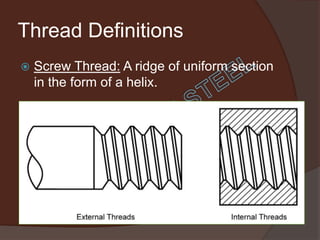

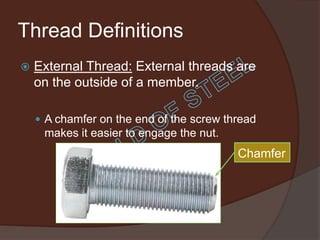

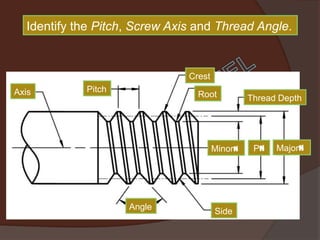

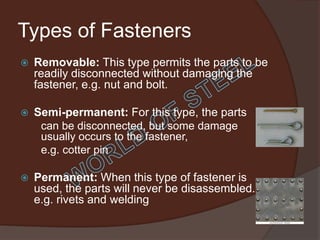

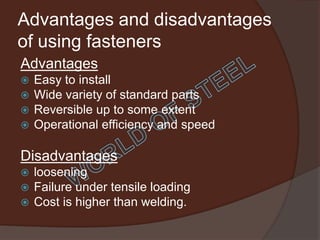

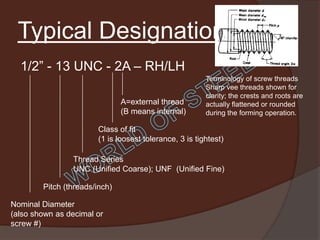

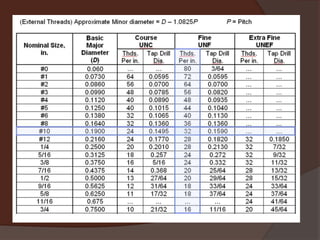

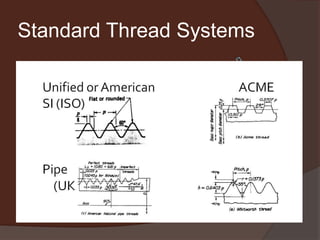

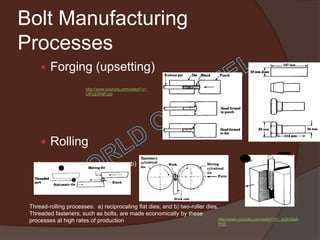

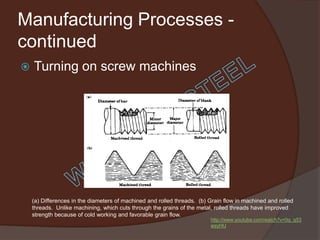

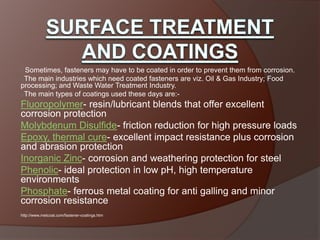

Fasteners are hardware devices that mechanically join or affix objects together. There are many types of fasteners including threaded and non-threaded. Threaded fasteners have external or internal threads and are defined by properties like pitch, diameter, and thread angle. Fasteners can be removable, semi-permanent, or permanent. Manufacturing processes for threaded fasteners include forging, rolling, and turning. Standards organizations define specifications for fastener design. Special fasteners may require unique designs or coating for corrosion resistance. The fastener industry is important for automotive, industrial, and construction applications.