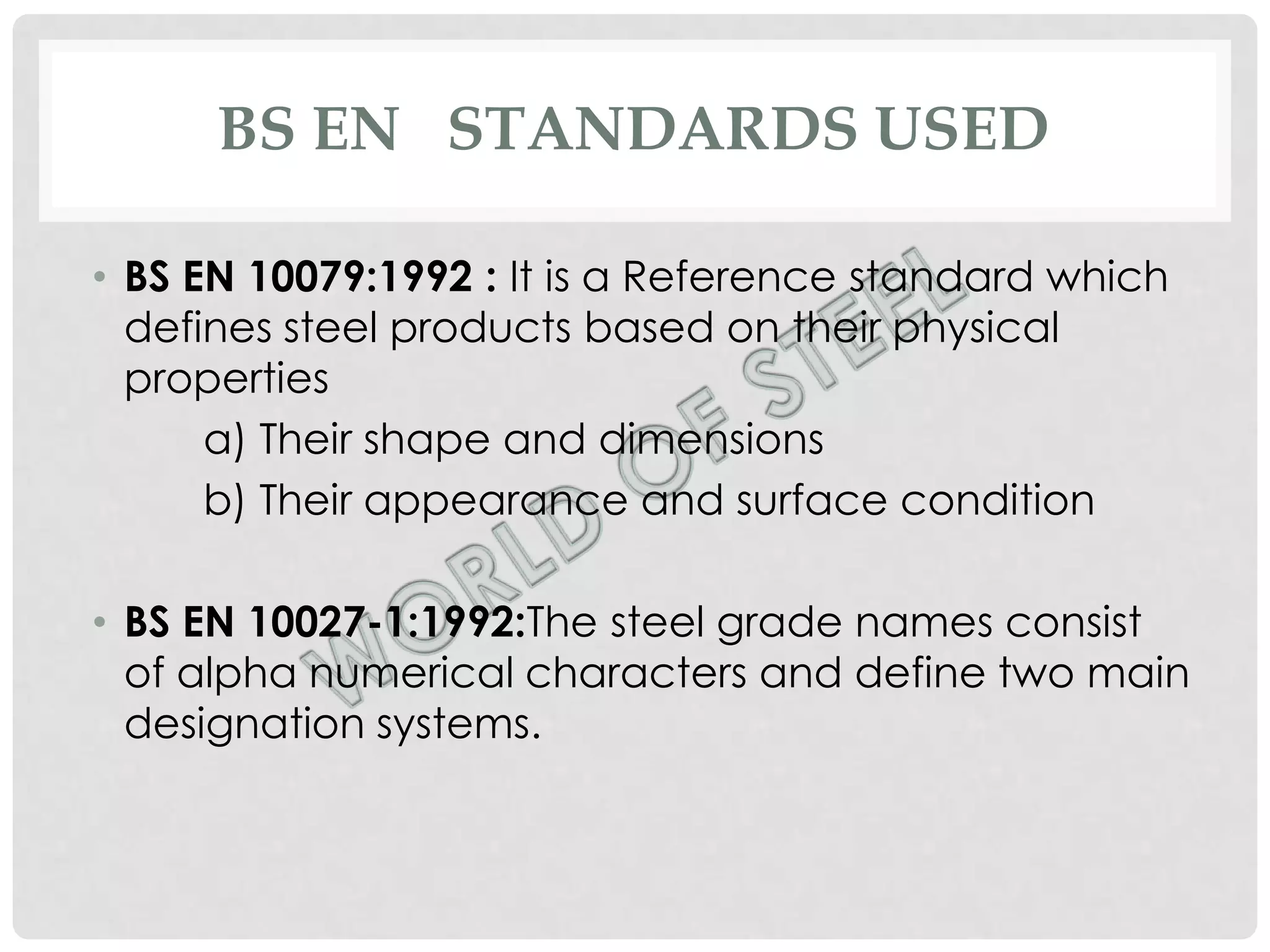

The document discusses various steel grading systems used internationally such as AISI, SAE, BS EN, JIS, and ASTM. It provides details on the naming conventions and systems used to designate steel grades based on their intended end use, mechanical properties, chemical composition, and more. BS EN 10027-1 and 10027-2 standards are described in depth for designating structural, alloy, tool, and stainless steels based on factors like carbon content, alloying elements, yield strength, and assigned number systems. Common end uses of certain grades are also briefly mentioned.

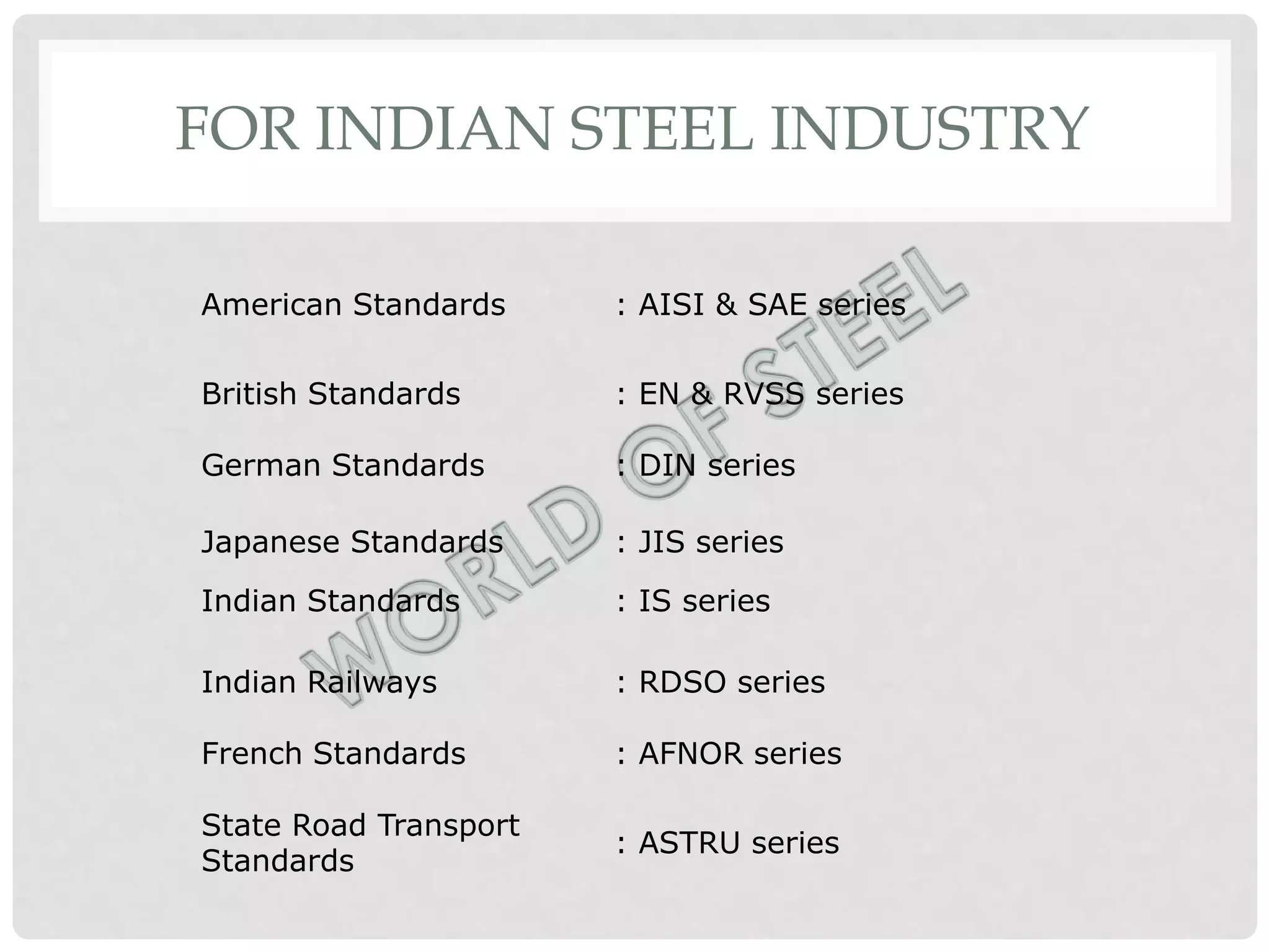

![BS EN 10027-2:1992

Alloy Steel :

1.08XX & 1.98XX ..Steels with special physical properties

1.09XX & 1.99XX ..Steels for other applications

1.2000 -1.2999 ..Tool Steels

1.20XX..Tool Steels-Cr

1.21XX..Tool Steels-(Cr-Si , Cr-Mn ,Cr-Mn-Si,

1.22XX..Tool Steels-(Cr-V , Cr-V_Si ,Cr-V-Mn,Cr-V-Mn_Si

1.23XX..Tool Steels .. (Cr-Mo, Cr-Mo-V, Mo-V )

1.24XX..Tool Steels .. (W, Cr-W)

1.25XX..Tool Steels .. (W-V, Cr-W-V)

1.26XX..Tool Steels .. (other W)

1.27XX..Tool Steels .. (with Ni)

1.28XX..Other Tool Steels )

1.29XX..Other Tool Steels ]](https://image.slidesharecdn.com/namescommon-120702002002-phpapp01/75/Steel-Naming-Conventions-11-2048.jpg)

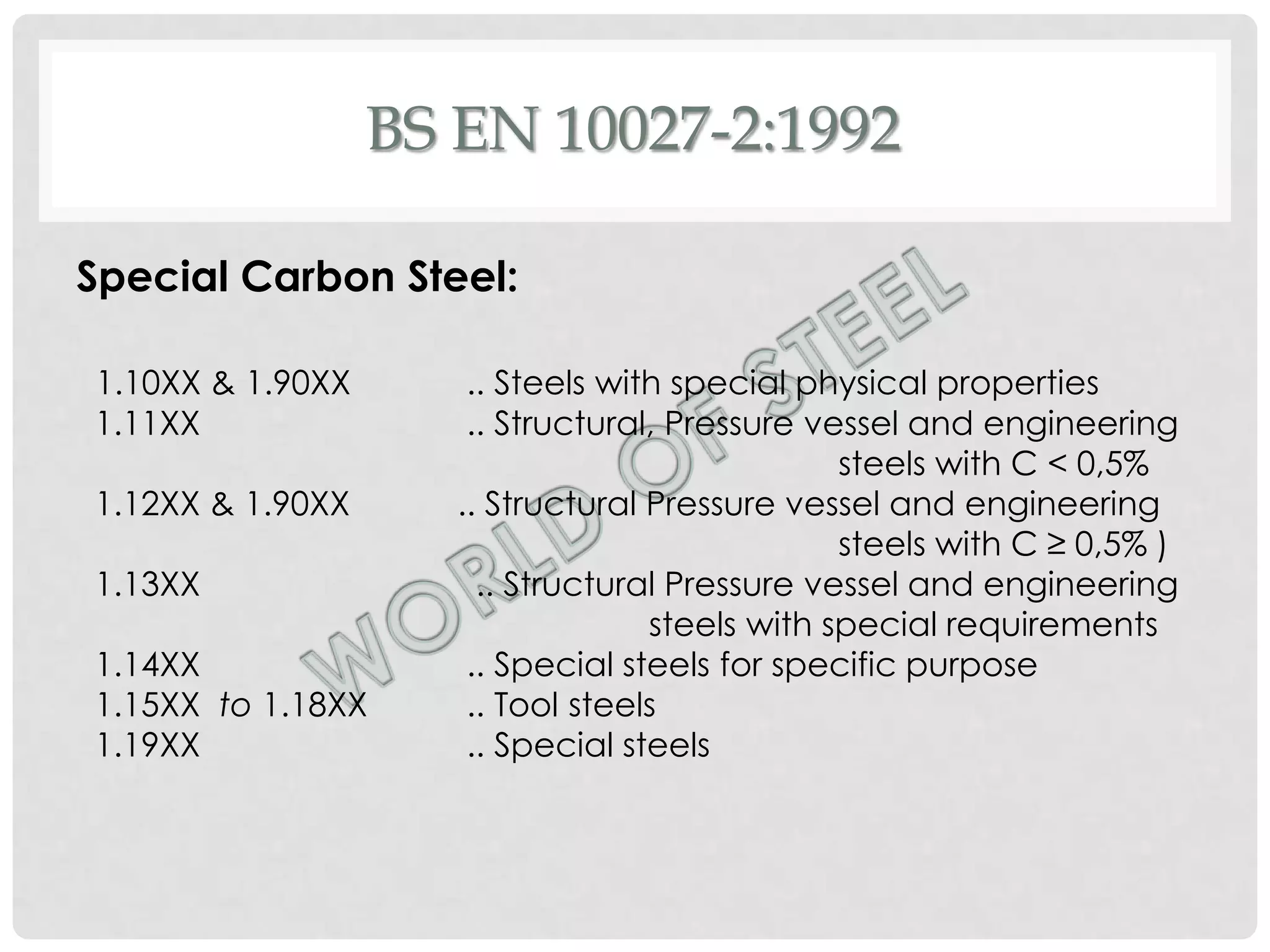

![JIS AND BS STANDARDS

"JIS X 0208:1997" • X will be G for ferrous alloys

and H for non-ferrous

• Stainless steels ae named according to AISI

conventions (SUS 304)

• SUH -> Heat resistant alloys

A letter that denotes

the

• SCS and SCH numbers are used for stainless

area of application steel castings.

of material

“BS XXXX[-P]:YYYY”

Number of the year

standard

Sub-division number

in the standard](https://image.slidesharecdn.com/namescommon-120702002002-phpapp01/75/Steel-Naming-Conventions-19-2048.jpg)