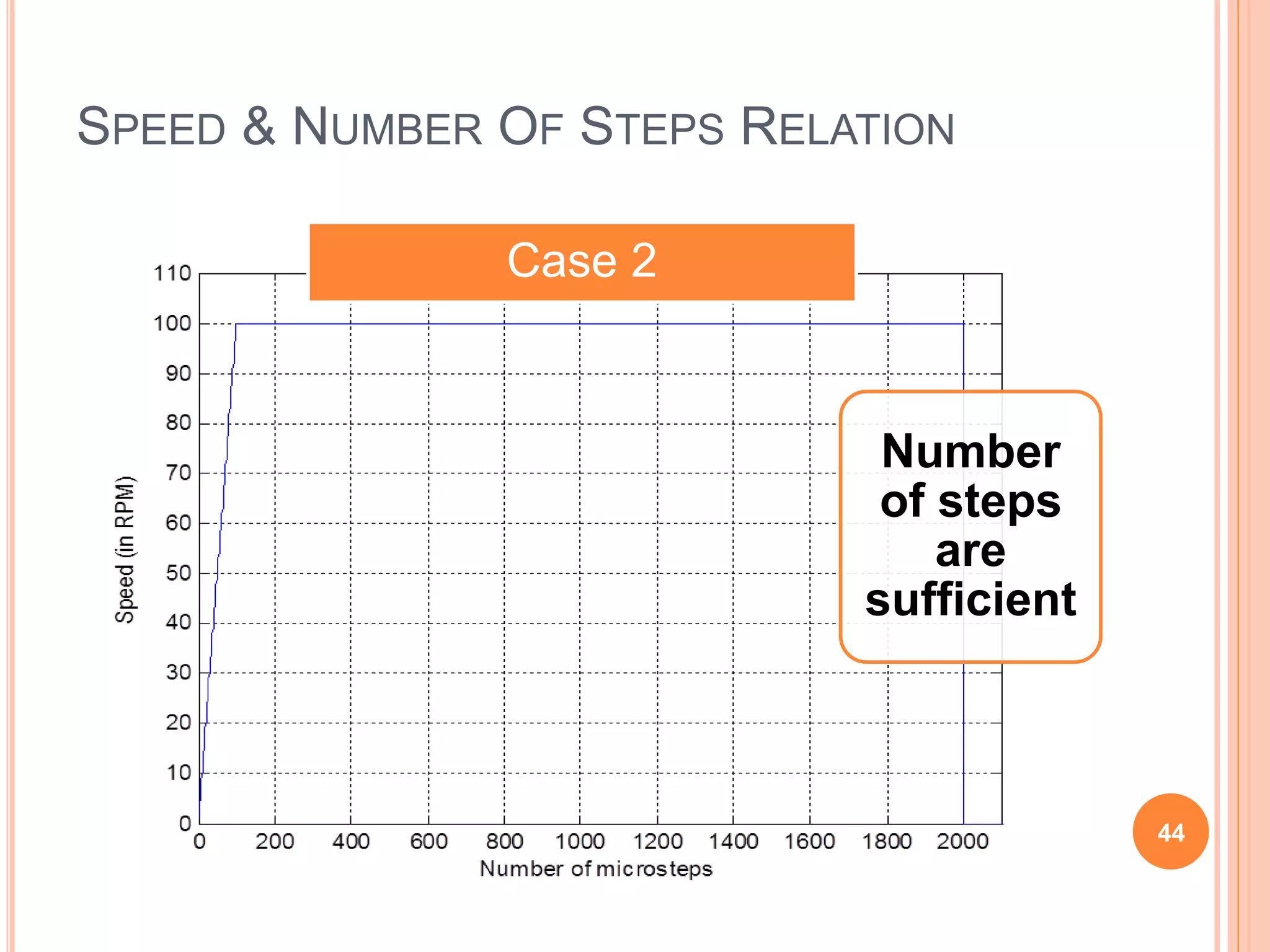

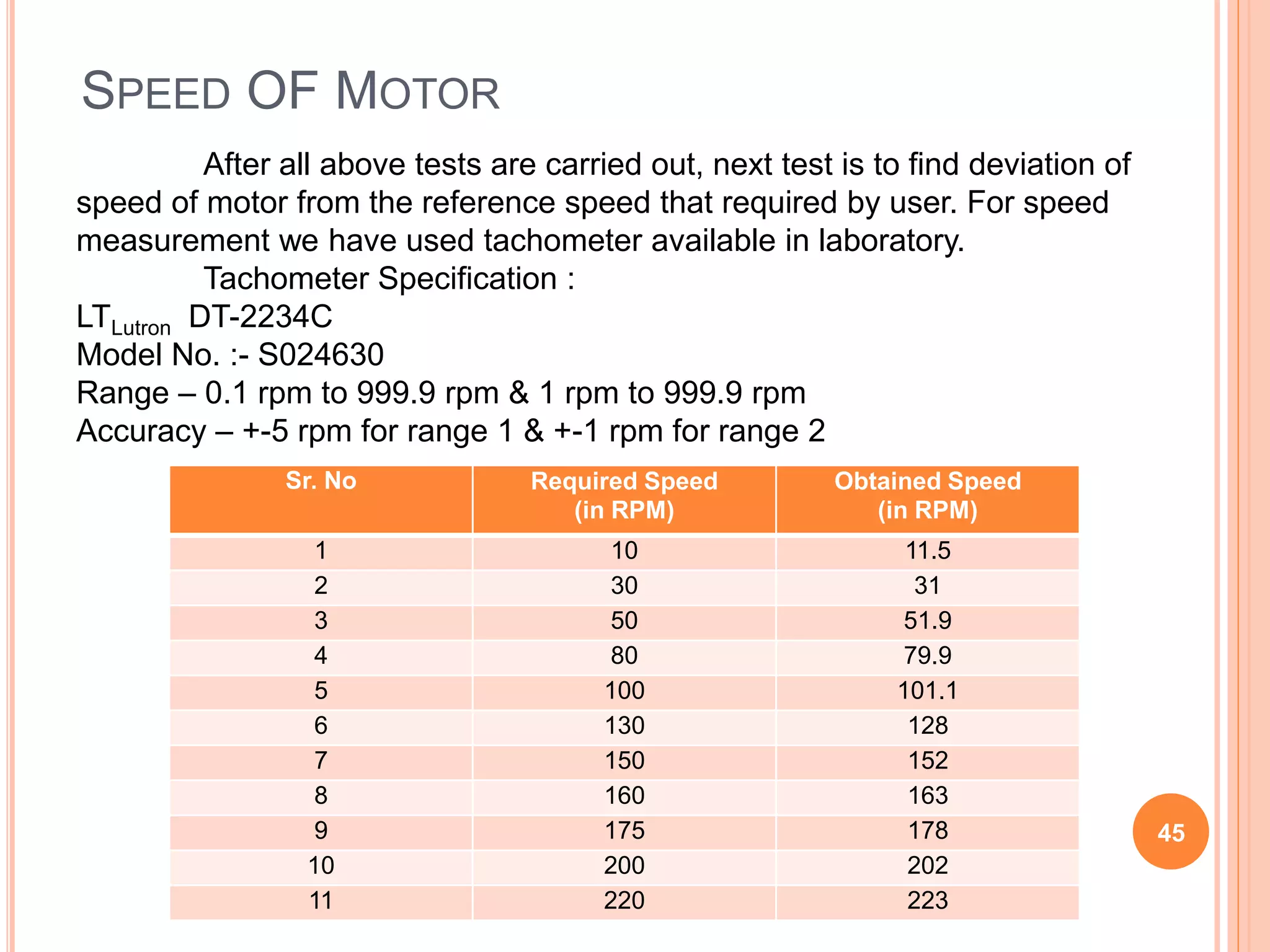

This document presents a project on microstepping of a stepper motor. The project aims to divide the step angle of the motor into 16 microsteps to achieve smooth motion. An ATmega32 microcontroller will be used to drive the stepper motor in microstepping mode and control its speed up to 220 RPM using pulse width modulation. A driver circuit with IR2104 H-bridge driver ICs will be used to supply current to the motor windings based on the microcontroller output. Limit switches will also be implemented for position control. Schematics of the controller board and driver board are presented along with the component selection process and working of the modules.